Concrete supply by conveyor belt, hydraulic chute

Concrete mixer trucks (ABC) at a construction site cannot always drive close to the object being built. In this case, the supply of concrete from the mixer can be organized using transport with a hydraulic tray, or using a conveyor belt. offers its customers both of these effective methods of delivering the solution.

Conveyer belt

A mixer equipped with a conveyor belt is an excellent alternative to a concrete pump. This technique is capable of delivering and delivering concrete of any brand over a distance of up to 12 m, even to hard-to-reach places.

Price list for concrete supply services

Name Cost, rub.

| Ribbon | 500 (per m3) |

| Pipe | 1500 (per mixer) |

| Hydro tray | 1500 (per mixer) |

The conveyor belt is a movable conveyor track with a rubber base and controlled by a hydraulic drive. The width of the belt is 10-140 cm, and the radius of its movement is 3600 when turning 900. This conveyor is installed on ABS.

Belt conveyors are widely used in the warm season and in areas with mild climates. In cold weather they are insulated and equipped with heating devices.

Hydro tray

This equipment is installed on the ABS and is controlled using hydraulics, which allows you to adjust the length of the tray and change the angle of its rotation. A hydraulic chute is used when it is necessary to supply concrete mixture at a distance of up to 9 m.

The disadvantage of this system is the inability to supply concrete to a height. Its most effective use is for pouring foundations and other work at the ground floor level.

Why is it important to choose “MONOLITH-REC”?

To begin with, you can get acquainted with reviews of cooperation with the company to make sure of its reliability. And, having become a customer of “MONOLITH-ZhBI”, you yourself:

- receive a guarantee of high quality service;

- you will have the opportunity to choose both the brand of concrete and the method of supplying it to your site;

- pay less for services than their average cost on the market;

- you can choose a form of payment.

Order concrete delivery from a concrete manufacturer in a way convenient for you and increase the efficiency of your construction.

Source: https://beton.monolit-gbi.ru/beton/podacha_lentoi/

GENERAL OCCUPATIONAL SAFETY REQUIREMENTS

1.1. Workers at least 18 years of age who have undergone appropriate training and have professional skills in performing concrete work, before being allowed to work independently, must undergo: - mandatory preliminary (upon entry to work) and periodic (during employment) medical examinations (examinations) for recognition fit to perform work in the manner established by the Ministry of Health and Social Development of Russia; — training in safe methods and techniques for performing work, instruction on labor protection, on-the-job training and testing of knowledge of labor protection requirements. 1.2. Concrete workers are required to comply with labor safety requirements to ensure protection from the effects of hazardous and harmful production factors associated with the nature of the work: - location of the workplace near a height difference of 1.3 m or more; — sharp edges, corners, protruding pins; — vibration; — moving machines, mechanisms and their parts; - increased voltage in the electrical circuit, the closure of which can occur through the human body; — spontaneous collapse of structural elements and fall of overlying materials and structures. 1.3. To protect against mechanical influences, water, alkali, concrete workers are required to use the following provided free of charge by employers: - canvas suits or water protection suits made of synthetic fabric with a film coating; — rubber boots with a hard toe cap or leather boots with a hard toe cap or leather boots with a hard toe cap; — combined mittens or polymer-coated gloves; — signal vests of the 2nd protection class. For outdoor work in winter, you should use the following additionally provided: - suits with insulating lining or suits for protection against low temperatures made of mixed or woolen fabric; — felt boots with rubber bottoms or insulated leather boots with a hard toe box; — frost-resistant gloves with a protective coating, with woolen liners; — signal vests of the 2nd protection class. In addition, depending on the working conditions, concrete workers are required to use personal protective equipment on duty, including: - when working on slopes of more than 20°, as well as in the absence of fences for the workplace at height - safety belts; — when working with jackhammers, use anti-vibration gloves and safety glasses; - when working with electric vibrators, as well as electrical heating work - dielectric gloves and boots. Concrete workers must wear safety helmets while on a construction site. 1.4. While on the territory of a construction (production) site, in production and service premises, work areas and workplaces, concrete workers are required to comply with internal labor regulations. The admission of unauthorized persons, as well as workers in a state of intoxication, to the specified places is prohibited. 1.5. In the course of daily activities, concrete workers must: - perform only the work assigned by the work manager; — use small-scale mechanization tools, machines and mechanisms during work for their intended purpose, in accordance with the instructions of the manufacturers; — maintain order in workplaces, clear them of debris, snow, ice, and prevent violations of the rules for storing materials and structures; — be careful while working and avoid violating labor safety requirements. 1.6. Concrete workers are obliged to immediately notify their immediate or superior work manager about any situation that threatens the life and health of people, about every accident that occurs at work, or about a deterioration in their health, including the appearance of an acute occupational disease (poisoning).

Mixer With Concrete Feeding Belt. Mixer with feed belt

5 years ago

Pouring the strip foundation from a mixer with a conveyor belt. Fill the strip foundation of a mixer with a conveyor belt.

