The sewer system is an important component of a modern home. If apartment residents do not need to worry about making sewerage from scratch, then owners of country houses should take care not only of installing internal, but also external pipelines.

To save on the services of professional craftsmen, residents of houses undertake installation work with their own hands. But there are cases when you cannot do without the advice of a professional. This applies primarily to drawing up a sewerage project, because here you need to think through everything down to the smallest detail.

You should think about installing a sewer system at the initial stage of building a house, when laying the foundation. If a special hole is made for the pipeline, you can save yourself from serious problems, because the passage is much more difficult to drill when the house has already been built and lived in.

Laying sewerage under the foundation

Note! The sewer line can be installed either in the foundation or under the foundation. The first option involves the presence of a hole in the base of the house; it is used if the foundation is deep enough. Laying the pipeline under the foundation is necessary if the foundation does not go deep into the ground. Pipes are laid below the freezing level of the soil.

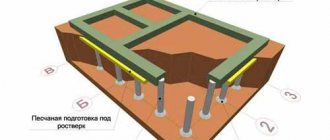

Types of asbestos pipe foundations

A foundation made of asbestos-cement pipes is used for low-weight buildings

Asbestos pipes by themselves cannot bear a large load; they are only permanent formwork for columnar and pile structures.

There are three types of foundations equipped with these products:

- columnar, shallow;

- piled with backfill below the soil freezing level;

- columnar or pile with grillage arrangement.

The first type is suitable for small buildings - sheds, temporary storage. A piping is laid on top of the pipes, on which walls are built from wood, USB slabs, frame buildings and houses from sandwich panels.

Pile foundations can be used on heaving soils, lands with close groundwater, and flooded areas. On slopes it is also more profitable to make a pile foundation, since the height of the piles can be easily adjusted to the level of laying the supporting beam (channel).

The combination of piles and grillage significantly increases the load-bearing capacity by redistributing the load across the entire foundation strip.

Characteristics of pipe foundations

As you know, there is no such foundation that would be suitable for all situations and for any soil. The same applies to columnar foundations, which are used only in certain cases. When compared with other types of bases, it has many advantages.

Strengths of a columnar foundation:

- Low installation costs. In this case, they are several times lower than those of prefabricated or monolithic foundations.

- Land work is needed, but to a very limited extent.

- Construction is quick and simple.

- A very reliable option for houses with a small number of floors.

- Load-bearing structures are carried above ground level, which significantly reduces the likelihood of being washed away by floods.

- The load from the weight of the building is better distributed over the ground.

- Heaving soils are not an obstacle to the construction of this type of foundation.

In addition to the above advantages of pipe foundations, some others can also be mentioned:

- Due to the standard equipment, which is freely available for sale, there are no restrictions on the laying depth and diameter of the pillars.

- The price of consumables is usually quite small.

- As for transportation costs, they are also mostly insignificant. This is especially true when using plastic pipes (for more details: “How to make a foundation from plastic pipes - DIY construction options”).

- Excavation work, through the use of drilling, is kept to a minimum. The drilling rig is a cheaper mechanism than the same excavator. If the laying depth is shallow, which often happens when constructing small houses, the work can be carried out using an electric, gasoline or manual garden auger.

- In this case, the pipes act as permanent formwork, which ensures the clarity of the geometry of all design parameters.

- If metal pipes are used, additional reinforcement of the pillars will not be required.

- A foundation made of horizontal pipes does not require masonry.

In certain situations, it is not recommended to use columnar foundations:

- If the site contains horizontally moving soils with weak stability, because there is a high risk of capsizing.

- Weak-bearing, water-saturated and subsiding soils are also a poor option for a columnar foundation. The same applies to cases when it is necessary to erect a powerful stone structure.

- The presence of significant differences in height under the building on the site (more than 200 cm).

- If it is necessary to arrange a basement, it is better not to choose a foundation made from a profile pipe, since such an undertaking will require significant costs and effort.

Pros and cons of pile and columnar foundations

Foundations on piles have a number of advantages:

- low cost compared to strip slab type;

- long service life, which is enough for the entire operating cycle of the building;

- application on any type of soil, including flooded lands;

- minimum number of preparatory activities;

- ease of installation, the work requires only 2-3 people;

- versatility;

- construction speed.

A large number of piles during the construction of a massive building is considered to be a design disadvantage. Construction of a basement is possible if the piles are installed at the bottom of a previously dug pit.

Description, characteristics and properties of asbestos pipes

Pipe characteristics

Asbestos pipes are divided into pressure and non-pressure. The first option has increased strength and a high price, which is why it is not used in the construction of foundations. These products are used for laying pressure water pipelines with a pressure of up to 15 atm.

Non-pressure asbestos pipes are used for arranging gravity sewer systems, laying communication cables and constructing drainage wells in land reclamation areas. The products are inexpensive and available everywhere.

Factories adhere to GOST 1839-80 when manufacturing. “Asbestos-cement pipes and couplings for non-pressure pipelines”, therefore the quality of the building material is guaranteed to be high.

