Performing calculations

Find out exactly what communications are going on at the construction site in order to avoid future problems with neighbors and utility services. It is better to make calculations according to SNiP 2.02.03-85 Pile foundations. During the calculation, the bearing capacity and strength of the foundation are determined.

Values and characteristics taken into account:

- bases of piles and their shells;

- the values of the horizontal load when combined with the slopes of the structure;

- design features of concrete supports and foundation grillage.

A very important part of the calculations is the calculation of loads:

- The weight of snow on the garage roof, which is recommended to be 190 kg/m2 for the northern regions, 50 kg/m2 for the southern regions and 100 kg/m2 for the middle zone.

- Load from façade insulation and wall finishing.

- The load from the structure, not only from the roof covering, but also from the weight of the sheathing, insulation, rafters and other materials. Ceramic tiles - 60-80 kg/m2, asbestos-cement material - 40-50 kg/m2, roofing felt 30-50 kg/m2, sheet steel 20-30 kg/m2.

- Floor load, taking into account the weight of the insulation.

- Overall weight of the structure.

- Operating loads. This takes into account the availability of furniture, equipment, appliances, etc.

Calculating the foundation is a very complex matter, associated with a large number of formulas, calculation of dynamic loads, deformation and settlement, seasonal loads, the weight of the garage along with its contents.

And even a small mistake can lead to a big disaster, so to start quickly building supports with your own hands, you should entrust the calculations to professionals.

Do-it-yourself construction of a pile foundation for a garage

This is an important task, because along with strong walls and ceilings, it must protect the car or other equipment located in the room from severe humidity, and, accordingly, corrosion.

Preparatory stage

It consists of preparing all the necessary materials, tools and aids.

To build a garage on screw piles with your own hands, and specifically a foundation, you need:

- shovels;

- any tool for measuring length;

- building level or plumb line;

- marker;

- lever arm;

- wooden stakes and rope;

- an angle grinder, popularly called an angle grinder;

- sledgehammer.

And also basic materials:

- screw piles of the required sizes;

- caps for grillage;

- reinforcement bars;

- crushed stone, sand and cement.

Marking and excavation work

A pile foundation does not involve leveling the earthen surface, this is its advantage, but for ease of marking it is still worth clearing the area a little from tall grass and debris. To begin with, wooden pegs are installed in the corners and all sides of the future garage.

Installation of piles

If the size of the piles is small, then it is enough to have a regular crowbar on hand, which is inserted into the hole in the upper part and onto which levers in the form of pipes are put. In the case of garage construction, it is economically feasible to use piles 5 m long.

There are several installation options:

- Drilling. Using a drill, you need to manually make a hole into which the support is immersed.

- Screwing. The pile is screwed directly into the ground.

During the screwing process, the support is installed in a vertical position and screwed into the ground clockwise until it reaches the desired tight level. A correctly twisted support should pass the lower freezing point of the ground and rest against a dense layer. This will be signaled by difficult screwing.

Reinforcement and concreting of piles

After all the designed garage supports have been installed, the piles should be leveled in height using a building level. Each pile is marked and the excess part of each support is cut off with a grinder. To increase the strength of the pile, it is allowed to install additional reinforcement cage inside.

Concrete solution poured inside the rod helps increase the strength of the support and prevents metal corrosion. Concreting is done using conventional mortar. As a rule, the solution contains 1 part cement and 3 parts sand.

Installation of heads

At the end of the installation of the foundation for the garage on piles, the caps for screw piles must be secured to the cut ends of the supports. Heads come in any shape, but the simplest of them is welded. All pile heads must be located at the same height.

The size of the head is determined based on the specific weight of the structure and the diameter of the pile. For simplicity and convenience, you can take a metal plate 8-10 mm thick and 3-4 mm larger in diameter than the pile.

Personal execution of construction work

Construction of a garage is a highly complex job. It is necessary to build a box where the car will be stored. The machine must not be subject to corrosion. Create optimal humidity conditions in the room.

