Wooden poles for canopy

This is the simplest and most affordable type of canopy supports, which you can install yourself even without special skills. Any wood will do, but it is durable and hard; it is optimal to give preference to deciduous trees.

The post can be solid wood, buried at the base in the ground, or combined - when the base of the post is stone, and only the top is wooden. In the first case, it is especially important that the material is well saturated with antiseptics that prevent rotting.

The installation of wooden poles for a canopy is suitable for a structure made of polycarbonate or boards.

Canopy poles made of profiled pipe

Metal is a strong and durable material that can serve as a support for maintaining a canopy for many decades. Metal poles for a canopy are the most reliable and strong supports that are not that expensive.

Ordinary metal pipes of different diameters are usually used as racks; before digging into the ground, their lower part must be coated with anti-corrosion enamel, which extends the service life of the support, and polymer for waterproofing.

Canopy posts made from profile pipes are used in many cases:

- To obtain a reliable and strong frame for canopies made of polycarbonate, boards, metal profiles;

- For wet and water-saturated soils;

- For installation of a base for trusses;

- For installing a frame “forever”.

Metal poles (pipes) are more expensive than wooden ones, but they last much longer without the need for repairs, and are also more aesthetically pleasing and can withstand an unlimited number of colors.

Types of canopy support posts

There are several types of support posts:

- Wooden canopy poles are strong and durable. Installing them is quite simple; no additional devices are required, such as a welding machine for working with metal; No bricklaying experience is required, as in the case of brick supports. The only thing that must be done is to treat the timber racks with an antiseptic against fungus and mold, and with fire-retardant impregnation. Summer residents choose a wooden frame for sheds when the new structure should be in harmony with a residential building and other buildings.

- When constructing large objects - a residential building, for example, concrete pillars are used. They are durable and will last a long time. But when installing them, you need to use technology, so they are used for awnings only within the city.

- Brick supports look beautiful. Such racks will last a long time, but building them is a labor-intensive task and requires construction skills. It is difficult for an amateur summer resident to lay out perfect brickwork. It will look more bulky than wooden and metal structures.

- Metal poles for a canopy are the most reliable type of support. The material is publicly available - it can be round or profile pipes with a square cross-section. You also need to treat it with an anti-corrosion compound, especially the buried part of the support. The easiest way to paint is with primer and then paint.

- Combined prefabricated supports. Small column-sleeves with embedded parts on which the supports are attached are made from a cement-sand mixture with the addition of crushed stone. Before concreting them, it is necessary to bury the formwork in the holes. Metal poles are attached to them.

Brick supports

Brick posts look beautiful and solid, but they are the most expensive type of support and labor-intensive to install. Brick supports look good against the background of a facade or fence made of the same material under any canopy. Polycarbonate plays interestingly on the brick, allowing the sun's rays to pass through.

Red, white and silicate bricks are suitable for construction; the choice should be made based on the decorative features of the site.

This group also includes supports made of decorative stone.

How to build a columnar foundation from asbestos pipes with your own hands

The longest and most expensive stage of construction is considered to be the installation of the foundation. This process is especially difficult and expensive on difficult soil, where any structure needs especially reliable support. This stage can be simplified and made cheaper by installing supports made of asbestos pipes. When used correctly, this inexpensive material can, saving the time and effort of the builder, withstand groundwater, precipitation and soil movement, preserving the geometry of the house or outbuilding.

Calculation of pillars

Before purchasing material and starting work, it is necessary to calculate the number of supports and their depth, and select the type of device for the underground part of the rack.

Calculation of the number of supports for a canopy

When determining the number of supports, you need to calculate the load on 1 pillar and correlate it with the permissible pitch of the pillars. On average, one metal pipe with a diameter of 80...100 mm can withstand a load of up to 250 kg. It includes:

- Weight of the roofing section (canopy);

- Self-weight of the pipe;

- Snow mass.

Usually a canopy is equipped for 1 car or a small area. Using the example of a 6x3 meter perimeter, you will need 8 supports:

- 4 in the corners;

- 2 on each side between the corner posts.

The average distance between supports is 2.0 meters, but more can be taken – 2.5 meters.

The same goes for stone racks. In this matter, it is also important to take into account the flexibility of the roofing so that it does not sag under the weight of snow. More than 2-2.5 meters between supports should not be taken without an additional roof beam.

