One of the methods for analyzing the quality of the road surface is the examination of asphalt, which allows you to determine the strength of the pavement and detect possible defects. The research is carried out in special laboratories by expert services, which render a verdict. The results of the examination can be very useful in legal proceedings. They also allow us to assess the integrity of the work of road workers. Leave an online application and find out more about the service during a free consultation

To get a consultation

What issues does the examination solve?

Thanks to the examination of the condition of the road surface, it is possible not only to determine the strength and reliability of asphalt. It can serve as proof of the quality of work and has recently been often used by municipal services when collecting reports. The study allows us to determine:

- level of road surface disturbance;

- the quality of materials used in laying asphalt and their compliance with the required standards;

- quality of drainage structures;

- quality of construction and installation work during installation;

- cross profile parameters;

- exact cost of road work.

A comprehensive examination helps to promptly identify and eliminate errors that arise when laying the roadway. An independent opinion can be considered evidence of the good faith (or, conversely, bad faith) of workers and contractors, as well as road repair managers.

Prices

| № | Name of works | Cost of work at the estimated cost of construction | Note | ||

| up to 2 million rubles | from 2 to 5 million rubles | from 5 to 10 million rubles | |||

| 1. | Checking the alignment of construction axes and marks of a country house. | 24,000 rub. | 30,000 rub. | 36,000 rub. | Builds over 6. axles, 3 tr are added to each axle. |

| 2. | Foundation examination. | 24,000 rub. | 30,000 rub. | 36,000 rub. | |

| 3. | Identification of construction defects. | 24,000 rub. | 30,000 rub. | 36,000 rub. | |

| 4. | Excavation work, installation of formwork, reinforcement, concrete work (if concrete work has been completed). If necessary, calculate the ventilation ducts of the basement floor. | 24,000 rub. | 30,000 rub. | 36,000 rub. | |

| 5. | Analysis of design and construction solutions. Recommendations. | 24,000 rub. | 30,000 rub. | 36,000 rub. |

Request a call

How to choose the thickness of asphalt pavement when paving

Asphalting roads is a complex and labor-intensive process. Before starting work on laying asphalt, it is necessary to correctly determine the operating conditions of this surface in the future, and depending on this, determine the optimal thickness of the asphalt pavement. In our country, 80% of highways are located in a zone of unfavorable climatic conditions - sharp temperature fluctuations, high humidity, deep freezing of the soil, all this negatively affects the asphalt and reduces its service life. It is for this reason that when laying asphalt it is necessary to ensure the correct technology, including the correct thickness.

First of all, it should be noted that laying asphalt in the courtyards of private houses, in parking lots and on public roads should be done using different technologies. The service life of a road surface primarily depends on its operating mode: how many cars will travel along the road every day, what the speed limit will be, and whether trucks and buses will move along this section. The correct choice of asphalt thickness depends on all these factors.

Paving the site of a private house

The coating near a private house does not have to be very thick, because this area is not intended for moving a large number of vehicles and other equipment. At the same time, GOST sets the minimum thickness of asphalt for pedestrian areas and courtyard areas at 40mm (4cm). If you try to save too much and carry out asphalt paving with too thin a layer, after the very first winter this surface under the influence of frozen groundwater may crack and become unusable.

In addition, laying asphalt near a private house must be carried out in accordance with all the procedures prescribed by building codes, with the obligatory leveling of the site, adding sand and crushed stone under the main layer.

Asphalting of car parks

In the area of car parks and parking spaces, asphalt must be laid with a thickness of at least 60mm. This is important because, regardless of the parking capacity, sections of asphalt will be subject to increased load even from statically standing cars. This is especially true for parking lots near shopping centers and other popular places, where the daily volume of traffic may not be much less than on a busy road. Increased demands are placed on both road alignment and the thickness of the sand and crushed stone layer under the hard surface.

Laying asphalt on highways

The requirements for asphalting roadways are even higher. The minimum thickness of the asphalt layer here is established according to GOST starting from 80mm (8cm), but in the case of construction of a busy highway, with active movement of heavy vehicles, it can be increased to 10cm. In addition, asphalting roads should be carried out in several layers: on top of the first layer of asphalt 4-8 cm thick, after it has hardened, a layer of asphalt mixed with gravel and small crushed stone, another 4-6 cm thick, is applied. Moreover, to increase the durability of the pavement, some companies also use a special cement layer under the asphalt, so that the road can be used without repair for many years.

Thus, the thickness of the asphalt should be:

- for sites of private houses - at least 4 cm;

- for parking lots - at least 6 cm;

- for roadways - at least 8 cm.

