On this page you will learn about the cost of our services.

ο Price lists for works (198.27kb)

Types of jobs:

ο Cost of drilling ο Cost of ο Cost of gating ο Cost of diamond cutting ο Cost of cutting openings ο Cost of strengthening openings ο Cost of dismantling ο Cost of other types of services ο Forms of payment

The cost/price of drilling holes in concrete depends on such parameters as the diameter of the holes, the thickness of the walls, floors and foundations, material - brick, concrete or reinforced concrete (monolith), and the formation of the price for diamond drilling of holes is influenced by the number of holes (scope of work on the object).

If you would like to know more accurately the cost and prices for diamond drilling of holes in concrete, brick, reinforced concrete/monolith and other building materials, please call our managers by phone: +7(495)991-81-26.

ο Price list Diamond hole drilling (27.42kb)

Our managers will quickly and accurately calculate your order, based on your task and needs.

The cost of drilling is indicated in Russian rubles. for 1 cm excluding VAT

| Hole diameter mm. | Brick | Concrete | Reinforced concrete |

| Ø 25-52 | 16 | 18 | 20 |

| Ø 62-72 | 18 | 22 | 24 |

| Ø 82-102 | 20 | 24 | 26 |

| Ø 112-122 | 22 | 26 | 32 |

| Ø 132-142 | 24 | 30 | 34 |

| Ø 152-162 | 30 | 34 | 36 |

| Ø 172-202 | 36 | 40 | 44 |

| Ø 225-252 | 44 | 52 | 58 |

| Ø 302-325 | 48 | 58 | 68 |

| Ø 352 | 62 | 74 | 96 |

| Ø 402 | 86 | 94 | 124 |

| Ø 452 | 96 | 116 | 138 |

| Ø 502 | 112 | 132 | 156 |

| Ø 502+ individually | — | — | — |

- Drilling holes, prices and costs are indicated in Russian rubles. for 1 cm.

- The cost of diamond drilling is discounted even for medium volumes. Call!

- The cost of the minimum order/departure is 6,000 rubles.

Photo: Diamond drilling of holes in the finished foundation for air vents and ventilation in a dust-free house.

Diamond drilling of foundations: +7-925-768-66-07.

2. For reference: diamond drilling of foundations [*45]. Work on diamond drilling of foundations. Option 1: FBS-500 foundation blocks are drilled, concrete characteristics: M250-M300, class B20-B25, density 2400 kg/m3, reinforcement 10%, 2 layers, A3 reinforcement 12 millimeters. Option 2: we work on a strip or monolithic foundation with a burial depth of 1.8 meters (below the soil freezing level in the Moscow region), strip width 500-700 millimeters. The choice of diamond tools and drilling technology is influenced by 3 main factors: the first is the thickness of the concrete foundation block or strip, the second: the grade and class of concrete on which the strength of the material for a diamond cutter depends, the third: external factors, individual for each individual case.

Diamond drilling of holes in building foundations

The foundation of the building, which serves as the base for the walls, bears a large load, so they are usually made of high-strength types of concrete with reinforcement. At the same time, after construction it is often necessary to make additional holes in the foundations for laying communications, such as sewerage, water supply, gas pipelines, and so on. The high speed and simplicity of diamond drilling, the large permissible depth of holes, the absence of shock loads and damage to the foundation make this method the only alternative, allowing you to obtain holes from 10 to 600 mm in diameter and a depth of up to several meters without disruption or damage to the structure.

We work without intermediaries.

3. We work without intermediaries and believe that this is the most profitable work scheme for both the customer and the master. We do not have employees who are not involved in the diamond cutting or concrete drilling process, and this affects the price level and quality of work. Our prices for work on making holes using diamond technologies are 15% lower than the average in this market segment. Your call goes directly to the diamond cutting and drilling specialist, all organizational and technical issues are discussed directly between the Customer and the Work Contractor: prices, terms, volumes and other working nuances of the order. As practice shows, this work scheme has proven to be the most effective and mutually beneficial.