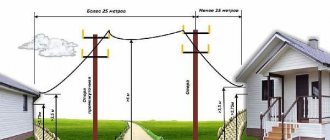

Support depth

Installation of poles for a canopy is carried out in the ground. In order for the stand to stand level, it is necessary to take the correct depth for burying its base and the method of immersion and fixation in the ground. The post can be inserted into the ground in the following ways:

- 1) Driving in is suitable for metal supports under small canopies with light covering materials. Driving in is possible only on dense soils; in no case should you resort to this method on loams and heaving soils;

- 2) Concreting can increase the bearing capacity of a pillar on any soil. Metal poles are subjected to concreting, less often wood;

- 3) Butting. Essentially, this is digging a post, but using materials that compact the soil - crushed stone, gravel.

What is special about a foundation made of asbestos pipes?

A columnar or pile-type foundation is built from asbestos-cement pipes, making kind of legs for the future structure - pillars, or piles, going deep into the soil.

A feature of such a foundation is the installation of piles under key points of the structure: corners, areas where walls intersect.

A distinctive feature of a piled asbestos-cement foundation is the filling of hollow asbestos pipes with cement mortar with additional reinforcement. As a result, the support pillars are strong and resistant to soil pressure and capable of supporting the weight of the erected structure.

This structure of the supporting structure is relevant in cases where it is impossible or impractical to construct a slab or strip type foundation:

- When constructing outbuildings, country houses and frame houses that do not have a cellar or bathhouse. Lightweight buildings for various purposes do not need to be equipped with a support strip around the perimeter; moreover, it is inappropriate to pour a monolithic slab under them.

- On difficult ground or in cold regions where excavation work requires significant costs. On unstable soil prone to crumbling, digging a trench and installing a foundation is impossible without formwork equipment. In cold regions, where the ground does not thaw even in summer, as well as on rocky soil, the risk of collapse is lower, but the work itself is much more difficult.

- When the groundwater level is high or when the building is located near bodies of water prone to spills. In wet soil, strip and monolithic foundations will be in constant contact with water, gradually collapsing and subsiding into cavities washed out by underground flows.

How to install poles for a canopy

Canopy supports can be installed in a variety of ways. The choice depends on the material of the pillar, the type of soil and the expected load on the coating.

Installation of wooden poles

How to install wooden poles for a canopy:

- Bury the pillar. To do this, dig a hole, fill the bottom with a cushion of a mixture of sand and crushed stone. A prepared wooden stand, carefully treated to prevent rotting, is also lowered there. After this, the soil is backfilled and compacted. This method is suitable for organizing a temporary or light canopy.

- Attach the post to the existing columnar foundation. This is a gentle way to use wood studs. Plates are laid in advance into ready-made columnar foundations, to which wooden supports are subsequently attached.

Installation of metal poles

Pipe racks are made more often than others, which is why more installation methods have been invented for this material.

Clogging

You can drive metal poles into dense soils. This is a great way to save on installation work and get a reliable frame.

A pipe is installed in the marked place, a cap (a thick layer of cardboard) is put on and driving begins until dense soil is reached. Since there is no cushion of sand and crushed stone with this method, it is worth focusing on solid supporting layers. Excess length at the top can be trimmed. At the same time, the depth of the pillars for the canopy should not be less than 1.5 meters or ½ from the top of the pillar.

Butting poles for a canopy

This is a method similar to instillation. In the marked place, a hole is prepared with a depth below the freezing level of 0.3 meters. A sand-gravel mixture is poured onto the bottom and a post is installed. Next, the pit is filled layer by layer with a sand-gravel mixture, constantly adding water to compact it.

When there are 15-20 cm left to the top of the hole, concrete mortar is poured, which serves as reinforcement for support.

- High efficiency with low financial and labor costs;

- Fast installation speed.

- The disadvantage is the small load-bearing capacity of the pillars.

Concreting pillars for a canopy

To get a reliable and universal support, take metal pipes and bury them in the ground, using concreting at the base of the pillar. The method is suitable for use on moving and heaving soils, where it is difficult to reach dense layers and it is necessary to protect the stand from being pushed out when heaving water-saturated soil.