Preparation

At the preparatory stage, it is necessary to purchase building materials and prepare tools.

Tools:

- shovel;

- roulette;

- building level, plumb line to control horizontal and vertical evenness;

- marker;

- lever arm;

- wooden pegs;

- rope;

- Bulgarian;

- sledgehammer.

From building materials you will have to buy:

- screw type piles;

- caps for grillage;

- metal fittings;

- sand;

- crushed stone;

- cement.

Marking, excavation work

The peculiarity of the foundation for a garage is that it is not necessary to prepare the earthen area. But to organize the correct marking of the construction site, it is better to remove large weeds and bushes. Wooden pegs are driven into the soil at the corners of the future building.

The distance between individual pegs should be within 150 cm. The location of future piles is marked in the form of a small depression of 10-15 cm. The width of the pit should be 20 mm greater than the diameter of the blades.

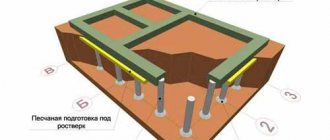

Foundation marking

Installation work

To install small piles under the foundation, it is recommended to prepare a regular crowbar. It is inserted into the top hole of the pile and scrolled. Thanks to the screw mechanism, the element is inserted into the cavity of the earth. To build a garage, it is profitable to buy products 5 m long.

There are a couple of installation methods suggested:

- Drilling. A drill is used to manually make a hole into which the pile element will be inserted.

- Screwing. The pile is driven into the ground with a crowbar.

The support becomes vertical. Screw clockwise until it reaches the recommended pile height. A correctly inserted support passes the lower freezing point and rests on a dense ball of earthen layer. It will be difficult to tighten the support any further.

Screwing

Reinforcement, concreting

After installing the required number of piles, it is necessary to align them in height. A building level is used. Each individual screw unit is marked. Excess height is removed with a grinder. To increase the strength characteristics of the pile, a metal frame is constructed. Conventional metal fittings are used.

Reinforcement

The concrete composition is poured into the cavity of the rod to increase the strength of the structure. The occurrence of metal corrosion is minimized.

The concrete solution is made as usual. Standard ratio: 1 part cement, 3 parts sand. Regular purified river sand is suitable.

Concreting

Grillage installation

Upon completion of installation work, it is recommended to secure the head for the screw mechanism to the cut ends of the supports. Heads are produced in different designs. A popular option is welded. It is recommended to place the heads at the same height.

Types of grillage:

- monolithic design. Formwork required. Metal fittings are placed inside. Filled with concrete solution;

- prefabricated structure. It is distinguished by the presence of solid reinforced concrete and wooden elements. The latter are securely connected to each other at the top of the support.

A hybrid option is often used, simultaneously combining a prefabricated, monolithic structure.

Grillage installation

The dimensions of the head are selected depending on the specific gravity of the structure and the diameter of the pile. To simplify the process, you can select a regular metal plate with a cross-section of 0.08-0.1 cm. The diameter is 4 mm larger than the pile element.

Construction of a garage

Construction on screw-type elements requires the use of foam concrete blocks and bricks. Supporting structure - metal rods, wooden supports.

The roof frame is made of two cascades made of timber, metal pipes, and angles. If the roof is wooden, it needs to be protected from precipitation. Ondulin is used.

The inner surface of the walls is covered with lining and chipboard. Material with low thermal conductivity. An optimal microclimate is created inside the garage.

Installation of flooring is carried out in several stages. The connection of screw supports located opposite each other is made in pairs, using channels. It is necessary to strengthen the perpendicular line. 8 units of channels are used. 4 units are laid out for each wheel pair of the car.

The remaining space is covered with lathing. Take a metal pipe with a wall thickness of at least 4 mm. The cross-section diameter is not less than 50 mm.

Roof installation is done quickly. No insulation required. There are many options for roofing materials.