Diamond drilling of foundations, vents.

4. How to make perfumes. Drilling vents in foundations with a diamond tool. Making holes in concrete foundations for ventilation is a fairly common type of order. Quite often, during low-rise construction, at the stage of pouring the foundation, ventilation holes are simply forgotten. And after the construction of the load-bearing structures of the building, finishing and occupancy, the question arises about ventilation in the basement. To independently make vents in a concrete foundation 500 millimeters wide is, to put it mildly, a difficult task. Using diamond drilling and concrete cutting technology, a hole with a diameter of 160 millimeters for the vent is drilled in 25 minutes, the thickness of the concrete is 0.5-0.7 meters with reinforcement. The basic requirements for the manufacture and parameters of vents are set out in SNiP 01/31/2003 “Residential multi-apartment buildings”, section 9.10. The optimal size of 1 vent is 0.04-0.05 square meters, the total area of the ventilation holes in the basement is at least 1/400 of the area of the basement or basement. As a rule, vents are drilled in pairs, one opposite the other, in height: 300 millimeters from the zero level.

Plot

19 votes

+

Vote for!

—

Vote against!

The foundation of a building is where the construction of a house begins, and the destruction of the entire structure can also begin with it. Cracks appear at the base of the building, which will compromise its integrity. The reason for their occurrence is improper foundation ventilation or its complete absence. If you do not equip vents at the base of the house, then wooden elements - walls or floors - will begin to rot, which will entail irreversible destruction of the entire structure. Often during construction these small but important holes are forgotten, thereby reducing the life of the building:

Table of contents:

- In what cases is it not necessary to install vents?

- How many vents to make and what size?

- Arrangement of vents

- How to remove wooden beams from concrete

- What to do if vents were not designed during construction

In what cases is it not necessary to install vents?

Vents or vents are important elements of the foundation of a house that need to be thought through at the stage of constructing the foundation. They are small holes. Their organization has some rules and parameters that must be followed. This is laid down in the basic rules of construction. These structures are necessary in order to keep the temperature difference between the floor and the underground room at a level of no more than 2 degrees. Such conditions are created in the presence of properly organized ventilation.

But there are cases in which the arrangement of vents is not necessary. This is possible if:

- the basement is used as a cellar or food storage;

- there is a direct passage between the underground space and the living rooms above it;

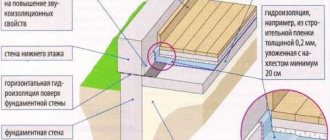

- the material that was used to finish the basement is a vapor-proof film material, laid on top of each other in a layer of at least 15 cm;

- in the basement there is a ventilation system that pumps from 0.5 to 1 liter of air per second for every 5 square meters. m. area;

- When processing the inner surface of the foundation and the soil inside it, heat-insulating materials were used.

The foundation design does not provide for the presence of vents in it in the cases listed above, but in other cases it is necessary to design the correct ventilation of the underground rooms.

How many vents to make and what size?

The number and size of vents is calculated individually in each individual case. This indicator depends on the conditions in which the building is operated. When calculating, the following factors should be taken into account:

- climatic conditions;

- the composition of the soil on which the house is being built;

- landscape features of the area.

Foundation design technology provides the largest possible number of vents for swampy lowland areas or climates with high rainfall. Experienced builders recommend making vents in every wall of the foundation, even those laid under the internal wall of the building.

The size of the vents is calculated as follows: the total floor area is measured, then this figure is divided by 400. The resulting value is divided by the number of vents that are planned to be made. This figure will be the size of their optimal area. It is not difficult to calculate how many vents you need to make - the holes should be located every 2-3 meters along the entire length of the walls.

But these calculations are not correct for all climatic zones. For areas with high humidity, experts advise basing your calculations on the following example: per 100 sq. m of the basement, make 25 vents with a diameter of 11 cm.

Building regulations state that in a room that is not equipped with exhaust ventilation, vent openings must be sized in a ratio of 1 to 400, relative to the area of the entire basement. Make holes less than 5 square meters. cm is not allowed. If the area has a high radon content, the estimated number of vents should be increased by 3-4 times.