In private construction, the products are popular due to their positive properties. Asbestos pipes are distinguished by:

- easy processing and cutting with home tools - a hacksaw or a grinder with a stone wheel;

- moisture resistance;

- not susceptible to rotting;

- low coefficient of thermal expansion, which helps maintain dimensions in all weather conditions;

- resistance to chemicals and aggressive environments;

- low weight, which allows you to work without the use of lifting equipment;

- low cost;

- large range of standard sizes.

The downside of pipes is their low load-bearing capacity.

Manufacturers produce pipes of precise sizes. The minimum internal diameter of the pipe is 100 mm with a wall thickness of 9 mm. The maximum internal passage is 368 mm with a wall thickness of such a pipe of 17 mm. The outer diameters of asbestos pipes are 118, 161, 211, 307 and 402 mm. Product lengths from 2950 to 3950 mm.

Support design

Asbestos-cement piles are a prefabricated structure.

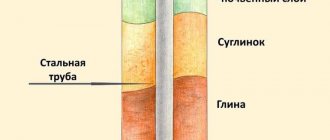

The pipe serves as formwork for a reinforced concrete pile. A frame made of steel reinforcement is installed inside the pipe. The number of longitudinal rods is from 1 to 4. To ensure stability and maintain the shape of the frame when pouring concrete, the longitudinal rods are welded with transverse rods.

The thickness of the longitudinal rods is from 8 to 12 mm. The grade of concrete for pouring is not lower than M200.

Calculation of the number of pipes

The number of pipes depends on the bearing capacity of the soil and the weight of the building

The number of piles in the foundation depends on several parameters:

- the total mass of the building, taking into account the walls, ceilings, roof and snow load, as well as furniture and equipment that will be placed in the premises;

- soil structure and bearing capacity;

- diameter of the pile base.

The structures must be installed at the corners of the building, as well as at the intersection of external and internal walls. The calculations determine how many piles will need to be installed along the walls.

The maximum distance between pillars cannot exceed 2 meters, and the minimum - at least three pipe diameters.

Algorithm for calculating the required number of pipes:

- Calculate the total mass of the house.

- Find out the bearing capacity of the soil at the construction site. You can find it out from reference books.

- Divide the total mass of the structure in kg by the bearing capacity of the soil, taken in kg/cm2. The result is the total cut area of the pipes.

- By dividing the required area of the base by the area of one pile, the required number is obtained.

To build a foundation, the pipes must be buried in the ground below the freezing level, which is determined from the tables for your area. The height of the snow cover is added to the resulting length so that the house is not covered with snow.

If asbestos-cement piles will be reinforced, several sections of pipes can be used.

Design of supports for pipelines (to SNiP 2.09.03-85)

Or is there some other solution to my problem? The need is that by the end of summer there will be a small residential wooden house in the yard and it needs to be heated somehow.

We have problems with electricity - my house is on the edge and the voltage is always low for the air conditioner and sometimes there is not enough. And it’s expensive to heat with electricity.

Piles are widely used in various fields of civil and industrial construction, making it possible to significantly reduce the overall cost of constructing objects by reducing the cost of arranging the foundation. At the same time, the pile foundation structure is not only not inferior to traditional analogues, but also surpasses most of them in many technical and operational characteristics. Branded products fully comply with current standards and international requirements, therefore they can be fully used in all climatic zones of the Russian Federation and CIS countries.

So I decided to cut into the heating system of the main house and heat the small house. The distance to the new house is only 4 meters. Here. So I’m wondering if it won’t turn out that by spring we’ll all be living in a new little house!

My parents also have a one-story house, only it is not wooden, but masonry walls, water supply and sewerage are located under the foundation.

In principle, I don’t see anything wrong. Nothing bad should happen from heating the ground.

Advantages of a pile foundation for a pipeline

Unless your house is on permafrost. If only through the window It will be somehow ugly Pipe all over the yard Although most likely in my case an above-ground above-ground pipeline will be safer. DWG Forum.

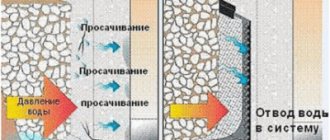

How to properly organize the passage of sewer or water pipes through a strip foundation? How to protect the basement of your country house from dampness or flooding with groundwater through pipe passages through the basement walls? In this article I will try to answer these questions by talking about the most common methods for arranging pipe passages through walls and foundations. By the way, some channels in Zen now have the opportunity to comment on new publications.

Advertising placement. Feedback - Up. Views: Find more messages from Alexey PGS.

Required amount of materials

To give strength to piles, reinforcement is needed

When making a foundation from asbestos-cement pipes with your own hands, you must purchase cement sand and steel reinforcement in advance. When purchasing reinforcement, take into account the length of all piles. In some cases, the rods are released from the pipe in order to weld the supporting channel channel to it.

If a grillage is made around the pile foundation, its connection with the pillars is also carried out by releasing horizontal sections of reinforcement.