The gates are mounted as swing gates. Although you can install sliding, sliding, sectional ones.

The advantage of a pile foundation is installation at any time of the year. Even in places with permafrost, screw piles are used. Construction difficulties are reduced to a minimum. The reliability of the structure will not be affected by the weather.

Construction of a garage

The roofing frame is often made of a gable frame from 40 mm timber, profiled pipe or angle. We recommend covering a wooden roof with ondulin, which looks good and is affordable. The inside of the garage is lined with chipboard or clapboard, which has low thermal conductivity, so that a comfortable temperature regime is maintained inside the garage.

How to make a floor? The installation of the floor is carried out in stages: screw piles located opposite each other are connected in pairs with a channel. Then the perpendicular line is reinforced, a reinforcement of 8 channels is placed, 4 under each wheel line.

The space that remains is covered in increments of 400-500 mm with lathing, which is welded from a pipe with a diameter of 40 mm and a wall thickness of 4 mm.

The installation of the roof is quick enough because it does not require additional insulation. The market offers a huge number of roofing materials for any budget, capable of satisfying even the most demanding ones.

A garage on screw piles can be called one of the easiest construction methods, given its quick and simple installation. It is possible to build a reliable and high-quality foundation for your future garage with your own hands, provided that you comply with all building codes and correct calculations, which should still be made with the help of specialists in this field.

Screw piles for garage

A garage on screw piles is constructed like any “metal structure”. The selection of screw piles used in constructing a garage is determined based on the size of the future structure and the complexity of the supporting structure. It is necessary to determine the choice of material for the construction of the building. Based on the size of the garage, the height from the ground level to the roof and the installation depth, piles of the required length are selected. You can choose piles of diameter 89 or 108, length 4.5 m or 5 m. The piles are screwed to the required depth (below the soil freezing level of 150 cm). The lower parts of the piles rising above the ground surface are connected (welded) with 10 or 12 channels along the entire perimeter, except for the place for the entrance gate at a height of 15-20 cm from the soil surface. Next, the piles are connected by a channel or angle along the perimeter with a step of 80-100 cm. The upper part of the piles is also connected by 8 or 10 channels, which makes the structure a solid reinforced structure. The upper part of the piles must be cut in different height planes in order to then set the desired angle of inclination of the roof when installing the rafter system.

Garage on screw piles, diagram

Quick construction of a garage on screw piles with your own hands: stages of work and photos

It happens that when purchasing a country house with beautiful views and nature, the owners end up with a plot with unstable soil.

Such soil, having high mobility, does not allow the owner of the site to make do with little effort when laying the foundation . Insufficient research of the site and saving money on strengthening the foundation sometimes lead to disastrous results.

Therefore, when constructing on shaky soil, it is necessary to get to the solid layer located underneath it. A significant difficulty in this matter can be the large depth of solid rock, which can be located at a depth of 5 to 20 meters .

What solutions apply in this case?

With such soil conditions, the most effective solution is to build on a pile foundation .

Foundation piles are rectangular, pyramidal, round, solid or hollow. The materials for their manufacture are reinforced concrete, concrete, wood, metal.

The pile also distinguished by a vibration protection mechanism, which is installed on top.

Existing installation options:

- retaining piles . They stand on solid ground at a great depth of burial. The technology is characterized by a complete absence of shrinkage;

- hanging piles . Used when it is impossible to reach solid ground. They are firmly driven into the moving layer and held by friction forces.

- drilled and driven piles . Installed in pre-dug holes;

- piles with driven elements . Pointed piles are driven with a special installation designed for this work;

- screw piles . They are screwed into the ground like a huge screw, either automatically or manually.

What are the advantages and in what cases are they installed?

- Of all the listed methods for installing a pile foundation, the fastest is the pile-screw method.

To carry out the work, no preparation is required before screwing the piles into the ground.

If the piles are no more than a meter long, they can be screwed in manually using a barbell or a wrench.