Arrangement of vents

Before you begin, you need to prepare your tools. To arrange vents you will need:

- shovel;

- sledgehammer and hammer;

- hammer drill or drill;

- drill for wooden materials 2.5 cm thick;

- metal drill 1.4 cm;

- straight and semicircular chisel;

- pipes with a round cross-section, diameter - from 11 to 13 cm, material - plastic or asbestos cement;

- sand.

The design of vents must begin at the stage of laying the foundation. For a strip foundation, this process begins during the installation of formwork for pouring concrete. The distance from the soil to the vent must be at least 30 cm. This is necessary so that when the snow melts, moisture does not get into the hole. In parallel walls, all openings must also be parallel.

To make the vent, round pipes are used; you can use a wooden beam, but in this case it may be difficult to remove it. Read below for information on how to properly remove timber from frozen mortar.

The process of laying vents looks like this:

- The pipes are cut into pieces, the length of each piece must correspond to the size of the formwork and the width of the base of the house.

- Sand is poured into each pipe, the ends are covered with rags or paper so that sand does not spill out of the pipe and building material does not get inside the pipe.

- The prepared pipes are placed in places designated for vents. This must be done so that they rest tightly against the parallel sides of the form.

- The pipes are filled with concrete.

- In the case of making vents from wooden bars, the process looks approximately the same, but the bars are laid in the concrete, which are left for a month until the solution is completely dry, and then removed.

How to remove wooden beams from concrete

Wooden beams embedded in wet concrete must be removed. To carry out the work you will need the following tools:

- Set of drills for metal.

- Electric drill or hammer drill.

- Wood drills.

- Semicircular chisel.

- Straight chisel.

- Sledgehammer or heavy hammer.

Routing:

- Using a metal drill, make two parallel holes around the perimeter of each wooden block. For a thin bar, one hole in the center is enough.

- Use a wood drill to make a through hole in the marking areas.

- Take a semicircular chisel and widen the hole towards the side of the beam. Using a straight chisel, use a straight chisel to break off a piece above the hardened concrete. Remove two timber corners in this way.

- Take a sledgehammer and break off the remaining two corners.

Tip#1

For small concrete blocks into which small cross-section bars are placed, you can use the traditional method. Lubricate each block with any oil in advance. Removing the bar is much easier and does not require physical force. The ends of the vents are freed from paper and sand after the concrete mortar has hardened on the strip foundation. Foundation ventilation needs protection; for this purpose, a special grille is installed at each ventilation hole. A preventive measure necessary to ensure a constant flow of air into any room, including the basement. The mesh will additionally prevent rodents and insects from entering the house. The lattice can serve as a decorative element of the decoration. Modern industry offers different colors and types of these products.

Tip#2

To effectively supply air to the vegetable storage room, ventilation ducts are provided. A common option for installing a system is to install paired pipes. One is placed under the ceiling, the second is lowered to a distance of 0.5-0.7 m from the floor level. Natural traction is created. A hood can decorate the exterior of a house and the foundation; photos with interesting, original types of grilles will help you determine your need for such a design and choose the option you are interested in.

Tip#3

Carry out seasonal cleaning of ventilation vents. Purchase a long, strong, lightweight stick or pole. Place a polypropylene whisk on one end and insert it into the hole to the maximum possible depth. Rotate the tool several times clockwise and counterclockwise. Rinse in clean water and clean again. Wash protective nets or grilles with a soda solution, not a soap solution.

What to do if the vents were not designed in advance

There are many reasons for the lack of vents in a built house. There is only one way out of the situation - to correct the defect.

Method one, for the case of an unfinished building.

- One of the radical and reliable ways to eliminate deficiencies in the construction plan would be to erect a plinth on the foundation. Ventilation holes are made in the basement floor. In a brick plinth, it is enough to insert the brick edgewise to form an vent.

