The foundation is a very important structure of a building. Up to a third of all financial investments in construction can be spent on work below the ground floor level. In addition, the situation is complicated by the fact that after the workers begin constructing the box, access to the foundation will be limited, and its repair is very labor-intensive. The choice of type of support for a building depends on its design, the presence of a basement and the characteristics of the foundation soil. One of the most common types is a strip foundation.

Classification of foundations

Foundations

Foundations are the main and most important structural element of the load-bearing frame of a building.

General provisions

Impacts on foundations. Foundations operate in difficult conditions, subjected to force and non-force impacts of various types (Fig. 6.1).

Rice. 6.1. Scheme of influences on foundations

Force influences - loads from the weight of the building and soil, heaving forces, seismic shocks, elastic reaction of the soil, vibrations - cause compressive, shear and bending stresses, which can result in unacceptable deformations of foundations and their destruction.

Non-force influences - variable temperature and humidity of soil and air, excessive moisture, exposure to aggressive chemicals and biological factors - can lead to undesirable destructive processes in foundations.

Requirements for foundations. Taking into account force and non-force influences on foundations determines the basic operational requirements for them:

– resistance to overturning and sliding;

– resistance to groundwater, chemical and biological aggressiveness of the environment.

In addition, foundations must meet the requirements of manufacturability of the device and the economic requirements of minimizing the cost of funds, labor and time for their construction, which is achieved by industrial construction methods.

Classification of foundations

according to their structural type and shape (Fig. 6.2):

– strip , located along the entire length of the walls or in the form of a continuous strip under rows of columns;

– columnar , in the form of separate supports under the columns of frame buildings, as well as under the walls of low-rise buildings without basements;

– solid (slab), which are monolithic slabs under the entire area of the building or part of it;

– piles , in the form of rods immersed in the ground (arranged in the ground) – piles.

| Tape | Solid |

| Columnar | Pile |

Rice. 6.2. Main types of foundations

Based on the material, foundations can be made of natural stone, rubble concrete, soil concrete, concrete and reinforced concrete.

Based on their depth into the ground, foundations are distinguished: shallow (up to 5 m) and deep (more than 5 m). Most buildings are designed and built with shallow foundations, which have the following distinctive features:

– the load on the foundation is transmitted primarily through the flat base, while deep foundations (for example, piles) also transmit the load through the side surface;

– the ratio of dimensions – width and height – is insignificant, which allows us to consider them as rigid structures;

– the construction of foundations is carried out in open pits that are torn off or in cavities created in the soil mass.

According to the manufacturing method, foundations can be built monolithic, prefabricated monolithic and prefabricated . The use of monolithic foundations is most rational, since they are cheaper than prefabricated ones and have better technical characteristics.

By the nature of their work, foundation structures can be rigid , working only in compression, and flexible , designed to withstand bending forces. Flexible foundations are made of reinforced concrete, which reduces concrete consumption, but at the same time increases steel consumption.

Based on the nature of the loading, a distinction is made between centrally loaded and eccentrically loaded foundations.

Based on the method of resting on the ground, foundations are distinguished: directly resting on the ground (on a natural foundation); Friction foundations – hanging piles (on an artificial foundation).

Foundation bases

The basis for the foundation is that part of the soil on the site to which the load from the building is directly transferred. Therefore, a lot depends on the reliability and characteristics of the foundation:

- stability and strength of the house itself;

- choosing the type of foundation and its parameters;

- the need for engineering measures to increase soil strength.

The layers of soil located below the base of the foundation and to the sides of it are called the base. It is to these layers that the load from the house is transferred and it is these layers that affect the stability and movement of the foundation. For competent design of a house, geotechnical survey data is required. This is due to the fact that the design of the foundation of the future house largely depends on the characteristics of the soil and foundation on the land plot.

The bases for foundations are distinguished between artificial and natural. Natural foundations are understood as soils that, in their natural state, are capable of withstanding the required load from a house without any additional strengthening or hardening. Artificial foundations are understood as soils that require special engineering measures to strengthen and harden them. Without this, such soils cannot be used as a reliable foundation.