The use of high-quality piles from reliable manufacturers in the pile-screw method is highly valued by construction specialists.

For example, the German company Krinner produces a large number of elements of improved shape, adapted to various foundations and soils.

- Such piles are used almost everywhere; they can be easily installed even in permafrost , which has made them very popular in the far north.

Wall installation

The classic garage frame is a mesh, complemented by two (upper and lower) solid crowns. In this case, installation consists of the following steps:

- Installing garage door frames on channels.

- Assembly or welding of wall frames without filling.

- Installation of wall frames and their assembly into a single frame.

- Cutting and fixing vertical posts inside frames.

- If necessary, install additional reinforcing transverse ties.

- Formation of a roof frame (flat, with one or two-sided slope) and its attachment to the overall structure.

Frame made of metal structures for cladding.

Assembly can be carried out by welding or using bolts and anchors.

It is better to build even an unheated frame garage with wall insulation. Sheathing the structure can be done using any sheet material that is resistant to moisture and temperature changes and can withstand significant loads.

When using the above-ground parts of installed piles as vertical posts, the height is increased in the direction from the side walls to the center. To impart rigidity to the structure, the vertical supports are tied using a channel or angle in increments of 0.8-1.0 m.

Covering the frame with sheet material.

If a garage on a pile foundation is to be built from blocks or bricks, it is necessary to make a concrete grillage.

Garage-workshop with block windows on a pile foundation.

Garage on screw piles: where do you need to start this work?

Before starting work, it is necessary to carry out geological exploration of the area on which the foundation will be built. This will allow you to find out:

- level of flow and seasonal fluctuations of groundwater;

- characteristics of soil types on the site;

- depth of soil freezing (piles will need to be buried below this mark).

Next, you need to calculate the foundation design. It must be carried out according to SNiP for pile foundations, paragraph SP for pile documents.

Due to the complexity of such calculations associated with many formulas - calculation of loads associated with the direction and strength of the wind, calculation of seasonal loads, calculation of dynamic loads, calculation of the weight of the garage with a car and all tools, calculation of settlement and deformation, it is better and safer to entrust this work to a professional architect. Indeed, in the event of even a small mistake, it can be fatal for the entire erected structure.

Despite this, you can always contribute your own wishes to the development of the project by becoming an active participant. But for this you will need to delve into the project calculation algorithm.

After receiving a set of design documents, with foundation characteristics, drawings and approximate cost of work, it will be possible to begin work.

How to build a garage on stilts with your own hands? The pile-screw method requires virtually no preparatory work - the piles are simply screwed into the ground. If the length of the piles is no more than a meter, they are screwed in manually using a rod or a key.

A foundation on screw piles for a garage, given the small number of piles, can be installed in one working day.

Piles are successfully installed at sub-zero temperatures, only the complexity increases at the initial stage of screwing in the pile. At very negative temperatures that have persisted for a long time and the ground is deeply frozen, the soil area that is frozen is drilled out and the pile is screwed in. install screw piles at subzero temperatures using a drilling rig .

Garage on screw piles - photo:

It should be noted that making an inspection pit or cellar in a standard 3x6m or 4x6m with a pile foundation is extremely difficult due to the need for a distance of two meters from the walls of the cellar to the piles. Violation of this technology threatens to bend the piles towards the pit or cellar due to the movement of heaving soils, with subsequent disruption of the geometry of the entire structure.

If the garage still allows for a sufficient distance from the piles , experts highly recommend ordering all the work on arranging the cellar and pit to specialized companies with a contract and a guarantee for the work.

Before entering the garage, it is advisable to make drainage with drainage - dig a trench, lay a drainage pipe and lead it to the nearest water outlet. This will allow excess moisture to move away from the garage.

- Marking for a pile foundation is not difficult. It is enough to mark the area with the base of the foundation and the places where the piles will be installed.

