Technology and main advantages of diamond drilling

Diamond drilling of concrete is used when it is necessary to further fix the equipment or carry out drilling at the next stage. Among the main advantages of this technology is the impressive power of the equipment, which allows you to achieve the desired performance. These works are almost not accompanied by vibrations. They provide high precision, and you can work with almost all materials and at any angle.

Diamond drilling of walls involves the use of a crown. Its steel body has soldered segments. Drilling can be done using liquid or dry. In the latter case, it is possible to ensure the cleanliness of the structure. This approach has the disadvantage of a lot of garbage. When you have to work with high-strength materials, it is better to resort to wet drilling. The water cools the surface and removes dust.

Diamond drilling in 90 percent of cases is carried out using the wet method. The water then enters the drainage ring.

EQUIPMENT AND TOOLS FOR DIAMOND DRILLING

Equipment for diamond drilling Dr. Schulze GmbH (Germany).

presents professional German equipment for diamond drilling of holes in concrete, reinforced concrete, brick, stone, granite and other materials. Complete diamond drilling units, diamond drill bits, as well as individual motors and frames.

DRILLKOMPLEKT diamond installations are the optimal choice of complete equipment for diamond drilling of various diameters.

Diamond drilling is currently the highest quality and most cost-effective technology for making holes in high-hardness building materials, including granite and reinforced concrete.

When working using the diamond drilling method, a specialized stone-processing tool (diamond drill bits) is used, the cutting part of which contains diamond elements. The rotation of this tool at high speed ensures the greatest efficiency in making holes in concrete, reinforced concrete, masonry, asphalt, granite and similar materials.

Work with equipment for diamond drilling can be done in various conditions, for example, with limited access to the workpiece. This is due to the fact that there is no need to tie the machines to a specific plane or angle of inclination.

The distinctive advantages of using diamond core drilling technology include the following:

Saving on human resources - tasks with diamond drilling units can be successfully completed by one specially trained worker.

Making holes using diamond drilling equipment does not result in excessive dust or contamination of the site where the work is being performed.

Working with diamond drilling installations does not lead to vibrations, so there is no risk of compromising the integrity of the structure.

The use of specialized core drills (diamond drill bits) during the work process allows us to produce perfectly straight holes in accordance with the required dimensions.

The ability to make technological holes in materials of varying degrees of hardness: concrete, reinforced concrete, brickwork, asphalt, granite and similar materials.

The time it takes to make holes using the equipment we offer is significantly lower than when using other drilling methods.

All diamond drilling equipment on the market, as a rule, can be divided into three groups:

1/ Diamond installations for manual and stationary drilling with a diameter of up to 120-150 mm (diamond drills).

These machines have a power of 1.8 - 2.2 kW and allow you to work both “hand-held” and using a stand. In addition, some of the manual diamond drilling machines have the ability to work both cooled and dry.

2/ Single-phase diamond installations for stationary drilling with a diameter of up to 250-400 mm.

These machines have a power of 2.6 - 3.3 kW and allow making holes with a diameter of up to 250-400 mm, depending on the power of the engine and gearbox.

Scope of drilling with diamond tools

Diamond hole drilling has a wide range of applications. The work algorithm is used when constructing niches in concrete and brick walls, strengthening foundations and making wells. When drilling, you can make holes for laying communications and utility networks. The technology is applicable in geological exploration and construction industries. It can be used to extract core samples of asphalt, concrete and rock.

When is diamond drilling for concrete necessary?

The need to drill holes in concrete and brick usually arises during construction or repair work. Diamond drilling services are in demand in the following situations:

- laying communication systems (from water supply to sewerage) and the need to carry them through walls, including load-bearing ones, and ceilings;

- creation of technological holes for various purposes;

- arrangement of a natural ventilation system, connection of forced ventilation devices;

- drilling holes for installing anchors, etc.

The above list may be supplemented by other situations. For example, diamond drilling may be required when installing stair railings or other structural elements. The technology may also be in demand during dismantling.

Regardless of the task at hand, you can turn to our company for help. We are always ready to help you no matter what hole diameter is required or other factors. We have modern equipment from leading manufacturers and crowns of different diameters at our disposal.

Diamond drilling services are equally in demand among individuals and construction companies, firms engaged in reconstruction and repair work. We successfully cooperate with individuals and legal entities.

