Home |Blocks and floors |Swedish slab foundation

Date: April 24, 2017

Comments: 0

Construction technologies aimed at increasing the sustainability of constructed objects and creating a favorable indoor microclimate are developing at an accelerated pace. New methods of work using modern materials have affected the base of the building - the foundation, one of the common options of which is a slab-type foundation. The insulated Swedish slab is a type of monolithic foundation that represents a serious alternative to the traditional slab foundation.

Building foundations in the form of a solid slab are common for the construction of residential buildings on problematic soils with increased freezing depth. Developers experience many inconveniences associated with the significant costs of constructing the building base, the increased cycle and complexity of construction activities. The new technology for forming a monolithic concrete slab reduces the duration of the zero cycle.

The construction of a Swedish slab as a foundation for objects under construction makes it possible to combine in a high-tech design a reliable base of the building, an insulated floor of the lower floor and a space in which the installation of utility networks is carried out.

At the heart of any home is a foundation that determines its durability and reliability.

Let us consider in detail how a Swedish stove is constructed, which is characterized by increased energy-saving characteristics and an affordable price. Let us dwell on the design features and technological nuances.

Types of slab foundations, their characteristics

Currently, there are three types of slab foundations, each of which has its own distinctive features. The Russian version, which was designed by domestic designers, is considered traditional. The product is a thick monolithic reinforced concrete slab with massive ribs. The foundation is characterized by a large strength reserve and lack of deformation, due to which it can be used under extreme operating conditions.

Finnish slab manufacturing technology step by step

The disadvantages of the design include insufficient insulation and the need to pour concrete twice: the first - to create stiffeners, the second - to form the slab itself. However, this increases the service life.

The foundation is in the form of an insulated Finnish slab, originally from Finland. The design has a smaller thickness, but is characterized by sufficient strength. It is well insulated and adapted to a heated floor system. Such a foundation is a cold circuit. Thermal insulation with a thickness of at least 150 mm is mounted on the slab, cutting off the cold contour of the foundation from the warm floor of the first floor of the building, which is installed in an additional reinforced screed.

Less energy-saving, but more economical compared to the Finnish version, is the insulated Swedish stove. USHP does not require additional screed, since the heated floor system is mounted directly into the slab, the thickness of which reaches a minimum size.

What is USP: areas of use

The insulated Swedish foundation slab is represented by a shallow monolithic slab foundation. It has insulation along the entire perimeter and sole area. This is a finished rough floor surface of the first floor with built-in heated floor and utilities.

The high strength and heat resistance of the USHP foundation allows it to be used in difficult climatic conditions for buildings made of any material

This type of foundation is used in building projects without a basement or basement. It is advisable to use USHP technology for structures with a side size of 15 m in the following cases:

- for cold regions where, thanks to such a foundation, heat loss from the house is reduced;

- in areas with high groundwater levels;

- in projects of private houses where heated floors are used;

- in the case of using half-timbered technology, as well as in the process of creating a panel, panel or frame house;

- when choosing block or brick masonry;

- on heaving and weak soils that are not characterized by good bearing capacity, which requires the construction of bored or screw foundations.

Scope of application

The construction of buildings based on USP is widespread in Estonia.

USP can get the most popularity: [flat_ab id=”33"]

- in areas with a harsh climate (except for permafrost areas);

- in places close to the groundwater surface;

- for low-rise frame, panel, panel, block, brick construction;

- on soft soils.

USHP foundation design: cross-sectional photo of the product

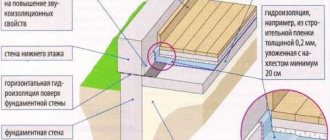

The structure consists of the following layers, which are clearly shown in the cross-sectional drawing of a Swedish foundation slab:

- concrete pouring;

Swedish slab foundation in section

- reinforced layer;

- depreciation layer;

- insulating layers.

A concrete pour, or monolith, is represented by a conventional foundation with a thickness of only 10 cm, thanks to which the structure is created in one day. This has a positive effect on the quality of the slab, namely: layering is eliminated and the cost of work is reduced. A heated floor system is laid in this layer. The base is insulated from the ground with insulation, which is represented by extruded slab polystyrene foam.