Classification and requirements for foundations

Foundation –

the most important structural element that absorbs all the loads from the higher elements of the building and transfers them to the foundation soils.

According to the structural scheme, foundations are divided into:

! Tape

– under the entire length of the walls or in the form of continuous strips under rows of columns;

! Columnar

– under light walls with a depth of suitable foundation soil below 2 m. have the form of separate supports for walls, columns or pillars;

! Pile

– are especially relevant if it is necessary to transfer significant loads to weak soil, with a high level of groundwater. Separate piles immersed in the ground, through which loads from the building are transferred to the ground, are combined along the top of the pile with a concrete or reinforced concrete slab, or a beam - grillage; hanging and pile-racks

! Solid

– monolithic slabs under the entire area of the building (used for particularly heavy loads, weak heterogeneous foundation soils, to create waterproof protection for basements, in wet soils with a high level of groundwater).

Materials used for foundations:

* heavy concrete grade 50 and higher

* reinforced concrete (monolithic or prefabricated, products made from them);

* metal, asbestos-cement pipes (for pile foundations);

* burnt red brick (durable grade 1 00 or more);

* antiseptic wood (for wooden buildings);

* rare for the middle zone natural stone from heavy natural rocks of grade 200 and above.

§ hard (

the material of which works in compression) no bending deformations occur in the body of these foundations. For their construction the following materials are used: natural stone masonry, rubble concrete, concrete

§ flexible

(work on bending)

By device method:

o prefabricated (factory production)

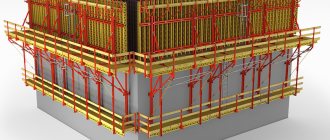

o monolithic (formwork for walls, pour concrete, 24 days...)

By depth:

¨ deep (more than 1m)

*10. Soil freezing. Depth of foundations.

Foundation depth

– the distance from the leveling soil mark to the base of the foundation.

The depth of foundations depends on a number of conditions:

-type of structure (house, bathhouse, garage, outbuildings) and its design features (presence of a basement, basement, etc.);

- the magnitude and nature of the loads acting on the foundation;

- geological conditions of the site (physical and mechanical parameters of the soil);

– hydrogeological conditions of the site (and their changes during construction and operation)

Foundation depth

Img by wisemandarine - flickr

In order for the foundation to efficiently fulfill its purpose - to evenly distribute (transfer) loads from the above-ground parts of the house to the foundation (soil), it is necessary to correctly calculate the depth of its laying - the distance from the base to the surface of the earth.

Usually, when designing houses, the minimum required depth is indicated. Moreover, it is based mostly on data from engineering and geological surveys. Due to the fact that the cost of the foundation and the work on its construction constitutes a significant part of the total cost of building a house, it is clear that mistakes at this stage will be very expensive.

The depth of the foundation depends on:

- geological conditions of the land (type of soil and foundation, groundwater level);

- type of building under construction (house, garage, bathhouse, etc.);

- design features of the building (presence of a basement, plinth, etc.);

- loads (magnitude and their nature);

- climatic conditions of the area (temperature changes).

In each specific case of foundation design, the depth of its laying must be calculated individually, based on the conditions on the selected plot of land. A competent solution to this problem allows you to find that “golden mean” in which the foundation will have the necessary stability, strength characteristics and, at the same time, optimal consumption of materials. The latter is more than relevant today - houses are becoming larger and heavier, and accordingly, the costs of the foundation are increasing. When building a large house, it is already financially tangible to lay the strength of the foundation “with a margin”, that is, the depth of the foundation should be rational and based on calculations.

The cost of the foundation is directly proportional to the depth of its laying: the deeper the foundation, the higher the costs of its construction, associated excavation work and materials, and vice versa.

Important points

The strip base is laid under the walls of the building or under specific supports.

The columnar foundation is laid to the required depth under light structures.

The pile type is used when the groundwater level is high, as well as when it is necessary to construct a building with increased load. Currently, it is actively used in the installation of low-rise buildings on water and in the construction of houses on swampy soils.

