A garage is a separate room intended for parking and storing a car, which most car owners want to acquire. Before you learn how to make a foundation for a garage with your own hands, let’s define the main purposes of the garage:

- ensuring the safety of the car from intruders and hooligans;

- protection from aggressive atmospheric influences - snow, rain, wind, solar ultraviolet radiation;

- closed area for maintenance and minor repairs.

In modern conditions, the opportunity to build a garage with your own hands next to your home is severely limited. More often, this is feasible on the territory adjacent to a private house or in a garage-building cooperative.

Before you start building a garage, you need to familiarize yourself with the scope of work and their sequence. It must be remembered that unskilled construction without preparation and special knowledge of technology usually leads to emergency situations and loss of material resources.

Sequence of actions when building a garage with your own hands

Where should you start building a garage?

Typically, this activity is divided into separate stages that correctly describe the order of work. The first stage is called engineering-geological survey or study of the construction site. In the process of their implementation, the following are determined:

- physical and mechanical properties of soil;

- type;

- load bearing capacity;

- freezing depth (especially important for garages on heaving soils);

- groundwater level;

- terrain slopes.

Installing a foundation on screw piles

A foundation on screw piles is the most inexpensive and least labor-intensive type of foundation for any heavy or frame structure. Piles are pipes with screw tips that are literally screwed into the ground. They have a high load-bearing capacity and will last for many decades. They are suitable for any type of soil and for any type of garage (brick, frame, wooden, etc.)

Sequence of work:

- The required area for a garage is outlined. Piles are screwed into the marked places;

- screwed exactly perpendicular to the ground;

- after the height is selected, the upper part is cut off and filled with crushed stone and gravel inside, followed by pouring concrete mixture for greater stability. Also, the remaining space in the ground between the pile and the ground needs to be filled with concrete - for better fastening;

- a garage on screw piles, can afford any type of walls and floor;

- When choosing a frame garage, you need to take into account that the piles will be connected by special metal profiles on which the frame will be attached.

Having considered all types of foundations for a garage, we can conclude: if the type of soil and the purpose of the garage allow it, then it is better to choose an easy-to-build and inexpensive type of foundation. Such as - columnar or on screw piles. The main thing is that the foundation is built competently and efficiently.

Making the project

The project includes an architectural part

Describes:

- type of structure;

- external dimensions;

- the presence of a basement or second floor;

- Plans and sections with axes and marks are drawn.

Structural section

Here are calculations of load-bearing capacity, determination of configuration, as well as the need for building materials and structures:

- foundations, their depth, type and material;

- walls, thickness, material;

- ceilings, thickness, material;

- waterproofing of structures;

- coatings, composition, material;

- roofs, type and properties.

Engineering Communication

The connection to the garage and the development of wiring diagrams are being studied:

- electricity;

- water supply;

- sewerage;

- other networks (telephone, Internet, cable TV).

Executive permitting documentation and cost estimates . It contains:

- permits and approvals for the construction of a garage;

- estimate calculation.

Reinforcement of the future foundation

Foundation diagram for a garage with reinforcement

The principle of reinforcement is the same as for any residential building that is erected on a monolithic strip foundation. Only when choosing a monolithic slab there is no need to install a large number of reinforcing steel bars, you just need to remember a number of rules:

- Install the reinforcing belt above the waterproofing layer of the sole at a height of up to 5 cm.

- The reinforcement should not protrude beyond the formwork.

- All connections should be made using wire or plastic ties; welding is not allowed.

If a concrete slab is to be formed inside, then the reinforcing belt of the slab must be securely connected to the reinforcement of the monolithic strip base itself.

Choosing a foundation for a garage

The part of the building on which the service life of the garage largely depends, that is, one of the most important, is the foundation. This design can be made in a variety of ways. He can be:

according to the composition of materials:

- brick;

- stone (rubble);

- concrete;

by type of construction:

- tape;

- slab;

- grillage;

- pile;

- columnar.

For an individual garage, if you make it yourself, a strip reinforced concrete foundation is better suited. If there is a basement, use a strip-slab basement.

Pouring strip foundation

To build a strip foundation, you will need:

- rope and stakes, tape measure;

- shovel, boards for formwork. If you want, you can buy ready-made assembled formwork. It is sold in standard sizes;

- reinforcing bars, sand, crushed stone, cement.

Sequence of work:

- First we dig a trench, 70 cm deep - 1.5 meters. If the soil is problematic, then you need to additionally dig a hole below the freezing point of the soil;

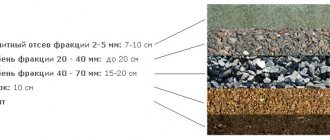

- fill with sand and crushed stone, everything is filled in successively and compacted well. You can, if desired, lay waterproofing under the soil and crushed stone;

- after, we lay the reinforcing bars: 2 from below - 2 from above;

- everything is filled with concrete mixture gradually. You need to wait at least a week for the concrete to dry.