Main characteristics of the drill

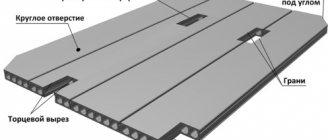

Diamond drilling of holes in concrete is carried out with a drill, which has a ring structure and is called a crown. She can handle different materials, for example:

- tile;

- brick;

- tile;

- concrete;

- foam materials;

- stone;

- reinforced concrete.

Crowns can have different diameters and lengths. They are used in conjunction with installations to mechanize the process. When choosing this consumable, you need to pay attention to the safety margin. When a comparison is made with a conventional drill, which works along the entire plane of the material, the fact that the crown works only with the cutting edge is highlighted. This reduces friction and noise, reducing debris and increasing productivity. The edges of the crown are smooth. Such products may have different threaded connections and working lengths. You need to pay attention to the number of segments and the width of each of them.

Application Areas of Diamond Drilling System

Equipment for diamond drilling of holes in concrete is used to solve the following problems:

- forming grooves in concrete walls for laying electrical wiring;

- drilling holes for water mains, garbage chutes, gas pipes, heating risers;

- making recesses for installing sockets and switches;

- drilling foundations to supply utilities to buildings;

To maintain the accuracy of the drill angle, the drives are equipped with a support flange

- connecting air conditioning and ventilation systems;

- installation of automatic fire extinguishing systems;

- demolition of reinforced concrete structures of buildings: internal partitions, interfloor ceilings, walls;

- making various niches in concrete that allow installation of equipment and interior items;

- forming openings of various configurations for installing doors and windows.

Types of diamond drill bits for hammer drills

Before you start drilling, it is important to choose the right drill bit. It can be professional or household, disposable. If we consider the types of concrete, they can be:

- spiral;

- self-sharpening;

- with a flat spiral part.

The former are best used when it is necessary to remove large structures. The second ones are designed for making large holes. Crushed material and debris can be removed from them. The latter require effort during drilling and are used for shallow holes.

If you need to carry out diamond drilling of reinforced concrete, you should use a special-purpose diamond drill, but its cost is quite high. Among special-purpose drills we can also highlight:

- flat chisels;

- chisels;

- crowns;

- channel drills.

If you need to carry out work in a room with a fine finish, a diamond core bit for dry drilling is suitable. After working with it, there is no wet dirt left, which is formed after the wet method. If you additionally connect a vacuum cleaner to the equipment, the workplace will remain completely clean.

Diamond bits for drilling concrete can also be used when individual segments may be lost or the motor is overheated. In this case, when working with hard materials, you need to use wet drilling technology. The erasure will be less intense the stronger the flow. The diameter of the equipment will determine the volume of water.

Features of diamond tools

The cutting element is drills, crowns and cups with a cutting edge coated with diamond granules, which are selected depending on the material being drilled and the diameter of the perforations. Diamond grains are attached to the edge using special solder. The cutting edge has the property of self-sharpening - new diamond grains are exposed during wear of the top layer.

Drilling rigs and cutters allow you to make holes from 6 to 1500 mm, depending on your requirements and scope of application. The choice of motor type and power (from 1300 to 7500 W) depends on the expected range of hole diameters and the type of material being processed.

Tools for drilling large diameter holes

When diamond drilling porcelain stoneware, it may be necessary to make a large hole. For this, additional equipment is used. It is impossible to make large diameter holes with a diamond drill. For these purposes, core drills are used. Their main elements are a metal cup and a shank.

The cutting teeth are well fixed on the working edge at the end. In the central part of the crown there is a drill with a screw. It protrudes beyond the crown by approximately 2 cm and is required to center the hole. When drilling holes with a diamond crown, you can even work with concrete reinforced with metal reinforcement. Such equipment is rarely purchased for independent use, because its cost is high, so you can most often find it from specialists who are professionally involved in construction and repair.

Equipment for diamond drilling of holes in concrete

Depending on the purpose and application features, various equipment is used for diamond drilling of holes in concrete:

- A small-sized hand drill that allows you to drill concrete using high-strength tools. Used for household purposes and minor repair work. The device allows you to make holes with a diameter of up to 18 cm.

- Machine installation for diamond drilling of concrete. This is industrial equipment used on large construction sites. It allows you to form recesses with a diameter of up to 80 cm. The equipment is equipped with a powerful stand that allows you to change the angle of the working body.