- Guide boreholes are manufactured for precise planting of piles . Wells can be deepened to 0.5-0.7 m with a hand drill or motor drill. The size of the pile blade should be slightly larger than the diameter of the well.

- The pile is immersed in the well, a crowbar into the pile (a hole is provided for this), tubular levers are placed on the crowbar and two workers rotate the body of the pile around the axis, while the third worker controls the vertical level of the pile with a bubble level. With a sharp increase in tightening force (and when the soil freezes level is passed), the pile can be considered installed.

After installing all the piles align them to a single level in the horizontal plane, for this:

- a single level is marked with any special tool;

- pipes are cut according to the selected markings.

After the pile , it is necessary to fill it with concrete to ensure waterproofing of the metal surface of the pile from the inside. M300 - M400 is best suited due to the absence of coarse filler in its mixture, which can cause cavities and voids. In addition to protecting against moisture, concrete increases the spatial rigidity of the structure.

Then a square metal plate-head , the thickness of which is 8-10 mm, protruding 2-3 cm from all sides of the pile.

After preparing the piles, a grillage .

- Wooden grillage

The grillage beams are attached to the plates by bolting or welding. It is necessary to provide a gap between the grillage and the ground surface.

Concrete grillage

The formwork is assembled and lined with waterproofing . Next, a two-layer frame of mesh and metal is laid down. One layer of mesh is placed on top of the waterproofing, the second layer is secured with vertical rods 5 cm from the top of the formwork. The formwork is being poured with concrete.

Reinforced concrete grillage

The width of the formwork in this case is greater than the thickness of the garage walls . Waterproofing is laid at the bottom of the formwork. A reinforcement cage is laid along the foundation. Concrete is poured.

- Metal grillage : example

Options for grillages according to height :

- high. 15 cm from the ground or more. This is done for problematic (heaving) soils and large uneven areas;

- elevated. Installation height 0-10 cm;

- recessed Done below ground level.

The walls of the garage can be lined with sheets of iron . The roof can be made with a corner, a profiled pipe, or a 40 mm board mounted on an edge. The optimal finish is quick-installed andulin; it is quite beautiful and reliable, and also inexpensive.

The interior decoration of the garage is best done with clapboard or other materials as desired. The floor can be laid out from paving slabs with crushed stone compaction. You can also cast a reinforced concrete slab.

To summarize, we can once again repeat the main advantages of a foundation on screw piles:

- the installation of such a design does not require large-scale excavation work;

- the price of a foundation on screw piles is quite reasonable;

- installation of a pile foundation is very simple and quick.

Construction of a foundation in the classic reinforced concrete version is quite expensive and associated with significant time costs. Installing a screw-pile foundation is a good choice in such a situation.

Construction rules

To properly make the foundation for any building, be it a house or an outbuilding, you must complete several mandatory steps:

- Pre-design work and project preparation. This step includes a set of engineering surveys of the territory, on the basis of which the necessary calculations are carried out.

- Selection of materials for creating a foundation.

- Construction on site.

Professional craftsmen also necessarily carry out quality control of the work performed.

Installing piles in the ground is not difficult - the determining factors are strict adherence to the geometry and rules for immersing the supports. The design has an obvious advantage in that the work to create a high-quality foundation will take extremely little time and will not require waiting for the structure to gain the necessary strength (as is the case with concrete).

Screw piles for garage foundations are the optimal solution today. After creating a network of supports, all you have to do is make a comfortable floor in the garage on screw piles and the building is ready for use.

Garage on screw piles

Pile foundation for garage

The foundation is the supporting structure of any structure, so it is very important to choose the right type of foundation and carry out the appropriate calculations. Foundations on piles can be called a fairly popular option for the construction of light buildings, which include garages. Widespread use is explained by a number of advantages that characterize the pile foundation:

- Firstly, construction can be carried out in any weather throughout the year.

- Secondly, labor and financial costs are minimal.

- Thirdly, the pile foundation is considered one of the most reliable and durable.