Reinforcement is also carried out in a short time due to the use of a small number of metal rods. A tightly knit reinforced mesh prevents cracking of concrete and prevents damage to the foundation due to natural soil movement.

The traditional depreciation layer, consisting of sand and crushed stone, which is used in a conventional foundation, is supplemented using this USP technology with a layer of clay. Thanks to this, geotextiles laid between mineral layers are not exposed to moisture. An additional waterproofing layer in the foundation is necessary in order to protect the structure from the influence of groundwater, which can erode the layers. In the thickness of the sand under a layer of insulation, sewerage and a water supply system are installed, the nature of which affects the price of the USP.

Reinforced mesh prevents cracking of concrete and prevents damage to the foundation

To create a durable and strong structure, it should be insulated, so that the foundation will not crack and heave during temperature fluctuations. The process is carried out using styrene derivatives, as a result of which the service life increases several times. The insulation is laid not only from below, but also vertically along the perimeter of the slab, duplicating the base formwork. Also, the layer is located under the blind area of the building horizontally at the depth of the base of the reinforced concrete structure. This technology increases the cost of USHP, but reduces further costs for heating the room.

Drainage communications are necessary to create a system for removing moisture from the foundation, which prevents it from damage. A waterproofing layer with vapor barrier properties protects concrete from moisture.

Advantages and disadvantages of USP foundation

The USHP foundation, which can be ordered from any large construction company, is characterized by a number of distinctive advantages:

- low cost of work, which is associated with a small amount of building materials and the involvement of a small number of workers;

Heating (warm water floor system) and other utilities are built into the Swedish stove

- high speed performance;

- thanks to the additional layer of insulation, the possibility of freezing of the soil under the base of the foundation is eliminated, which will save the slab from heaving and shrinkage of the base;

- the foundation slab is a full-fledged subfloor on which tiles can be laid without first leveling the surface;

- installing a heated floor in the foundation will reduce heating costs in the future due to lower thermal energy consumption;

- the insulation is characterized by high compressive strength and shrinks the building by 2%;

- the thermal insulation layer is not affected by moisture, which increases its service life;

- due to the fact that the foundation is insulated, dampness and mold will not form in the house;

- the appearance of insects and rodents is excluded in the insulating layer;

- the small thickness of the thermal insulation layer provides the required thermal conductivity coefficient;

- the presence of edges on the thermal insulation slabs eliminates the creation of cold bridges;

- the plate simultaneously performs heating, thermal insulation and load-bearing functions;

The base of the USHP foundation is already a subfloor, ready for any floor covering

- has a durable design while maintaining all technical and economic characteristics;

- due to its high heat capacity, it can be used in regions with cold climates.

Disadvantages of USP:

- the foundation slab is created exclusively on a reliable foundation, which excludes its installation on muddy, peaty or vegetative soils;

- a significant part of the engineering communications is located in the thickness of the slab, as a result of which access to them is limited;

- USHP cannot be used in the construction of heavy multi-story buildings;

- the foundation excludes the creation of a basement in the house.

Useful tips when installing a foundation

The Swedish foundation consists of several layers, each of which has an important functional purpose. It is very important to properly organize each layer in order to obtain a reliable, strong and durable structure. There are important points to consider here. The thickness of the sand or gravel substrate is determined based on the type of soil, that is, it depends on its bearing capacity. This value is in the range of 300-600 mm, which affects the price of the USP foundation. For the hardest, densest soils, the minimum value is used, and for heaving soils, the maximum value is used.

USP is a combination of a strip base and a concrete floor, which is why this type of base requires precision calculations and adherence to clear technology during construction

Before building a slab foundation, the top layer of soil should be removed. Using a level and a building level, the verticality and horizontality of the surface is checked. The pit must have larger dimensions than the perimeter of the slab. For this purpose, it is necessary to retreat 50-70 cm from the edges of the base markings on each side.

Plates of insulating material should be laid over the entire surface of the foundation. It is not recommended to fasten them with additional adhesive. To create a uniform, dense layer, concrete pouring must be done in one go. Therefore, it is important to correctly calculate the amount of material required to fill the formwork.