How to concrete pillars for a canopy:

- 1) Dig a hole to the calculated depth;

- 2) The bottom is covered with crushed stone-sand mixture and compacted;

- 3) A metal frame is installed to strengthen the “glass”;

- 4) Install the formwork;

- 5) Insert the pipe and fix it to the frame with metal fittings;

- 6) Concrete is poured.

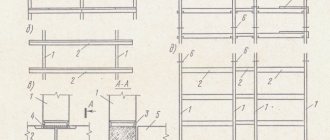

Installation of pillars

You cannot ignore the installation of brick pillars, which are also sometimes used to support awnings. To install such a support, a foundation is needed. More often it is a columnar structure.

- 1) Dig a hole measuring at least 50x50 centimeters;

- 2) A cushion of sand and crushed stone is placed at the bottom to compensate for loads from the soil;

- 3) Lay a thin layer of cement or masonry mortar to level the site. You can skip this step if you level the area well;

- 4) Now start laying the columns. To support a canopy, laying 1-1.5 bricks is enough.

When the underground part is ready, the side walls of the base are covered with roofing felt or coated with bitumen, then they are buried and the masonry is brought from above to the design mark.

When the racks are ready, installation work begins on installing the canopy ceiling.

The service life of the erected structures depends on the correct choice of materials for installing canopy posts.

Can be used as supports

- Asbestos cement pipes. This option, due to its fragility, cannot be called optimal.

- Monolithic concrete. Such support is energy-consuming and labor-intensive. In addition to the need to construct additional formwork, the solution will need time to acquire the necessary strength.

- Brick or stone masonry. Prestigious appearance, resistance to high loads, durability - all these advantages are offset by high labor intensity and financial costs, which is why such racks are rarely used for canopies.

- Wood. Beam support is only suitable for lightweight canopies, for example those made of polycarbonate sheets. And although installing wood support posts is not particularly difficult, any lumber requires regular biosecurity measures.

- Metal. Of all the options listed, this is the most acceptable from any point of view. As a rule, we are talking about metal pipes.

Advantages of asbestos pipes

The choice of materials for building a fence today is extremely large. Asbestos pipes are used as fence holders due to a number of advantages:

- Moisture resistance;

- Resistance to pests;

- Long service life;

- Copes with increased loads.

- No need for processing;

- Affordable price;

- The products have different diameters, which allows you to choose the best holder option for any fence.

Standard installation technology

The strength of the entire structure directly depends on how correctly the support posts are secured. Typically, builders have to choose from the following options:

- Driving in. Relevant only for particularly dense soils. Its variation should be considered the installation of screw piles.

- Concreting. This is the most reliable way to install strong supports for your canopy. This technology does not require the use of any complex equipment, because mixing the solution and other work can be done with your own hands.

- Fixation using reinforcing bars. The technology is used in areas that were previously subjected to concreting or asphalting, and whose opening is extremely undesirable. First, pins are driven into the ground to a depth of 90 cm, to which metal poles for the canopy are attached by welding.

Metal supports and their concreting

The technology for installing poles for a canopy outlined below allows you to complete it within 24 hours.

To achieve this, the following activities are carried out:

- Preliminary site clearance.

- Marking the location of future supports: driving in auxiliary stakes in the corners, pulling a rope (thread) between the corners, driving in intermediate equidistant pegs along the string in increments of up to one and a half meters.

- In marked places, holes of calculated depth are dug and filled with a mixture of sand and crushed stone. During the filling process, the mixture is compacted with a tamper.

- The finished metal supports are installed one by one in the holes and filled with a concrete raster. At the same time, they strictly monitor the adjustment of the verticality of the racks using a plumb line or a building level.

Within 7 days after concreting metal piles, they must be ensured complete rest - do not pump or test for strength.

Aligning the rack

The more vertical the supports are, the more stable your structure will be. The most accurate instrument here is a plumb line, which will accurately determine the degree of vertical position of the racks.

During the process of concreting the foundation, the columns are leveled using supports (metal or wood), which are dismantled after the solution has hardened. Correction is possible only during the first hours of concreting.

To level the pillars in height, experts recommend marking in advance the level of immersion in the ground in their lower part. Such marks will become a reliable guide in further installation work.

source

Brick pillars

Brick or stone supports for a canopy involve the parallel construction of a solid concrete foundation. The algorithm of this technology consists of the following steps:

- Marking the location of the supporting elements for the canopy.

- Digging square holes with a depth of up to 60 cm and a cross-sectional area that exceeds the same parameters of a brick support.

