Today, when building a house, more and more demands are placed on building materials. One of the most important is a reasonable ratio of quality and affordability. People are starting to save money and prefer to build on their own. Manufacturers, in order not to lose customers, are trying to satisfy demand and fill the market with inexpensive but effective goods.

Foam concrete has become an excellent solution to pressing problems. Positioned as a budget replacement for brick, it surpassed it in many performance indicators. At the same time, the simple production process and low cost have led to its widespread use in private and industrial construction.

What are the advantages and disadvantages of aerated concrete?

Foam concrete, or aerated concrete, is a building material that is very common due to its cheapness and reliability. In addition, there are many more positive properties and characteristics that developers pay attention to first. For blocks of standard size 20x30x60 mm these are the following parameters:

- High thermal insulation coefficient - its values are shown in the table below. Buildings do not require additional insulation;

- Quick installation using special adhesive for foam blocks. A small gap between products is ensured by high dimensional accuracy of construction products, so the quality of the connection increases, and the adhesive consumption for foam blocks per 1 m2 is reduced by 20-25%. In addition, the larger size than brick also allows for increased masonry speed;

- Cheap production and inexpensive construction process due to savings on delivery and movement around the construction site.

| Construction material | Brand | Thermal conductivity W/m°C | |

| Sand | Ash | ||

| Thermal insulation | D300 | 0,09 | 0,09 |

| D400 | 0,11 | 0,1 | |

| D500 | 0,13 | 0,13 | |

| Structural and thermal insulation | D500 | 0,14 | 0,14 |

| D600 | 0,15 | 0,14 | |

| D700 | 0,19 | 0,16 | |

| D800 | 0,22 | 0,19 | |

| D900 | 0,25 | 0,21 | |

| Structural foam block | D1000 | 0,3 | 0,234 |

| D1100 | 0,35 | 0,27 | |

| D1200 | 0,39 | 0,3 | |

| Plaster layer | — | 0,59 | — |

| Brick building | — | 0,57 | — |

There are two main negative points:

- High coefficient of moisture absorption per cubic meter. This drawback is corrected by waterproofing the walls of the building, which makes construction more expensive;

- Reduced strength compared to concrete and brick. The service life of structures made of foam concrete is up to 50-100 years;

- The unpresentable exterior of the products forces one to resort to exterior decoration of buildings.

Advantages

Subject to compliance with GOST in the production of foam blocks, its advantages are as follows:

- The strength of the product can reach 1200 kg/m2;

- Long service life - up to 50-100 years under correct operating conditions;

- Light weight (35 kg with dimensions 20x30x60 cm, or 580 kg per cubic meter), simplified installation and, due to this, reduced construction time;

- Due to the light weight of the entire structure, it is possible to erect an MZLF or columnar foundation for a building made of foam blocks, which is much cheaper than other projects;

- Low thermal conductivity (0.1-0.4 W/m°C) and high sound insulation coefficient (48 dB per square meter) due to the porous structure of the material;

- High fire resistance (NG group) and fire safety;

- Ease of machining: the blocks are easy to cut, saw, plan and drill. This quality allows you to quickly and easily lay routes for various utilities in foam walls;

- Low cost of producing foam blocks, low consumption of glue for foam blocks;

- High biological resistance - the building is not prone to fungal diseases and mold development on foam concrete walls;

- Maintaining an optimal microclimate in a house made of foam concrete products due to its porosity, which allows the walls to “breathe”.

| Properties | Parameter |

| Weight | Weight - from 6 to 35 kg |

| Density | Designation – D, value – 500-1300 kg/m3 |

| Dimensions | The standard block has a size of 20x30x60 cm |

| Moisture absorption | 15-20% per 1 m3 |

| Thermal conductivity | 0.1-0.5 W/M°K |

| Compressive strength | 2.0-7.0 MPa |

| Compound | Cement, foaming agent, sand, water |

| Sound absorption | ≤ 48 dB |

Flaws

The main and most common drawback of foam blocks is non-compliance with GOST in the manufacture of building products. Among the physical and technical indicators, the following insufficiently high parameters are noted:

- Frame construction technology, which requires fairly high labor costs and highly qualified builders. Although building with brick, wood or concrete is still much more expensive;

- The porosity of the building material means high moisture absorption, which worsens the air exchange characteristics;

- The need for external and internal decorative finishing of the building due to the unattractive appearance of foam concrete walls;

- Fragility of the material;

- Finishing work is recommended to be carried out only 2-4 months after completion of construction;

- Foam blocks must be covered with special paints or a layer of plaster;

- When laying products on glue for foam blocks, be sure to build in reinforcement to increase the strength and reliability of the structure. Standard consumption per 1 cubic meter. – according to the manufacturer’s recommendations;

- Long-term development of residual strength after the facility is put into operation - at least four weeks;

- There is a high probability of shrinkage of the building, which can lead to cracks in the walls.