A supply of rods will be required if the reinforcement bars have to be joined. In this case, the overlap should be 30 rod diameters. For example, reinforcement bars with a diameter of 10 mm should overlap each other by 30 cm.

The amount of concrete required is calculated by the sum of the volumes of the cavities of all pipes.

The volume of the mixture for one rack is calculated by the formula: V=3.14*R2*L, where V is the volume of concrete to be poured, R is the internal radius of the pipe, L is the length.

Materials for concrete

Asbestos pipes for the foundation are filled with concrete grade M200 or M300.

Composition of concrete to produce 1 cubic meter of mixture from M400 cement.

| Components | Concrete M200 | Concrete M300 |

| Cement, kg | 260 | 340 |

| Crushed stone, kg | 1270 | 1250 |

| Sand, kg | 740 | 640 |

| Water, l | 130 | 220 |

Proportions when using cement grade M400.

| Components | Concrete M200 | Concrete M300 |

| Cement, kg | 1 | 1 |

| Crushed stone, kg | 4,8 | 3,7 |

| Sand, kg | 2,8 | 1,8 |

| Water, l | 0,5 | 0,6 |

Typically, the components of concrete during self-construction are measured in buckets.

The proportions (cement/crushed stone/sand) for concrete grade M200 are 1x3.9x2.5, and for M300 - 1x2.5x1.6.

Arranging the passage of pipes through the walls and foundations of country houses

Quote: Message from Alexey PGS Please tell me how sad the consequences of laying a heating pipeline under the foundation will be for the house?

Message from Alexey PGS The foundation of a one-story wooden building is strip, without reinforcement; soil - fine sand; foundation depth - 30 cm. Find more posts by lycurgus. Immediately after driving the pile, you can begin directly installing the pores and further laying the pipeline.

The immersion of piles is carried out pointwise, therefore eliminating the need to uproot green spaces in the immediate vicinity.

Installation sequence

Construction of the foundation consists of several sequential procedures:

- carrying out the necessary calculations;

- purchase and delivery of building materials;

- site preparation and marking of pile locations;

- drilling the soil, forming pits for supports;

- installation of piles and their concreting.

A set of building materials, including asbestos pipes for the foundation, can be purchased in one place, saving money on delivery.

Before construction begins, issues with connection to electrical networks and the method of delivering process water to the site are resolved.

Preparatory work on site

Before starting work you need to make markings

Construction site preparation algorithm:

- Clear the site, access roads and approaches from vegetation, large stones, and construction debris.

- They remove 20–30 cm of fertile soil, uproot the growth of trees and shrubs - after construction it will be difficult to fight the vegetation under the floor of the first floor.

- They mark the boundaries of the future building by installing casing boards and pulling the construction cord.

- Mark the exact location of the piles.

- Check the accuracy of the markings by checking the length of the diagonals.

After preparing the construction site, construction of the foundation begins.

Pit preparation

Asbestos pipes for the foundation are installed in pre-prepared pits.

The length of the well should be 20–30 cm greater than the length of the pile. The hole diameter is chosen 10 cm larger than the diameter of the asbestos pipe. You can make holes in the ground using hand drills or gasoline-powered units. To lengthen the working part, special extensions are used.

It is necessary to strictly follow safety regulations when working with power tools. Tree roots and large stones can jam the drill and lead to injuries—it is impossible to stop the engine’s rotation instantly; the torque is enough to throw a person several meters to the side.

If necessary, the bottom of the hole is widened using a TICE type device. This allows you to increase the support area of the pile, increasing the design load.

10–15 cm of crushed stone is poured into the bottom of the pit and compacted with a block attached to a handle of the required length. A layer of sand 15 cm high is laid on top of the crushed stone, which is spilled with water and compacted to compact it.

Drilling a hole in the foundation

If the owner did not think about installing a sewer system when laying the foundation of the house, he will now have to make a hole to lay the sewer pipe. To do this you will need the following tools:

- hammer drill - you can’t do anything without it;

- punch - metal rod;

- electric drill with drills;

- diamond rig if simpler tools fail to make the hole.

Do not expect that the drilling process will be easy, as you should work with a concrete or reinforced concrete base. In some cases, a grinder is used to cut reinforcement. The material from which the base is made is durable and strong. It will take more than one hour, or even a day, to reach the goal.

Sewerage inside the foundation

The first step is to mark the location of the pipeline in the foundation, draw a circle there, the diameter of which is slightly larger than the diameter of the sewer pipe with the sleeve. Now, using a hammer drill, we drill out the concrete as deep as possible. The reinforcement is destroyed with a grinder or electric drill.

Note! If you need to make a hole of a large diameter, for example, to install a sewer system that will serve a house with two or three floors, you cannot do without using a drilling rig.

First the sleeve is laid in the finished channel, then the pipeline. All gaps should be sealed with polyurethane foam, which will act as a heat-insulating material. The question of how to remove the sewer pipe through the foundation has been successfully resolved. Now you can begin installing the internal and external pipelines.