Columnar foundation - how is it presented?

Externally, it looks like several rows of load-bearing pillars located relative to the load-bearing walls. That is, in places with significant load. In principle, this is typical for all types of foundations. In addition to load-bearing walls, pillars are placed at the intersection of external and internal walls. The foundation for the stove, based on pillars, is also prepared according to its size and schematic location. If according to the project a heater will be used for heating.

Over many years of practice, builders have determined the optimal distance between two supports to be 1.5–2.5 meters. To make the structure monolithic, and in order to strengthen the overall frame, for the purpose of subsequent installation of the basement row, above the ground, the supports are connected to each other with a grillage.

The most reliable option for columnar support is reinforced concrete pillars. They are durable and can withstand almost any weight of the structure. But given the relatively light weight of baths, even brick ones, the use of rubble concrete, stone, brick, steel and asbestos-cement pipes is allowed. These materials allow you to save on work. But before choosing them instead of reinforced concrete supports, the soil at the construction site is carefully checked for the presence of groundwater.

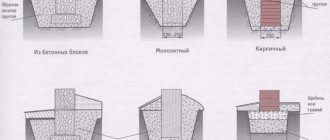

What to make columns from

Support posts can be constructed from different materials:

- natural stone;

- reinforced concrete blocks;

- asbestos-cement pipes;

- bricks

They can be made monolithic by filling the prepared formwork with a reinforcement cage installed in it.

Each material has its own positive and negative qualities; the choice depends on how many years of service you expect for the building.

The choice is often influenced by whether the developer has leftover building materials that he can use to build a bathhouse on a columnar foundation.

In the vast majority of cases, brick remains on the farm after the construction of a residential building. However, not every brand of this building material is suitable for the construction of support posts.

Technical aspects of admission

Regardless of what material is used for the work, whether the bathhouse is built frame or brick, the arrangement of a columnar foundation is accompanied by the following factors:

- the columnar base is not conducive to arranging a basement;

- this type of foundation is less susceptible to freezing with all the ensuing consequences;

- the price of materials relative to the quantity required for pouring is much less.

In addition to the fact that a columnar base is preferable for light-weight buildings and is recommended for pouring on washable soil, there are a number of additional recommendations regarding structural design. For example, the total height of the foundation should not exceed 1.5 meters, and the shrinkage deformation, in relation to the most popular type of strip foundation, is 40% lower.

Installation of finished walls

Laying depth

The third stage is preparing the marking of the area for the installed support pillars. This is done as follows:

- Arrangement of cast-offs - installation of support pillars in the corners at a distance of up to 200 cm from each other. The same scheme is used to move the remaining supports in accordance with the approved development plan;

- Tensioning ropes along the external axes for each load-bearing wall, as well as along the internal axes for partitions;

- Checking the accuracy of diagonals for all internal and external walls.

Installation of pillars requires the preparation of holes, which can be dug manually or using specialized equipment. The depth of the holes is 20 cm, width is up to 50 cm.

People who have experience in how to build a frame bathhouse advise building and fastening the walls for this building on the ground, after which they should be lifted and installed in place.

We invite you to familiarize yourself with: Finishing the attic with clapboard photo

A few recommendations before choosing

In order not to overpay for the purchase of material for pouring a columnar base, take into account the weight load on the foundation. Baths built from rounded logs or frame buildings are not very heavy, so the pillars do not need to be poured too deeply. This is explained by the fact that low temperatures in winter will affect the entire foundation, exceeding the kinetic load exerted by the weight of the structure. This will lead to cracking of the concrete and the appearance of a slope. The size of a non-buried foundation is 40–50 cm. At the same time, the depth of pouring the pillars, unlike, for example, a strip foundation for a bathhouse, should not exceed 70 cm, that is, not reaching the level of soil freezing. With the average value of this indicator across regions being 1 meter, it is enough to fill the pillars to a depth of 60–70 cm.