The use of manual equipment is characterized by increased labor intensity, but allows limited amounts of work to be completed at low cost. Industrial devices are characterized by increased size and performance.

When drilling holes of large diameters, a special bed is used

Special equipment also includes:

- spline milling devices;

- ring cutters;

- machine wall cutters;

- seam cutters;

- devices with a rope working body.

Diamond drilling price

If you cannot make a hole in a reinforced concrete wall yourself due to lack of skills and appropriate tools, you can use the help of professionals. They work with brick and concrete, natural stone and even road surfaces. The cost of the work will depend on the diameter of the hole and the wall material. If the first value does not exceed 50 mm, then for 1 cm of a hole in a brick you will pay 20 rubles. In a monolithic surface, 1 cm will cost 25 rubles.

If the hole diameter increases to 152 mm, then per centimeter in brick and concrete you will need to pay 28 and 36 rubles. respectively. Diamond drilling of brick and porcelain tiles will cost you 120 and 160 rubles. per centimeter, respectively, if the hole diameter is 452 mm.

Diamond Drilling Tool

In order to properly perform diamond drilling of holes in concrete, you need to select a special tool. The main feature of the tool is increased strength associated with the abrasive coating of the working part or the installation of special segments on the working body.

The diamond drilling unit is equipped with the following types of working tools with an abrasive coating:

- Special crowns.

- Powerful drills.

- Circular saws.

- Rope cutting devices.

- Drills.

Stages and subtleties of drilling holes

When diamond drilling in reinforced concrete, ring bits can be used. They should be selected according to the base material. When applying liquid, it should flow onto the crown, eliminating the accumulation of dirt. Depending on the strength of the material, a certain speed of work can be achieved. You can drill up to 6 cm per minute.

When diamond drilling porcelain stoneware, you can even work on concave surfaces.

The technology is selected taking into account certain conditions. Dry drilling is used extremely rarely. They resort to it if there is no water intake equipment at hand. Without it, all the liquid will end up on the floor. But the hole diameter also decreases to 20 cm.

Diamond drilling of bricks does not provide for the creation of special conditions. To do this, you need a power supply that will allow you to make holes up to 500 mm in diameter. In this case, there is no shock impact, there are no destructive vibrations, which is especially important if the work is carried out on the foundation. No chips or cracks appear around the drilling site, and the wall remains completely intact.

It is easiest to work with silicate and ceramic products. A more complex option is clinker masonry. It has high strength, and clay particles are sintered during drilling. But even here, a diamond crown will cope with its task.

Before starting work, cover the floor with film or insulating material. When water is used, it can seep into your neighbors. When through drilling, work must be done from two opposite sides. To do this, markings are made on one of the surfaces.

The installation is secured with special anchors. There will be no difficulties if the device must be fixed on strong walls. But if the partitions are lined with plasterboard or the facade is decorated with a ventilated system, it will not be possible to gain a foothold. For work, it will be necessary to remove the cladding in a certain area, only then can work begin. Fastening to ceilings is carried out according to the same principle as to walls. In some cases, you can use a spacer to the floor and ceiling. This allows you to protect the floor finishing from dismantling. But when installing anchors, the surface is damaged.

Advantages and disadvantages of diamond drilling

Advantages:

Diamond drilling produces smooth and precise holes in concrete.

- the holes are accurate and round;

- the process of drilling and drilling holes is almost silent;

- operation requires only a 220 V power supply and running water;

- no dust;

- maintaining the load-bearing capacity of the walls;

- high drilling and drilling speed;

- absence of cracks and chips at the entrance and exit holes;

- drilling depth up to 3 m with a diameter up to 1 m;

- ability to work on curved surfaces.

Flaws:

- the greatest productivity can be achieved only by increasing the axial force of the tool feed and its peripheral speed;

- Diamond drilling does not allow even the slightest distortion and beating of the tool;

- To cool the instrument, it requires a supply of running water.

Drilling concrete without impact

Diamond drilling of porcelain stoneware or concrete walls is carried out without impact. For this purpose, special installations or hand tools can be used. The second can provide only a small diameter, while stationary equipment shows more outstanding results. Using crowns and drills, you can process the surface without subjecting it to vibration. After all, the process will be quieter and more accurate. The walls of the tunnel look surprisingly perfect. They look like they've been polished. They do not require additional processing. This allows you to prepare channels for water supply and installation of exhaust systems, as well as sewer pipes and much more in a short time. There is no need to spend money on internal surface reinforcement.