- In a concrete, poured base, a hole for ventilation is made according to the method described above for a concrete foundation.

- If it is impossible to raise the floor level using a plinth, holes for vents are made in the foundation. You will need a special drilling device. It can be a pneumatic hammer, a diamond drill, or a hydraulic hammer. The process is difficult and responsible. Impact instruments cause dynamic destruction, microcracks form, fragments of the base collapse, and the structural configuration of the reinforcement is disrupted. Subsequent operation of the building will lead to moisture penetration into cracks, oxidation of the metal frame, and scree.

- It is reasonable to invite a specialist with modern working tools to perform this section of the work. Find advertisements for companies, read several offers, choose based on the advice of former clients.

- When drilling the foundation, ensure that the frame is inserted. This is an important point. The frame will bear the pressure of the concrete and will not allow the vent to deform.

Method two for a residential building:

- Create a ventilation system not through the foundation, but through the living rooms. A place in the floor that is not subject to load changes is selected and holes are drilled. The optimal areas are located in rooms under furniture legs, in corners, under stairs. The vents are covered with metal mesh.

- Ventilation in the foundation is carried out not so much due to the classics of construction, but for one’s own comfort. High-quality vents are guaranteed to protect the wooden parts of the building and auxiliary buildings inside the house from moisture, rot, and mold. For strip foundations, the installation of vents is a mandatory measure to protect the building from premature deterioration.

- The construction of a foundation with holes for vents provided in advance extends the life of the building, eliminates the need for constant repairs of basements and cellars, and protects the house from subsidence.

Types of foundations.

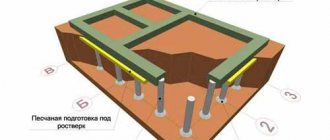

5. In 90% of cases we work on two types of foundations: 1 - strip, 2 - capital (block or monolithic). Let's briefly look at each option. Type 1: the most common and budget option: strip foundation. Widely used in low-rise frame construction, when the calculated load per 1 square centimeter of concrete strip does not exceed 250 kilograms. For the construction of a strip foundation, as a rule, concrete mortar of grade M250, strength class B20, is used. The width of the foundation strip is from 400 to 600 millimeters. The second most common type of foundation is a monolithic foundation for a brick or concrete structure. For the construction of a monolithic foundation, concrete mixtures with higher strength and density are used: concrete M300-350, class B25, or concrete foundation blocks FBS-500, 500 millimeters wide.

How to provide an opening at the foundation construction stage

To answer this question, you first need to consider in detail the design of the foundation and the technology of its manufacture. The type of foundation shown in the photo is called a slab foundation with a monolithic recessed reinforced concrete strip. This type of foundation is best suited if openings are needed.

Optimal base for foundations with openings.

Stages of foundation construction:

- Digging a pit with excavators 2.5–3 m deep;

- Tamping the bottom of the pit using special equipment;

- Creation of trenches with a depth of at least 40 cm along the inner perimeter of the pit;

- Reinforcement of trenches along the entire perimeter;

- Filling the central part with a 10 cm layer of crushed stone with a fraction of 40-70 mm;

- Pouring the bottom slab of the foundation and perimeter trenches with concrete;

- Installation of vertical formwork panels and extension of vertical reinforcement grids;

- Filling along the entire perimeter of the monolithic recessed tape;

- Installation of basement floor slabs or monolithic slabs.

Construction of foundations for openings.

The standard opening in a monolithic strip for a garage door is 240 cm, while the height of the opening is not set to the entire height of the basement floor, but is approximately 220-230 cm. The height of the basement floor itself is usually 260-280 cm. Based on this, in the upper part of the opening, a monolithic lintel is made, with sides 40x40 cm or 40x35 cm. This connecting lintel is very important, as it will distribute the vertical load received from the load-bearing walls of the first floor located above.

A connecting lintel for distributing the load from the wall to the foundation with the opening.

When constructing this type of foundation, concrete grade M400 and higher is used and, of course, great importance is given to the reinforcement of both the slab itself and the buried vertical strip. Moreover, if reinforced concrete slabs are used to cover the basement, then they will be installed along the opening left for the garage door.

