A cellar is an important element of any suburban area; it is indispensable for storing vegetables, fruits and canning. The article contains information on how to build a cellar in a country house with your own hands: a step-by-step description will help you take into account a lot of nuances, from the correct choice of location to the installation of waterproofing and electrical wiring. The external arrangement of the building is also of great importance, and the construction of shelving and drawers will help to effectively use the space.

The process of constructing red brick cellar walls

Types and features of cellars

Do not confuse the cellar and the basement. Building a cellar at your dacha with your own hands can come down to simply digging a hole and minimally arranging it. The choice of the type of structure depends on many parameters, for example, on its intended purpose, on the climatic conditions of the region, financial capabilities, etc. Also, when choosing the type and materials for building a cellar in a country house with your own hands, you need to take into account its location.

It is easier to build a separate building than, for example, to build a cellar under the house, but this option will require more materials, and therefore more finance. Making storage under a residential building or outbuilding will be cheaper, but this option is limited in space.

Arranging a cellar will allow you to preserve preserved food and other products for a long time

One of the most popular options is an ice cellar. It copes well with the function of long-term storage of food even in the hot season and is especially in demand in the southern regions. It is quite difficult and expensive to build this type of cellar in a private house with your own hands, but the result is characterized by high performance characteristics, durability and reliability.

Another good option for this building is a storage unit with two sections. As a rule, this type is used when it is necessary to avoid mixing the odors of various vegetables and fruits that are simultaneously stored in the cellar. To build such a storage facility, you need less materials than for a glacier.

A separate type of cellar is a wine cellar. It is used for storing wine products and has its own design features and nuances that must be taken into account in order to properly build the cellar. As a rule, in such storage you can store not only wine, but also various preserves.

A wine cellar has design features that must be taken into account at the construction planning stage

Pit construction technology

It is optimal to build a cellar in mid-summer, when groundwater reaches its maximum depth. A shallow pit is dug by hand; if the volume is large, it is advisable to use the services of an excavator. If there is no access to the work site, excavation of earth from great depths is carried out with buckets. The work can be completed by at least two people. The soil is stored next to the pit; it will be needed for filling.

If the soil is dense and not prone to crumbling, a hole is dug according to the size of the cellar. On loose soil, the dimensions of the pit are increased. The walls are reinforced against crumbling with shields with spacers.

The pit is given a rectangular shape. There are round storage units, but they are less popular due to the complexity of arranging shelves and other nuances. On the side of the future entrance (if the cellar is of a recessed or semi-recessed type) in the pit, one wall is made under a gentle bevel for steps. When a manhole is constructed through a hatch using an extension ladder, there is no need for a bevel.

The nuances of arranging a cellar with your own hands at a high groundwater level

When choosing a location for storage, it is very important to take into account factors such as total soil moisture and groundwater level. The lower it is, the easier it will be to build the structure, and the less often repairs will be needed. If we are talking about a free-standing structure, then you should choose the highest place on your site. It is best to determine the groundwater level when it is at its maximum, that is, in spring or autumn. If there is a well or borehole on the site, then you can determine the maximum elevation using them, otherwise you will have to drill a well separately.

It will be somewhat more difficult to build a cellar if groundwater is close. How to do this as efficiently as possible? First of all, it is necessary to pay great attention to the waterproofing of the structure. Also, with increased soil moisture, for better waterproofing of the cellar from groundwater, it is worth using building materials characterized by increased resistance to water. In this case, you should not use wood or plywood, but rather give preference to concrete and brick.

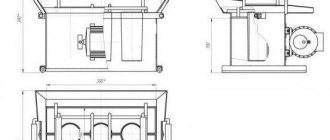

Scheme of a separate cellar: 1 - foundation; 2 - steps; 3 - protective fence; 4 - walls; 5 - ceiling vault; 6 - ventilation; 7 - waterproofing; 8 - bulk soil

Helpful advice! You can also check the groundwater level using folk signs. To do this, you need to leave a piece of wool and a chicken egg at the construction site, and cover them with a clay pot on top. If in the morning there is dew on both the wool and the egg, then groundwater is close, but if there is only dew on the wool, it is far away.