Advantages of dry drilling

You can drill walls not only using wet, but also dry technology. Among the main advantages of the latest algorithm, the ability to work in clean rooms should be highlighted. If the process is carried out where there is no source of water nearby, then this technology cannot be avoided either, and this is its advantage. Air ventilation will be responsible for cooling the cutting edge.

Processing tool used

When you have figured out the diameter and length of the drills, you can move on to studying the types of tools that are used when drilling. Among the most common options are permanent installations. On sale you can find drilling drills and machines. For small holes, you can use electric drills and hammer drills with an impact mechanism, which can be found today in almost any home craftsman. You will only need to purchase additional consumable equipment. Drills, however, are not as powerful as rotary hammers, and not all devices have a vibration-impact option. It makes the instrument more expensive. If you do not plan to make holes in solid walls on an ongoing basis, then you should not overpay for the function.

If you still haven't chosen a tool, you should consider its types.

- Lightweight installations with 1800 watts of power.

- More powerful models up to 2500 W.

- The third group contains powerful units that operate at a maximum of 3300 W. These devices are capable of making holes up to 350 mm or more. These machines can be used to manipulate the foundation, where holes are made for anchors. In this case, you have to go deep up to 1.5 m. But 350 mm holes are made for the air ducts.

Light installations are not capable of handling more than 130 mm. The main advantages of such machines are their weight and affordable cost. The work algorithm does not provide for the need to use a second handle. But this may cause a reduction in the life of the drill. Sometimes such work leads to segment breakdowns.

Main stages of the technical process

The first step is to select a diamond installation and prepare the surface. The area around the perimeter is cleared of debris and unnecessary elements that could interfere with the work. It is necessary to mark the axes and determine the diameter. If the technology provides for the supply of water, it is supplied. Otherwise, you can use dry drilling technology. It is important to take care of the power supply and air supply.

Now comes the turn of the equipment, which is installed at the site of the future hole. Once all connections have been checked, the equipment is connected. It should not be positioned as tightly as possible to the surface, as this can tear the machine off and damage the equipment. Which is not only detrimental to the installation, but also dangerous to humans.

Diamond drilling prices

Below are estimated prices for diamond drilling of holes in brick, concrete and reinforced concrete (reinforced concrete).

If you have a need to organize work on diamond drilling of holes in walls and ceilings and you would like to know the prices for diamond drilling of holes, please contact our manager by phone: +7(495)991-81-26.

We will promptly advise you and calculate your application for diamond drilling of holes at the site.

Drilling holes prices

Prices are indicated in Russian rubles. for 1 cm of drilling holes in walls and ceilings without VAT

| Hole diameter mm. | Brick | Concrete | Reinforced concrete |

| Ø 25-52 | 16 | 18 | 20 |

| Ø 62-72 | 18 | 22 | 24 |

| Ø 82-102 | 20 | 24 | 26 |

| Ø 112-122 | 22 | 26 | 32 |

| Ø 132-142 | 24 | 30 | 34 |

| Ø 152-162 | 30 | 34 | 36 |

| Ø 172-202 | 36 | 40 | 44 |

| Ø 225-252 | 44 | 52 | 58 |

| Ø 302-325 | 48 | 58 | 68 |

| Ø 352 | 62 | 74 | 96 |

| Ø 402 | 86 | 94 | 124 |

| Ø 452 | 96 | 116 | 138 |

| Ø 502 | 112 | 132 | 156 |

| Ø 502+ individually | — | — | — |

- Prices for diamond drilling of holes in concrete, reinforced concrete and brick are indicated as approximate prices.

- Diamond drilling prices, drilling holes in bricks, the price will pleasantly surprise you.

- Diamond drilling of concrete price is calculated individually.

- The cost of the minimum order/departure is 6,000 rubles.

For large volumes, individual pricing policy.

Requirements for the Customer:

- Connection point to a 220V power supply (power at least 2.5 kW);

- Availability of a source of clean water on site;

- Providing markings for all types of work.