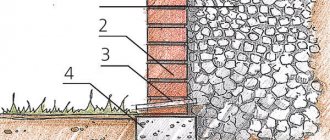

As already mentioned, heaving forces exert high loads on the columnar base and are directed mainly at the plantar and lateral surfaces. This force can be reduced by treating all posts with synthetic lubricants or bitumen-based mastic. In order not to rack your brains over the choice of means, and in order to save money, each post can be wrapped in roofing felt or other similar materials.

Columnar brick foundation: subtleties of construction

The general rule applies to a columnar brick foundation for a bathhouse: the entire construction cycle must be completed before winter.

The supports should not be left unloaded until spring - processes occurring in the soil layers can deform them to such an extent that further use of the constructed columns will become impossible.

Therefore, it is important not only to know how to make a columnar foundation for a bathhouse, but also to begin the process of its construction on time.

What type of brick can be used

Any random brick is not suitable for the construction of support columns. Silicate (white), hollow, lightweight - all these types of bricks are not suitable for the foundation, even if you are building a very tiny bathhouse.

Only solid burnt red brick is suitable for the construction of columns. It is durable enough to withstand abuse for decades. In addition, this type of brick is characterized by low moisture permeability, which is especially important when building recessed columnar foundations.

Another parameter that you should pay attention to is the frost resistance of the brick. This figure indicates how many freezing/thawing cycles the brand can withstand.

Foundation work - preparation

The initial process, during which the place for the foundation is prepared, is the most important. This is a recommendation not only for pouring the foundation, but also for building a bathhouse in general. There should be no debris on the site; the top layer of soil must be removed to a depth of 5 cm. Subsequently, this will further facilitate the work of laying drainage and sewerage.

After this, the installation location of the pillars is marked. Initially, you need to outline their filling at corner joints and at the junctions of internal partitions, only after that can you calculate the distance according to the standard (1.5–2.5 meters) relative to other supports. If it is not possible to meet these indicators, and the distance exceeds the stated standards, then it is necessary to reconsider the location by adjusting the parameters. Remember - installing supports closer than 1.5 meters is also unacceptable, this can lead to a weakening of the bearing capacity of the soil.

Pile-screw foundation

A variation of the columnar base for a frame bath is the pile-screw method, which is also called the drilling method. It will take only 20 minutes to prepare a one and a half meter hole using a hand drill. The entire process includes the following steps:

- In soil with normal bearing capacity, holes Ø 24 cm are prepared.

- An asbestos pipe with a cross-section of 20 cm is placed inside.

- To maintain a vertical level from the outside, it is compacted with soil.

- Pouring concrete solution takes place in three stages. Initially, a third of the asbestos pipe is filled, after which it is raised so that the concrete mixture forms an expanded base of the pile.

- At the second stage of arranging a pile-screw foundation for a frame bath, the concrete mixture is poured to a level of 10-15 cm below the upper edge of the pipe.

- The solution is compacted by penetrating it with a metal rod, then the reinforcing rod is fixed.

We invite you to familiarize yourself with the dimensions of the shelves in the bathhouse - All about the bathhouse

Depending on the surrounding climate, hardening takes place within a week, after which you can proceed to the installation of a frame bath.

Advice! When choosing piles, pay special attention to the quality of the coating.

To save money, the protective layer is thinner than required. This leads to scratches and rapid development of rust. The problem is especially acute for alkaline soils.

Instructions for pouring pillars

When the work site is ready and the locations for installing the supports have been identified, we begin digging holes for them. This is done manually or with specialized equipment, the main thing is to maintain the depth of the bookmark. The floor width of the pit should be 10 cm larger on each side. This reserve is necessary to create a reinforcement frame. It is worth recalling that this must be done under the condition of monolithic filling. If a columnar foundation is installed under a light bathhouse made of logs, then it is better to make it from ready-made reinforced concrete supports.

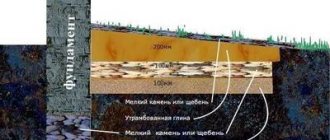

The pit is ready, add a sand and gravel cushion to the bottom. We water it all with water and tamp it down a little. Now you need to insert a reinforcement frame, welded in advance to size, into the hole. It will be inconvenient to install the harness here, so it is better to prepare it in advance, according to the height of the fill. The frame is thoroughly trimmed horizontally and vertically using appropriate devices. Afterwards, according to the plan, the formwork is installed or its use is omitted due to the design features of the bathhouse.

