The key building material is concrete. One of its many varieties includes air nanoconcrete. Innovative additives - nanoinitiators, using nanotechnology, transform solutions into a material with new physical and mechanical properties and a special scope of application. Their strength, light weight, and heat resistance force us to abandon traditional building materials. Thanks to modern developments, the walls of buildings will acquire the ability to “breathe”, retain heat, self-heal and serve people for 1000 years.

What are nanoconcrete?

In 1993, St. Petersburg scientist Ponomarev A.N. first tested the new composition. Further research continued in Moscow, Novocherkassk, Kemerovo and Western countries. The concept of nanoconcrete is collective. This is not a single unique solution. In a broad sense, this is a set of nanomaterials and methods, using which various properties of composites are obtained.

The use of modern equipment ensures changes at the molecular level, and the composition acquires unique properties due to the special structure of the substance. The base matrix can be not only concrete, but also other mineral binders, for example, gypsum. Highest strength with low material weight, frost resistance and extreme temperature changes are the most valuable qualities of nanomodified stone.

Types of nanoconcrete and their properties

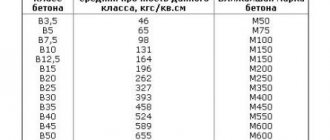

Sale of concrete is carried out in

several varieties depending on strength and weight:.

• Light cement is used in the construction of cottages and interior decoration.

• Medium is used for laying road surfaces and airfields.

• High-strength is needed for the construction of high-rise buildings, bridge platforms and farms.

• Ultra-high strength is used in the construction of bridges, squares and bus stations.

Advanced concrete is extremely resistant to high temperatures - it can withstand up to 800°C. Thanks to nanomolecules, physical and mechanical properties are improved, strength increases up to 200%, and cold resistance increases up to 70%. Oxygen distributed in concrete nanoparticles has bactericidal properties, which is safe for health. Thanks to the changed structure of the material, the weight of the products is reduced by 5 times, and the possibility of cracks is minimal.

Plasticizers improve adhesion to metals. This makes it possible to interact with particles at the molecular level and reduce the appearance of rust. The material is recommended for use in the construction of reinforced concrete products with a height of 70 meters or more, as well as in the construction of buildings that require high requirements for fire safety and seismic resistance. Concrete does not need protection for building structures. Its high degree of strength makes it possible to reduce installation volumes by 35%. Thanks to lightweight nanostructures, the cost of construction work and labor costs are reduced, since there is no need to build a powerful foundation.

How did the composition of the mixture change?

Nanoinitiators

The performance characteristics were improved due to the selection of cement components and special additives. The latter were conventionally called construction fiber. They differ in manufacturing method, composition, and technical qualities. Fullerenes and similar materials made a breakthrough in nanotechnology. These are huge frame molecules made of carbon atoms (nanotubes). The classification includes the following types:

A carbon nanotube has the appearance of a framework with molecules that come in different types.

- Steel (the most durable).

- Polymer (corrosion-resistant and cheap).

- Basalt and alkali-resistant fibers.

- SMV - ultra-high modular polyaramid fibers.

- High modular carbon fibers.

Technologies

The use of new plasticizers has led to minimization of water consumption in the mortar. This significantly lightened the material and increased the mobility of the composition, which eliminated the possibility of cracks. Air concretes come in different grades and classes. Different formulation variations open up unlimited application possibilities. and continue to be studied. In the laboratory, nanoadditives trigger a cascade of reactions that ultimately provide high strength without the need for reinforcement. This stage of the technological process has received its definition.

Dispersed self-reinforcement is the acquisition of super strength due to the growth of crystals of a mineral substance provoked by nanoadditives.

Technology development is proceeding in several directions, including strengthening reinforced concrete with converted reinforcement.

Technologies are developing in several directions, which include:

- adding special ingredients;

- applying protective coatings of special properties to ready-made bases;

- strengthening reinforced concrete with converted reinforcement.