Increasing factor for diamond drilling and cutting:

| K1-water drainage during diamond drilling/drilling | 1,05 |

| K2 - high reinforcement of walls/floors | 1,25 |

| K3 - horizontal drilling/drilling and diamond cutting | 1,10 |

| K4 - diamond drilling/drilling in hard-to-reach places | 1,15 |

| K5 - drilling/drilling/cutting at height (at a height of over 2.0 meters) | 1,10 |

| K6 - for diamond drilling/drilling/cutting in M400 concrete | 1,15 |

| K7 - for diamond drilling/drilling, cutting in concrete grade M500 | 1,25 |

| K8 - when performing work without the possibility of supplying water to the drilling/cutting site | 1,10 |

| K9 - when working in winter conditions, excluding the cost of coolant | 1,10 |

| K10 - with a subsequent increase in drilling depth by step = 50cm from the base 1m | 1,05 |

| K11 - if it is necessary to carry out work from 22.00 to 8.00 (night time) | 1,10 |

| K12 - if it is necessary to carry out work on weekends and holidays | 1,25 |

| K13 - when carrying out work in dangerous places and at heights | 1,10 |

Concrete drilling

Diamond drilling services: Drilling reinforced concrete and drilling concrete walls, floors and foundations today are in great demand among organizations that equip facilities with utilities, as well as other construction and design organizations in Moscow and the Moscow Region.

Drilling holes in concrete

When drilling holes in concrete, diamond bits are used, which smoothly and accurately make a hole in concrete, reinforced concrete (monolith) and brick. Drilling concrete walls and covers for utility lines is the main activity of the Buravchik in Moscow and the Moscow region.

Diamond drilling for concrete

Diamond drilling of concrete and reinforced concrete (monolith) is performed by experienced specialists from the Buravchik in Moscow and the Moscow Region. Our master operators use high-quality equipment to drill holes in concrete, reinforced concrete and other types of building materials.

Scope of application of diamond drilling of holes in concrete, walls and ceilings:

- Drilling holes with diamond core bits in floors and walls for laying communications for heating, ventilation and air conditioning;

- Drilling holes with diamond core bits for installing plumbing fixtures and shower cabins;

- Drilling holes with diamond core bits for installation of fire extinguishing and alarm systems;

- Drilling holes with diamond core bits for laying communications for swimming pools, baths and saunas;

- Drilling holes with diamond core bits in vents and foundations of houses and cottages;

- Drilling holes with diamond core bits for laying communications for water supply and sewerage;

Diamond drilling of holes in Moscow and the Moscow region, diamond drilling of walls and diamond drilling of floors from the company Buravchik . Diamond drilling of holes in concrete and drilling of holes in the wall exactly according to the specified dimensions of the customer and design documentation.

Diamond drilling of holes in concrete at an angle

Advantages of diamond drilling for concrete:

- No vibrations harmful to concrete and brick, no cracks;

- Working with materials in hard-to-reach places;

- Round, geometrically precise holes in concrete, brick;

- No noise and dust;

- Large depth and diameter of holes in walls and ceilings;

- Possibility of drilling in concrete, brick, reinforced concrete at an angle of 45 degrees;

- Speed of diamond drilling in concrete, brick without loss of quality;

Diamond drilling price and diamond drilling prices can always be found out from our managers by calling the company office. The price of drilling holes in brick, as well as diamond drilling of concrete, will pleasantly surprise you.

Diamond drilling technology for concrete and reinforced concrete

Diamond drilling of holes in concrete, reinforced concrete, brick is by far the most advanced method for making technological holes for laying utility lines in buildings, structures and premises. With diamond drilling, holes in concrete are smooth, and the accuracy of drilling holes in concrete and brick corresponds to the specified dimensions.

For these tasks, a drilling machine was selected, for which diamond drills and diamond core bits are selected to match the required hole size. On one side of the diamond bit there is an element that is attached to the motor shaft of the drilling machine. On the other side of the diamond crown there are cutting elements (teeth - segments) that contain diamonds.

When drilling holes in the wall and ceiling, the crown heats up to high temperatures. To cool diamond bits, water is used, which is supplied through a diamond drilling machine to the diamond bit, thereby cooling the bit to the desired operating temperature.