Floor arrangement

It is optimal to cover the buried storage with concrete floor slabs. You can lay channels and sheet metal with a thickness of 5 mm or more, but it must be reliably protected from corrosion with bitumen or special mastics. When none of the options are suitable due to lack of materials, the concrete ceiling is made with your own hands.

First, a floor frame is formed from boards or timber. It is given an arched shape by elements cut from moisture-resistant plywood. The parts act as rafters and are placed on each beam.

The resulting structure is sheathed on top with moisture-resistant plywood. The wood is treated with a protective impregnation. A reinforcing mesh made of rods with a thickness of at least 12 mm is laid on top of the ceiling. Wooden blocks 40-50 mm thick are placed under the reinforcement. The pads will raise the mesh and ensure that the solution is poured under it.

The assembled structure is poured with concrete and covered with film to reduce moisture evaporation. In about a week, the ceiling will be ready, and further work on the arrangement can be carried out.

Recommendations for building a cellar with your own hands: how to do it as efficiently as possible

Regardless of what type of construction you have chosen or what materials you are going to use, there are a number of general recommendations that you should follow when building a cellar step by step with your own hands:

- if you are going to use wooden elements, they must be pre-treated with a special impregnation to protect them from the harmful effects of moisture;

- It is best to start building a cellar in the summer, when the groundwater level is at the lower level. In this case, the soil will be the driest, and the risk of flooding of the structure will be minimal;

- To ensure efficient storage of products, it is very important to consider a ventilation system;

- if you want the structure to maintain the desired temperature, it is recommended that when building a cellar with your own hands, you make two doors separated by a vestibule;

To build a really good cellar, you need to carefully study the features of materials and types of structures

- special attention should also be paid to thermal insulation, then the optimal temperature in the cellar will be ensured at any time of the year;

- The choice of tools and materials for construction is very important, so it is worth familiarizing yourself with the advantages and disadvantages of the different types in advance. The construction itself must be carried out in a clearly recommended order.

Features of using various materials

Most often, materials such as brick or concrete blocks are used in construction. They best tolerate high humidity and low temperatures, and are also characterized by durability, reliability and relatively low cost. When building a brick cellar with your own hands, you should take into account the operational characteristics of each type of this material:

- cinder block or foam brick is characterized by increased fragility, so these varieties are not recommended for use in the construction of underground storage;

- sand-lime brick is more durable, but reacts very poorly to high humidity. This means that a building made from it cannot boast of a long service life;

The ideal material for building cellar walls is red brick.

- red brick is an ideal option for a cellar in a private house. How to make a building from this material as efficient as possible can be learned from numerous step-by-step instructions from specialists.

If you decide to use concrete blocks in construction, then you will definitely need specialized construction equipment, since they are characterized by heavy weight. A cellar made from them will last a long time and maintain the temperature well.

Also, when building a cellar in a house with your own hands, you can use bricks that have already been used, if its condition allows it. And if you are simply going to line an earthen pit with wooden boards, they must be thoroughly treated with antiseptics to prevent rotting.

Note! The use of metal-reinforced concrete slabs is also possible. But in this case, it will be quite difficult to maintain the desired temperature, so this material should not be used for the building in which you are going to store food.

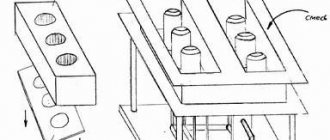

Diagram of a semi-buried brick cellar

Walling

The construction of walls begins after the foundation has hardened. It is optimal to let it sit for 1-2 weeks. Laying bricks, cinder blocks or other blocks is carried out using mortar and bandaging the seams. Reinforcement is embedded into the solution after 1-2 rows.

An opening is provided on the wall from the entrance side. The forcing is done until the height from the floor to the top row is at least 1.8 m. Low cellars are inconvenient to use, since you will have to constantly bend down to walk inside.

Do-it-yourself cellar at the dacha: step-by-step construction guide

Strict adherence to the sequence of actions is the key to a proper cellar. How to make the construction as efficient as possible, spending a minimum of time and effort on it? To do this, installation work must be performed in a certain order.

Arrangement of the pit

The turf is removed from the selected area, after which the ground is leveled and markings are made. Many photos of a do-it-yourself cellar show that specialized construction equipment is often used to build a pit, but if this is not possible, then you can use shovels and spades. The advantage of working with hand tools is that it allows you to maintain the structure of the soil. If the soil in the selected area is loose, then the walls of the pit should be sloped to avoid crumbling.

