About fencing slabs

Fencing slabs carry the function of an enclosing building element, which can be used in industrial and residential construction to limit a certain territory. A fence made of reinforced concrete slabs is the simplest and most reliable way to install a fence today. Thus, reinforced concrete products have increased strength, stability and durability, without which no modern construction can do. In addition, the production and installation of concrete fences is much cheaper than similar brick fences. Concrete fences are made from heavy concrete and steel reinforcement and are able to withstand significant temperature changes, and also withstand tension and compressive loads well. In addition, the properties of concrete are enhanced by additional inserts, and the reinforcement is perfectly protected from the negative effects of the environment. The most promising and popular technology for the production of concrete fences is their production from prestressing reinforcement, which is capable of deforming in the direction opposite to the working one. The fact is that when installing a concrete fence, the entire working load brings the reinforcement to its original position, in which all stresses in normal mode are reduced to a minimum. Concrete fences are installed using special lifting equipment and on soils suitable for installing fence foundations. As a rule, concrete fences consist of reinforced concrete panels made from class B20 concrete and a grade of at least F75 (compressive strength and frost resistance, respectively). Reinforced concrete fences have the following technical characteristics: weight - from 1.25 to 2.1 tons (one panel), height above the ground - from 2.2 to 2.72 meters. Reinforced concrete sections are inserted into the grooves of the foundation cups, the weight of which is about 500 kg (one cup), and there is no need to install a foundation under the entire fence area, which is typical for brick fences. To do this, so-called “glasses” are installed on the ground - special bases made in the shape of a truncated pyramid, into which support pillars are inserted. In addition to the enclosing and protective function, concrete fences can also have an informational and decorative function. Advertising is often installed on such fences. Concrete fences are transported by vehicles and can be stored under any conditions.

Kinds

Concrete fencing comes in the following types:

- Decorative, the size does not exceed eighty centimeters, and is used to decorate flower beds or roadways from animals and children.

- Blind hedges with decoration on the top or bottom, the height of which is more than 1.7 meters.

- Fencing structure for fencing children's playgrounds and front gardens.

- A solid blind fence with a height of more than 200 cm is used for fencing industrial structures.

- Concrete fences for vegetable gardens and gardens, the height of which reaches two meters.

Return to contents

Freestanding

Fences can be free-standing or on fixed posts.

A free-standing fence has strong stability due to a lower center of gravity. Has the following advantages:

- there is no need to build a foundation;

- speed of installation;

- high performance characteristics in areas of low-lying groundwater.

The installation of a free-standing structure has a base made of a layer of crushed stone, on top of which sand is poured. The plates are fixed by welding, and their installation is impossible without special mechanisms.

Return to contents

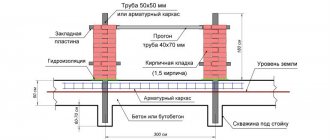

Fixed on racks (glasses and poles)

Concrete fencing mounted on cups is used to enclose various enterprises, construction sites, institutions and warehouses. Installation occurs by lowering the glass into the soil and fixing it with a metal stake. The glass requires a foundation with a layer of crushed stone and sand, 0.4 meters thick. The structures fixed to the glasses depend on the topography and have the following slab sizes:

- height: 300 cm, 250 cm;

- width: 250 cm, 400 cm;

- weight: 1.45 t, 1.6 t, 1.8 t.

After installing the glass of slabs, the structure is fixed. To do this, the slabs and support are poured with cement mortar and secured with metal backfills and welded. A concrete fence on posts allows you to use various decorative methods and build fences of any height.

From the outside, the surfaces of the slabs look like brickwork, natural stone, wooden beams and marble railings. For decoration, forged grilles and painting with multi-colored paints are used. Installation of fences on poles does not require the use of special equipment. Installation requires hand tools and a team of several people. The pillars are installed in prepared holes half a meter deep. The formwork is installed and the gap between the slab and the ground is filled with cement mortar.

Return to contents

Concrete fences

An important element of any site is the fence; it can be seen in almost any locality. The main functions of this product are: protecting everything that is in a closed area, sheltering from prying eyes, preventing unwanted guests from entering this area and soundproofing the object. The most practical and reliable are reinforced concrete fences . Precast concrete fences are competitive in the building materials market due to their durability, reasonable price and ease of installation. In addition, its flat surface does not require special fastening elements. Such fences have wide practical application in residential and industrial construction, fencing warehouses, closed facilities, etc. The height of the fence can be up to several meters.

Types of reinforced concrete fences

There are 2 groups of fences: decorative fences for the private sector and industrial ones.

