The famous floating foundation is named so unusually because it actually moves unnoticed by the eye on unsettled soil - where any other zero level would immediately give a good crack. And for a bathhouse, this type of foundation is one of the most versatile and effective. We can say that this is a good alternative to the modern pile one, both of which are the only possible option on unsettled soil. Yes, piles last longer and more solid buildings can be built on them, but “floating” ones need repairs much less often. And the most important thing is a relatively warm floor in the bathhouse, which cannot be said about houses “on chicken legs”.

True, such a foundation is not cheap. So let's figure out when its construction is really justified and what advantages a floating foundation has over other types, since almost all of Europe builds its small and beautiful houses on it.

What is a floating foundation

A floating foundation is essentially a reinforced concrete monolithic slab mounted on a bed of bulk building materials (sand, crushed stone). A floating foundation can be used for almost any building, but it is especially good for buildings on “capricious” soils.

If seasonal soil changes do not allow the use of standard types of foundation, since partial or even complete destruction is possible, a floating foundation (or poured monolithic slab ) may be a good alternative. The building is erected strictly on a slab, due to which seasonal soil movements do not affect its structure - the entire structure “walks”. A floating foundation is quite complicated to implement, since its construction entirely with your own hands is almost impossible; in any case, you will have to resort to the help of heavy construction equipment.

Technology for laying a floating foundation and its types

Being the foundation of any building and ensuring its strength, durability and reliability, a floating foundation is erected on the most unstable, weak soil. These include heaving or swampy ones.

The purpose of such a foundation is to ensure the stability of the entire building and protect the walls of the house from possible cracking under the influence of soil subsidence.

The foundation of the building, made on the basis of a monolithic slab, is characterized by maximum bending strength and durability of the entire building.

Advantages and types of floating foundation

In accordance with SP 50-101, the construction of non-buried and shallow foundations is permitted, which, due to the design features, are called “floating”. Their main distinguishing feature and feature is very powerful reinforcement and a fairly large supporting surface. Such a surface can be a slab or grate.

floating slab

A monolithic floating foundation is a slab that provides a high-strength foundation. Before arranging it, they try to reliably protect the soil under the future house from freezing. For this purpose, drainage is used, dried or removed, replacing it with one of the inert materials that does not contain clay, which is subject to severe swelling.

Floating slab design

Among the varieties of floating slabs:

- the bowl is overturned;

- caisson slab;

- bowl.

Each type has its own characteristics in the form of reinforced stiffening ribs or the ability to ensure the construction of a concrete plinth of any desired height. The caisson slab is used in the construction of buildings with a cellar. Such a room is usually located under one of the existing rooms.

Floating grille

This floating foundation or structure differs from the usual shallow foundations by the presence of intersecting internal stiffeners. The resulting lattice has a cell pitch of at least one meter and no more than three. This lattice is very close in essence to a monolithic slab. When the soil swells, it is able to rise and fall back into place when the soil thaws.

Features of the installation of such a base include the use of a polyethylene film, which is spread on a bedding of sand, crushed stone or a combination of both. Expanded polystyrene (foam) blocks are laid at a distance of 40 centimeters from each other. The thickness of each such block reaches 40 centimeters.

After finishing the concreting work, the permanent formwork takes on the role of a thermal insulation layer for the floor. Such a foundation is installed when constructing the lightest buildings.

Floating columnar foundation

Floating columnar foundation

Such a floating foundation is installed on sandy, rocky soils and soils based on gravel, when constructing light buildings in the form of panel cottages. The technology for performing the work requires the installation of a cushion and waterproofing.

The main difference from the first two options is the possibility of using FBS blocks rather than monolithic structures. This design does not have a base; the distance between the pillars reaches 2.5 meters.

A floating foundation has many advantages, but there are also some disadvantages. The main one is the high cost and high labor intensity of the work.

When arranging the foundation of a building, it is necessary to take into account accurate data on the depth of soil freezing. The foundation is located just below the freezing mark, and the soil should be naturally compacted.

Installation and construction of a monolithic floating foundation

Having selected and cleared the site for construction, you need to mark the length and width of the future building with pegs and stretch a non-stretch cord over these pegs. When digging a pit, it is necessary to increase it on each side by about one meter. A concrete blind area will be installed at this location, protecting the base from the penetration of excess moisture.

When carrying out work, it is necessary to strictly observe the dimensions of the pit. Excessive deepening, the so-called digging, is unacceptable. A building erected on a trench will not be durable. It will definitely start to crack soon.

Sand pillow

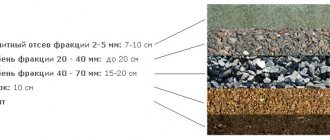

A floating foundation begins with the preparation of several layers of cushion:

- crushed stone;

- sand;

- waterproofing.

The sequence of work and process technology are strictly observed. Only after waterproofing, which can be polyethylene film, can thermal insulation material be laid and the first layer of concrete can be poured.