Building a cellar with your own hands. Step 1: Digging a Hole

The dimensions of the cellar depend solely on your needs, but remember that the size of the pit should be 0.5 m larger than the size of the structure itself. In the process of building a cellar with your own hands, the excavated fertile soil can be distributed throughout the summer cottage. After finishing the work, the evenness of the bottom should be measured with a level and corrected if necessary.

Construction of the foundation

Although you can do without this stage (by simply filling the bottom of the pit with crushed stone or filling it with bitumen), the arrangement of the foundation will increase the level of waterproofing of the cellar from groundwater. How to make the foundation as efficient as possible, but not too expensive? To do this, you can use a reinforcing frame, on top of which a concrete mixture is poured. The recommended foundation height is about 40 cm. Installation of the foundation is a prerequisite when building a cellar in a country house with your own hands if groundwater is close. Thematic videos on the Internet will tell you how to make the foundation correctly.

Building a cellar with your own hands. Step 2: laying out the foundation

Walling

If you use brick to build a cellar under your house with your own hands, then you will need a number of specialized tools. These include a trowel, mortar line, mason's hammer, mortar level and mortar bucket. For greater work efficiency, you should use the help of another person.

A mixture of clay and sand or cement can be used as a mortar connecting the bricks. When building an underground or above-ground cellar with your own hands, laying should begin from the corners, and the first row should be laid without using mortar in order to more accurately plan the position of the wall. The bricks of the next rows must be sunk into the mortar until the seam thickness is approximately 12 mm.

Building a cellar with your own hands. Step 3: building walls

Helpful advice! Be sure to use a building level and plumb line when laying walls. Using the first, you check how evenly the brick is laid, and using the second, the correctness of the angles.

DIY cellar floor installation

When constructing a ceiling, it is best to use wooden boards. If the structure is being built under a house, then beams can be used as a ceiling, and the ceiling of an above-ground cellar at the dacha is made with your own hands step by step from PKZh slabs or slate. In this case, the surface can be flat or gable.

Thermal insulation of the ceiling is done according to the same principle as the thermal insulation of a conventional roof - the gap between the wooden beams and the roofing material is filled with a layer of thermal insulation.

Building a cellar with your own hands. Step 4: installation of the ceiling

Types and features of floor installation in the cellar

There are many different options for arranging a floor in a cellar; which one is better depends on your preferences, the purpose of the building, the characteristics of the soil and other factors. You should also familiarize yourself with the specifics of each method in advance; this will help you quickly and efficiently build a cellar with your own hands. Both video and photo instructions can greatly facilitate the installation process.

An earthen floor is the simplest and cheapest option. There is a misconception that the correct floor in the cellar should only be earthen, but this is not so. Even well-compacted soil will not protect the room from dampness and mold.

If you nevertheless decide to make a dirt floor in the cellar, then the base must be carefully leveled and compacted, after which a layer of gravel about 10 cm thick is poured. The advantage of this option is zero installation cost, but there are many more disadvantages. These include a high risk of flooding and a high probability that metal elements will rust and wooden elements will rot.

Cellar with bulk sand floor

A concrete floor is a good option to protect the room from high groundwater. Concrete screed can act not only as a floor covering, but also as a base for the installation of other materials.

To build a concrete floor, it is very important to level the surface, after which a cushion of crushed stone and sand 15-20 cm thick is installed. The sand must be thoroughly moistened and compacted, and bitumen must be poured on top. In order for the concrete base to be as strong as possible, a metal grate can be installed on top of the bitumen layer. After this, you can begin pouring concrete.

You can install the waterproofing layer either on a sand cushion or on top of concrete. In the second case, it is necessary to pour another concrete layer on top.

Clay flooring is a reliable, but very labor-intensive installation option. Requires a large amount of high-quality material, so it is used quite rarely. Clay is considered one of the most environmentally friendly materials. It is laid on a base of crushed stone 10-15 cm thick, which can be impregnated with bitumen. Under the clay, it is worth installing a layer of waterproofing made of roofing felt or other material, and cracks that may form after drying are sealed with a clay-lime mixture.

The floor in the self-built cellar is made of concrete.