Helpful advice! The best option for installing USHP is considered to be concrete of class B20-B25.

Before starting construction, pipes for all communications should be prepared and a diagram of their location should be developed. It is necessary to provide a drainage system along the perimeter of the foundation, which ensures the removal of moisture from the base of the building.

It is important that communications are buried below the soil freezing mark in winter

Design

In order to begin installation work, you need to carefully design the USP foundation. The calculation must be made based on the design of the building itself. The need to take into account design data ensures the correct location of all necessary communications. When designing a foundation, you can only rely on primary sources provided by Swedish manufacturers, because Russian analogues of the calculation do not yet exist. Many construction companies have developed instructions that describe only the sequence and correctness of the work on forming the foundation.

Survey work, USP calculation and terrain tracing

Survey activities precede the start of construction. They are carried out to determine the nature of the soil and its bearing capacity. The level of groundwater in the area, the composition of the soil and possible fluctuations in the lower layers of the soil are clarified. These indicators must be as correct and accurate as possible in order to subsequently provide a solid foundation. Therefore, here you should use the services of specialists.

The main difference between the calculation of an insulated foundation slab is the sequential determination of the parameters of each layer during construction, taking into account actual loads and impacts. For this purpose, special computer programs are used that determine the individual characteristics of the foundation.

Helpful advice! It is better to design a Swedish foundation with the involvement of professionals, which will avoid many errors in the calculations.

After all the preparatory measures have been completed, they begin directly to build the foundation. To do this, you should mark the territory, which is the drawing of full-scale axes. The contours of the pit are outlined along the ground, cast-offs are installed along which the cords necessary for installing the formwork are pulled. The main advantage of cast-offs (compared to conventional pegs) is the convenient U-shaped design, the position of which is leveled once in the horizontal plane. If the cord is temporarily removed when necessary, no adjustments are required once it is in place.

Before laying the foundation, survey work is carried out, which is aimed at determining the type of soil and its bearing capacity

The pit should be planned larger than the foundation slab. An allowance of about 1 m should be left on each side. Such indents will be used for installing drainage. This can be a ring drainage to lower the groundwater level or a wall drainage used to drain high water, which is formed with the constant accumulation of rain and flood waters of the underlying layer in technogenic zones.

USP: how to reduce the cost

The technology belongs to the group of shallow foundations, so a significant part of the money can be saved on renting special equipment used for digging pits - the procedure can be done manually. Knowing the cost of installation services of construction companies, we can conclude: making a USP yourself, with the help of friends or relatives, will save a significant part of the budget.

Attention! Unfortunately, it will not be possible to reduce the cost of delivering concrete - the slab must be poured as quickly as possible in one go.

Another of the few saving options is the use of L-shaped slabs when installing formwork. In this situation, there is no need to use additional materials.

However, in order for the foundation to last as long as possible, experts strongly do not recommend saving on other materials: sand, concrete, reinforcement, polystyrene foam. Only with full compliance with the design technology can it be guaranteed that the structure will last at least 50 years.

List of required materials and tools

Doing USP with your own hands is not as difficult as it seems at first glance. Before starting work, it is necessary to have a design for a new building and determine the location for construction. You can, of course, use the services of specialists and order a turnkey USHP foundation. However, strict adherence to technology and the use of high-quality materials will allow you to independently create a solid and reliable foundation for subsequent construction.

Before pouring concrete, it is necessary to prepare a flat area and compact it properly with a special machine.

List of materials required for the construction of the USHP foundation:

- medium sand;

- medium-sized crushed stone;

- geotextiles;

- extruded polystyrene foam 100 mm thick;

- drainage pipes;

- wooden boards;

- reinforcement bars;

- knitting wire;

- pipes of different diameters for utilities and water heated floors;

- nylon clamps;

To work you will need the following tools:

- scoop and bayonet blades;

- wheelbarrow;

- level;

L-blocks are lined with flat slate for laying the foundation

- building level;

- screwdriver;

- knife;

- Bulgarian;

- vibrating plate;

- deep vibrator;

- hacksaw;

- concrete mixer;

- trowel;

- protective clothing.