Solid slab foundations are used on soils with low bearing capacity. This type is used for additional waterproofing when constructing the foundation for a basement.

Types of strip foundations

There are several design options for strip foundations, each of which is used for certain cases and has its own load-bearing capacity. As a general classification, the following division can be given:

- non-buried foundations;

- shallow strip foundation;

- buried foundations.

These types are applied depending on certain circumstances. When choosing, you need to pay attention to:

- load from the building on the belt;

- groundwater level;

- depth of soil freezing;

- required base height.

Non-recessed tape

Scheme of a non-buried strip foundation.

Suitable for small buildings made of lightweight materials. Cannot be used for stone buildings (brick, aerated concrete, reinforced concrete). There are two types:

- reinforced concrete belt;

- reinforced concrete rib.

These types can only be built using monolithic technology. When using concrete blocks (FBS blocks), the structure may collapse with minor soil movements. In this case, concrete absorbs compressive loads. To accommodate bending, reinforcing bars are placed into the structure. It is necessary to install a cushion of medium-sized sand or a sand-gravel mixture under the tape.

The reinforced concrete belt has a height less than the width, and the edge is the opposite. The use of a rib as a strip base allows you to raise the base and provide greater reliability. With the same cross-sectional area, the rib will withstand greater bending loads compared to the belt.

This can be explained by the fact that the tape is calculated as a beam on an elastic foundation. To determine the deflection, it is necessary to calculate the moment of inertia, which is found by the formula:

I = (b*h3)/12,

where b is the width of the section, and h is its height. It can be seen from the formula that the height of the section most strongly influences the magnitude of the moment of inertia. The greater the value obtained from the formula, the greater the bending the structure will withstand.

This type of foundation is used when the groundwater level is high (water is located at a distance of less than 1 meter from the ground surface). Suitable for the construction of frame extensions, verandas, terraces and the like.

Important! For any type of strip foundation, it is necessary to provide a support pad. It is made from sand (coarse or medium) or a sand-gravel mixture. The thickness of the pillow is determined depending on the characteristics of the soil (most often 30-50 cm).

Read more: Non-buried strip foundation: do it yourself.

Shallow belt

Scheme of a shallow strip foundation.

Unlike the previous one, this type of foundation has a slight penetration into the ground. The depth of support is located within 0.5-0.6 m from the surface. There can be two types:

- rectangular section;

- T-shaped section.

The second option has greater load-bearing capacity, but requires increased material consumption and increases labor intensity. The T-shaped section combines a belt and a rib placed on it. The lower widened part absorbs bending and increases the support area, i.e. distributes the load, and the upper vertical loads from the building.

Scheme of a T-shaped shallow strip foundation.

Both of these types can be erected in a monolithic or prefabricated manner. When choosing a T-shaped section from prefabricated elements, special factory-made cushions (FL slabs) are laid under the concrete blocks.

Important! When supporting foundations above the freezing depth of the soil (accepted according to the joint venture “construction climatology”), it is necessary to provide for their insulation and replacement of heaving soil with medium-sized sand. Otherwise, cracks will appear in the structure.

Shallow types are used when the groundwater level is located at a distance of 1 meter or more from the ground surface. Frame or wooden houses (timber, rounded logs) can be placed on such foundations. Stone houses can only be placed on a T-shaped strip, since with a rectangular section and small movements of the soil, cracks may appear along the walls.

More details: Shallow strip foundation.

Tape option

Let's take a closer look at the types of foundations. The classification puts the strip foundation in first place. This option is considered optimal for building a private house. The classification of foundations of this type is regulated by SNiP standards (3.02.01) according to the following criteria:

Based on the first criterion, prefabricated structures made from reinforced concrete factory blocks, monolithic options (they are poured into formwork at the construction site), brick or rubble structures are distinguished.

Based on their depth, strip foundations are divided into two groups:

strip foundation of slight depth (0.4-0.7 m);

deep burial (below the soil freezing level).