Brick covering is strong, durable and attractive in appearance. In addition, the material is quite cheap and easy to install. The brick floor is laid on a bed of fine crushed stone or gravel, and a clay mortar is poured on top. The bricks are slightly sunk into the mortar close to each other. You can also hammer cement mortar into the seams between the bricks using a stiff brush.

Wooden floor - used in above-ground cellars or where groundwater is very deep. Before installation, wood must be treated with special impregnations to extend its service life. Wooden boards are mounted on top of timber logs, which, in turn, are laid on a base of crushed stone and clay. It is best to fasten the boards using self-tapping screws, but you can simply nail them.

Note! For each of the materials you will need a separate set of tools, which it is better to purchase in advance.

Example of a ventilation device: 1 - for a cellar under the house; 2 - for a free-standing cellar

Design and installation of a ventilation system

If you are building a ground-based structure, then the flow of air into the cellar can occur naturally through small openings. For underground structures, ventilation must be supply and exhaust. The outlet of the exhaust pipe should be located near the ceiling, and the suction pipe should be located near the floor. Many do-it-yourself photos of a cellar in a country house show that the ventilation outlets are equipped with special curtains, this allows you to more accurately control the temperature in the room.

Installation of stairs and doors

If the cellar is being built under the house or if you need to save space, you should make an almost vertical staircase to the cellar with your own hands. How to make it as safe as possible for descent? It is recommended to use handrails. Photos of a do-it-yourself cellar staircase show that it can be built from wooden planks fixed directly into the ground, as well as from brick or other materials.

Doors are mounted in ground-based design options; in other cases, a hatch is used. Making a cellar hatch with your own hands is quite simple.

Layout of a cellar staircase

Making a hatch

If the cellar is located under a house or outbuilding, then a hatch is used as an entrance partition. You can buy a cellar hatch, or you can make it yourself. The second option will allow you to get a design that exactly suits your needs. Self-installation of the hatch includes the following steps:

- a location for the future entrance is selected. It is very important that access to it is as simple as possible and not cluttered with shelves, drawers and other objects;

- The dimensions of the hatch are determined. It all depends on your needs, but its parameters should not be less than 75x75 cm. In order for the room to be airtight, the side edges of the hatch must be sheathed with a sealant;

- a cellar hatch cover is being made. How to make it light and durable? For this, it is best to use wooden boards impregnated with drying oil. They are connected to each other with slats, and a sheet of plywood is nailed to one side of the lid. If we are talking about a cellar in a residential building, then the top of the hatch cover can be sheathed with the same floor covering as the floor around it. It is worth considering that if you plan to install a cellar hatch under tiles, its design must be made of sufficiently durable materials that can withstand all the ceramics. If you prefer to use steel, then for the lid you will need a sheet with a thickness of at least 3 mm, which is welded onto a metal frame;

Diagram of a cellar hatch

- a handle is attached. The best option would be a special hidden or folding design. If the cellar is located in a non-residential premises or there is a need to save money, then you can use a regular door handle;

- the hinges are screwed on. These can be regular door hinges or car hinges with springs. The latter option will make it easier to open the lid and fix it in any position.

There are many answers to the question of how to make a cellar hatch with your own hands, so you should choose the option that is most suitable in your particular case.

Wiring and lighting

Due to the fact that the design of the cellar provides for high humidity, the wiring in it must be reliably insulated. The best option for wiring is copper wires with a double layer of insulation. Light bulbs should be placed in the driest places and additionally equipped with protective caps. It is strictly forbidden to make sockets when building a cellar. How to properly make wiring as safe as possible can be seen in training videos from specialists.

Light bulbs in the cellar must be placed in dry places and must be equipped with caps

Installation of waterproofing in the cellar

As already mentioned, insulation from moisture is a very important point when building a cellar in a country house with your own hands. How to make waterproofing most effective - there are many options, and the choice of the optimal one depends on the level of soil moisture and the design features of the building.

Waterproofing can be external or internal. The external one is done during the construction stage, while the external walls are sheathed with insulating materials, and gutters, drainage wells and other structures are installed. Internal insulation is done after the cellar is built. In this case, before using insulating materials, groundwater must be drained, otherwise the work will be ineffective.