Preparatory operations

- The pit for the foundation is being prepared; for this, a layer of soil with a depth of 10 to 50 cm is removed according to the dimensions of the future foundation.

- If the soil on which the USHP foundation will be installed is very wet, you must first perform drainage and drain the groundwater. The drainage layer is a cushion made of crushed stone and coarse sand.

After arranging the drainage, geotextiles are laid at the bottom of the pit, and sand of a certain fraction, which is provided by the technology, is poured on top of it in layers and compacted.

- USP foundation, laying communications. This operation is quite responsible. It is necessary to provide for all inputs - sewer, electrical, water supply, etc., which must be laid with particular precision to ensure the correct connection of communication systems in the house.

- The formwork is being installed. After that, crushed stone is poured on top of the laid sand and compacted. This layer should be about 100 mm.

Excavation work and creation of a drainage system

A warm foundation cannot be laid on a plant layer whose thickness does not exceed 0.3-0.5 m, so it should be removed completely. To do this, you can use bayonet shovels. If the foundation is laid on a fertile layer, it will inevitably shrink, which will be a consequence of rotting organic matter.

Before pouring the USHP foundation, you need to remove the fertile layer, fill it with sand and compact it

Helpful advice! To be safe, it is recommended to treat the area cleared of vegetation with chemicals that stop further plant growth.

After removing the soil, the surface must be compacted using clay, which, in dry crushed form, is poured into the pit, moistened and compacted. Next, geotextiles are laid. The ends of the woven fabric should protrude beyond the future foundation by at least 30 cm.

In order for the slab to always remain dry, it is important to properly organize the drainage system, thanks to which groundwater, storm water and melt water will be drained from the base of the foundation. For this purpose, it is necessary to make a trench along the entire perimeter of the pit with a depth equal to the diameter of the perforated pipes that will be used for drainage. Here you should slope away from the building by 3-4 degrees, which will ensure gravity flow. It is necessary to install vertical wells in the corners of the building, which will provide access to the drainage system for periodic cleaning.

In order for the slab to always remain dry, it is important to properly organize the foundation drainage system

The sequence of actions is as follows:

- a layer of crushed stone is laid on the geotextile;

- in the corners of the structure, wells are installed, which are created from solid smooth or corrugated pipes with a diameter of 20-30 cm, installed vertically;

- installation of corrugated pipes along the perimeter of the building with the ends entering adjacent wells, where the corresponding holes are made;

- filling the trench with crushed stone, which is covered with geotextile on top.

Construction procedure for USHP

- Development of a pit;

- Drainage device;

- Construction of crushed stone-sand foundation;

- Installation of L blocks simultaneously with the input device and laying of all utilities;

- Laying vertical thermal insulation;

- Reinforcement device for load-bearing beams;

- Device for reinforcing a concrete screed with simultaneous installation of a water-heated floor;

- Installation of underfloor heating collectors and outputs of all utilities;

- Concreting the slab;

- Grouting the surface;

- Curing;

USHP base structure

Pit development

The foundation of the foundation pit is one of the most important stages. It should be smooth and uniform.

The soil and vegetation layer of the earth is removed after preliminary breakdown of the building on the land plot. The crushed stone-sand base is poured and compacted, and drainage is performed along the perimeter of the foundation.

It is necessary to pay attention to the accuracy of excavation at the design level and protection from waterlogging during construction and the quality of layer-by-layer compaction of the base. It is recommended to complete the excavation to the bottom mark manually to prevent loosening of the continental soil.

All elevations of the pit are controlled using a level.

Removing the fertile layer when preparing the base of the USP with an excavator

Drainage device

Foundation drainage eliminates the risk of excess moisture getting under the base of the slab.

The trench for drainage is made with a slope towards draining water from the site. A 3-meter wide geotextile sheet is laid and placed on the bottom of the drainage trench.

Next, the base is filled with crushed stone. A drainage pipe is laid on the prepared base. In accordance with the project, drainage inspection wells are installed.

The pipe is covered with crushed stone and wrapped with the edges of the geotextile sheet free from backfill.