Diamond drilling of foundations without deformation.

6. Deformations in concrete are the main drawback of ancient technologies for making holes in concrete structures, be they walls, floors, slabs, or foundations. As a rule, work was carried out with a hammer drill, a crowbar and a sledgehammer, and the elements of the reinforcing layer were cut with a grinder. As a result, deformations inevitably occurred in the load-bearing concrete structures of the structure, which required large financial and labor costs to eliminate. What happens when working with diamond technology? Using a Hilti DD-350 diamond drilling rig, a hole with a diameter of 240 millimeters in an FBS-500 concrete block is made in 25 minutes. The edges are absolutely smooth, polished and do not require any processing. There are no deformations in the internal structure of the foundation, the waterproofing is not damaged, the noise level is minimal (95 dB), and there is no dust.

Materials and technologies

Waterproofing of formwork openings and utility passages is carried out using polymer-based compounds. Two-component solutions are mixed immediately before use and injected into the concrete base using a pump and hose with an injector. The hydrophobic screen created inside the working surface can withstand water flow pressure of up to 2 bar.

Polyurethane resins

Innovative solutions consisting of an activator and a hardener isolate gaps as small as 0.1 mm from moisture. Polyurethane foam is used as a primer when injecting resin. The demand for material for waterproofing holes from formwork studs, passages for cables and other types of communications is explained by a number of characteristics:

- waterproof at water pressure of 0.2 MPa and above;

- resistance to mechanical stress, chemical aggression;

- high adhesion, incl. to wet surfaces;

- the elasticity of the formed protective membrane;

- frost resistance.

The economical consumption of sealing material is facilitated by a 20-fold increase in polyurethane resins upon contact with liquid.

Acrylate gels

Waterproofing of communication passages and formwork openings is carried out using compositions based on acrylates and methacrylates. The distinctive characteristics of this type of sealant include:

- the ability to adjust the start of the polymerization process;

- high adhesion regardless of surface dryness and type of building material;

- maintaining elasticity at sub-zero temperatures;

- low viscosity;

- stimulating the growth of concrete crystals to restore its original properties.

Acrylate gels create a hydrophobic screen not only inside the building structure, but also behind the lining space, strengthening the soil and foundation of the structure.

Mounting holes of any type are cleaned of concrete and previously used sealants before injection. If necessary, the gaps are filled with an elastic profile, and an external and internal seal is created using a waterproofing compound. Holes are drilled around the communication at an angle of 25° to introduce injecting compounds and control for leakage after the solutions have hardened. The service life of the created waterproof screen is 100 years.

Our foundation drilling tool.

| Drilling material | Reinforced concrete |

| Drilling hole diameters | Wet drilling with mounting: 52-500 mm |

| Maximum drilling horizon | 500 mm and *above |

| Drilling speed ranges | 10 |

| Installation weight | 35 kilograms |

| Dry or wet mode | Wet |

| Fastening the frame | Anchor or optional: vacuum |

| Mounting height | 1086 millimeters |

| Installation dimensions (LxWxH) | 608 x 192 x 216 mm |

| Drilling holes at an angle | Maybe |

| Hole drilling inclination angle | up to 45° |

| Support pipe dimensions (LxW) | 419 x 272 mm |

| Spacer | Yes (optional) |

| Availability of water collection system | Yes |

| Power tool protection class | Class I |

| Diamond cutter size (without insert) | 300 mm |

7. Table 1: characteristics of the Hilti DD-350 diamond drilling rig. We use a Hilti DD-350 diamond drilling rig. Hilti diamond tools - for professionals this says a lot. Hilti is a leading global leader in the production and service of professional diamond tools. The cost of a 350 series drilling rig is 25 thousand euros, a 150 mm original diamond bit for reinforced concrete is 400 euros. But the tool is worth the money - it can easily drill through horizons of reinforced concrete foundations up to 1000 millimeters; if it is necessary to work at greater depths of concrete, diamond cutters are made to order. The main characteristics of the Hilti DD-350 diamond drilling rig are shown in Table 1.