Types of materials used for internal waterproofing

If you made a cellar in your country house with your own hands from waterproof concrete, then you are unlikely to need additional cladding with insulating material. But for a brick structure you can use the following waterproofing options:

- mastic or bitumen - used in cases where the groundwater level is below floor level. The solution is heated and applied in a thin layer to the walls, resulting in the formation of a reliable waterproof film;

Membrane type waterproofing material

- penetrating waterproofing is the most expensive, but also the most effective option. It is good because it increases not only the level of resistance of walls to moisture, but also their frost resistance. Also, penetrating waterproofing reliably seals all cracks and micropores, is characterized by a long service life and is quickly installed;

- Cement-based polymer mortar is one of the most reliable and easy-to-apply waterproofing materials. It fits tightly to the walls and reliably protects them from mechanical damage;

- membrane-type moisture insulation - consists of various polymers, among which liquid rubber based on bitumen is very popular.

Note! It is very important to have effective ventilation for reliable waterproofing of a cellar in a country house with your own hands. How to build a ventilation system so that excess moisture does not condense in the storage? The installation of a supply and exhaust system is best suited for this.

Scheme of thermal and waterproofing of the cellar

Procedure for installing waterproofing

Numerous photos of a cellar in a private house show that waterproofing can be hidden under decorative wall panels. This is not a prerequisite, but only affects the appearance of the walls. The nuances of installing a waterproofing layer depend on the type of material chosen.

Waterproofing using bitumen or mastic for the walls of the cellar under the house with your own hands, as a rule, is not difficult. To do this, the walls must first be plastered, and the waterproofing itself is best applied in two layers. Before the coating dries completely, it is recommended to sprinkle it with fine dry sand.

Before installing penetrating moisture insulation, the surface of the walls must be thoroughly cleaned of dirt and dust, and then moistened with water. After applying the insulation layer for several days, it also needs to be constantly moistened. Before installing penetrating waterproofing, concrete walls are treated with a wire brush.

One of the most effective options for moisture protection is penetrating waterproofing.

To apply liquid rubber, the walls must be leveled and cleaned. After this, the surface is primed and a waterproofing material is applied to it using a brush, spatula or roller. Finishing materials can be mounted directly on a layer of liquid rubber after it has dried. Photos of wine cellars, for example, show that the walls are lined with wood panels.

The cement-polymer mixture is applied to well-moistened walls using a notched trowel or brush. It is best to do this in several layers.

Foundation

Due to the dampness present in the storage facility, the walls cannot be built from wood. They use red brick, cinder block, and stone. It is possible to cast a monolithic structure from concrete, but the technology is labor-intensive and expensive.

In any case, heavy walls need a foundation. If the groundwater lies deep, a depression is dug at the bottom along the perimeter of the pit on the bayonet of a shovel. The width must correspond to the parameters of the building material.

The bottom of the trench is covered with a layer of sand 10 cm thick and compacted. Crushed stone is poured on top, reinforcement is laid, and concrete is poured to the level of the general floor.

When there is a threat of rising groundwater, the foundation is made with a monolithic slab. First, they build a clay castle, compacting a layer of clay about 10 cm thick. The next layer is sand and crushed stone, and the whole cushion is compacted.

A screed of lean concrete 5-10 cm thick is poured on top of the crushed stone. After hardening, the concrete surface is treated with bitumen mastic, and two layers of roofing material or a waterproofing membrane are laid. The edges of the material are folded over the walls to prevent water from seeping in from the side. A reinforcing mesh is laid on the waterproofing, and the finishing screed is poured with concrete grade M-250.

Soil selection

Even if the site for the construction of a cellar is chosen according to all the recommendations, it does not hurt to check the quality of the soil - in many cases you will need to look for another location for the future structure. To determine the type of soil, it is necessary to remove the humus (top layer of soil) to a depth of 50 cm.

The optimal type of soil is sandy loam. But if you don’t have such specific knowledge, then pay attention to the following :

- the soil should not be wet or sticky;

- if it contains a lot of small stones, then such soil will be suitable specifically for building a cellar, but working with it will be very difficult;

- if the aroma of humidity and swamp rises from the ground, then this means that groundwater is close to the surface - nothing can be built here;

- If you find sand and/or clay in the soil, choose another place to work - this soil is load-bearing, the cellar simply will not be stable.