In addition, it is important not only to control the correct thickness of the asphalt layer, but also the paving company’s compliance with the entire asphalt paving technology.

How is the examination carried out?

Asphalt examination is a complex process that includes several main stages. Thanks to the versatile approach, the result is objective and includes a large number of diverse studies. Stages include:

- analysis of supporting documentation;

- assessment of the visual quality of the road surface (presence of potholes, cracks, holes);

- taking measurements to determine possible unevenness, bumps, and areas with an incorrect slope;

- taking asphalt samples to determine the thickness of the coating and its structural composition;

- analysis of samples taken in the laboratory, where they are checked for composition, dimensions and density;

- if necessary, testing of samples taken using destructive or non-destructive testing;

- drawing up a conclusion about the quality of the road surface and its compliance with the necessary characteristics.

For examination and evaluation of samples in the laboratory, as a rule, the core method is used. To do this, small sections of different sizes are drilled into the road surface, in several places and at different depths. These samples are used in the laboratory.

Types and composition of asphalt

There are two types of asphalt used to cover roads: cold and hot. The composition of any type will be the same, the difference lies in the percentage of components.

The components of asphalt are:

- sand;

- crushed stone;

- bitumen;

- mineral powder.

The federal standard adds a 10 cm layer of concrete, the layers of sand and crushed stone increase - 50 and 40 cm, respectively.

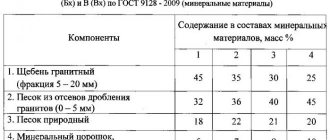

The percentage of components depends on the road for which purpose the coating will be laid.

GOST 11-10-75 recommends using the cold laying method for repairing main roads, in courtyard areas, and for constructing sidewalks.

Hot paving of asphalt is a method by which a new road surface is formed by compacting the mixture before it hardens.

Percentage composition of components

The percentage of all components of the asphalt mixture and the compaction coefficient are given by SNiP 3.06.03-85.

If asphalt is laid on a highway surface, then the percentage of crushed stone that can withstand short-term loads of up to several tens of tons will be large. When laying paths and driveways for passenger cars, crushed stone is either not used at all or is replaced with fine gravel.

The bitumen content (a refined petroleum product) can range from 1% (minor roads) to 11% (major highways). Bitumen is used to provide shock absorption to the road surface, increase tire adhesion to the road, and eliminate slipping.

Mineral powder is obtained by crushing limestone and fossilized remains. The structure of the powder is viscous and contains a lot of carbon, which helps relieve internal stress. It is most often used when laying asphalt pavements on bridges and highways; it is practically not used on secondary roads.

The last component of the asphalt mixture is sand. It is carefully cleaned of impurities to increase the strength of the final mass.

Asphalt impregnations

Asphalt laying technology involves the use of impregnations that improve the quality of the road surface.

Today GOST 11-10-75 recommends several types of impregnations.

Acrylic polymer based mass. It is very expensive, can be installed in small areas (tennis courts, special areas, etc.), has high quality protection, and is produced in several colors.

Coal tar. It is not subject to destruction from the ingress of petroleum products, lasts a long time, has a high-quality structure and color.

Asphalt emulsion. A common and affordable coating, short-lived, requiring constant repair.

To extend the service life when laying, SNiP 3.06.03-85 recommends using mesh under asphalt. They increase the density of the fabric and ensure its adhesion. The same characteristics are achieved by high-quality compaction of the asphalt concrete mixture, for which an asphalt roller is used.

Protective impregnations and coatings for asphalt - materials and equipment

Hot styling method

Hot paving of asphalt is common, less expensive and produces good results. SNiP recommends heating the finished mixture to 130ºС; at the time of filling the roadway, the temperature should be at least 100 ºС.

Hot asphalt can be laid manually. The step-by-step process is as follows:

- Preparing the concrete mixer. For this purpose, use a metal barrel in which holes are drilled in the bottom and top center using an electric drill (16 mm drill). A strong axle is inserted into them and scalded in a circle. Sturdy handles for scrolling are attached to the sides. The entire structure is installed on a support.

- Bookmark ingredients. Crushed stone and mineral powder are placed in a barrel and mixed. For bitumen, take another vessel, the mass is heated until homogeneous. Heated bitumen is added to a barrel containing a mineral-crushed stone composition. The barrel must be turned all the time. After adding a sufficient amount of resin (10%), sand is poured in and the resulting composition is mixed well.

- Rolling up. Place hot asphalt on the prepared area about 5 cm thick and compact it tightly with a hand roller. When in contact with the mass, the tool must be moistened with water to ensure a smooth surface.

