Advantages

- Foam blocks have excellent thermal insulation and frost resistance. A building erected from this product has properties similar to wooden baths. Thanks to the breathable building product, the building is famous for its special microclimate. However, at the same time, foam concrete is able to withstand fire, and this distinguishes it from wooden materials. It is important that natural and organic ingredients are used in production.

- The foam block has a large volume and low weight, which is more advantageous and convenient compared to brick. After all, with its help, construction time is reduced and transportation is easier.

- When compared with other building materials, it becomes clear that the advantages of foam block include its low cost.

- Since foam blocks contain special components, they have an increased strength index.

- To complete the stages of this construction, there is no need for specialized skills or knowledge. The bathhouse can be easily erected even by an inexperienced person.

- Due to its structure, foam concrete can be easily cut with a hacksaw.

- You can steam in a bathhouse made of this material immediately after installation, because it will not be subject to shrinkage.

How to calculate the number of blocks per house using a calculator?

Be careful and pay attention to the units of measurement in the fields of the calculator.

Haste and inattention can result in unexpected costs during construction. The block calculator allows you to calculate the amount of material for building the walls of a house, garage, bathhouse or any other building. The result directly depends on the initial parameters entered, so the correctness of the result depends entirely on the user. In order to calculate a specific block, you need to go to the corresponding page of the calculator and intuitively fill in all the necessary fields.

For those who experience difficulties, we have prepared brief instructions for working with the program, since the interface of all tools is almost identical.

Block parameters

- Block type (for brick only). You need to choose the type of brick (ceramic/silicate), as well as its design (hollow/solid).

- Block size. Our calculator already contains the most popular product sizes, but you can also add your own!

- Block density. The list lists all possible options that are mentioned in GOSTs.

- Price per block. Necessary to determine the final cost of the structure.

- Reserve for battle. Or otherwise, spare materials in case of accidental destruction or defects - it is recommended to indicate no more than 5%.

Characteristics of walls

- Length. The total length of all walls along the outer perimeter.

- Wall height. Estimated height of the walls from one floor to another.

- Masonry option. Estimated masonry thickness, measured in blocks.

- Mortar in masonry. Possible masonry mortar (foam, glue or cement mortar).

- Masonry mesh. When using, you need to indicate the frequency of laying and the diameter of the rods.

If you want to calculate the number of blocks per garage, use the "Doors" or "Windows" fields to account for gates and other openings.

Additional design elements presented below may be specified in the plural based on existing or proposed design. In addition, each element can be given individual parameters.

- Window. You must specify height, width, quantity.

- Doors. You must specify height, width, quantity.

- Pediments. More details below.

- Jumpers. You must specify thickness, length, quantity.

- Armobelt. You must specify the thickness and quantity.

To calculate the blocks for the pediment of the house, you need to select the appropriate type of structure among those proposed (triangular, trapezoidal and pentagonal). You can add additional elements, as well as specify individual parameters for each separately. If you are only interested in gables, fill the main fields of the calculator with random values.

The calculation result will contain the following variables:

- volume of structure, m3;

- gable surface area, m2.

- number of blocks, pcs.

- volume of blocks, m3.

In most cases, when building a house, the largest expense item is materials for the construction of walls and partitions. Depending on the type of building block, the price can be from 1/4 to 1/3 of the entire cost of the house.

Still have questions?

ARBOLITA BLOCKS

The lightness of the material and its elasticity do not require a powerful and rigid foundation.

Arbolite block

400x200x200 - 3700 rub/m3

400x200x300 - 3700 rub/m3

ARE DIFFERENT FROM OUR COMPANY'S ARBOLITH BLOCKS:

Excellent geometry

Ease of use

The quality of the materials included in the composition

High strength characteristics in compression and bending

High thermal insulation properties

High vapor permeability

Strong adhesion to finishing materials

Strength of holding fasteners in the block

Quality control of the production process

In terms of consumer properties, this is the best option for individual housing construction!

AREAS OF USE

The block is packed on pallets of 60 pieces (1 m3)

The weight of one 1 m3 block is on average 600 kg.

Production, office and warehouse are located in one place.

Our managers will be happy to help you figure out where you can use our fittings

PRICES FOR ARBOLITE BLOCKS

If you find it cheaper, we'll give you a discount!

| Name | Dimensions, mm | Winter price, rub. from: | Summer price, rub. from:. | Pieces per 1 m3 | ||||

| Dl. | Shir. | Thickness | 1 PC. | 1 m2 | 1 PC. | 1 m3 | ||

| Arbolite block | 400 | 200 | 200 | 59 | 3658 | 65 | 4030 | 62 |

| Arbolite block | 400 | 200 | 300 | 90 | 3690 | 99 | 4059 | 41 |

A LITTLE ABOUT ARBOLITH BLOCKS

“Arbolit” - GOST 19 222-84 originates in the sixties in the Soviet Union. This material is standardized and has passed all technical tests. The production of wood concrete blocks was recommended by the Central Research Institute of Industrial Buildings.