Fences are made of the following types:

- monolithic - they are massive, require the use of lifting equipment and the preliminary arrangement of a strip or columnar foundation;

- block fences - assembled from hollow or solid bricks, cinder blocks without installing intersectional pillars, but with the obligatory construction of a concrete strip base;

- stacked walls are sections consisting of 3-4 reinforced concrete (RC) slabs connected to each other: the lower elements are solid, and the upper one is decorated with a through pattern; there may be no foundation, the weight of each panel is 50-70 kg;

- self-standing fences made of concrete slabs are monolithic structures that do not require a foundation and have a profile in the shape of an inverted letter T or L;

- Fence panels on glasses are a type of self-standing fence made of reinforced concrete slabs, installed on concrete blocks with a central hole or slot for securing the panels.

Manufacturing of reinforced concrete fencing

Precast concrete fences are produced at factories for reinforced concrete structures under stationary conditions. These fences are made from heavy concrete (concrete not lower than class B20, frost resistance not less than F 75) using steel reinforcement using vibratory cassette casting. The fittings used are well protected from the negative effects of the surrounding atmosphere. The production of a concrete fence using prestressing reinforcement has received great resonance as a relevant and necessary technology. The resulting products have increased stability, strength and a long service life, they are able to withstand heavy loads of compression and tension, and tolerate temperature changes well.

Advantages of a fence made of concrete slabs

The ability to adjust the height of the fence is one of the advantages.

Concrete fencing structures have the following advantages:

- when working with concrete fences, it does not take much time to erect them;

- low cost;

- variety of decor;

- when working with a concrete fence, it is possible to adjust the height of the structure;

- fire safety;

- does not require the selection of special soils;

- ease of installation of a concrete structure;

- the opportunity to purchase a ready-made concrete slab with ready-made decor suitable for any landscape;

- does not require painting or other repair and construction work;

- the concrete slab for fencing is resistant to rust, shrinkage and deformation;

- work with concrete slabs for fencing can be done with your own hands;

- has a long service life.

Return to contents

Precast concrete fences - installation

Structurally, a reinforced concrete fence consists of a fencing slab and a foundation glass; when assembled, it is part of the fence. Reinforced concrete sections are inserted into the groove of the glass, its weight is approximately 500 kg, the slab rests on two glasses, so there is no solid foundation. concrete fences are reliable and easy to install. Installation of the fence is carried out on proven, reliable soil using lifting equipment. The installation technology consists of installing a foundation glass (has the shape of a truncated pyramid) on solid ground, a support column with grooves is installed in the central hole of the glass, into which fencing slabs are inserted. The second version of the fence is one-piece; it differs from a prefabricated one in that it is a one-piece structure (poured into a mold) and cannot be disassembled. Depending on the purpose and period of use, a solid or prefabricated fence is selected.

Recently, concrete fencing has acquired an additional function - advertising and information.

Installation of fences

Reinforced concrete fences will last for many years, performing their assigned functions only if they are installed correctly. Professional installation can be ordered from specialized companies or construction trade sites. Those who prefer to do everything with their own hands can install a fence from euroslabs themselves. Installation of a concrete fence requires precise calculations and careful preparation.

Reinforced concrete walls require preliminary concreting of pillars that serve as supports for the sections.

Fastening the fence slab involves installing each element on a support from above. If you follow the general installation rules and take a responsible approach to its implementation, you can build a high-quality fence from a sectional slab on your own.

| Name | Price, rub) | Length (mm) | Width (mm) | Height (mm) | Weight (kg) | Quantity per car (20t) |

| P6-V | 7716.00 | 3980 | 2550 | 160 | 1536 | 12 |

| P6V with apron (P6-1F) | 9093.00 | 4000 | 2450 | 160 | 1980 | 10 |

| PZ-1 | 5850.00 | 2480 | 2720 | 160 | 2100 | 9 |

| PZ-6 | 9530.00 | 6000 | 2000 | 70 | 2100 | 9 |

| BY 1 | 4500.00 | 2500 | 3000 | 150 | 1500 | 12 |

| PO-2 | 5850.00 | 2500 | 3000 | 150 | 1600 | 12 |

| PO-2m(f) with apron | 6550.00 | 2500 | 3000 | 150 | 1575 | 12 |

| PO-3 | 5740.00 | 2500 | 2500 | 150 | 1250 | 12 |

| PO-3m with apron | 6155.00 | 2500 | 2500 | 150 | 1300 | 12 |

| F-1 Support glass | 1960.00 | 900 | 700 | 450 | 480 | 40 |

| F2-1F Support glass | 1985.00 | 1200 | 700 | 450 | 500 | 30 |

| FO-1 for PO-3 | 2250.00 | 950 | 750 | 550 | 630 | 31 |

| FO-2 Support glass | 2289.00 | 750 | 950 | 550 | 630 | 31 |

Reinforced concrete fences are used for fencing the territories of industrial enterprises, energy, agricultural and warehouse facilities, areas of residential and public buildings.