Diamond drilling for ventilation, chimneys and air conditioning systems

If you need to drill, for example, a hole with a diameter of 125 mm for a kitchen hood in a brick wall 40 cm thick, you can, of course, do this with a hammer drill with an appropriate crown. This procedure will take an hour and a half, will create a lot of dust, and all the neighbors from the first to the last floors will be very unhappy with the noise created. The resulting hole will not be very smooth, and cement or brick dust will require lengthy and thorough cleaning.

In the case of diamond drilling of the same hole, it will take 15 minutes, only the closest neighbors will be able to hear a little noise, and there will be no dust at all. The hole will be neat and even. There are wet cutting technologies, which allow you to completely get rid of dust, and dry cutting, using a vacuum cleaner.

Diamond cutting of concrete.

8. Photo 7: Husqvarna K-760. Diamond cutting of concrete is essentially a related technology for diamond drilling and drilling holes in reinforced concrete. Often, performing a particular task of drilling or cutting concrete involves the use of related tools. Scope of application of diamond cutting of concrete: production and expansion of doorways in monolithic walls and ceilings, cutting of reinforced concrete structures into segments, dismantling work on concrete, correction of defects when pouring formwork, and so on. For diamond cutting we use tools from Husqvarna. The Husqvarna K-760 Cut-n-Break diamond cutter with a diamond blade diameter of 240 millimeters allows you to solve a wide range of tasks for cutting reinforced concrete structures. This diamond tool has the highest effective cutting depth: 410 millimeters of reinforced concrete.

Cost of gating

The cost of wall gating is calculated individually for each project. Find out the cost of gating walls for pipes and prices for gating walls for electrical wiring from our managers by phone: +7(495)991-81-26 .

Our managers will quickly and accurately calculate your order, based on your task and needs.

ο Price list for gating walls and ceilings (28.41kb)

CASHBACK up to 10%!, for wall and floor gating until the end of the week , call!

Price list for gating walls for pipes and wiring, price per 1 linear meter. without VAT

| Name of works | Brick | Concrete | Reinforced concrete |

| Grooving walls for electrical wiring 2x2 cm. | 250.00 | 300.00 | 350.00 |

| Grooving walls for a 5x5 cm plumbing pipe. | 700.00 | 1000.00 | 1500.00 |

| Grooving walls for a 10×10 cm plumbing pipe. | 1000.00 | 1500.00 | 1800.00 |

| Grooving a socket (socket box, switch, etc.) for 1 pc. | 250.00 | 300.00 | 350.00 |

- Prices, rates, and cost of gating walls for wiring may vary.

- The cost of gating walls, floors and ceilings depends on the volume of electrical installation work at the site.

- To clarify the cost of work on gating walls for wiring, please call: +7(495)991-81-26.

- The cost of the minimum order/departure is 6,000 rubles.

- The cost of gating in concrete, brick, reinforced concrete/monolith, walls and ceilings is CASHBACK up to 10%. Call!

Grilling of foam blocks and other “soft” materials price per 1 linear meter. without VAT

| Name of works | Price per linear meter |

| Grilling plaster walls | 200.00 |

| Grooving foam blocks for corrugated hoses | 200.00 |

| Passage/hole through foam block, brick, plasterboard | 250.00 |

| Passage/hole through concrete, reinforced concrete | 600.00 |

| Laying the wire in the groove | 100.00 |

| Groove putty (without material) | 100.00 |

| Grilling in other materials (wood, stone) | Negotiable |

- Prices, rates, and cost of gating walls for wiring may vary.

- This depends on the scope of electrical work at the site.

- To clarify the cost of work on gating walls for wiring, you may be interested in how much it costs to gib walls or gating screeds, call: +7(495)991-81-26.

- The cost of gating in concrete is indicated in Russian rubles. per 1 linear meter (l.m.)