When making wood concrete blocks, wood and concrete are combined, as well as their best qualities: environmental friendliness, durability of concrete, strength of wood and its vapor permeability.

When using wood concrete, the weight of buildings is reduced by 1.3 times or more. Arbolite provides excellent air exchange and also has high thermal performance. All this reduces the cost of heating and ventilation of buildings.

Wood concrete buildings have several positive qualities compared to wood structures. Firstly, wood concrete is fire-resistant . Its fire resistance is better than other building materials. Secondly, it does not rot or become infected with microorganisms and fungi. Thirdly, the sound and heat insulation of this material is also excellent.

Wood concrete is environmentally friendly , it is not harmful to human health or the environment. From wood it also inherited the ability to regulate the humidity in the building. If you are building a house from wood concrete blocks, then the microclimate in it will be excellent. All this ensures good properties of wood concrete.

It is also important to say that wood concrete belongs to lightweight building materials. It, unlike brick, has low density and weight . The density of concrete is 2300 - 2400 kg/cubic m. The density of wood concrete is only 400 - 850 kg/cubic m.

Wood concrete houses do not require preliminary laying of heavy foundations or the use of complex mechanisms. Because of this, the price of arbolite blocks is low, as is the total cost of building housing using arbolite blocks. It should be noted that finishing materials are well applied to wood concrete surfaces. Arbolite blocks are qualitatively combined with concrete and plaster. As for processing, wood concrete blocks are not inferior to gas silicate ones.

The thermal insulation performance of wood concrete is 2 times better than that of expanded clay concrete, and 4-6 times better than that of brick. Thermal performance indicators are better for wood concrete than for other building materials. Heating rooms with wood concrete walls is also more profitable, because if the wall is 20 cm, then you need half as much energy.

Therefore, reviews about wood concrete blocks are very good, from those people who have already used this material in building a house.

NEW!

At the request of customers, we have started production of a new size of wood concrete block: 30x40x20 cm.This size allows you to lay walls with a thickness of both 30 cm and 40 cm - which is very convenient when building baths, garden houses and cottages.

The size of the wood concrete block is 30x40x20 cm, which saves masonry time, and the excellent geometry of our block will allow you to reduce the volume of masonry mortar. The new block size can be used in combination with all our other blocks, both 40x20x20 cm and 120x60x40 cm.

Using the new block, it is possible to build external walls 50 cm thick (30+20) - which will make your new home durable and very warm.

The block is packed on pallets.

60 pcs. -40x20x20 cm, price - 56 rub/piece (3600 rub/m3) 40 pieces -40x30x20 cm, price - 83 rub/piece (3600 rub/m3) Pallet, price - 150 rub.

Protocol for determining the thermal conductivity coefficient of masonry

TECHNICAL PROPERTIES OF ARBOLITH

| Characteristics, units measurements | Filler: crushed wood. index. |

| Average density, kg/m3 | 550-650 |

| Compressive strength, MPa | 1,5-3,0 |

| Bending strength, MPa | 0,8-1 |

| Thermal conductivity, W/(m*°С) | 0,11 |

| Frost resistance, cycle | 25-50 |

| Water absorption,% | 40-75 |

| Shrinkage, % | 0,4-0,5 |

| Biostability | Group V |

| Fire resistance | 0.75-1.5 h |

| Sound absorption, 126-2000 Hz | 0,17-0,6 |

Lay wood concrete blocks on lightweight thermal insulating masonry mixture Ceramix-T

our production. This will increase the thermal resistance of your walls by 10% by creating a “warm seam”.

Plaster wood concrete walls with a special plaster mixture Ceramix PM24

using our Ceramix primer. The mixture will allow you to provide a high-quality and inexpensive primary rough protective plaster layer.

Wood concrete is a universal material for wall insulation, as well as for the construction of various structures.

Wood concrete blocks are used in the following structures and structures:

- in load-bearing and external structures of buildings for various purposes;

- in internal walls for high sound insulation;

- in existing structures and enclosing buildings for thermal insulation.

This material is very beneficial for the construction of various buildings because it:

- can significantly reduce the cost of construction of buildings and structures;

- can reduce the construction period of structures;

- has unique operating properties, therefore improves the quality of life of building residents;

- Excellent for use in northern and undeveloped areas.