Drainage system around the entire perimeter of the pit

Construction of crushed stone-sand base

The base transfers the load from the slab to the ground and back, the density must comply with the standards and be uniform and even over the entire area.

Geotextiles are laid over the entire excavation area with release onto the walls of the pit. Foundation preparation may include crushed stone, sand, ASG and other materials, in accordance with the design solution of the working design.

The base material is laid on geotextiles and compacted layer by layer with vibratory compactors. The material is additionally moistened before compaction. The backfill level is controlled by a level and smoothed to create a flat surface so that the thermal insulation is laid tightly, without air gaps.

Compaction of sand base with ramming

Thermal insulation of the slab and laying of communications

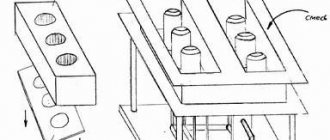

L-block installation

L blocks are installed along the perimeter of the USP, performing the function of permanent formwork, which in the future will be the basement part of the building. The L blocks are connected to each other using polyurethane foam glue and plastic fasteners for thermal insulation.

Installation of L-block formwork

The characteristics of thermal insulation in places of support of load-bearing walls are determined by structural design calculations. (If L blocks are not made, then wooden formwork will be required, which will increase the time and cost of the work).

Laying out utilities and creating a shock-absorbing cushion

Next, they begin to arrange a shock-absorbing cushion about 15 cm thick from gravel or crushed stone with fractions of 20-40 mm in size. The base is filled with fine sand, which is compacted every 20 cm with a hand tamper or vibrator until the design mark is reached.

All utilities must be laid before creating a monolithic foundation, so they are placed on a sand cushion with compaction according to the wiring plan below the freezing level. All ends of the pipes must be brought to the surface for further connection of the system. To increase the maintainability of networks, it is better to lay pipes in cases of larger diameter. For the sewer system, a well should be provided outside so that sewer inspection and repair can be carried out.

All existing pipes from under the foundation must be brought to the surface for further connection of systems

Helpful advice! As a backup option in case of failure of the main communications, a duplication of the engineering system is created, which can be switched to when repairing the old one.

After laying all utilities, the surface is covered with a small layer of gravel up to 15 cm thick, followed by compaction. For good waterproofing, the base is covered with waterproof material. Here you can use both inexpensive roofing felt and more modern products. The canvases are laid with an overlap of 10 cm and the joints are sealed. The edges of the waterproofing material must protrude beyond the foundation by at least 15 cm.

What to check during installation

Sand layers must be compacted layer by layer. If compacted manually, the layers should not exceed 10 cm. If compaction is done using special equipment, depending on the weight of the apparatus, the sand layers should be from 10 to 20 cm.

The foundation should be poured in one go - the frequency of concrete delivery should be less than an hour. Due to the large number of communications, the slab must be compacted with deep or surface vibrators.

Attention! When pouring concrete, the floor insulation system must be under pressure, which must be maintained a day after pouring. This is the only way to check the integrity of the system during installation.

Installation of a thermal insulation layer for a USHP foundation

Insulation of the foundation is an important measure, thanks to which heat does not escape from the building into the ground, and cold does not penetrate from the soil into the room. The insulation must have high strength. Therefore, in USP technology it is recommended to use slabs made of extruded polystyrene foam, which (due to the presence of graphite in their composition) are characterized by increased compressive strength.

Helpful advice! Expanded polystyrene can harbor ants and other insects. Therefore, the material needs additional protection. Here it is recommended to use broken glass, metal mesh or ceramic foam slabs.

Extruded polystyrene foam slabs for the blind area were laid and covered with film

The material in the form of slabs 10 cm thick must be laid in two layers. The first should cover the entire perimeter of the base and the blind area. The second layer should be laid offset from the edge by at least 45 cm, which will create stiffening ribs. In the middle of the slab, in the thermal insulation layer, grooves 20-30 cm wide are made for future load-bearing walls, under which the insulation does not fit.

When using flat sheets of insulating material, special plastic nails with wide heads are used to fasten them. The contact points can be treated with an adhesive composition. It is recommended to arrange the elements in a checkerboard pattern, which will help to avoid the formation of cold bridges at their junction points. You can also use l blocks for USHP, which are mounted at the ends of the structure. Having a special design, they do not require additional fastening during installation.