- Covering the bottom of each hole with a sand cushion and gradually compacting it layer by layer.

- Installation of formwork and laying waterproofing.

- Installation of reinforcement frame and concrete pouring.

- Stopping all construction activities for a while - the pause will allow the solution to harden.

- Dismantling the formwork and treating it with a waterproofing compound.

- Backfilling and direct laying of columns. If the support posts are finished with facing bricks, they will acquire a special gloss, and such masonry can be strengthened with reinforcing wire mesh, which is recommended to be laid at least every other row.

Sheds on the site have long been part of our lives and the scope of their application is quite extensive. Carports, canopies over barbecues, canopies for sun protection and a dozen more items. All these buildings have a protective function for equipment, people, and garden tools. It’s easy and quick to build a canopy, but how to guarantee the strength and stability of the structure? The key to this type of building is properly installed support pillars.

Materials for the construction of supports

You can build a canopy from any materials, but supports for construction are made mainly from the following:

- Wooden beam. Very easy to install material. If you subject the wood to pre-treatment, which will protect the wood from rotting and damage by insects, then the canopy on wooden supports will last quite a long time. In addition, wooden supports can be decorated with hand-made carvings. When choosing wooden supports for a canopy, they are usually guided by the fact that the canopy should be in harmony with the general appearance of the outbuildings. Houses made of wooden beams and a canopy made of wood will form a harmonious duet. You can fasten wooden elements with ordinary self-tapping screws.

- Metal supports. The most versatile type. A metal frame can be used in combination with any roofing material and it will look quite appropriate. The metal undergoes preliminary anti-corrosion treatment, then painting, and then your canopy will acquire an aesthetic appearance. The metal must be fastened using a welding inverter.

- Brick pillars. They can be built using a metal profile, lined with facing bricks.

- Concrete supports. They also have a right to exist, but using them as supports for the construction of a light canopy is not a very rational solution.

- The supports can be made of decorative stone. It is very beautiful, and in combination with a fence or the base of a house, decorated with decorative stone, it looks simply gorgeous.

Number of supports and calculation of their strength

Each building must withstand a certain load; in order to build a canopy with your own hands, you need to calculate the number of supports. In total, the supports must withstand the weight of the frame, roofing material and the weight of the snow mass that can form on the canopy roof in winter.

In order for the canopy to withstand such loads, it is necessary to correctly calculate the number of supports. Also, their number will directly depend on the size of the canopy.

If we take a carport for one car as an example, the number of racks will be eight, which means it is necessary to build two rows of four racks each.

The minimum thickness of support pillars is from 80 mm, height from 2.5 to 3 meters. It is necessary to purchase profile pipes 3-3.5 m, taking into account the depth of the foundation.

Step-by-step construction instructions

The construction of a pile asbestos-cement foundation is carried out in several stages:

- Carrying out calculations.

- Preparation of the construction site, building materials and tools.

- Well preparation.

- Installation of pipes.

- Preparation of cement mortar.

- Preparing the pile base.

- Backfilling of wells.

- Reinforcement of supports.

- Pouring pipes.

Carrying out calculations

This stage cannot be skipped; errors in foundation calculations can be costly for the owner of the building.

- Depth of wells for piles. The supports must extend to stable ground and end below the freezing depth of the soil.

- Length of pipes. Usually it is 10 cm greater than the depth of the wells, but in areas prone to flooding, the difference is increased by another 20 cm or by the height of flooding, if known.

- Number of supports. Piles are installed in the corners of the building, under the intersections of walls and under areas of increased load (heat-generating devices, plumbing equipment). In addition to anchor piles, additional ones are installed in 1-meter increments.

- Pipe diameter. First, calculate the total weight of the future building, according to tables from SNiP, then divide the resulting figure by the number of supports. If the obtained value is within 800 kg per pile, then pipes with a diameter of 100 mm should be used; if larger, pipes with a diameter of 200-250 mm should be used. Calculating the total weight is only necessary for large buildings and residential buildings. For small architectural forms and commercial buildings, this step can be skipped, choosing to use 100 mm pipes.

- Well diameter. This value is 10-20 cm larger than the calculated pipe diameter.