Applications for wood concrete are accepted by phone:

Chelyabinsk

+7(351) 900-04-14

+7-951-786-29-14

You can also leave a request on the website

Application

Flaws

- The main disadvantage of foam concrete is considered to be its susceptibility to moisture.

- Due to its structure, the material accumulates condensation inside itself, which at subzero temperatures can cause destruction of the building or walls.

- The disadvantages of such baths include the impossibility of constructing tall buildings. After all, the material is not able to withstand high pressure.

- If special finishing has not been done inside and out, mold and mildew may develop in the products.

- Despite the high level of environmental friendliness, this material is inferior in this sense to wood.

This product has both disadvantages and advantages. For this reason, it is important to think through all the nuances before doing anything. If we consider the shortcomings of a foam block bath, then almost all of them can either be refuted or corrected with the help of additional manipulations. Taking into account that the baths are one-story buildings, there will not be a large load on the material.

If the choice of material is final, then first of all it is important to make bathhouse projects from foam blocks. After this, you need to make a list of the necessary tools and materials, and make an estimate of construction costs.

Table of comparative characteristics of building materials

The modern market for construction products offers a large number of unique materials with completely different properties, but before you start using a construction calculator to calculate block walls, you need to take into account the basic technical and operational characteristics of the products, their advantages and disadvantages.

The most important criteria when choosing a building block are:

- Price. The rule almost always works: the more expensive, the better and better quality.

- Durability. You can build a house only for yourself, or you can build it for several generations.

- Weight. Heavy materials require a more powerful foundation, and this leads to a significant increase in the cost of the entire structure.

- Frost resistance. The wrong choice of block brand threatens premature destruction of the building.

- Thermal insulation. Construction costs may seem ridiculous if you pay a five-figure sum for heating every month.

- Labor costs. A house made of large blocks is built 3-4 times faster than a brick one.

Each material has advantages and disadvantages, but it is necessary to realize that with a limited budget, first of all, it is worth starting from the specific conditions of the area and the possibility of using the cheapest materials. Let's look at the most popular products separately and compare them.

An online calculator of blocks for building a house allows you to get a calculation of materials, but you must make their choice yourself.

We invite you to familiarize yourself with the Outdoor terrace with a swimming pool

Traditional brick

Everyone knows from childhood that there are two types of bricks - red (ceramic) and white (silicate).

Ceramic brick is made from baked clay with a minimum amount of foreign impurities. It has extremely high strength, does not allow water to pass through, can withstand any frost, and if it has pores, it serves as a good insulator. A brick house has the highest cost.

Sand-lime brick is made from sand and lime. In all respects, it is almost identical to the previous one, however, it has one distinctive drawback - strong moisture absorption. It cannot be used in the construction of basements and basements. However, this minus is compensated by the lower cost.

Ceramic brick

Sand-lime brick

Foam concrete blocks

The resulting material contains unevenly distributed closed pores, which require mandatory finishing of the block, otherwise it will begin to prematurely collapse under the influence of moisture. Foam concrete has deserved popularity among builders due to its good quality characteristics and ease of production. It is formed from a mixture of cement and foaming agent, which is poured into a container of a specified size, hardening in natural conditions.

Its advantages are excellent heat and sound insulation characteristics, relatively good frost resistance and low weight. The main disadvantage is the presence of a large number of unscrupulous manufacturers who do not comply with standards and technologies.

On a separate page you can make calculations using a foam block calculator.

Foam concrete block

Despite the external similarity with the previous one, aerated blocks use a slightly different manufacturing technology. Instead of a foaming agent, aluminum powder is used, which evenly saturates the mixture with gases, allowing it to “breathe.” Therefore, the blocks absorb moisture extremely easily and are not recommended for wet rooms.

Aerated concrete and gas silicate blocks differ in composition. In the former, most of the mixture is cement, while in the latter it is lime and sand.

Just like foam concrete, they weigh little, do not let in cold or give off heat, and have significant sound insulation. They have higher compressive strength, but also a higher price.

For the convenience of the user, we made two separate calculations - aerated concrete calculator and gas silicate calculator.

Aerated concrete block

Gas silicate block

Expanded clay concrete

Expanded clay concrete is a material consisting of a mixture of cement and baked clay (expanded clay). In our country it has not received proper distribution, but in Europe it is actively used and is one of the most common building blocks.

These products have significant strength and retain heat well, are unpretentious and resistant to aggressive environments. Due to the hollowness of expanded clay, they have a low mass and allow you to save on foundation construction.

But the advantages on the one hand are disadvantages on the other. Due to the presence of an extensive network of large pores, a large amount of liquid penetrates into the block, and when it freezes, it breaks the expanded clay concrete from the inside. As a result, the use of this material in wet and cold conditions is not justified.