Diamond drilling of holes in concrete walls

The main processes during diamond drilling of holes in concrete:

- Preparing a workplace for diamond drilling;

- Installation and fixation of the bed;

- Installation of a bur motor with a fixed crown;

- Organize a water supply to cool the diamond bit;

- Starting the machine and checking it for play;

- Implementation of the process of diamond drilling of holes in reinforced concrete, concrete;

High-quality and inexpensive drilling of reinforced concrete (monolith) and drilling of concrete walls with a surveyor visiting the customer’s site in Moscow and the Moscow region. Drilling prices are always acceptable for construction organizations. Diamond drilling of concrete and concrete drilling price on our website in the price list.

Security measures

During work, it is imperative to use personal protective equipment. During drilling, strangers should not be allowed closer than 2 m to the work site. If drilling is carried out at a height, a ladder cannot be used, it does not provide reliability. Only stepladders or scaffolding are acceptable. It is necessary to start working with low speeds, gradually increasing them in the process. You should not turn on equipment that is pressed tightly to the surface, otherwise the crown may be twisted. When drilling the surface under the plaster, you should pay attention to where the communications are laid.

Diamond drilling

| Hole Diameter (mm) | Brick | unreinforced concrete | Concrete with reinforcement up to 12 mm |

| up to 72 | 9,00 | 13,00 | 15,00 |

| 82-102 | 11,00 | 15,00 | 17,00 |

| 112-122 | 12,00 | 18,00 | 20,00 |

| 132-142 | 14,00 | 19,00 | 23,00 |

| 152-162 | 16,00 | 20,00 | 25,00 |

| 172 | 18,00 | 23,00 | 29,00 |

| 180 | 21,00 | 28,00 | 33,00 |

| 200 | 24,00 | 31,00 | 37,00 |

| 220 | 27,00 | 33,00 | 41,00 |

| 250 | 32,00 | 38,00 | 47,00 |

| 270 | 37,00 | 45,00 | 54,00 |

| 300 | 41,00 | 52,00 | 60,00 |

| 320 | 47,00 | 60,00 | 69,00 |

| 350 | 53,00 | 70,00 | 78,00 |

| 400 | 65,00 | 80,00 | 94,00 |

| 450 | 79,00 | 95,00 | 107,00 |

Technical requirements for the facility

1. Availability of power supply 220V/6kW 2. Access to water supply no further than 50 meters 3. Marking of hole centers at the drilling site 4. Access to the work site 5. Availability of scaffolding for drilling heights above 2 meters

Diamond equipment: surgical precision and high quality work

One of the advantages of the method is the absence of restrictions in terms of working with materials of different hardness. Using a diamond tool you can make holes in:

• concrete and reinforced concrete;

• natural and artificial stone;

• brick;

• ceramics;

• asphalt;

• granite, etc.

However, one of the main advantages of the method is the ability to create ideally shaped holes that do not require additional processing or grinding. All this allows you to save your time and money. While making a hole, the drill can deviate to the side by no more than 0.1 millimeters, which indicates the surgical accuracy of the diamond tool settings.

The advantages include:

- adjustable speed;

- durable body made of reliable materials;

- ability to connect to ungrounded sockets;

- the presence of systems for maximum operator safety when working with a drill.

Machines for diamond drilling of concrete surfaces - installation, assembly, work process on video, instructions for use

No matter which diamond drilling rig (Milwaukee), Dr.Schulze, Husqvarna, Diam, Messer or WEKA you need, we guarantee that by working with us, you will receive high-quality equipment that has all the necessary certificates. Our experienced manager-consultant will do everything possible to ensure that you choose the optimal installation option, taking into account the preferences, goals and allocated budget of the buyer. We value the reputation of our company, so we offer equipment only from trusted manufacturers who have proven themselves to be the best in their business.

Diamond crown

Diamond drilling of concrete is quite popular; it is used both for independent construction and on an industrial scale. This type of equipment for working on concrete surfaces has an impressive cross-section:

- Using such a device, you can quickly drill through a pipe, concrete wall, reinforcing bars, as well as foam concrete. This happens due to the special properties of diamond, which has increased hardness.

- This type of equipment includes a special tubular structure, which helps to drill to any depth in just one operation. To begin with, walls or pipes are drilled, and then one piece of concrete is pulled out of them.

- The device has one more feature - water cooling. At the same time, during operation of the device there will not be a lot of dust - this is an incomparable plus of the product.