If the asphalt is laid efficiently, it can withstand a weight of up to 5 tons without deteriorating from water and sun.

Cold styling method

These works are carried out using a ready-made mixture, which can be bought in the store. It will eliminate the laboriousness of preparing a hot mixture. But such a mass is expensive, and coatings made from it do not withstand high summer temperatures.

GOST 11-10-75 prohibits this method of paving on main roads and provides for the use of cold asphalt only for road repairs or in summer cottages.

This method is performed in stages:

- Preparatory stage. Purchasing a ready-made mixture in a store. On future paths, a layer of earth (10 cm) is removed, half of the depression is filled with crushed stone and compacted.

- Layer-by-layer laying of asphalt mixture. Two layers are laid at intervals of 20 minutes, each carefully compacted with a hand roller. The thickness of the laid layer is 2-3 cm.

- Final works. At the last stage, the canvas is compacted again and sprayed with water. You can use it within a day.

Cold asphalt laying technology

Laying asphalt this way will take a little time because the mixture is already ready. It will take several hours to lay the path, but the hole can be closed in 5 minutes.

Test results

As a result of research carried out in the laboratory, it is possible to determine with high accuracy such parameters as:

- composition - the amount of sand, bitumen, other elements and foreign impurities;

- thickness and volume - the durability, as well as the cost of the final coating, depend on their ratio;

- density - this parameter directly affects the wear rate of the road surface.

The obtained characteristics are analyzed and checked for compliance with building codes when laying the roadway. Any errors found are recorded and included in the final report.

The composition of Chelyabinsk asphalt is checked in the laboratory

A record amount will be spent on road repairs this year. Contractors are already working on highways in Chelyabinsk and the region. A total of 333 kilometers of roadway will be built and repaired. 23 streets in Chelyabinsk, 11 in Magnitogorsk, as well as roads in small towns. 16 and a half billion rubles will be spent on this. Of these, almost six billion were sent to the regional center. The money is really big, so the work of the contractors will be closely monitored. How to check the quality of asphalt - in the report by Egor Bragin.

Now not only specialists from the Ministry of Transport and Transport, but also residents of the region will check the quality of road work. There will be a lot of inspection. Under the federal program “Safe and High-Quality Highways” in the Southern Urals, 155 kilometers of highways, city streets and highways will be repaired and reconstructed.

“Road educational program” for novice public inspectors is conducted by road industry specialists. To undergo accelerated training and get into the working group of inspectors, you can contact the Ministry of Roads.

Head of the Road Department of the Ministry of Transport of the Chelyabinsk Region Alexey Nechaev: “Depending on those participants who will participate in these working groups, we will plan zoning. It is clear that they will not go from Chelyabinsk to Magnitogorsk. There are responsible persons assigned to the city. In Chelyabinsk this is the road management department. They will also participate with us.”

What asphalt is and how it is laid will be explained to people’s inspectors almost at the molecular level.

“Here they produce asphalt, which is laid on Chelyabinsk roads. To put it simply, the technology looks like this. The crushed stone is transported along a conveyor belt to special drying units. Then, using a special sieve, it is divided into larger and smaller ones. Each asphalt has its own recipe depending on the type of road surface. Therefore, in tanks where crushed stone is mixed with heated bitumen several times in an hour, this plant produces more than two hundred tons of asphalt.”

According to experts, this is enough to build a road seven meters wide and two hundred meters long. All asphalt components are tested before it is released.

Egor Bragin, correspondent: “The quality of the building material is checked in the laboratory of the South Ural Road Test Center. Crushed stone is examined for strength and abrasion, and bitumen, which binds the asphalt component, is examined for heat resistance and durability.”

After training, the working groups will begin inspections. Contractors will be forced to correct defects found on the roads.

Information service cheltv.ru, photo: sovsakh.news

Who needs it

Examination of the condition of road surfaces can benefit both municipal authorities, who must monitor the condition of roads in their region, and private residents - for example, if they need to provide evidence to the court of poor quality of the road surface. It is recommended to carry out checks regularly and in a timely manner: monitoring the condition of asphalt concrete will help to carry out the necessary work in a timely manner, assess the condition of the road surface and monitor the dynamics of its wear.

Asphalt quality check

cost of examination

from 10 000

Order

The exact cost depends on the specific case. Leave a request or check by phone.