- Finally, in some cases, piles are the only option, which is most often due to the properties of the soil.

However, the construction of garages on a pile foundation has its drawbacks: the inability to arrange an inspection hole or basement and the difficulty of arranging the entrance to the garage.

Floor installation

The classic technology for installing a frame floor in a garage includes the following steps:

- A system of load-bearing logs is formed by installing a channel (12 or 14) on each of the transverse rows of supports. It is necessary for the lag to protrude along the length beyond the perimeter of the frame by the thickness of the panels or more.

- Perpendicular to the logs, reinforcement for the drive (mortgages) is mounted - four lines of channel 8 (2 for each wheel line - right and left).

- The remaining floor plane is covered with lathing (for example, from a light pipe 40x40x4 mm) in increments of 40-50 cm.

- The internal space of the floor is filled with bulk insulation. Before laying the subfloor from boards or sheet material, a layer of vapor barrier is laid, and a windproof film is used on the sides.

Laying a log for installing a floor in a garage on a pile foundation.

The second method requires increasing the density of the pile floor, at which the distance between the supports will be at least 1.5 m. In this case, you can not install the sheathing, but put formwork to the channels and make the floor in the form of a monolithic reinforced concrete slab (layer thickness - at least 40 mm) .

Performing pile foundation calculations

To calculate the number of foundation supports, it is best to contact specialists. They will conduct the necessary soil studies on the site and determine its bearing capacity. In addition, geological studies help determine the depth of the dense layer, the groundwater level and the degree of soil freezing. All these criteria are necessary when calculating a pile foundation.

If it is not possible to attract experienced specialists, you can use simplified methods.

First, you need to determine the parameters of the future garage, on the basis of which the number of supports is calculated. It is taken into account that the screws are located in each corner and along the perimeter of the building at a distance of 1.5-2 meters from each other.

Pile foundation calculations

It is also important to determine the length of the piles, which largely depends on the depth of soil freezing and the location of the load-bearing layer. The easiest way to establish this data is to drill a well using a hand drill. In addition, the well will help determine the composition of the soil.

Determining the number of piles largely depends on the load-bearing capacity of one pile, which is calculated using a special formula.

When making calculations, we must not forget about the expected load on the foundation. Here, the weight of the vehicle, the weight of the entire structure, including the roof structure, as well as wind and snow loads are taken into account.

To independently calculate the number of piles for a garage foundation, you need to determine the total load on the foundation and divide it by the load-bearing capacity of the pile.

CONSTRUCTION OF A FOUNDATION ON PILES FOR A GARAGE

In order for the pile foundation to fulfill its main task for as long as possible - transferring the load from the building to the dense layers of the foundation soil, it is designed and built in strict accordance with the requirements of GOST and SNiP by specialists from the design organization.

We use wheeled equipment for piling work, so our specialists arrive at the site on their own, based on the design, mark the points on the ground where the piles will be located, and carry out, first, a trial and then the main driving of piles.

Next, the piles are cut down at the design height and filled with a monolithic grillage in the form of a reinforced concrete frame or slab.

We recommend reading these articles:

| Shell piles MORE DETAILS | Rack piles MORE DETAILS | Do-it-yourself installation of screw piles MORE DETAILS |

See also

Pile foundations in the construction of country houses.

Calculation of a pile foundation - how to calculate?

Foundation on reinforced concrete piles in the village of Shakhovskaya

Do-it-yourself construction of a pile foundation for a garage

A pile foundation for a garage can be erected with the help of professional builders. In this case, the result will be a reliable foundation, performed according to all the rules. However, the cost of such a foundation will be quite high. If you build a pile foundation yourself, listening to the advice and recommendations of experienced craftsmen, you can build an equally strong and high-quality foundation at minimal cost.

Preparatory stage

Any work begins with the preparation of materials and tools. To build a pile foundation for a garage, you need the following tools:

- Shovel.

- Plumb and building level.

- Roulette.