Sequencing

Let's look at step-by-step instructions for making a foundation using the example of building a garage with common dimensions of 6 x 6 meters with a basement.

Initial data:

- soil type – loam;

- freezing depth – 1.2 m;

- groundwater is 4 meters below the surface of the earth;

- foundation – strip, concrete, 400 mm thick;

- slab base – concrete, monolithic, 100 mm thick;

- basement height – 2_5 meters;

- the ceiling between the basement is monolithic, reinforced concrete, 150 mm thick;

- covering slabs – prefabricated ribbed slabs measuring 6 x 1.5 m;

- roofing – built-up roofing felt on a fiberglass base;

- walls - silicate (white) brick, dimensions 250 x 120 x 88 mm, thickness 400 mm (2 bricks).

Layout of axes of foundations and walls

The axles are broken on site using non-stretch nylon cord and wooden or metal pegs. First, we determine the red line - usually this is the outer boundary of the garage wall with the opening for the gate. Having retreated from it, as well as from the left outer border of the garage wall by 20 cm (half the thickness of the wall), we hammer in the first peg. Using a tape measure, we measure 6 meters from it and also hammer in a second peg at a distance of 20 cm from the red line.

The axes of the left and right longitudinal walls are broken using a rope triangle. From the Pythagorean theorem it follows that in a right triangle, the sum of the dimensions of the legs raised to a square power is equal to the size of the hypotenuse, also reduced to a square power. Using knots, we form a triangle with sides of 3, 4 and 5 meters from the cord. By stretching it at the required points, we obtain a right angle between the legs. By attaching this triangle to the left and then the mirror right peg, we will set the directions for the left and right axes of the garage. Let's put 6 meters on them and hammer two more pegs at the resulting points. By tying all the pegs with a cord, we get the axes of the foundations and walls of the garage.

In building design, it is customary for the axes to be located at a distance of 20 cm from the inner surface of the external walls. Therefore, when building a two-story garage with a thickness of foundations and walls of at least 600 mm, before marking the place for installing the first peg, you will need to retreat from the red line not by 20, but by 40 cm.

Excavation

The pit is torn off within the accepted dimensions of the structure. At the same time, to prevent the collapse of the soil, its walls must be made inclined - at an angle of 70...75 angular degrees. That is, in our case, if at the bottom the pit measures 6.4 x 6.4 meters, on the surface of the earth it will already be 7 x 7 meters. The depth of the pit should be 2.5 (height of the basement) + 0.1 (thickness of the base slab) + 0.1 (height of the floor slab buried in the ground) = 2.7 meters.

Concreting foundations, base slabs and floor slabs

First, the base slab is concreted . Before starting work, the bottom of the pit must be leveled and covered with 1.5...2 cm of sand. After this, roofing material or geotextiles are laid with an overlap of 15...20 cm.

Then, from reinforcement with a diameter of d=16...18 mm, a mesh with cells 10 x 15 cm is knitted . To create a protective layer of concrete, the mesh is raised with the help of pads above the surface of the pit to a height of 2 cm. The class of concrete for making the foundation must be at least B22.5 (concrete grade M300). It is better to use factory-made concrete delivered by a mixer truck. If this is not possible, it is prepared on the construction site in a concrete mixer.

Knitting reinforcement mesh

20...25 days after the base slab, the vertical walls of the foundation are concreted using formwork, which can be inventory or homemade. Inventory formwork is made of metal, plastic or special waterproof plywood. Homemade formwork consists of panels made from unedged boards or slabs, 3...5 cm thick. The height of the foundation walls is brought to a height of 10 cm below the ground surface. For reinforcement, frames with working reinforcement with a diameter of 16...18 mm and secondary reinforcement of 6...8 mm are made directly in the formwork. The working reinforcement is installed horizontally at equal distances in the lower, middle and upper parts of the foundation and tied with clamps in the form of closed contours from secondary reinforcement, vertically placed in the formwork with a pitch of no more than 40 cm. The rigidity of the resulting frame before concreting is ensured by spacers and braces between it and formwork.

After 3...4 weeks, they begin to manufacture the floor slab . Its boundaries, which support the vertical walls of the foundation, are located within the axes of the garage at a distance of 20 cm. To prevent direct contact and improve waterproofing, roofing felt is laid in the areas of the support areas. The difference in concreting the lower and upper slabs is the installation of horizontal formwork, which is installed on temporary wooden or metal supports in the form of pillars, columns, pipes, and spatial high scaffolding. A longitudinal cut 90 cm wide is made in the central part of the slab for access to the basement and repair of the underbody of the car. At the final stage of concreting the garage foundation, a mini-basement is made of red clay brick to a height of 15...20 cm from the ground level, which rests on the outside on the vertical wall of the foundation, and on the inside on the floor slab.

When concreting, to compact the mixture and eliminate air pockets and cavities, it is imperative to use a submersible vibrating mace with a flexible shaft. The outer vertical walls of the foundation are waterproofed with roofing felt or geotextile coated with hot bitumen. The return sinuses between the pit are filled with sand in layers and compacted. Subsequently, they are protected by a blind area around the building.