5 / 5 ( 1 voice )

For Russian roads stretching over vast distances and dense urban infrastructures, the condition of the road surface and asphalt is of importance that is difficult to overestimate. The problem with the quality of asphalt and road surfaces on a wide variety of Russian highways does not lose its relevance. Since their length is large and continues to increase, and construction in this area is proceeding slowly. In order to maintain the pace and quality of road construction and repair, budgetary and other funds are allocated, government programs are being developed, and experts in the field of road construction are working.

For a long time now, not only government, but also independent and professional expert organizations conducting road and construction research have been monitoring the quality of road construction and laying. We prepare facilities for acceptance and commissioning, inspect the laying of asphalt and check the quality of asphalt in any individual areas - from the smallest to the very large.

One of the independent expert organizations offering such. This is an entire institute, under the auspices of which many certified specialists work who have sufficient knowledge in any field to conduct the most accurate and in-depth examinations, analyzes and studies, including those related to the quality of any construction, engineering and road work.

The professional construction inspection to check the quality of asphalt, which we can offer you, will be carried out in accordance with all the rules of road inspection of today. This is the use of the most accurate and modern equipment, these are the correct modern diagnostic and expert techniques that allow us to give accurate answers about the condition of this or that fragment of asphalt or road surface in relation to any parameters and GOSTs.

We carry out certified testing of asphalt quality at the request of government supervisory institutions, private companies, customers of asphalt laying, at the request of citizens, private owners, residents of cities and towns. Also, our specialists conduct many studies at the request of municipal authorities and investigative authorities. In many cases, testing the quality of asphalt is associated with solving pressing social problems. Often these are problems that require prompt resolution.

In such conditions of increased social responsibility and the need to protect the rights of citizens and solve other problems, representatives of the NP “Federation of Forensic Experts” feel familiar and confident. This is due to our experience in resolving many cases related to inspections of the quality of services provided by individuals and legal entities, the quality of products, and the quality of various works. Road construction and asphalt quality testing in the Russian Federation are an important industry in which conflicts also occur between citizens, the municipality, the customer company and the performing company.

The executive power and residents of many Russian cities are today waiting for the start of work on the construction or restoration of roads, including with the help of new or first laying of asphalt. New programs from some parties are already engaged in such work in different districts of the country - for example, such a project as “New Roads”, organized by United Russia. All this work is very important for city residents, for authorities, and for those who use various highways due to their occupation. The NP “Federation of Forensic Experts” has taken and is taking part in this work, in inspecting many sections of the road surface in Russia. He plans to take the same active part in the future.

It is worth mentioning not only new buildings and already ongoing projects to improve asphalt pavements. Often our customers need to check the quality of asphalt where there are deficiencies and dangerous deficiencies in the quality of road surfaces. Where, due to poorly laid or collapsing asphalt, there is a risk of an accident, or one that has already occurred. Specialists of the NP “Federation of Forensic Experts” will successfully prove the inconsistency of any type of coating, if it really has flaws. We will accurately assess the condition of any surface, and a professional asphalt quality check will show how dangerous its condition is and what should be done first. A project for the necessary reconstructions can be drawn up, followed by monitoring of its implementation and information support from our specialists.

The construction, engineering, and geodetic examination departments of the NP “Federation of Forensic Experts” are capable of conducting broad and comprehensive research for you. Research on the prospects and safety of the construction of engineering and transport structures. Dedicated to the possibilities of improving highway projects, optimizing costs and processes, improving the quality of laying asphalt and other road surfaces. Certified asphalt quality testing can be part of comprehensive expert services for large projects, infrastructures, the urban sector, highways and highways.

Certified asphalt quality testing can be performed to determine whether project funds are being spent accurately. To confirm or refute any guesses that project inspectors have regarding the quality of the work performed. Part of the practice of the NP "Federation of Forensic Experts" is always devoted to work to ensure quality control and compliance with agreements that exist between participants in various construction projects, projects for the repair and renovation of roads or sections of urban infrastructure.

We closely monitor the quality of road work carried out. We have the opportunity to visit facilities located in any district of the Russian Federation. We offer certified studies and inspections of the preparation of areas for the application of asphalt coatings. We analyze opportunities for improving projects and optimizing costs. We also consider materials, estimates and other design components and documents. Therefore, you will find here not only a certified and responsible inspection of asphalt quality, but also some other services regarding repair, construction, and road work.

All articles on the topic “Construction Expertise” >>

Prices:

| Cost of examination |

| Depends on the complexity of the object |

Additional services:

| Departure of an expert on holidays and weekends | from 5 000 |

| Preparation of a duplicate of the expert’s opinion | from 2 000 |

| Departure of an expert outside the Moscow Ring Road | from 5 000 |