- The cost of gating walls for pipes, a specialist will visit Moscow and the Moscow region within 24 hours, EXACTLY!

Photo: Grooving concrete and foam block walls for wiring in a dust-free apartment.

Photo: grooves for an air conditioner in a concrete wall in an apartment without dust and much noise.

Diamond drilling of foundation, video

9. Video 2: a strip foundation is being drilled, a country house 4 kilometers from Mytishchi, Moscow region. Foundation parameters: depth 1.6 meters, thickness of the monolithic concrete strip 490 millimeters, concrete class M250, grade B20, density 2400 kilograms per square meter. 4 vents were made, the diameter of one hole was 140 millimeters, the work was carried out with a Hilti DD-200 diamond concrete drilling rig. Work time is 2 hours 30 minutes. The vents were drilled at a distance of 350 millimeters from ground level, the waterproofing of the basement was not damaged, the edges of the hole were smooth, and there were no deformations. The cost of one hole is 1200 rubles.

Diamond drilling prices

Hole diameter∅ in mm | Non-reinforced concrete (FRC)Cost 1 cm. | Reinforced concreteCost 1 cm. | BrickCost 1 cm. |

| up to 42 | Negotiable | Negotiable | Negotiable |

| 52 | 28 rub. / 1 cm. | 30 rub. / 1 cm. | 19 rub. / 1 cm. |

| 62 | 28 rub. / 1 cm. | 30 rub. / 1 cm. | 19 rub. / 1 cm. |

| 72 | 29 rub. / 1 cm. | 31 rub. / 1 cm. | 20 rub. / 1 cm. |

| 82 | 29 rub. / 1 cm. | 31 rub. / 1 cm. | 20 rub. / 1 cm. |

| 92 | 30 rub. / 1 cm. | 32 rub. / 1 cm. | 21 rub. / 1 cm. |

| 102 | 30 rub. / 1 cm. | 32 rub. / 1 cm. | 23 rub. / 1 cm. |

| 112 | 31 rub. / 1 cm. | 35 rub. / 1 cm. | 24 rub. / 1 cm. |

| 122 | 36 rub. / 1 cm. | 40 rub. / 1 cm. | 27 rub. / 1 cm. |

| 132 | 38 rub. / 1 cm. | 42 rub. / 1 cm. | 28 rub. / 1 cm. |

| 142 | 38 rub. / 1 cm. | 42 rub. / 1 cm. | 28 rub. / 1 cm. |

| 152 | 38 rub. / 1 cm. | 42 rub. / 1 cm. | 28 rub. / 1 cm. |

| 162 | 43 rub. / 1 cm. | 47 rub. / 1 cm. | 31 rub. / 1 cm. |

| 172 | 45 rub. / 1 cm. | 49 rub. / 1 cm. | 33 rub. / 1 cm. |

| 182 | 50 rub. / 1 cm. | 54 rub. / 1 cm. | 37 rub. / 1 cm. |

| 202 | 55 rub. / 1 cm. | 59 rub. / 1 cm. | 40 rub. / 1 cm. |

| 227 | 60 rub. / 1 cm. | 68 rub. / 1 cm. | 48 rub. / 1 cm. |

| 252 | 68 rub. / 1 cm. | 76 rub. / 1 cm. | 54 rub. / 1 cm. |

| 302 | 84 rub. / 1 cm. | 92 rub. / 1 cm. | 65 rub. / 1 cm. |

| 352 | 104 rub. / 1 cm. | 112 rub. / 1 cm. | 81 rub. / 1 cm. |

| 402 | 124 rub. / 1 cm. | 132 rub. / 1 cm. | 95 rub. / 1 cm. |

| 452 | 140 rub. / 1 cm. | 148 rub. / 1 cm. | 106 rub. / 1 cm. |

| 502 | 167 rub. / 1 cm. | 175 rub. / 1 cm. | 125 rub. / 1 cm. |

| 602 | 207 rub. / 1 cm. | 215 rub. / 1 cm. | 153 rub. / 1 cm. |

The final price specified by the manager when calculating the cost takes precedence over these prices.