Characteristics

The table shows the main qualities of the improved stone and its advantages:

| Properties | Comments | Advantages |

| Strength | 1.5 times higher than plain concrete | Durability |

| Destroys only intense and prolonged ultrasound | ||

| Resistance to temperature changes | Exposure interval - from -180 to +800 degrees Celsius | Use in extreme conditions |

| Bactericidal | Releases atomic oxygen | Maintains a special microclimate |

| Strong adhesion between concrete and metal | Penetrates the corroded area, restoring strength | Restoration work |

| Light weight | Provided with a reduced volume of water in solution | Lightening the entire structure, reducing the cost of construction due to a less powerful foundation |

| Uniformity of structure | Does not crack, delaminate or break | Possibility to use casting method |

| Waterproof | Does not require waterproofing | Does not allow moisture to enter the premises |

| Fire resistance | +800 degrees Celsius | Fire safety |

| Chemical resistance to acids and alkalis | As a result of the interaction of nanoparticles | Use in aggressive environments |

| Low abrasion | Due to the homogeneity and density of the mass, high impact resistance | Good for road and floor coverings |

Russian nanoconcrete

Miracle concrete was recently created by our scientists. In terms of its characteristics, it is much superior to the usual one: extreme strength combined with extraordinary lightness and resistance to temperature changes.

Such concrete will make construction much cheaper. In addition, it can be used in the reconstruction and repair of concrete and reinforced concrete structures, when the technologies familiar to builders cannot provide the required quality. This concrete was developed using the most modern nanotechnology. In its production, special additives will be used - nanoinitiators, which can significantly increase the physical properties of concrete.

The mechanical strength of nanoconcrete promises to be almost 150% greater than the strength of conventional concrete, frost resistance will increase by almost 50%, and the likelihood of cracks appearing during operation will be several times lower. It is also impossible not to note the fact that the weight of concrete and reinforced concrete structures made from such nanoconcrete will decrease by approximately five to six times.

The first results in the creation of new concrete were obtained back in 1993 by a scientist from St. Petersburg, Andrei Ponomarev. Then the work was carried out by a whole group of scientists. At the moment, Moscow LLC Nanotronika, Nanocenter MPEI, Novocherkassk NPO Synthetika-Stroy and St. Petersburg Scientific and Technical Center Applied Technologies are taking part in the project. In the process of research, two directions emerged - the creation of materials for the restoration of destroyed structures and the development of new concrete for the construction of new buildings.

In 2011, Russian scientists with their developments reached the finals of the prestigious competition of Russian innovations held by the Expert magazine. European specialists have also been developing nanoconcrete for a long time. But, according to Vladimir Moroz, Chairman of the Board of Directors of NPO Synthetika-Stroy, one of the developers of nanoconcrete, only our concrete, when applied to an “old” reinforced concrete structure, is able to fill all microcracks and micropores, and when polymerized, almost completely restores its strength. If the reinforcement becomes rusty, the new nanoconcrete reacts with the corrosion layer, replaces it and restores the adhesion between the reinforcement and concrete. Another advantage of our developments is the low cost of the new building material.

SDMO diesel power plants from the famous French manufacturer have long won well-deserved recognition from Russian customers. Unconditional reliability and quality are confirmed by the European quality certificate Qualigen. SDMO power plants are capable of providing both backup and constant power supply to a wide variety of consumers: at a construction site or country house, at an industrial enterprise, in an office facility, in a hospital and an educational institution.

Types and scope

The ultra-strong properties of the material make it possible to use it in the construction of high-rise buildings or airfield platforms.

The innovative composition is classified by density into the following varieties:

- easy;

- average;

- lasting;

- high strength.

Depending on the goals and objectives set, the appropriate nanomaterial is taken for the structure being built. For private buildings and interior floors, lightweight options are used. Roads, airfield strips, oil and gas production platforms, and access roads require a more durable form. Powerful reinforced concrete structures, bridges, high-rise buildings are the destiny of ultra-strong nanoconcrete. It is successfully used in construction in areas of high fire hazard and in seismically unstable zones.

What is nanoconcrete and its role in modern construction

Home / News / What is nanoconcrete and its role in modern construction

Concrete has long been known throughout the world and is widely used at all stages of construction work. Today you can often hear the concept of nanoconcrete. Although, in its essence, such concrete is very little different from ordinary and well-known concrete. Making a concrete mixture also involves the use of water, all kinds of binders and aggregates. At the same time, nanoconcrete has better technological characteristics compared to conventional concrete.

The plasticizer, which is used to make nanoconcrete, has miniature tubes, several microns in size. The most important thing is that these nanoinitiators are not at all afraid of alkaline and acidic environments. And this all happens at the molecular level, since when mixing cement and plasticizer, the latter crystallizes. Polycarbosilicate or silicon oxide, or rather their nanoparticles, are usually used as plasticizers. It is also possible to use titanium dioxide and carbon nanotubes.