Expanded clay concrete block

Cinder blocks

Cinder blocks have long been considered the most unclaimed material for building a house. A significant part of the solution is slag - waste from metal smelting and coal combustion. The environmental friendliness of this type of raw material was questionable, so it was used for the construction of outbuildings, garages, bathhouses, etc.

The main advantages of this material are extremely low cost, significant strength, durability and resistance to temperature changes. Among the disadvantages are the heterogeneity of the material and, as a consequence, high hygroscopicity, which in cold climates requires mandatory plastering and insulation.

Slag block (old style)

Slag block (new sample)

After you have become familiar with the general performance characteristics, in order to correctly calculate the blocks for wall construction, you need to visually compare the parameters of the materials in numbers. We have selected the most common products on the market and added them to the table.

By default, all blocks and bricks are considered to be solid, with smooth edges and in the shape of a parallelepiped. Since bricks are sold individually, the average price was multiplied by the quantity per cube (512 pieces). The cost is relevant for the Moscow region for 2019.

| Material | Price per 1 m3, rub | Durability, years | Frost resistance, cycles | Thermal conductivity, W/(m °C) |

| Single ceramic brick, M-150 | 4600-5100 | {amp}gt; 100 | 50-100 | 0,8-0,95 |

| Single sand-lime brick, M-150 | 3800-4400 | {amp}gt;100 | 50-100 | 0,8-1.1 |

| Foam concrete, 600x300x200, D500 | 2300-3000 | 80 | 40 | 0,12-0,21 |

| Aerated concrete, 600x300x200, D500 | 2500-3400 | 60 | 35 | 0,1-0,14 |

| Gas silicate, 600x300x200, D500 | 2800-3500 | 60 | 35 | 0,1-0,15 |

| Expanded clay concrete, 400x200x200, D1400 | 2500-3000 | 75-90 | 25-50 | 0,15-0,45 |

| Slag concrete, 400x200x200, D1400 | 1800-2500 | 80-100 | 20 | 0,3-0,5 |

Once you select the most suitable type of block, use our construction calculator to calculate block walls to get the most detailed report on the number of materials.

How to calculate the mass of wood concrete walls?

The simplest option would be to calculate the total cubic capacity and specific gravity of the wall blocks that were used to build the wall.

Important! When constructing walls of similar area and configuration from blocks of different sizes, their cubic capacity will always be the same! This is one of those riddles about what would be heavier than a kilogram of fluff or a kilogram of metal. Regardless of whether large or small blocks are used for construction, in the end their cubic capacity in the same area will always be the same.

For greater clarity, we suggest calculating the mass of the walls of a house with an area of 8 * 9 meters, a height of 2.5 meters and a thickness of 30 centimeters. To do this: 1. Calculate the perimeter of the building box - (8+9) * 2 and get 34 meters. 2. Now you need to find the total area of all the walls of the building - 34 * 2.5 = 85 square meters. 3. We need to subtract windows and doors from the total area of the walls. To make the task easier, imagine that we have one door 2 meters high and 80 centimeters wide and two square windows one meter per meter. We get – 2*0.8 = 1.6 and (1*1)*2 = 2 squares. Thus, the area of the openings is: 1.6 + 2 = 3.6 square meters. 4. Now we subtract the area of the openings from the area of the walls: 85-3.6 = 81.4 squares. 5. At the next stage of calculations, you need to multiply the actual area of all wall structures by their width: 81.4 * 0.3 = 24.42. 6. Finally, you need to find out the desired specific gravity of the walls; for this, we multiply the resulting figure of 24.42 by the weight of one cubic meter of wood concrete (the figure provided by the manufacturer), which is equal to 599 kilograms. 24.42*599 = 14627.58, i.e. As a result, we find that the estimated weight of the house box is 14.5 tons. Taking into account the masonry joint and reinforcement, the weight can approach 15 tons.

Attention! The above example can also be used to calculate the weight of structures made from any other materials. However, in this case it is worthwhile to first clarify all the initial data.

Information on the purpose of arbolite blocks

Expanded clay concrete blocks are a compromise solution between aerated concrete (or foam concrete) and brick. Expanded clay concrete blocks combine frost resistance and strength (the positive properties inherent in brick) as well as light weight, large dimensions and low thermal conductivity (the positive properties of porous blocks).

Expanded clay concrete is made from the following components: cement, sand, expanded clay gravel (or expanded clay sand) and water. The final properties of the expanded clay concrete block depend on the proportion of raw materials used and the characteristics of the raw materials themselves. Also, in the production of expanded clay concrete blocks, various additives are used that affect the plasticity of the solution and subsequently reduce the likelihood of cracks appearing on the block when subjected to physical impact.