Increasing coefficients under the following conditions:

Additional terms | Coefficient |

| Dust-free work (water collection ring and vacuum cleaner) | 1.2 |

| Work in hard-to-reach places | 1.2 |

| Work at a height of more than 3 m | 1.2 |

| No access to water | 1.2 |

| Night work | 1.2 |

Diamond drilling of foundations, photo gallery of works.

Photo 1,2: drilling a concrete foundation with a diamond tool in the vicinity of the city of Podolsk, Moscow region, 2 objects in the suburbs, country houses. Hole diameter 121 millimeters, work with a Hilti Equidist S-shape diamond bit for concrete.

Photo 3,4: drilling a hole for ventilation in a concrete foundation. The diameter of the vent is 140 millimeters, the thickness of the concrete is 500 millimeters. Neighborhood of Odintsovo, 8 kilometers to the Moscow Ring Road.

Photo 5,6: holes in the foundation for introducing heat supply pipes into the individual heating point of the cottage.

Photos 7, 8: a concrete foundation is being drilled, the hole diameter is 125 millimeters. 2012, Volokolamsk, Moscow region.

Photo 9: drilling at an angle for laying a cable power supply line. Photo 10: a high-quality hole in the concrete foundation for ventilation of the basement of the house.

Photo 11: vent in the basement, diameter 161 millimeters, Khimki city, Moscow region. Photo 12: drilling the concrete base of the road overpass.

Photos 13, 14: drilling the concrete foundation of a house for the entry of a sewer pipeline.

Photos 15, 16: drilled hole in the basement for a ventilation duct, view from the inside. Diameter 180 millimeters

Photos 17, 18: making technological recesses in the foundation using diamond drilling of concrete.

Photos 19, 20: holes in the concrete foundation for the power supply line of a country house, 2014, outskirts of the city of Dmitrov, Moscow region.

Advantages of using injection waterproofing

PVC pipes are filled with cement for sealing purposes. However, the adhesion rates of polyvinyl chloride and the solution are very low. This facilitates rapid washout of the sand-cement filler from the formwork holes under water pressure. Compositions for injection waterproofing are resistant to suffusion and are characterized by strong adhesion to wet and dry surfaces.

The cylindrical tubes remaining after removing the formwork are removed and filled with hydrophilic cushioning rubber or polyethylene foam to protect against leaks. After this, the holes are caulked with a non-shrink solution. The disadvantage of this waterproofing method is the difficulty of removing the tubes and uniformly distributing the material throughout the entire thickness of the wall, and its washability under high water pressure.

Polyurethane resins and acrylate gels are characterized by high adhesion to concrete, reinforced concrete, polystyrene, brick and other building materials. Injection is carried out without removing PVC pipes. The low viscosity of the solutions used for waterproofing formwork holes allows them to penetrate into the depths of the structure and strengthen the working surface from the inside.

The plugs used by GKNR act on the principle of a plug, swelling upon contact with water and filling the mounting hole. Rubber products with polymer components are suitable for sealing pipes with a diameter of 22 mm only. If the diameter of the formwork entry points is large, hydrophobic gaskets and cement putties are used simultaneously with plugs. When installing bushings consisting of tie bolts and EPDM rubber, holes are drilled in the walls to a depth of up to 50% of the thickness. This type of sealing is quite labor-intensive.

Injection waterproofing compositions are used to fill joints between floor slabs, technological seams of any size, thread-like cracks and PVC pipes without restrictions on indicators d. The depth of holes in concrete for injection of gels and resins is small due to viscosity comparable to the fluidity of water. There are no restrictions for the use of penetrating waterproofing in

- places where cable channels pass,

- air ducts

- communication pipes.

Liquid rubber and other mastics fill the formwork entry points without deep penetration into the pores of reinforced concrete and concrete structures. Injection sealants create a strong bond to the building material. The created hydrophobic membrane becomes part of the seams and other surfaces of the monolithic structure.