Preparatory stage

At the initial stage, the location for building the foundation for the garage is selected. To determine it correctly, you need to have the following information:

- about soil type;

- about the groundwater level and the depth of soil freezing;

- about the approximate mass of the structure.

Soil type

The structural features of the soil can be determined independently. Depending on the type of soil, the dimensions of the foundation for the garage with the corresponding laying depth will be determined.

The following types of soil are distinguished:

- Skalnaya. Quite dense soil, which will allow you to build a garage directly on a leveled area.

- Clay and gravel. The foundation for the garage is laid below the freezing depth of the soil.

- Sandy. The sand does not freeze or compress under the weight of the structure, and water flows through it without delay. Therefore, the depth of the foundation is in the range of 0.4-0.7 m.

- Sandy loam. The foundation for the garage is poured at a depth of over 2 m.

- Peat. It is not recommended to build a garage on it. If, nevertheless, it was not possible to find another place for construction, then the peat layer should be completely removed and the trench should be filled with coarse sand.

Groundwater level and soil freezing depth

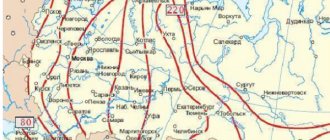

Data on the depth of soil freezing, which varies depending on the region, can be found in reference literature.

The level of groundwater is compared with the depth of soil freezing. After which a decision is made to lay the foundation. There are three options for determining the depth of the foundation for a garage:

- The depth of soil freezing is above the groundwater level. In this case, the foundation is laid at a depth that is 0.1 m higher than the soil freezing mark.

- If in winter the groundwater level is higher than the soil freezing depth by up to 2 m, then the lower part of the foundation for the garage can be created at the freezing depth level. Moreover, the soil located below 0.5 m is removed, and the space is filled with sand or gravel.

- When the groundwater level exceeds the freezing depth of two meters, it is recommended to lay the foundation at a depth of 0.4-0.5 m.

Garage weight

This criterion is also one of the important ones when determining the size of the foundation. Please note:

- the material from which the garage is constructed;

- complexity of the building configuration;

- operational characteristics of the building (height and width, wall thickness, reinforcement fixation pitch).

Naturally, if you have a garage that is too heavy, the foundation must be more reliable. In principle, different types of foundations can be used for a garage:

- pile;

- columnar;

- slab;

- tape

The most common is laying a strip foundation.

Concrete price

A cement mortar made in a factory will cost more than one prepared by hand: 1 m 3 of M400 grade concrete brought from the factory will cost 5-6 thousand rubles, and a cubic meter of a self-made mortar of the same brand will cost from 3 to 4 thousand rubles.

The difference in price is affected by the brand, the cost of additional components, the solution manufacturing technology and the region itself. When choosing a factory-made solution, it is better to immediately calculate how much is needed for the entire perimeter of the garage.

Share this article with your friends on social media. networks!

The key to a reliable and durable building is a solid foundation. Therefore, it is recommended to pay maximum attention to the choice of building materials. The grade of concrete for constructing a garage foundation must fully comply with the requirements of the architectural structure. To do this, it is recommended to study the possible types of materials in advance and feel free to go shopping.

Methods for preparing the solution

There are several methods for mixing concrete for a garage foundation. However, no matter what method it is decided to use, it is imperative to observe the proportions of the relevant materials. On average, the concrete mixture should have the formula: for 10 kilograms of cement, about 30 kilograms of sand and 45 kilograms of crushed stone are required. It is recommended to take half the total weight of the components.

Manual

When mixing the components by hand, you will need a shovel and a large tin container with sides. To begin with, the dry raw materials are mixed, forming a slide with a notch in the middle. Next, observing the proportions, water is gradually poured in and the ingredients are thoroughly mixed. The concrete must be homogeneous, without lumps or debris.

It is also recommended to monitor the consistency: the solution should not easily flow out of the shovel, but a constant shape upon contact with the tool is also a bad sign.

Mechanized

A mechanical concrete mixer will help make the process of preparing a concrete solution for the garage foundation easier. The design is quite easy to use and contains the following components:

- the basis of the structure on which the remaining parts are installed;

- tilt axis for securing the mixing container at the desired angle;

- a propeller with blades that ensures mixing of the solution components;

- small engine;

- hole for disposal of ready-mixed concrete.

When building a garage, you can use a gravity or forced construction. These units differ in their operating methods, but are generally similar in the results achieved. However, due to good transportability and small dimensions, the first one is in high demand.

Important! Depending on the concrete mixer you select, the order in which components are added and operating safety precautions will change.

Factory production

There is not always a specialist nearby who can advise something or take control of the construction. Then factory-made concrete will come to the aid of people who are not sure of the correct proportions of the components. The solution can be ordered by specifying the parameters of the future garage.

Professionals will calculate the required strength, respectively, the brand, and send it to the site in a concrete mixer. The cost is calculated in cubic meters.