We suggest you familiarize yourself with How to insulate the ceiling in a bathhouse with your own hands

Expanded clay concrete blocks can be divided according to their load-bearing capacity:

- structural;

- thermal insulation;

- structural and thermal insulation.

You can find out more detailed information about expanded clay concrete blocks, their properties and construction features in this article.

Arbolite blocks can be used for:

- internal partitions;

- load-bearing walls;

- thermal insulation of load-bearing walls;

- monolithic, dense blocks are used for load-bearing walls;

- Hollow blocks are used for internal partitions.

Wood concrete is an interesting material, consisting of lightweight concrete with a natural filler, which has been time-tested, but has not yet come into mass use at this time.

The composition of wood concrete includes:

- organic filler (woodworking waste prepared using a special method);

- binder (cement);

- chemical additives (depending on the required properties);

- water.

More information about wood concrete and its properties can be found in this article.

You can learn about the production technology of wood concrete blocks in this article.

A comparison of wood concrete blocks (sawdust concrete blocks) with other blocks, as well as their technical characteristics, is detailed in this article.

Weight of arbolite blocks

Before moving directly to the answer to the question, what is the weight of wood concrete, you should understand such a concept as the specific gravity of building materials. This term usually refers to the mass of one cube. So, for example, if we are talking about the fact that one cube of coniferous lumber weighs one and a half tons, this means that the specific gravity of the timber in question is 1500 kg/m3. To obtain specific numbers, let's turn to GOSTs. According to GOST, the specific gravity of wood concrete, depending on the brand, ranges from 500 to 900 kg/m3. If the figures declared by the manufacturer are less than these values, then the material cannot be used for the construction of load-bearing wall structures; with large values, there is a high probability of violation of the production technology of the block material, as a result of which it turned out to be too dense, and therefore cold.

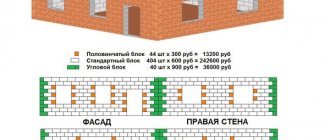

Bath calculation

Before starting the phased construction of the building, it is necessary to complete bathhouse projects made of foam blocks. All baths are similar to each other, so you can choose a project from existing ones. After this, you can begin settlement operations.

It is important to correctly calculate the required amount of building material, so that later there will be enough of everything, but at the same time there will be no excess left. For example, we perform calculations for a 6x8 bath. To perform such an operation, you need to divide the calculation method into 3 types. The first type includes load-bearing walls, the width of which is approximately 2 foam concrete, installed on an edge.

The volume of the product in such a situation should be 20x30x60 cm. The second type includes the internal partition of the building; foam concrete is installed here in one row. In such a situation, the volume of the product used is equal to the first type. The third type includes the walls inside the bath; they are mounted in the same way as products of the second type. However, in this situation, the volume of the product is 10x30x60 cm.

When the types of species have been clarified, you can study the basis of settlement operations of such a bathhouse. Each product has its own dimensions. Having carried out the necessary calculations, you can find out the size of all the walls of the structure. Next, you need to find out the size that different types of openings in the walls will occupy. At the end, you need to subtract the size of the openings from the total size of the walls.

The resulting number must be divided by the volume of one product. As a result of calculation operations, you will find out the required volume of material for installing a 6x8 bathhouse with your own hands. However, it is important to take into account possible errors and nuances, so the purchase of products is made with a margin of 10%. According to this calculation and reserves, it is worth purchasing building material.

Initial data

Initial data for calculating wood concrete blocks in the online calculator and their description:

- It is necessary to indicate the width, length and height of the building on the outside. If the height of the walls is different, you must enter the average value. Example: if 2 walls are 7 meters high and the other two are 5 meters high, then (7 7 5 5)/4=6;

- Select the sizes of wood concrete blocks for construction from the proposed list or enter your own sizes. When selecting wood concrete blocks from the list, the “Block weight” parameter is inserted automatically. When entering your dimensions and the need to calculate the “Load on the foundation from the walls” parameter, you need to enter the weight of the wood concrete block;

- It is necessary to select the wall thickness from the proposed options (without facing and finishing materials). The thickness of the wall affects the load-bearing capacity, which must provide the structure with the necessary stability, as well as withstand the weight of the floors and roof, taking into account the loads acting on them. Depending on the climate zone in which construction is taking place, there are standards for optimal wall thickness, depending on thermal insulation;

- The thickness of the masonry mortar is selected depending on the geometry of the block and the type of masonry. The most common solution thickness is 10 mm. The thickness of the seams should be the same. The seams must be completely filled with mortar without the formation of voids;

- Masonry mesh in masonry is used to increase the strength of load-bearing structures. Reinforcing mesh is usually placed every 5 rows of masonry;

- For a more accurate calculation, it is necessary to indicate the number of fronts (the pediment is the end of the facade, which is limited by the roof slopes on the sides and the cornice at its base), doors and windows, as well as their sizes. In case of different sizes, enter their total area in the appropriate columns (the areas can be calculated in this calculator and added up).