Another distinctive feature of nanocement is that its initiators have excellent strength, which reduces the requirements for reinforcement of a concrete structure. The strength of this concrete is approximately 150% higher compared to conventional concrete, while the weight of a structure made of nanoconcrete is much less, about 5 times, compared to a structure built from conventional concrete. In addition, the frost resistance of nanoconcrete is approximately 50% higher.

Having such high quality characteristics, nanoconcrete is used for the construction of buildings that are subject to increased requirements, for example, for seismic resistance or fire resistance. Another interesting fact is that nanoconcrete is not subject to any additional processing; no waterproofing is required, which significantly reduces the cost of constructing a building. And the strength of the material allows it to be reduced during construction by up to 30%. Developments in the field of nanoconcrete are still ongoing, and the emphasis is already being placed more on the durability of concrete. Everyone knows that any concrete has a fairly limited shelf life.

It is very important that with the advent of nanoconcrete, it became possible to build structures in dangerous seismic areas. It is possible to build a building underground or in difficult mountain conditions. This type of concrete is ideal for monolithic structures and bridges. We can say that the future belongs to nanotechnology, since nanotechnology is already used in the manufacture of paint and varnish coatings; glass is coated with a mixture of nanoparticles that allow dirt and moisture to drain and not contaminate the surface, and so on.

Directions of development

In addition to construction, the scope of application is rapidly expanding, as is the development of new forms of air solution. Composite coatings based on nanoconcrete are used for sewer structures where the action of an aggressive environment is obvious. As a result, the concrete does not collapse and the metal does not rust. The multilayer composite is suitable for floors and walls of public buildings - shopping and administrative centers, parking lots, schools.

The possibility of application by pneumatic spray allows you to strengthen a variety of surfaces and use the nanomaterial as glue.

Modified artificial stone is non-toxic, has bactericidal and water-repellent properties, therefore it is used in structures that carry drinking water. A new direction has become the production of composite reinforcement. It is actively replacing steel. Using the good plasticity of nanoconcrete, original household items are created using the casting method - tabletops, vases, sinks, lampshades.

Nanoconcrete

In construction, nanotechnology is receiving increasing attention. Construction includes various sciences: physics, chemistry, computer technology. This promotes the development and development of new materials. When constructing structures, the quality of materials, in particular concrete, plays an important role. The durability, strength and decorativeness of buildings and structures . Technologies for producing concrete mixtures are constantly evolving, and the term “nanoconcrete” is boldly entering our lexicon.

in the production of nanoconcrete . Special additives, called nanoinitiators, significantly increase the strength of concrete and its other qualities.

Nanoconcrete can be called specialized concrete made using a new method. Types of nanoconcrete: nanofoam concrete, medium-density nanoconcrete, high-strength nanoconcrete. Nanofam concrete is used for lightweight partitions in individual construction.

In the production of nanofoam concrete , plasticizing additives are used to improve the quality of foam concrete. Medium-strength nanoconcrete is used in the construction of roads, bridges, and airfields.

High-strength nanoconcrete is used in the construction of elevator shafts and load-bearing structures, both in residential construction and industrial construction. The use of nanoconcrete allows you to save money on the construction of new facilities.

Also, the use of nanoconcrete helps to reconstruct old buildings where conventional methods are useless. The use of silicon oxide, carbon nanotubes and titanium dioxide gives concrete new properties.

Increases the resistance of concrete to adverse conditions, prevents the appearance of cracks, increases frost resistance, does not require additional reinforcement, meanwhile the weight of concrete is reduced.

All types of nanoconcrete use waste basalt fiber as a reinforcing material. Basalt fiber is made from basalt rocks, it is crushed and other components (caustic soda, water, fulleroid material) are added to the composition.

The production of nanoconcrete does not require improvement of technological equipment. Nanoconcrete has a special structure that is formed at the nanolevel.

The use of nanoconcrete has already begun. With the help of nanotechnology, the bridge across the Volga in Kimry was restored, the wastewater treatment plant in Novocherkassk was also restored, and buildings in Sochi were strengthened. While working on these sites, it was found that nanoconcrete is a worthy building material.

Today, developments in this direction are underway, and the results obtained are constantly being improved. The development of nanoconcrete allows us to expand the capabilities of designers when creating projects for fundamentally new structures, and will also allow us to make new design solutions in seismically unstable areas and in the underground construction of megacities.