- Concrete consumption. To obtain this value, you need to calculate the total internal volume of the pipes. It is obtained by the formula for the volume of a cylinder: V=0.785*D2*n*(L+0.2), where V is the volume of the pipe, D is its diameter and L is the length, A n is the total number of pipes. The resulting value is rounded up - this will be the concrete consumption.

Installation of metal and wooden supports

Installing the supports yourself will take you one day. In the prepared area, the places where the support posts will be installed are marked with pegs. Next, dig a hole 50 cm deep with a shovel or using a drill. The bottom of the hole is compacted and covered with fine crushed stone or sand.

If you have chosen metal pillars as racks, then metal bearings are welded to them for stability. The pillars are immersed in the pits and their position is checked by level, which must be strictly vertical. You can use supports to keep the posts upright. Next, the pillars need to be concreted.

Advice: so that all the pillars are immersed in the ground to the same depth, before starting work, you can make marks on the metal profile itself at a level of 50 cm. Metal supports are installed at this depth.

Wooden supports can be installed with your own hands in another way. You will need to lay a columnar foundation made of blocks or monolithic pillars, which subsequently needs to be concreted. Typically, the depth of laying such a foundation is about 50 cm. Fastening is done using metal plates or anchor bolts. The advantage of this method is the prevention of rotting of wooden poles. But, despite all precautions, wooden supports have to be replaced after 10-15 years.

If metal supports need to be treated with an anti-corrosion compound, then wood also needs pre-treatment. This will extend the life of wooden poles, and painting will add to their attractiveness.

Features of installing canopies and awnings on an asphalt surface

- Sometimes it is necessary, even in a summer cottage, to install support posts on a concrete or asphalt surface. In this case, we also weld the pennies onto a profile or round pipe, drive the reinforcement pins into the asphalt (to a depth of 20-40 cm), and finally, weld the bearing bearings of the supports to the pins.

- Attached-type canopies - adjacent to the building on one side - differ in the number of supports, their location, and installation method. As a rule, the vertical posts of such canopies are strengthened on embedded parts that are pre-concrete.

- If the canopy is planned to be lightweight, portable, with aluminum support tubes, then when installing the canopy it will be enough to stick the tubes into the ground.

The process of installing support structures, as you can see, is simple and does not require special skills. All you need is desire, patience and the appropriate tools - and you can install the supports for the canopy yourself. As for the roof for the canopy, you can choose from the materials suggested below:

- polycarbonate (the lightest material);

- tiles;

- slate;

- corrugated sheeting;

- roofing felt;

- polycarbonate

In addition to basic construction tools, you will need a welding machine. It is advisable to invite an assistant, since it is more convenient for two people to fix the support posts in a vertical position.

A canopy in a country or suburban area will protect part of the site from precipitation and sunlight. It can be installed for temporary parking of a car, tools can be placed under it, there are dozens more options for using a canopy made of polycarbonate or wood.

In order for it to serve for a long time, it must be installed on strong and reliable supports. Accurate calculations and adherence to installation technology guarantee that the canopy can easily withstand any vagaries of nature. How to properly set up poles for a canopy?

Installation of brick supports

The brick pillars look solid, it seems that even such a simple structure as a canopy was created to last. But installing such supports with your own hands requires painstaking work.

The progress of work on installing brick pillars is as follows:

- In the cleared area, the boundaries of the planned structure are marked. In those places that are marked with pegs, holes are dug. Their depth should be 50 cm.

- Sand is placed at the bottom of the pit, moistened with water, compacted, reinforcement is laid, and wooden formwork is installed.

- After carrying out the necessary work, the pits can be concreted. After it has hardened, the formwork can be disassembled, waterproofing can be laid on top and you can start laying bricks with your own hands.

- The masonry is made of facing bricks, which are laid using a mortar of cement and sand.

Brickwork will be stronger if the joints are not stacked on top of each other. For a perfectly straight line of pillars, two ropes are pulled, indicating the boundaries of the pillars.

You can choose the roofing of the canopy from those materials that are more attractive to you or are suitable for the price. There is no shortage of materials to choose from, so it’s up to you to choose what your canopy will be like. You may want wooden poles to be decorated with metal tiles or corrugated sheets, metal racks - polycarbonate, slate, plexiglass or PVC plastic. There are many options, and there are plenty of ways to build a shed to suit your needs.

We looked at several ways to install canopy poles with your own hands. These are generally accepted rules that will help you build a strong and durable structure.