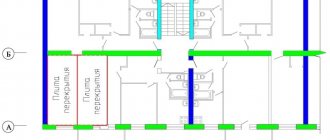

Using an online calculator for calculations

Currently, the fastest and easiest way to calculate the required number of foam blocks to build a house is to use special online calculators available on construction websites on the Internet. This service is completely free.

You must enter the required parameters in the appropriate fields:

- length, width and height of all walls;

- the number and dimensions of all window and door openings in the walls;

- geometric dimensions of the foam block used.

After clicking the “Calculate” button, we instantly get the required result.

Most online calculators, when calculating the number of foam blocks required for building a house, simultaneously provide a number of other important and necessary parameters, such as the volume of foam blocks in cubic meters, the number of pallets required for transportation, etc.

In the next article we will tell you how to calculate the amount of siding for cladding a house.

Block sizes and masonry sizes

According to GOST 13015.1, ten standard sizes have been developed for foam blocks with glue, and eight for the construction of walls with cement-sand mortar.

The following standard sizes (in cm) have been developed for adhesive masonry:

- 18.8 x 30.0 x 58.8;

- 18.8 x 25.0 x 58.8;

- 28.8 x 20.0 x 58.8;

- 18.8 x 20.0 x 38.8;

- 28.8 x 25.0 x 28.8;

- 14.4 x 30.0 x 58.8;

- 11.9 x 25.0 x 58.8;

- 8.8 x 30.0 x 58.8;

- 8.8 x 25.0 x 58.8;

- 8.8 x 20.0 x 39.8.

The following standard sizes (in cm) have been developed for cement masonry:

- 19.8 x 29.5 x 59.8;

- 19.8 x 24.5 x 59.8;

- 29.8 x 19.5 x 59.8;

- 19.8 x 19.5 x 39.8;

- 29.8 x 24.5 x 29.8;

- 9.8 x 29.5 x 59.8;

- 9.8 x 24.5 x 59.8;

- 9.8 x 19.5 x 39.8.

The maximum length of the product according to GOST 21520-89600 is 60 cm.

Garage projects

- 2 rooms

- 1 bathroom

- 192.58² Total area

- 19 x 9m Construction area

- 2 rooms

- 1 bathroom

- 105.8² Total area

- 12 x 6m Construction area

- 28² Total area

- 4 x 8m Construction area

- 158² Total area

- 36² Total area

- 6 x 6m Construction area

- 37² Total area

- 10 x 5m Construction area

- 42² Total area

- 5 x 9m Construction area

- 11.7² Total area

- 3 x 4m Building area

- 143² Total area

- 21 x 7m Construction area

- 89.79² Total area

- 12 x 7m Construction area

- 31.8² Total area

- 6 x 5m Construction area

- 37² Total area

- 6 x 6m Construction area

- 24² Total area

- 6 x 4m Construction area

- 33² Total area

- 6 x 6m Construction area

- 20.6² Total area

- 6 x 4m Construction area

- 27² Total area

- 6 x 6m Construction area

- 40.6² Total area

- 6 x 7m Construction area

- 58² Total area

- 10 x 6m Construction area

- 1 room

- 1 bathroom

- 48.97² Total area

- 12 x 5m Construction area

- 22² Total area

- 4 x 6m Building area

Foam blocks that appeared on the construction market immediately won their niche due to their good technical characteristics, plus an acceptable price, which is lower, for example, than concrete blocks and bricks. Houses and outbuildings of two or three floors, but not higher, are erected from this building material. Garages are no exception. Today in the article I would like to understand the question of how to correctly calculate a foam block for a garage, that is, how much of it needs to be purchased in order to raise a garage of the required size.