Which insulation is better to choose for the foundation?

Today, the construction market offers a wide range of insulation materials from the well-known Stirex, Technoplex, Penoplex and URSA. The PSB-S material is not suitable for these works, since it is produced without a pressing stage.

The thickness of the foundation insulation is determined by many different factors.

Among all the proposed options, extruded polystyrene foam Penoplex occupies a leading position. The cost of the product is 1200 rubles/pack. The material is characterized by a number of distinctive advantages:

- durability;

- multifunctionality, since it simultaneously creates hydro- and thermal insulation;

- environmental safety;

- increased resistance to moisture;

- not prone to the emergence of various microorganisms in the thickness of the layer.

Also no less popular is the insulation for USHP TechnoNIKOL. The material does not absorb moisture, does not shrink, does not swell, is characterized by a low thermal conductivity coefficient, exhibits chemical resistance and does not rot. To produce extruded polystyrene foam, TechnoNIKOL uses nano-sized carbohydrate particles, which increases the strength of the material, reducing its thermal conductivity, thereby increasing energy efficiency.

Insulating the foundation is a very important task, therefore, when choosing a suitable material, it is necessary to take into account its characteristics

The material is characterized by high compressive strength and stable thickness under load, as a result of which it can be used for loaded structures. You can buy the material from 1400 rubles/pack, the cost of l blocks for USP is on average 1300 rubles/pack.

At this stage, wooden formwork is laid under the future monolithic tile. To do this, racks are mounted to which the edged boards are attached using self-tapping screws and a screwdriver. The wooden frame is additionally reinforced with braces to give the structure greater strength. The formwork is lined with heat-insulating material from the inside. After the slab has gained sufficient strength, the fence is dismantled, and the insulation remains as protective sides for the lower part of the building.

The value of a double layer of thermal insulation and a heated floor system for a home at USHP

Due to the fact that USHP technology requires laying thermal insulation material in two layers, all the heat will remain in the house. The first layer of 10 cm along the entire perimeter of the base prevents the penetration of moisture. Another 10 cm of thermal insulation creates a good barrier against the cold that comes from the ground.

Since the heated floor is poured into concrete, the monolithic slab serves as an excellent heat accumulator

Thanks to the underfloor heating system, which is installed in separate circuits in each room, uniform heat distribution in the room is ensured and climate zones are adjusted. If you create the necessary insulation of the walls and roof of the building, it will be enough to maintain the temperature in the heating system no more than 28 degrees, which corresponds to the temperature of the circulating fluid (31-32 degrees), in order to create a comfortable microclimate in the house. However, this also depends on the finishing floor covering. Such measures will provide an additional benefit when using low temperature heat sources such as gas condensing boilers and heat pumps.

Thanks to the foundation in the form of a warm Swedish stove, you can save about 30% on heating. This is possible due to the fact that the underfloor heating system heats the concrete slab, and the concrete accumulates heat into the room. The thermal conductivity coefficient is 0.17 W/m²K, and for non-insulated concrete bases it is 0.4 W/m²K.

The essence of technology

Schwedenplatte technology allows you to build a modern foundation, which has the following characteristics:

- multifunctionality;

- use of innovative materials for heat and waterproofing;

- combination: foundation plus subfloor of the 1st floor;

- laying all communications before concreting the USHP.

Appearance of a Swedish warm stove

European countries have been using insulated foundations for a long time, but on the Russian market the technology is still considered progressive and little known. This slab perfectly combines all the costs and quality of the finished base. All financial investments in foundation operations pay off within a short time - operating a house on USHP implies high energy savings.

A Swedish foundation is laid for one- and two-story houses, the walls of which are made of timber, brick, logs or stone.