One of the areas with increased danger is various industrial buildings, so they need to be fenced with fences, the ideal option is a reinforced concrete fence , a similar fence can also be used to fence various warehouses or agricultural premises; in the manufacture of these fences, the M300 grade of concrete is used.

There are several options for concrete fences and each has its own marking, 1P30, 2P30, PD24 and others. Also, when installing a fence, the fence panel must be installed in the support glass, and this will be the foundation for the fence . If you have the opportunity to deepen the glass into the ground, the stability of the entire structure will be higher. Then fence panels without an apron will suit you, but if the glass can only be installed on the surface of the ground, it is advisable for you to purchase a concrete fence with panels that have an apron. The cost of these types of panels is slightly higher, but thanks to the apron you will be able to close the space that is formed under the fence panel if, for example, you chose a fence panel without an apron in such a case.

Fence panels are made of sand concrete and have high frost resistance characteristics, very low water absorption and high wear resistance. Thanks to these characteristics, the service life of reinforced concrete fences is very long.

The main thing is to install reinforced concrete fence panels correctly, since the durability of these fences depends on the correct installation. When installing fences, it is advisable to use the services of specialists and special equipment, since the weight of one panel can be more than 2 tons. Also, when choosing a seller, you need to pay attention to the reputation and how long the company has been on the market.

Design features of reinforced concrete fences

Concrete slabs and cups for fences are strong and durable structures, designed for operation in conditions of high humidity, temperature fluctuations, and exposure to aggressive environments. A solid fence made of slabs 2-2.5 m high is a reliable barrier for intruders; it can provide the maximum level of security for a facility.

Advantages of reinforced concrete slabs:

Durability. For the production of structures, concrete of a grade not lower than M200 and steel reinforcement are used. A fence made of reinforced concrete products will last at least 50 years.

Strength. The fence slab can withstand numerous cycles of freezing and thawing, exposure to wind, and mechanical attempts at destruction. The products are protected from corrosion and moisture.

Versatility. Reinforced concrete structures are used for fencing a wide range of industrial and commercial facilities, as well as personal plots. Installation of fencing is possible on any type of soil.

Installation of massive slabs protects the area from debris, wind, and reduces noise levels.

Fence slabs do not require maintenance, they are self-cleaning and retain their original appearance for many years.

Easy installation. A special support in the form of a glass on the fence serves as the foundation for the slabs. Assembling individual sections into an overall structure takes little time.

Prescription of fences

A properly installed fence will last for many years, successfully performing all the functions assigned to it. Professional assembly is carried out by specialized companies, although everything can be done independently. But we are talking only about euroslabs, which are light in weight; standard ones, while concrete slabs require the use of special equipment, calculations and preparation (it still depends on how much the product weighs).

Before the main installation positions, concrete pillars can be concreted, which act as supports for the sections. The fence slab is mounted on top of the support. Each milestone must be made with high quality (in order for the fence to be reliable and last for a long period of time.

Basic installation rules

Europlates may have different accessories depending on the type of fixation, so the installation methods differ like heaven and earth. But the general rules and demand are usually identical in (types of any fencing.

General way of thinking when installing concrete slabs:

First, they determine the slope angle of the fence: fortunately, it is too large and there are serious irregularities, the fences are mounted in steps. At the top edge, the slabs will be shown in a favorable light from each other, and the distance from the ground at the bottom of the section will be the same. The slab needs to be drunk. Ant. dismantle efficiently: evaluate the properties of the soil, study the high relief of the perimeter of the fence, take into account the characteristics of the region. Later, where heavy rainfall is common, the impact on intake flows must be considered during the design and installation process.

If the installation is planned to be done personally, it is carried out by installing sections in the grooves; therefore, it is desirable to have several workers. When making estimates, they take into account not only the slab, but also other elements. So, for example, a standard euro concrete slab has a length of 200 centimeters. Assuming there is a small gap and the thickness of the pillar lintels, add a second 6 centimeters to the length of the slab. During the installation process, it is necessary to cut the slabs: for this, a diamond circle is used. The cross-section of standard supports is equally 15 by 15 centimeters, ayushki? taken into account in the project. For private areas, concrete slabs are selected in accordance with the architectural ensemble of the building, buildings in the yard (gazebo, terrace), and again the general color scheme. The color of the panels should be in harmony with the rest of the colors in the area. The ornament of the slab can blend into the surrounding relief.