The order of laying blocks

- Masonry starts from the highest corner of the foundation;

- An adhesive composition 5-6 mm thick is applied to the foundation waterproofing using a notched trowel. The next rows are laid on a layer of glue 2-3 mm thick. The consumption of adhesive solution per m2 is about 1.5–1.6 kg of dry mixture with a layer thickness of 1 mm;

- The first bricks are installed at the corners of the base so that they can be oriented. The blocks should overhang the base by 30–50 mm to protect the foundation from moisture;

- Each block is compacted with a rubber mallet, the horizontalness of the masonry is controlled by the building level. A plane is used to level the row;

- Along the wall, using a wall chaser, a groove is cut in the first row into which the reinforcement is laid;

- The remaining rows are laid in the same way, but offset, in a checkerboard pattern, to ensure that the blocks are tied together;

- Not every row can be reinforced, but after three to the fourth. In addition to reinforcement, you can use reinforced mesh;

- Internal partitions are connected to the outer wall by 50% along the length of the foam block. The joints are also reinforced;

- Factory foam concrete lintels are used to form window and door openings. The connections are also reinforced with reinforcement ties;

- After the walls are erected, removable formwork is installed along the entire perimeter of the box and the internal load-bearing walls. The structure is reinforced and filled with concrete mortar to a height of 200-300 mm;

- After the concrete has hardened, the reinforced belt is insulated, and ceiling slabs are laid on it.

Instructions

Dear users! Please pay attention to the units of measurement in the calculator fields.

A universal calculator for calculating foam blocks for building a house allows you to obtain the most accurate but approximate amount of materials. Remember , the more fields you fill in the calculator, the more accurate the result will be.

Block characteristics

- Size. Select the size of foam concrete block you want to use.

- Density. Depending on the function performed (load-bearing wall, partition), it is necessary to select the correct density of the block.

- Price. You can immediately select the cost of the product in order to understand how much the building frame will cost (optional) .

- Stock To avoid unforeseen situations, it is better to protect yourself and purchase a small reserve - 5% will be more than enough.

Wall parameters

- Length. The total length of all walls or the length of one wall.

- Height. Estimated ceiling height.

- Type of solution. Polyurethane foam (1 mm) or glue (2 mm).

- Masonry mesh. Many manufacturers do not recommend using masonry mesh, since, according to them, the material is strong enough and does not need additional reinforcement. However, experienced specialists have a different opinion and suggest reinforcing the masonry every 3-4 rows.

Additional options

If you need an approximate calculation of the foam block only based on the “box” of the building, you can skip the paragraph and immediately click on the “ Calculate ” button. For more accurate results, you need to continue filling out the interface blocks.

- Window. Specify the width and height of the window opening, then add their number. If you have many different windows, then for each individual type you need to add a separate field.

- Doors. Similarly, specify the parameters of the openings.

- Pediments. Three types of construction for different types of roofs.

- Jumpers. Fill in the characteristics of the jumpers and their quantity.

- Armobelt. A monolithic closed belt that is laid on top of the blocks.

Result

If you have filled out all the fields of the foam block calculator, the following results will be available to you at the output:

Blocks:

- Volume of one block.

- Price of one block.

- Number of blocks in 1 m3.

- Price for 1 m3 of blocks.

- Total volume of blocks.

- Total number of blocks.

- Total mass of blocks.

- Total price for all blocks.

Solution:

- Volume of solution.

- Mass of solution.

- Equivalent in container.

A number of other similar parameters will be presented for all design elements that were used by the user.

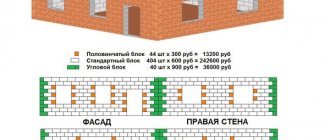

How to calculate the cost of building a garage

Calculating the cost of a garage is not easy. After all, it is necessary to take into account not only the prices of the building materials used. It is necessary to carry out a full calculation taking into account the ongoing construction operations. And this should be done by professional estimators. That is, a calculation is an estimate that indicates construction operations with their cost, volume, and at the end the amount of building materials used.

All this is summed up, after which the resulting result is multiplied by various coefficients that are responsible for savings, profit, additional expenses and price changes. Today, some construction portals offer the use of calculators for calculating the cost of a garage using foam blocks or other building wall materials. Site owners believe that this will help people. In fact, calculators are just programs with a specific mathematical algorithm.

It is impossible to create an algorithm that would take into account all the above mentioned coefficients used in calculations by estimators. In addition, the programmer probably doesn’t know about these coefficients. Some of them are constantly changing; the construction community is necessarily informed about this through decrees, orders and other legislative documents. Of course, the calculator can be used as a tool for rough calculations. But he will not give an exact value of construction costs.

Only a professional estimator guarantees the accuracy of calculations Source hackworth.co