The arrangement of formwork is carried out according to all the rules using boards whose thickness is at least 25 millimeters. The panels knocked down from them are sealed with roofing felt so that the wood does not absorb moisture from the solution. After completing this work, you can begin reinforcement.

Reinforcement and pouring of a floating foundation

To effectively strengthen the entire structure, reinforcing rods with a diameter of 8 to 14 millimeters and knitting wire, which is crocheted with a special hook, are used. An important point is to arrange the reinforcing mesh so that the free ends of the reinforcement serve as a tie with which the slab will be fastened to the walls of the house, remaining protruding from the concrete. The pitch of the cage, that is, the distance between the reinforcement bars, is 20-25 centimeters. Watch the video on how to pour a monolithic slab foundation.

Having prepared the mesh, you can begin pouring concrete. This must be done in layers. The thickness of each concrete layer is 15 centimeters. After pouring, it is leveled and thoroughly compacted, expelling air bubbles from the solution. It is better to carry out this work with a bayonet. The final layer of the floating foundation must be compacted and thoroughly leveled, and in the next few days it must be regularly moistened by pouring water. This is necessary in order to avoid cracking.

A week later, the formwork is removed, but, as technology requires, further work on the construction of the building will begin no earlier than six months later, when the floating foundation is finally established.

For some builders who list the disadvantages of a floating foundation, one of the most important of these disadvantages is the long waiting period. But in accordance with the technological process, the waiting period before the start of the next stage of work is one year.

fundamentaya.ru

Advantages and disadvantages

Like any other, a floating foundation has its own advantages and disadvantages that must be taken into account when choosing it. Its main advantages include:

- Unlimited choice of soil. Even the most difficult soils are quite suitable for constructing such a foundation, with the exception, perhaps, of permafrost.

- No special technical or engineering knowledge is required. The most difficult thing, most likely, will be calculating the places where communications such as water supply and sewerage will enter and exit.

- Good load -bearing capacity. Achieved by additional reinforcement of individual sections of the foundation.

- Protection of the structure from local deformations and destruction. During periods of frost, when the soil heaves, the entire building will lower/raise on a monolithic slab.

- The foundation itself can serve as a subfloor , without the use of additional building materials.

However, there are also disadvantages To build a floating foundation, it is simply necessary to use heavy special equipment, and the volume of building materials will be quite considerable.

Floating or piled?

When using a floating foundation, the structure is well stabilized, since it has a large supporting area. A reinforced solid foundation effectively distributes the entire load. Such a foundation is used in the construction of buildings of any shape.

As for the pile foundation, it consists of piles (vertical wooden, concrete or metal pillars immersed in the ground). This technology is mainly used on all problematic soils. Unlike a floating foundation, the cost of a pile foundation is much lower. Plus, it requires less financial and physical costs. A large number of operations are mechanized.

| Expert advice ! Not in all cases it is possible for special equipment to arrive at the site. Plus, it’s very difficult to lay such a foundation on your own. In this case, the ideal solution is to make a floating foundation. |

Our company, specializing in pile driving in Moscow and the region, will provide assistance in constructing a pile foundation. To start cooperating with us and begin performing all the necessary work, contact us using the application:

Foundation for a bathhouse: their types and comparison

carries out immersion of piles during the construction of foundations for various buildings: residential, industrial, economic, therefore, according to...

More details

Pillar foundation

From this article you will learn what advantages and disadvantages support-column bases have; we will consider in detail the technological features...

More details

Cottage foundation project

…

More details

Useful materials

Foundation beams

Foundation beams (BF) are used for internal and external walls with free-standing foundations.

Piles 20 by 20

This page provides information on the performance characteristics and design features of piles with a cross section of 20x20 cm.

Construction technology

- Preparing the area. We decide on a specific location for the work, mark the future foundation, and dig a foundation pit. Already at this stage, special equipment may be needed. If the building under construction involves the presence of not even the deepest basement (cellar), the foundation pit will have to be dug according to the depth of the basement, taking into account the thickness of the foundation and the cushion under it. And since the pit must be slightly larger in width than the expected dimensions of the building, manual digging can take more than one week. Conclusion - there will be special equipment!

- Site preparation is far from the least important. To avoid problems during the functional use of a floating foundation, the bottom of the pit must be carefully leveled. The differences in the surface of the bottom of the pit should be no more than 5 cm. Otherwise, with a maximum load on the foundation, it may begin to collapse or crack, which will have an extremely bad effect on the entire structure.

It is additionally recommended to equip the bottom of the prepared pit This will save the cushion of sand and crushed stone from being washed away by groundwater.

- Pillow for a monolithic slab. The pillow is usually made of crushed stone, sand (coarse-grained) and soil; it is also possible to use a mixture of them. Sand and crushed stone (mixture) are poured in a layer of 10 to 40 cm. It all depends on the quality of the soil and the expected thickness of the foundation. The prepared pillow must be soaked with water and thoroughly compacted.