2 years ago

Review of a concrete mixer with a conveyor belt.

3 years ago

Construction company in Dnepropetrovsk. Production and delivery of concrete. Ordering concrete and equipment in Dnepropet...

3 years ago

Delivery of concrete and mortar in Chelyabinsk and the Chelyabinsk region. 89085700787.

1 year ago

Concrete / Mixer with 12 m belt from 240 rubles (Minsk). The benefits are obvious: - only quality, no games with the brand of concrete;...

5 years ago

https://ess.dp.ua/prajs-beton Order concrete and construction equipment in Dnepropetrovsk by phone: 093-10-10-100 Concrete in Dnepropetrovsk...

10 months back

We pour an armored belt. Ribbon feed mixer.

5 years ago

Instead of fiddling with boxes (feeding them to the mixer bridge, manually dumping fiber from them into the mixer - what...

3 years ago

Concrete plant, concrete production plant, mixer, concrete mixer, cement, concrete, machine from China.

6 years ago

The Stroytekhnika plant presented a new product - Concrete Plant Rifey-Beton-20. The story was filmed by ZTRK. In details…

4 years ago

Features of the construction of sidewalks and paths made of concrete

Designing paths in a country house begins with the development of an interesting and practical sketch that takes into account the features of the local topography, the location of buildings, utilities and green spaces. To create a cozy garden or park space, all straight lines are rounded if possible, taking into account the characteristics of the planned landscape.

Standard pegs and rope are used to mark lines. In areas being concreted, grass and the top layer of soil 5-7 cm thick are removed. Laying geotextiles at the bottom of a small trench protects the structure from grass germination. The use of geotextiles also eliminates the risk of gradual settling of fine sand particles into the ground.

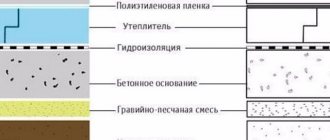

After marking the area and preparing the soil, the elements of collapsible formwork are installed along pre-approved lines. Bendable plywood, plastic or metal sheets are used to form curves. A cushion of carefully compacted sand and crushed stone is placed at the bottom of the trench. The surface of the pad is carefully leveled to obtain a uniform layer of concrete. Alternative cushion options are a pre-made concrete screed or a layer of flat stones.

To strengthen the finished structure, reinforcement with steel rods, wire or welded mesh can be used. Fiber-reinforced concrete compositions eliminate the need for costs for steel reinforcement. To increase the durability of country paths, expansion joints are installed, dividing the structure into separate slabs. The main task of expansion joints is to compensate for expansion of the material during heating, eliminating the risk of cracks and deterioration in strength characteristics.

The supply of ready-mixed concrete for garden paths helps to carry out concreting work as quickly and efficiently as possible. The mixture is poured into the prepared formwork without interruption to form a durable monolithic layer. The formwork elements are removed a few days after the natural hardening of the concrete structures. Periodic moistening of surfaces during the hardening stage of the composition eliminates the risk of accrual cracks that reduce the overall strength of the structure.

Mixer with concrete feed belt

Full specifications

| Feed range | Power | Price |

| 14 | 70 m3/hour | 15.000 |

| 16 | 70 m3/hour | 16.000 |

| 22 | 70 m3/hour | 16.000 |

| 24 | 70 m3/hour | 17.000 |

| 28 | 70 m3/hour | 20.000 |

| 32 | 90 m3/hour | 20.000 |

| 42 | 120 m3/hour | 24.000 |

| 52 | 120 m3/hour | 42.500 |

| 62 | 200 m3/hour | 59.500 |

| Feed height | — |

| Feed length | 9 m. |

| Cost of pumping | — |

| Delivery | Great Dane |

| Feed height | 4 m. |

| Feed length | 12 m. |

| Cost of pumping | 4,000 rub. |

| Delivery | Great Dane |

Conveyor belt for unloading concrete

Various devices are used to supply concrete at a construction site using a concrete mixer truck. Among them are conveyor belts. They are rubber tracks with a length of 10 meters and a width of 40 cm.

It is advisable to use conveyor belts for unloading construction mixture to a height of no more than four meters. Based on the principle of supplying the solution, these devices resemble conveyor production. The belts are installed directly on concrete mixer trucks; if necessary, they can be rotated 90 degrees to the right and left.

OCCUPATIONAL SAFETY REQUIREMENTS IN EMERGENCIES

4.1. If faults are detected in the fastening of formwork, scaffolding, mechanization or power tools, as well as when tension appears on non-concrete reinforcement of reinforced concrete structures or metal parts of formwork and supporting scaffolding, work must be suspended and the foreman or work manager informed. 4.2. When installing formwork or supplying concrete with a lifting crane, work must be suspended in the following cases: - wind speed increases to 15 m/s or more; - during thunderstorms, snowfall or fog, excluding visibility within the work area.