- Using such a device, you can drill holes in foam concrete and other materials with a high level of accuracy. If its caliber is about 25 centimeters, then the resulting hole will be approximately the same size. There are no deviations from the norm or errors in the operation of the device.

It should be noted that such a good device also has its disadvantages. The main one is the high cost. The drill and the crown itself cost a lot. But if work is being done in the apartment to drill minor materials, for example, tiles, then you can buy small crowns, their price is affordable for any user.

This type of drill is usually mounted on drills or hammer drills that are not cooled with water. They have a certain limit on the depth of drilling performed, due to a certain volume of cladding. In this case, we are talking about a diamond-type drill, which creates a hole at absolutely any angle.

The main advantages of the device can be considered the ability to drill various building materials - porcelain stoneware, granite, brick and some others .

Diamond drilling for concrete

Application of diamond drilling rigs

The areas of application of diamond drilling technologies in construction are expanding year after year and continue to displace less efficient jackhammers and rock drills, as they represent progressive methods of work that cause less damage to building structures when making holes in concrete. Drilling holes with high-performance diamond drilling installations allows you to perform work in residential and non-residential premises without violating the integrity and load-bearing capacity of reinforced concrete structures. Diamond drilling is characterized by a low level of vibration, a complete absence of dust and a large selection of diamond bits with a diameter from 12 mm to 650 mm, as well as the ability to drill to a depth of up to four meters. The use of diamond drilling units in construction and repair allows one to successfully cope with the following tasks: drilling holes in ceilings for pipes of water heating systems; drilling holes in concrete walls and ceilings for ventilation and air conditioning systems; drilling holes in foundations to connect heating, water supply and communications systems, drilling holes for other communication systems or to gain access to planes hidden behind the concrete surface. Sometimes drilling with diamond core bits is used to take samples from rocks, monolithic structures, and asphalt. Advantages of using diamond drilling installations: high speed of drilling hard surfaces (concrete, reinforced concrete, monolith, asphalt, brick, marble, granite, natural and artificial stone and others); precisely located holes of an ideal round shape that do not require additional processing; the reverse side of the drilled surface remains undamaged when the bit comes out, the drilled core remains inside the diamond bit; absence of dust, strong noise and vibrations; possibility of drilling to great depths. Very often, in work, simultaneously with diamond drilling installations, wall sawing machines, rope units and hydraulic concrete breakers are used, which makes it possible to significantly increase the pace of work. When working with diamond drilling installations, it is very important to securely fasten the frame; this will allow you to perform high-quality drilling to any depth, increase the life of the diamond bit, and avoid loosening and beating during work. There are several ways to securely install the frame: using a spacer rod, anchor fastening, fastening using a vacuum plate. Attachment using a spacer bar for diamond drill installation - the support post of the drilling unit is secured using a telescopic spacer bar between the floor and the ceiling of the surface. Anchor fastening - the installation frame is fixed to the load-bearing surface using a hammer-in anchor. Vacuum fastening - the installation is fixed to a smooth surface using a vacuum plate; this method allows you to perform work without damaging the surface. Fastening with a drive-in anchor is the most common method and the most reliable of all. Vacuum fastening can only be used on a perfectly flat surface and for crowns with a diameter of up to 200 mm. The set of equipment for diamond drilling includes: electric motor (drilling motor); support stand (bed); fastening kit (M12 drive-in anchor with stud and nut, or spacer rod); drill bits (diamond bits with diamond cutting segments); system for supplying and collecting water.

Technology for drilling holes in concrete

Making holes in concrete should begin only after marking the surface of the wall that will be used for work. It doesn’t matter whether an impact drill or a hammer drill is used, it is recommended to start work by switching the tool to a simple drilling mode at low speeds; in the no-impact mode, you need to make a recess. This approach will allow you to create a hole with less labor, and the drill will not move chaotically along the base, this will ensure the accuracy of the work. At the next stage, drilling can be done by switching the tool to impact mode and adding speed.

Table of minimum depths for planting dudels.

When using a plastic dowel, the hole should be made deeper than the length of the dowel.

Drilling involves the formation of a certain amount of crushed material in the hole, so you need to leave a length margin of 10 mm.

Drilling is a process that requires great physical effort, since the drill has significant weight, to which vibrations from the operation of the drill are added. You also have to deal with the fact that dust will come out of the hole. A dust collector, which can be purchased at a hardware store, will help with this.