Reinforcement of the Swedish slab foundation and installation of heated floors

Foundation reinforcement is performed to allow the structure to absorb tensile loads. The technology is performed according to the following scheme:

- creation of stiffening ribs for the grillage: frames are laid from reinforcement 10-16 mm thick, connected with rectangular clamps 6-8 mm in increments of 300 mm, taking into account the protective layer of concrete;

Cutting reinforcement for USHP foundation

- slab reinforcement: installation between the stiffeners of two reinforcing mesh with cells 150x150 mm from rods 10-14 mm thick, cell width 15 cm with tying structural elements with twisted wire every 25-30 cm.

The thickness of the rods is selected taking into account structural, snow and operational loads on the surface. Utilities should not be installed in stiffeners. In order not to damage the insulation, it is recommended to assemble the spatial reinforcement frame separately, and then you need to lay it ready-made on special clamps in the grillage area where the frames are connected to each other. The mesh for the slab is tied on site. The lower structure is installed on PVC clamps.

The technology of the Swedish insulated slab involves the installation of a heated floor in the thickness of a monolithic foundation. The heated floor contour is laid on the upper mesh and secured with nylon clamps. In this regard, the thickness of the upper protective layer of concrete should be taken into account, which should be 50-70 mm. In places where load-bearing walls or doorways are located, pipes should be placed in sleeves made of durable material. There must be a distance of at least 10 cm between the pipes.

It is better to fasten the reinforcement with a special gun

If the laying is more dense, this will not affect the efficiency, but will result in excess consumption of material. A distance exceeding 25 cm will impair the uniform distribution of heat over the surface. Near the walls, pipes must be placed more densely than in the central part of future premises. An indentation of about 15 cm should be made from the wall.

Important! The heating pipes of a water heated floor should be arranged in an insulated circuit for each room separately, which will allow each room to be heated independently of the others.

The distribution elements of the system are brought up and fixed on rods hammered vertically. The collector should be located in the place provided for by the design at a given height. To install it, four reinforcing bars 1.5 m long are driven into the foundation. A board is fixed to them and the collector is temporarily fixed. Heated floor pipes are connected to it. Where flexible pipes rise to the collector, they must be protected using a special corrugated pipe.

Important! The heating system must be tested for leaks by filling it with coolant.

In a USHP foundation, the entire area is covered with welded reinforcing mesh, and reinforcement bars are used in the stiffeners

Structural reinforcement

This process has its own characteristics and involves two successive stages:

- For the grillage, a special longitudinal spatial structure is made with a step of transverse dressings of 300 mm. The diameter of the fittings used should be 12 mm. It is necessary to produce only a bunch of reinforcement by twisting, which will be installed on the USP foundation; the technology does not allow the use of welding. Welded connections of reinforcement can affect the strength of the future foundation monolith. This reinforced structure is assembled outside the foundation, and then transferred to it and installed.

- The foundation surface is being reinforced. This work must be carried out using reinforcement with a diameter of 10 mm. The rods are laid longitudinally in increments of 150 mm, after which transverse rows are laid at the same distance and the reinforcement is tied together. The overlap of the joined rods cannot be less than 25 mm.

USHP foundation: foundation concreting technology

The final stage of installing an insulated foundation slab is pouring the base with concrete mortar. The important thing here is to do the process one time. To do this, you can use a concrete mixer truck with an installed concrete pump. The solution is evenly distributed over the surface using shovels and trowels. To obtain a uniform surface, the fill should not spread over a distance of more than 1.5 m in diameter.

Batch filling can be done at intervals of 1 hour. If it is necessary to interrupt for a longer period of time, work seams should be arranged. After resuming work, they are moistened with water and treated with a cement laitance primer. The solution should be compacted using a vibrating plate or deep vibrator.

To ensure that the final surface is smooth, the base is sanded. This is an important undertaking because the concrete slab is the floor of the first floor. Otherwise, you will have to spend additional money on a leveling screed.

Helpful advice! It is recommended to build a USP foundation at the end of summer, when the groundwater level drops.

The work on the USP foundation is being completed by pouring concrete and grinding it.

During the hardening period of the base, proper care of the concrete surface should be provided. In hot weather, it is necessary to moisten the foundation and cover it from precipitation with plastic film. Stripping can be carried out after 48 hours at a temperature of 30 degrees, and after 5-7 days - in cold weather at a temperature of 10-12 degrees.