Initial data for calculating expanded clay concrete blocks in the online calculator and their description:

- It is necessary to indicate the width, length and height of the building on the outside. If the height of the walls is different, you must enter the average value. Example: if 2 walls are 7 meters high and the other two are 5 meters high, then (7 7 5 5)/4=6;

- Select the dimensions of expanded clay concrete blocks for construction from the proposed list or enter your own dimensions. When selecting expanded clay concrete blocks from the list, the “Block weight” parameter is inserted automatically. When entering your dimensions and the need to calculate the “Load on the foundation from the walls” parameter, you need to enter the weight of the expanded clay concrete blocks;

- It is necessary to select the wall thickness from the proposed options (without facing and finishing materials). The thickness of the wall affects the load-bearing capacity, which must provide the structure with the necessary stability, as well as withstand the weight of the floors and roof, taking into account the loads acting on them. Depending on the climate zone in which construction is taking place, there are standards for optimal wall thickness, depending on thermal insulation;

- The thickness of the masonry mortar is selected depending on the geometry of the block and the type of masonry. The most common solution thickness is 10 mm. The thickness of the seams should be the same. The seams must be completely filled with mortar without the formation of voids;

- Masonry mesh in masonry is used to increase the strength of load-bearing structures. Reinforcing mesh is usually placed every 5 rows of masonry;

- For a more accurate calculation, it is necessary to indicate the number of fronts (the pediment is the end of the facade, which is limited by the roof slopes on the sides and the cornice at its base), doors and windows, as well as their sizes. In case of different sizes, enter their total area in the appropriate columns (the areas can be calculated in this calculator and added up).

We suggest you familiarize yourself with Which wood is best for a bathhouse - what is the best material to use to build a bathhouse and do the finishing?

Calculation method for expanded clay blocks

As an example, a one-story house with gables and an interior partition.

Let this house be square in shape with each wall 10 meters long and 2.8 meters high. The house has two windows 1.6x1.4 meters and an entrance door 1x2 meters. The thickness of the external walls is 19 cm (half a block). The outside of this house is lined with facade brick. Therefore, the length of each expanded clay wall will be 30 cm less than on the building plan. These 30 cm will be taken up by insulation and facing bricks - 15 cm from each of the two ends of the wall.

- We find the total perimeter of the expanded clay walls: (10 – 0.15*2)*4=38.8 m.

- Let’s say the length of one expanded clay block together with the seam is 40 cm. How many blocks are needed for one row of walls: 38.8/0.4 = 97 pieces.

- The height of the selected block is 20 cm. Find the number of rows: 2.8/0.2=14 rows.

- We find the total number of blocks for the perimeter: 97*14= 358 pieces.

- How many blocks does one window take? Length 1.6/0.4=4 pieces. Height 1.4/0.2=7 pieces. Two windows: 4*7*2=56 blocks.

- Next, the calculation is performed for the front door. Length: 1/0.4=2.5 pieces. Height 2.0/0.2 = 10 pieces. The door takes up 2.5*10=25 blocks.

- We subtract the volume of voids of doors and windows: 1358-56-25 = 1277 blocks are required for laying external walls.

https://www.youtube.com/watch?v=playlist

Now you need to calculate the number of expanded clay blocks for the wall inside the house. The calculation is carried out in the same sequence. In our example, the length of the internal wall is 9.2 meters, the thickness is 0.4 meters (1 block). There is a door in the wall with dimensions of 1x2 m.

- Number of expanded clay blocks along the length of the wall: 38.8/0.2 = 46. In this case, we divide the length of the wall by the width of the block instead of the length, since the blocks will be laid crosswise.

- The number of rows is 14, since the height of the inner wall is equal to the height of the outer ones. In total, 14 * 46 = 644 expanded clay blocks are needed to lay the wall.

- The volume of the door is calculated differently than for external walls. It is necessary to take into account the direction of laying the blocks. Length 1/0.2 = 5 pieces. Height 2.0/0.2 = 10 pieces. The door takes up 5*10 = 50 blocks (instead of 56 for the outer door).

- We find the total number of blocks: 644–50 = 596 pieces.

We invite you to familiarize yourself with: Bathhouse with a large steam room

In the example, the height of the pediment is 2 meters, and the length is also 9.7 meters. Calculations are performed according to geometric formulas, according to which the total area of the gables is equal to the area of one wall of 9.7 × 2 meters.