- Pencil or marker.

- Lever for screwing piles.

- Bulgarian.

- Pegs and cord for marking.

- Sledgehammer.

It is impossible to imagine the construction of a foundation on piles without the following materials:

- Screw piles with technological holes in the upper part of the rod for convenient screwing.

- Heads for creating a grillage.

- Reinforcement bars. We recently described how to correctly select, calculate and install reinforcement.

- Cement, sand and crushed stone.

Pile-screw foundation for a garage, its advantages and disadvantages

Laying a foundation for a garage in the traditional way - in the form of reinforced concrete structures such as strip or slab foundations - can be associated with a number of difficulties:

- Presence of weak, heaving, water-logged soils

- Uneven terrain where the garage was built with large differences in elevation

- Long term for putting the foundation into operation - until the concrete hardens completely (more than 30 days)

- High labor intensity of work

- Excavation of a large amount of soil and its removal from the site due to its unsuitability for agriculture

- High cost of installation

Screw pile technology copes well with all these difficulties. Its main advantages:

- Easy bookmarking

- Relatively low labor intensity

- Low cost compared to other types of foundations

- Speed of construction

- Possibility to start building a garage immediately after installing the pile-screw foundation

- Piles can be screwed into problematic (waterlogged, heaving, loose, etc.) soils with dense layers of uneven height

- Installation on sites with a large slope

- Possibility of installing any type of garage

- Minimal preparation work for the installation of piles and the absence of large excavations of earth

The disadvantage of using piles is the impossibility or limitation of constructing large inspection holes or subfloors

Tips and tricks

When installing a pile foundation for a garage, various problems may arise. To reduce the risk of their occurrence, as well as to avoid many mistakes during the work process, it is important to listen to the advice of experienced craftsmen:

- It is recommended to use only high-quality piles made in compliance with all technologies for the construction of the foundation.

- When choosing a pile foundation for a garage, you should first know the exact composition of the soil on the site, since rocky soil will make driving the piles problematic.

- The vertical position of the pile in the ground should be constantly monitored, otherwise the support may go downhill, and in this case it is quite difficult to level it.

- Screwing in screw supports involves constant walking around the pile, so you should thoroughly clear the work area of debris and vegetation. This will prevent injury during work.

- Welding work must be performed efficiently, since the strength and reliability of the garage depends on this.

- If during the screwing process the pile rests against any foreign object or there is a large stone or stump at the installation site, then it is better to move the screwing site.

- If the design provides for welded seams that will be located in the ground, then it is very important to treat the joints with anti-corrosion mastic.

- If calculations show a sufficiently large foundation depth, then it is recommended to abandon the pile foundation, since in this case its use will be irrational.

A garage on screw piles can be called an ideal construction option, given its simple and quick construction. A high-quality and reliable pile foundation for a house for a car is easy to make with your own hands, provided you follow the construction technology and follow the recommendations of experts.

General information

Many owners of their own land plots choose modern designs for outbuildings. A frame garage on screw piles allows you to erect the necessary structures in a short time with minimal investment of time and money. A garage on stilts fully provides the user with performance characteristics that can protect your car and create useful space for working inside.

The basis for the construction of any building and structure is a reliable foundation. The design of the building allows you to build projects of any complexity, and the construction remains simple. The use of special piles ensures the stability of the structure. The practical advantages of the project are the following:

- Construction can be carried out with small forces, with a minimum number of workers and, in most cases, with virtually no special equipment.

- Construction of the foundation is possible in any weather and throughout the year. The classic foundation is highly dependent on air temperature and in winter the project cannot be implemented.

- Structural reliability indicators are among the highest in the construction industry.

- The only option for constructing a foundation on different soils. There are practically no restrictions for this technology in the underlying soils.

A frame garage on stilts becomes not just an original, but also a functionally justified option for creating a durable structure for a long time. The construction of a garage on screw piles can be completed on a limited budget, which is especially important in modern conditions.