If you want to insulate the foundation, then you need to start doing this already at this stage using the following technology. A dense polyethylene film is placed on the prepared pillow , and then a layer of extruded polystyrene foam. This insulation is intended for use specifically with monolithic foundations. It is produced by both domestic and foreign manufacturers, but there is no fundamental difference between them.

- begin for pouring the floating foundation. First, the formwork is made. It is best to make it from a laminated board so that it can be reused, and the edge of the foundation will be smoother, which will make it easier to install the insulation on the sides of the foundation. The boards are fastened together with ordinary self-tapping screws, and in order to prevent the formwork from “moving apart” during the concrete pouring process, pegs are driven into the ground at a distance of about 50-100 cm.

- The most important part in the technology of arranging a floating foundation begins. The formwork is being poured with concrete. This is not done to the full depth at once. Let's consider the option of a foundation for a one-story house built from foam blocks. The thickness of the foundation slab should be about 30 cm. First, about 10 cm of concrete is poured, after the concrete has partially dried, the future slab is reinforced. A mesh of steel rods is woven at several levels, connected to each other with special wire. Using welding in this case is not a good idea, since fastening with wire can provide a certain flexibility to the structure, and welding will only create additional stress at the joints of the reinforcement.

Next, the remaining space is filled with concrete. Here it is important to pay attention to the continuity of the process. Only the foundation for a light frame summer house can be poured in parts. For a permanent structure, it is very important to fill the foundation completely at once . Here you will have to call on special equipment to help, since only a concrete construction mixer is capable of providing high-quality mixed mortar in large quantities.

The density of the concrete mixture is no less important. In order for the floating foundation slab to have maximum strength, it is necessary to use special tamping equipment. At the end, the surface of the slab is checked with a level for unevenness. If there are any, we correct them. If everything is fine, the slab is left alone until it hardens.

In order to obtain a high-quality monolithic slab, after all the work done, the slab is covered with film for approximately two weeks. During these days, it is necessary to periodically moisten the stove with water. This will give better hardening of the foundation.

Types of foundations in construction

There are several types of foundations in construction. Each of them is intended for a specific case. Let's talk about each of them in more detail: Strip foundation. Most common in low-rise and private housing construction. They are a concrete strip with reinforcement. It is located along the perimeter of the entire building. This foundation is perfect for houses with basements and garages. On such a foundation you can build both heavy brick houses and light ones made of wood. In the first case, it will be deepened, but for the construction of light structures a strong deepening is not required.

Columnar foundation. The name speaks for itself. It is erected by placing pillars in the corners of the building and at the intersections of walls. Between the pillars, lintels are made of concrete, brick or rubble. With such a foundation, it is impossible to install a basement in the house. In addition, it is suitable for the construction of light houses. It is best to build a columnar foundation on stable soils.

Monolithic. It is a single slab poured from concrete with reinforcement. This option gives freedom of planning and protects the structure from deformation due to soil subsidence. Its installation does not require special equipment, which allows you to carry out the work yourself.

Knowing the strengths of each type of foundation, you can easily choose the one suitable for building your home.

Floating foundation: what is it, how to fill it correctly with your own hands using technology

A floating foundation is a shallow solid or lattice slab (not buried), the technology of which provides for rigid spatial reinforcement, and the laying depth is 30-50 cm.

Load-bearing building structures that move with the soil depending on the season are called floating. For the construction of such foundations, high-strength concrete from B12.5 and reinforcement with a diameter of 12-16 millimeters are used.

A floating foundation can reduce concrete consumption by up to 25-30 percent, and the cost of operating moments by up to 30-40 percent compared to other building load-bearing structures.

This type of foundation can be justified (due to the high consumption of concrete and reinforcement) when other types of building load-bearing structures do not provide the required level of technical characteristics on the ground.

The heat from the building reduces the freezing depth along the entire perimeter of the floating load-bearing structure, which has a thickness of 20-25 centimeters of monolithic reinforced concrete. Particularly important is foam insulation around the perimeter, which prevents heat loss and transfers heat through the slab to the underlying soil.

Let's take a closer look at the important points and questions in this article. It does not always turn out that the soil on the site is suitable for classical foundations. The area may contain clay, sand or loam, saturated with groundwater - such soil is slippery, prone to seasonal heaving, and groundwater, in turn, can become an aggressive destructive medium, which over time can partially or completely destroy classic concrete load-bearing structures.

It is for these reasons that on soft soils subject to seasonal movements, they try to build a relatively expensive, but strong and reliable shallow slab foundation. The technology for constructing this load-bearing structure is almost the same and does not depend on the type of soil. The concrete slab must withstand soil movements and natural loads from supporting structures.

There are three main types of floating foundations, each of which is suitable for clay soil, so it is worth familiarizing yourself with these options in more detail.