- We calculate the number of blocks for two gables: (9.7/0.4)*(2.0/0.2)= 242.5 blocks.

- Laying begins with a full row. The perimeter of the walls is 97 blocks, and two complete rows are 48.5 pieces. Total required: 242.5 48.5 = 291 pieces.

- Since the blocks are sawn when laying the gables, you should buy them with a small margin. Let's round the resulting value to 300 pieces. This amount takes into account the masonry of both gables.

Calculation result

Description of the results of calculating wood concrete blocks in the online calculator:

- The perimeter of enclosing structures is the sum of the lengths of all enclosing structures, units of measurement are meters;

- Wall area – the area of the external sides of the enclosing structures, excluding gables/doors/windows, units of measurement – square meters;

- The total area of the gables is the area of masonry on the gables, which is added to the area of masonry on the walls;

- The total area of windows is the area of all windows, which is subtracted from the area of the walls, units of measurement are square meters;

- The total area of the doors is the total area of the doors, which is subtracted from the area of the walls, the units of measurement are square meters;

- The total area of the walls is the area of the external sides of the enclosing structures, taking into account gables, doors and windows, units of measurement – square meters;

- Total number of blocks – the number of blocks required to construct a structure according to the specified parameters, units of measurement – pieces;

- The total weight of the blocks is the weight of all the blocks required to construct the structure according to the specified parameters, units of measurement are kilograms. A useful parameter when calculating delivery;

- The total volume of blocks is the volume of blocks required for construction, units of measurement are cubic meters. A useful parameter when calculating delivery;

- Total amount of mortar - the total amount of mortar required to erect a structure according to the specified parameters, units of measurement - cubic meters;

- The total weight of the mortar is the approximate weight of the mortar required for masonry according to the specified parameters. Weight may vary depending on the volumetric weight of the components and their ratio in the solution; units of measurement are kilograms;

- Total weight is the approximate weight of the finished walls, taking into account blocks, mortar and masonry mesh, units of measurement are kilograms;

- Wall thickness – the thickness of the finished wall including seams, units of measurement – millimeters;

- Number of rows including seams - the number of rows is given without taking into account the gables, depends on the overall dimensions of the selected block and the thickness of the mortar in the masonry, units of measurement - pieces;

- Quantity of masonry mesh - the total amount of masonry mesh used to strengthen the structure being built, units of measurement are meters;

- The optimal height of the walls is the height of the walls, excluding the gables, which is obtained when laying blocks, the selected size and thickness of the mortar in the masonry, units of measurement are meters;

- Load on the foundation from the walls - this parameter is necessary for choosing a foundation. Given without taking into account the weight of the floors and roof.

Arbolite calculation

Before purchasing, you need to find out the number of blocks needed. There are construction calculators on the Internet for calculations like the Chinese, but you can perform the calculation correctly only after understanding the topic. If you were designed by a good architect who loves the job, then you most likely should already know what materials will be needed in construction.

Typically only two sizes are used:

- 500x300x200 mm - for walls;

- 500x150x120 mm - for interior partitions;

- Often there are projects with 400x200x200 mm.

Without a detailed description of the project, you will not be able to find out how much wood concrete is needed for construction. You will have to act at random.

It is also necessary to remember that there are no houses without windows and doors, and their square footage also needs to be calculated in advance.

For a complete calculation, you, of course, need to know the length of the load-bearing walls. Thickness is no less important, but this figure is 99.9% the same - 300 mm (load-bearing wall) and 150 mm (interior wall). If the building has more than one floor, you should of course know the height of each.

The calculation itself is divided into 5 steps:

- First of all, calculate the perimeter of the walls, to do this you just need to fold them - this will be the total length;

- Next, add up the height of each floor;

- Then we multiply the height by the length of the load-bearing walls;

- Don’t forget to subtract window openings and doors;

- Multiply the result by the number of blocks needed to lay 1 m2 of wall.

If this is already behind you, proceed to the calculation stage.

Let's take numbers out of nowhere (in your case, from measurements):

- let's say the length of all walls is 28 m;

- wall height – 7 m;

- total area of all windows and doors – 13 m2;

- We take 500x300x200 blocks as the basis of the house; to build 1 square meter you need 10 such blocks.

We count: x= (28*7-13)*10. As a result, we get 1830 blocks.

Do not forget that there are defects and defects, so you need to take 8% more.

Calculation of wood concrete in a cube

To calculate everything inside and out, you need to know how many blocks are in one cube. First, consider the standards of load-bearing walls 500x300x200 mm - in a cubic meter you get 33.3 pieces.