Next, the frame is wrapped along the contour with roofing material, taking into account that the solution will be poured inside it. The edges are fastened with a stapler. Now all that remains is to pour the solution and, if possible, expel air from the layers to reduce the possibility of cracking. The base is ready. All that remains is to let it gain strength and you can start building any bathhouse, even a brick one.

Considering the filling option as the most complex and worthy of attention, it is necessary to highlight several points regarding its characteristics and design features.

- A columnar foundation for a bathhouse, made by pouring a reinforcement frame, can last up to 150 years.

- In order for the building to stand for a long time and reliably, it will be enough to prepare a shallow version, which will save on material.

- If the building does not have a basement, then there is no need to make formwork and raise the foundation above the soil. You can protect the basement level with roofing felt.

That's all the tricks for laying a columnar base for a bathhouse. If everything is done correctly, the foundation will be as strong as possible. And the possibility that, relative to such a basis, it is as simple as possible to supply water to a bathhouse, speaks of its attractiveness for those who do everything with their own hands.

Columnar foundation - description and conditions of use

As noted above, the simplicity of the design and the technological processes used make it possible to create a columnar foundation for a bathhouse with your own hands. But before starting work directly, you should choose the material from which the base of the structure will be made - the pillars. There are a large number of possible options.

Bored piles have become very popular. This happened due to their advantages:

- ease of production directly on site;

- low cost of necessary materials and work;

- carrying out concreting, both in casing and without it;

- high performance characteristics of the resulting design.

However, given the prevalence of bored piles, other options are often used:

- wooden pillars. They are rarely used, mainly in non-massive and non-permanent buildings (wooden terraces). The reason for this is the low load-bearing capacity and low service life. However, in some cases, the use of wooden supports is justified due to their extremely low cost;

- pipes made of metal or asbestos cement. They are used both as independent load-bearing structures and as permanent formwork. The second option is widely used in private housing construction and in the construction of fences and bathhouses. This is explained by the combination of the low cost of materials and work and the high performance properties of the resulting foundation structure;

- brick pillars. Most often used for non-buried foundation construction. They are made square with a side size of half a meter;

- concrete pillars. The most reliable columnar foundation design, with the greatest strength and service life. It can be carried out both in a monolithic version and using concrete blocks.

We suggest you familiarize yourself with Which foundation is best for clay soil

The variety of possible design options and the building materials used allows us to consider a columnar foundation one of the most flexible and convenient structures.

In addition, a combined column-strip foundation is often found, when a grillage is made on piles, and the building has a base.

Each material that can be used to construct a columnar foundation has its own installation features.

For example, a pile of pipes should protrude above the surface of the site by at least 0.4 meters. Its surface must be protected with a layer of waterproofing. The distance between the pipe wall and the edges of the pit is filled with earth or sand and gravel mixture and then compacted. Then reinforcement is installed inside the pipe, exceeding the length of the pipe by 20%.

After all preparatory measures have been carried out, concrete is poured into the pipe cavity (grades M250 and M300 are most often used). After receiving about a third of the required concrete, the pipe rises slightly, allowing the concrete to create a kind of cushion at the bottom of the pile. It increases strength and reliability, as well as the load-bearing capacity of the entire structure.

Poured concrete must be constantly compacted. After concreting is completed, the pile must gain the necessary strength; this requires at least 7-10 days.

When constructing pillars made of monolithic concrete, the role of a pipe is played by ordinary wooden or plastic formwork. And the process of producing the work itself is approximately the same.

When constructing piles from brick or concrete blocks, you need to pay special attention to two points:

- mandatory installation of a sand cushion and a concrete base on top of it for the pillar (for bricks the base thickness is 20 cm, for blocks – 50-70 cm);

- for brick pillars, additional reinforcement is required; concrete blocks are laid on a mortar bed and the requirements for dressing the masonry are observed.

Following the recommendations given, as well as using high-quality materials during construction, will result in a reliable and durable columnar foundation design.