In individual construction, a monolithic version is used.

Making tough choices wisely

Any foundation requires calculations taking into account the assessment of landscape features

In fact, it’s not easy to make a choice right away. And it’s not just about personal preferences of one design or another. It is much more important to compare your financial capabilities and objective conditions with the chosen type of foundation. The mandatory parameters by which the foundation for a house is selected include:

- type of soil at the construction site;

- terrain;

- presence or absence of a base;

- groundwater flow level;

- parameters of soil freezing in a given area;

- structural parameters of the building;

- weight of the structure, number of storeys;

- construction time;

- issue price.

Attention! A complete calculation of soil loads for various types of foundations takes into account the overall impact of a variety of parameters that affect its physical and mechanical characteristics: the influence of frost heaving, ground and surface water. Two main calculations are made: by deformation and by bearing capacity.

Pile structures

What is the classification of pile foundations? First, let's give a brief description of this base option. These are underground structures with an elongated shape. They are located as individual elements or in a group, installed obliquely or vertically. Some of the piles are driven directly into the ground. Also, this version of the foundation is installed by screwing, pressing, immersing, or stuffing.

Each option requires its own installation technology, material of manufacture, and operating conditions. The classification of piles and pile foundations involves determining their functionality related to increasing the bearing capacity of the soil. Such foundations are used in the construction of residential buildings and country houses.

What are the types of pile foundations? Both classification and application are based on several parameters:

Depending on the design features, you can choose solid or composite piles made from several sections for construction. They may have a pointed or blunt bottom end, as well as additional extensions at various levels.

By size, piles are divided into hard (short) and long (medium hard).

Currently, the following pile shapes are offered: polygonal, round, pyramidal, trapezoidal, cruciform, conical, hollow, solid.

Materials for making piles: concrete, reinforced concrete, wood, metal. Recently, a combination of several materials has been increasingly used, which significantly increases the technical characteristics of piles.

Based on the nature of the work, there are supporting and hanging options. When installing piles, driving, screwing, stuffing, and pressing are used.

Problems and errors of pouring the foundation

Some types of soil tend to swell, which leads to destruction or deformation of the finished foundation. The degree of swelling depends on the depth of groundwater and the degree of freezing. Studies show that a small house in winter can be subject to a buoyant force of 200 tons. This can only be prevented if the foundation is laid correctly.

In order to avoid mistakes in building a foundation, choose the type that is most suitable for your future home. Be sure to take an interest in the provisions of the house design, even if you have entrusted the development to experienced architects and planners.

Typical mistakes made during construction:

- Incorrect calculation of soil bearing capacity;

- Construction of a foundation on a base that has not been pre-compacted;

- Insufficient deepening of the foundation parts on which the interior of the building will be located;

- The level of soil moisture is not taken into account, which can lead to flooding of basements;

- Drainage and waterproofing systems for water removal are not installed.

Pouring a concrete foundation

Those who are going to build on their own, and experienced specialists should know and remember that any related activity is divided into three important stages:

- Preparing the mixture. The usual components of a concrete mixture are water, cement, construction sand and crushed stone. For large volumes, use a concrete mixer, and if a small amount is required, you can mix it manually.

- Filling. The option of pouring directly into the ground requires the presence of a trench with well-compacted walls. This method is suitable for building small private houses. For heavy and massive buildings, concrete is poured into formwork.

- Aftercare. Represents compliance with the conditions ensuring concrete hardening.

In order for the foundation to be strong and stable, mistakes should not be made at any of the stages described. A builder working with concrete must have certain knowledge and experience. Each of the points that make up the overall process is subject to responsible compliance. Mistakes made at any stage will make it impossible to obtain a high-quality and reliable foundation.

Wetting and freezing conditions

Creating unimpeded conditions for hydration, or in other words, hardening of concrete, is a key aspect of foundation care. As a result of this process, concrete gains special strength. It depends on the type of cement, the type of building being constructed and climatic conditions. For example, in winter it is recommended to fill the formwork with cement with frost-resistant additives and use electric heating until the foundation is half hardened.

In practice, the time for hardening is usually about 30 days. At the same time, scientists believe that concrete requires several years, a certain level of humidity and an air temperature of 25°C to completely harden.

To protect from direct sunlight, on the first day after pouring, the foundation is covered with film, wet sawdust or burlap. The surface is moistened with water, which prevents cracks from appearing on the surface. The foundation is wetted for the first time 4 hours after pouring. Then 3 times a day after 3 days from the moment of filling and after a week. You should also pay attention to the following points:

- The cement foundation, which hardens slowly, is watered for 4 weeks;

- The foundation is made of fast-hardening aluminous concrete, watered for no more than eight days;

- Portland cement foundation – 3 weeks.

Key points for caring for a concrete foundation in summer

Based on the fact that in summer the air temperature can reach critical heights, after pouring the foundation requires proper moisture. This process is quite complex, but it provides protection against drying out and cracking on the surface. It is important to protect the hardening foundation from direct sunlight and maintain the level of moisture achieved during watering. In addition to moistened burlap or sawdust, the concrete base is also covered with slate or roofing felt to protect it from the sun. Experts in working with concrete foundations highlight the following points:

- The concrete solution is poured either early in the morning before sunrise or in the evening after sunset;

- For the first three days, the foundation is wetted every 2-3 hours. This frequency of watering is explained by the fact that the heat generated during the concreting process quickly evaporates moisture;

- Further watering is carried out 3 times a day for 28 days by spraying drops of water over the entire surface.

- It is important to deliver the prepared concrete solution to the construction site within 1 hour and pour it as quickly as possible.

- At temperatures above +15°C, the concrete foundation and formwork are watered every 12 hours. And if the wind joins the heat, then every 3 hours.

- At temperatures below 5°C, watering may not be necessary.

If unexpected interruptions in water supply occur at a construction site, the foundation, immediately after pouring, is treated using a sprayer with special moisture-retaining film-forming agents. They are sold in every hardware store, these are latex liquids, soluble bitumen and emulsions.

Key points for caring for a concrete foundation in winter

If the process of pouring a foundation in winter cannot be postponed until a warmer time of year, be prepared for additional financial costs. Before hardening, the concrete foundation must be protected from freezing. It is best to turn to professionals, but if this is not possible, you can do the work yourself. The main thing is to take into account all the norms for filling and subsequent care. In essence, it comes down to one goal: preserving the water contained in the solution in a liquid state. If in summer it is important to prevent water evaporation, then in winter the main task is to heat the concrete. There are three ways to achieve this goal, which can be used separately or combined with each other.

- Mixing concrete mortar with the addition of antifreeze additives that reduce the freezing point of water. The addition of such chemicals and their combinations allows operation at subzero temperatures. Concrete produced in factories is processed in this way;

- Maintaining warmth using heating means. The most expensive method uses electric or infrared heating elements. The foundation is also covered with a dome, under which warm air is blown with a special hairdryer;

- Minimizing losses of heat generated during the hardening process. To do this, the concrete is covered with heat-insulating covers and the formwork is insulated.

You should take into account the fact that when concrete hardens, it releases a large amount of heat and energy. Portland cement, for example, emits about 120 kcal of thermal energy. Based on this, it can be calculated that 1 meter of concrete containing 300 kilograms of cement releases about 36,000.0 kcal of energy when hardening. The concrete solution releases 50% of the heat during the first three days after pouring. The next 25% within a week and the rest over six months. The advantage of this fact is that water under the influence of such heat release does not freeze for a long time. But this is also fraught with the appearance of cracks on the surface. This happens due to the fact that there is a temperature difference inside and on the surface of the foundation. To prevent cracks from appearing, you need to try to insulate the foundation as best as possible so that all the thermal energy is retained inside it.

The optimal temperature for pouring a foundation in cold weather is considered to be at least 3°C. In this case, the use of special additives and antifreeze agents will prevent problems during hardening. It is known that ice may form on the surface of the solution within several days after pouring. And if you comply with all the requirements for insulation and maintaining moisture inside, there will be no problems in the future.

Proper care of a concrete foundation in winter minimizes shrinkage of the mixture and prevents the formation of cracks and deformations. Also, compliance with optimal temperature standards protects the base from drying out and damage, ensuring the durability of the structure in the future.

Some useful tips

- After installation is complete, check the condition of the formwork. Until the concrete begins to harden, there are only a few hours to eliminate defects and problems.

- Before starting pouring, mark the area using fishing line and reinforcement.

- To insulate the foundation in winter, you can use the formwork insulation method. Polystyrene foam, hay or cotton wool are used, materials that are designed for self-heating.

- Try to protect the solution during the hardening stage from impacts and all kinds of damage.

- The resulting cracks can be removed while the mixture is still plastic, using vibration.

- The concrete surface in the formwork is poured less, as it holds moisture better.

- If possible, it is best to use factory-made, ready-made concrete, as it meets the norms and quality standards.

- Don't take into account the popular belief that the foundation must overwinter or sit for a year before building a house. This is not necessary, since after completion of construction the operating conditions will be completely different.

Features of choosing piles

When selecting the type of piles, it is necessary to take into account the characteristics of the soil, the height and structure of the house. For example, for areas with permafrost, solid railway piles without transverse reinforcement are not suitable.

It is important to first study the foundations: classification, requirements, features, select the best option, and only then begin building a new structure. The safety and performance characteristics of the created structure directly depend on the correct choice.

Rack piles are pillars that pass through soft soil and rest on its layers. Suspension piles are shafts that transfer the load from a building to the ground through the side surfaces.

What is a strip foundation

The structure is a stone strip that serves as a support for the walls and can be made from the following materials:

- reinforced concrete;

- brick;

- rubble stone.

The most common option is to make it from concrete with reinforcement. This solution can be implemented using two technologies:

- prefabricated strip foundation;

- monolithic design.

When using brick, you need to pay attention to its brand in terms of strength and frost resistance. If possible, it is better to focus on other materials (concrete, rubble). The foundation strip is provided for all walls, both load-bearing and non-load-bearing. There is no need to lay foundations under the partitions.

The strip type is suitable for the construction of massive buildings on soils with fairly good performance. It is not suitable for swampy soils. If there are bulk soils, they should be replaced with medium-sized sand with layer-by-layer vibration compaction. If the soil has high strength, some types of strip foundations can even be used for the construction of multi-story buildings. On a solid foundation, you can easily erect buildings of 9-12 floors. When using prefabricated blocks, a monolithic reinforced concrete stiffening belt will be required.

Equipment

To immerse a pile foundation to a certain depth by pressing or driving, special equipment is used: pile drivers, hammers, and other impact or vibration installations. The following options are available:

If cast-in-place types of piles are used in construction, wells are initially drilled or hollow pipes are driven into the ground. The resulting hole is filled with concrete solution.

Depending on the quality of the soil and the chosen technology, the shell is either left or removed after installation of the piles.

Features of piles

For the manufacture of screw piles, metal or reinforced concrete is used. They consist of a barrel and helical blades, which are located on a special shoe-tip. The pillar can be hollow or filled with concrete. The blades can be welded metal, cast steel, or plastic.

The material used for wooden piles is pine or spruce wood. Sometimes larch, oak, or cedar become the basis for a wooden pile. Straight logs are selected for the piles and the bark is first removed from them. In case of significant deepening, wooden piles are spliced in 3-5 elements.

Reinforced concrete piles are produced in factories, and monolithic structures are built directly on the construction site (according to the project). The reinforcement is poured with concrete taking into account the climatic characteristics of the region.

For metal piles, pipes, rolled profiles, and welded structures are used. To protect against atmospheric corrosion, they are treated with coal tar, bitumen, and special anti-corrosion compounds.

The pile foundation consists of a system of grillages and piles, which are the connecting and distributing elements of the structure’s load. The ground elements of the building being constructed will rest on the load-bearing beams or slabs that connect the piles.