Having carried out the preliminary calculations above, we learned that to build a 28x7 we need 1830 pieces, let’s convert our numbers into volume:

V =1830/33=55.5 m3.

It is also worth knowing the volume of bulkheads, for filling which arbolite 500x150x200 mm is always used, in one cube there are 66.6 pieces. Even no less often, when constructing a building, carbolite of size 400x200x200 is used - in this case there will be 62 blocks in 1 m3.

We have given you the necessary knowledge needed to perform the calculation of wood concrete.

Foundation

There is no need to build too strong a foundation for such a building. This is possible due to the light weight of the material used. Due to this property, the construction of a strip foundation is permissible. It is used in conjunction with a sand base. This substrate will need to be waterproofed using bituminous materials.

To build such a foundation, it is necessary to dig a hole in the shape of ribbons along the entire perimeter of the building. Their height should be 600 mm and thickness 300 mm. After completing the pit, it is worth making markings. This is done using a building level. Next, special rods are installed around the perimeter, at a distance of approximately 2 meters. In order to do everything as accurately as possible, it is recommended to use a cord. By tensioning the cord, the correct installation of the rods is checked.

The next stage will be the formation of a reinforcing frame and the collection of formwork from wooden boards. Next, concrete is poured, but it is important to first lay all communications inside the base. After pouring, everything is covered with a special mesh. For a base with a height of 1 meter, you will need about 1 m3 of concrete solution. The last step will be to waterproof the base using bituminous materials.

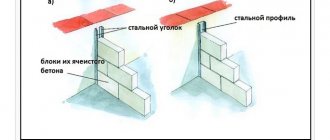

Walling

After the stage of waterproofing the base (with bituminous materials) is completed, you can begin the stage of wall construction. For such purposes, it is recommended to use products of type M25, which has a density index of D700. The dimensions of this material are considered optimal for various types of construction manipulations.

First you need to find out the highest corner of the building. This operation is performed using a building level. Taking this knowledge into account, further construction of the building from foam blocks is carried out.

Installation of the first row is considered to be the most important stage. The quality of subsequent rows and the entire building as a whole depends on it. When installing this series, the products are installed using a cement mixture. When the laying of the row is completed, the surface should be carefully leveled. Only if this stage is performed correctly will further steps be correct.

Subsequent rows are installed using special glue. The technology for its preparation is described in the manufacturer's instructions. However, there are no difficulties in breeding; this can be done directly on the site. This material is produced in the form of a dry solution. It will take 15 minutes to knead. Despite its considerable cost, its use is still profitable, because the consumption is minimal.

Material characteristics

Arbolite blocks have several components - a base, binders and additives to improve the quality of the material. The new composite material has the advantages of all its components, and also allows you to get rid of their disadvantages.

Block and monolithic material first appeared in the thirties in Holland. Over the next twenty years, wood concrete spread throughout Europe, America and came to the Soviet Union, where it was widely used in the construction and finishing of finished structures.

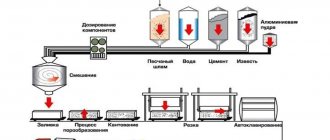

Industrial material consists of the following components:

- wood chips;

- cement;

- water;

- fillers.

The block recipe uses pine chips, woody stems, cotton or rice straw.

Cement plays the role of the main binding component; the density and strength of wood concrete depends on it. Fillers are needed to neutralize wood sugars, which cause rot and attract insects. Aluminum sulfate, calcium nitrate or liquid glass are used in production mixtures. Water dissolves all fillers and catalyzes the cement reaction. When produced at special enterprises, the recipe uses 500 ml of liquid glass, 25 kg of cement, 40 liters of water and 130 liters of wood chips. This is useful: how to make wood concrete blocks with your own hands.

The characteristics of wood concrete combine the features of cement and wood materials. The second name of the material - wood concrete - was formed precisely because of the presence of wood chips in the composition. In terms of technical indicators, wood concrete is superior to brick in terms of thermal conductivity and ease of installation.

In this video you will learn how to mix wood concrete:

Main characteristics:

- density - 600-800 kg per cubic meter;

- thermal conductivity - 0.10-0.17 W/(m*s);

- frost resistance - a wet cube can be frozen 30-50 times;

- water absorption - 50-85%;

- biostability - fifth group;

- shrinkage - 0.5%;

- sound insulation - 0.15% transmitted sounds up to 2000 Hz;

- fire resistance - 60-90 minutes before destruction in a flame.

Indicators may vary depending on the density of the material, which depends on the type of cement and fillers. The use of plaster or decorative panels to cover the facade allows you to reduce some parameters of wood concrete.

In this video you will learn about the composition of wood concrete: