Seeing a house for the first time, any person pays attention to its facade, the external design of which tells a lot about the taste and preferences of the owner.

The facade block used for the construction of buildings indicates the level of well-being of the owner. These building elements provide reliable protection for the building from unfavorable external manifestations, and they also noticeably decorate the building.

With the help of façade materials manufactured in industrial production conditions, suburban and multi-storey buildings are erected. They allow you to easily and quickly build any monolithic building.

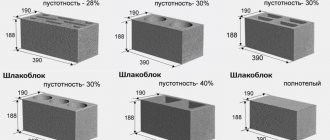

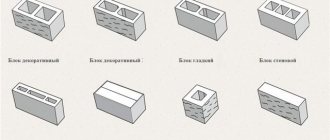

These structural elements can be cut, sawn, and holes made for wiring. Most often, such tiles are rectangular in shape and made of concrete; they can be large or small, hollow or with partitions.

Building materials of the type under consideration differ in geometric dimensions, and any structure can have its own dimensions.

What to use for cladding

How to veneer a foam block with what? Various materials are used for finishing the facade. This could be plaster, siding, decorative stone, fiber cement boards, corrugated sheets, blockhouse, tiles. Often, home owners prefer to clad the building with brick, which can be clinker or special decorative.

The technology for cladding houses made of foam blocks with bricks may be somewhat more complicated than when using, for example, siding, but the result is very high quality. Just remember to increase the width of the foundation in advance so that there is room left for working with bricks.

Another important point to remember: foam blocks with any cladding require a ventilation gap, with its help excess moisture will be removed, so it is recommended to use a “breathable” heat-insulating material, for example, mineral wool.

Brick lining of foam blocks can be done in two ways:

- In parallel, literally and figuratively, with the construction of walls. As the foam blocks are laid, a decorative layer is also built at the same time. Labor intensity increases, but the quality of the finish is excellent.

- Consistently, that is, finishing work is carried out on a fully constructed building. This technology is more common as it can significantly reduce construction time.

Simultaneous construction of walls made of foam blocks and brick cladding

Insulation using single-layer materials

Most construction organizations prefer to insulate the building under construction using multilayer technology with the creation of three layers, namely load-bearing, insulation and finishing. Two methods of insulation are used:

1. Insulation from inside the room.

2. Insulation from outside.

Internal insulation is resorted to in exceptional cases when it is impossible to insulate the building in any other way. When insulating from the inside, the surface is initially primed, then sheets of heat-protective material are attached with glue. Then the resulting base is again treated with a primer and a spatula, then the finishing material is applied.

Design option for a double insulated frame wall: 1. OSB board (OSB), base for exterior finishing; 2. Counter grille forming a ventilation gap; 3. Ventilation gap; 4. Wind protection in the form of a vapor-permeable membrane; 5. Fiber insulation (basalt insulation); 6. Independent double frame racks; 7. Vapor barrier; 8. Internal OSB board (OSB); 9. GKL, base for interior decoration; 10. Layer of interior finishing.

Despite the simplicity and low cost of this method of insulating premises, it has significant disadvantages, these are:

- significant reduction in area due to the thickness of the internal insulation;

- high humidity, which allows mold and mildew to grow;

- The walls will not retain heat using this method.

Therefore, the correct method of insulation is only external insulation .

Stages of work

The technology of lining foam blocks with decorative bricks has its own characteristics. Firstly, there is a mandatory ventilation gap of 20-40 mm wide, and when using thermal insulation, the gap must also be maintained. Secondly, since the masonry is done in one brick, it is advisable to use a reinforcing mesh to strengthen it, as well as organize a connection between the brick and the wall. For this, galvanized perforated strips, flexible basalt-plastic connections, and chemical anchors are used, which are installed at the rate of at least 4 pieces per 1 m2 of wall.

When installing on walls made of foam blocks, use special ones that will facilitate installation and securely fasten the materials.

These connections are installed in the mortar joint between the foam blocks, but this is permissible if the facing brick and the foam block have seams that coincide in the same plane. Otherwise, you will have to drill a hole in the foam block itself, and in this case it is better to use chemical anchors, which will provide the required rigidity and reliability of fastening.

The work can be divided into several stages:

- The first row is laid out first. There must be waterproofing between the foundation and the masonry, which can be a layer of roofing felt. Levelness is checked by level.

- It is necessary to provide ventilation holes, leaving gaps between the ends of adjacent bricks. These holes should be evenly spaced along the entire length of the wall.

- Having laid and leveled the first row, you can lay the second. The mortar is applied to the bottom row, and the brick to be laid is smeared from the end, after which it is laid. It is worth saying that the solution may contain additives such as, for example, ash, which in the case of light brick can create a spectacular geometric pattern.

- The technology for further cladding a wall made of foam block with brick is similar, only it is no longer necessary to control the horizontalness of the masonry with a level, which is ensured by the evenness of the first layer.

- It is necessary to ensure that the foam blocks have the same gap with the cladding, and in the last row, organize ventilation ducts in the same way as those arranged in the first row of masonry.

If a fibrous heat-insulating material is used, then it is advisable to cover it, for example, with fiberglass, protecting it from blowing and ensuring reliable ventilation of the space between the walls.

Alternative

Almost any building material used for the construction of walls requires subsequent finishing and decoration of the facade. With all its advantages, foam block and some kind of facing material are used in combination, and in the case of using brickwork, a second wall actually has to be erected. Is there any way to make the process easier by matching the foam blocks with the trim?

There are options with a facade side on which a texture is applied that imitates plaster, brickwork, or even have a marble-like surface, artificial stone of different colors, patterns and textures.

Foam block with textured facing side

The use of this option for construction eliminates the need to use facing tiles, bricks or other facade materials.

Options for foam blocks with facing side

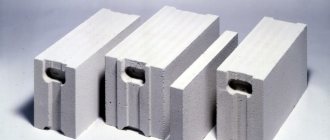

What is a foam block

Foam block is a material in the form of building blocks made from foam concrete. Foam concrete is formed when a foaming agent is added to the solution due to hardening of the resulting mixture.

Today, there are three different production technologies for this material:

- Classic

. An ordinary cement-sand mortar is prepared, into which foam is added using a foam generator. After this, the solution is thoroughly mixed with foam, and the finished mixture is poured into molds. Due to hardening, foam concrete is formed. This production technology is considered the most reliable and is used by most manufacturers. - Dry mineralization

. The dry mixture of components is mixed with low expansion foam, continuously supplied by a foam generator. As a result, we obtain a stable foam concrete mixture with a small volume of free water. - Barotechnology

. The bar mixer is filled with foaming agent and water, after which all remaining components are added. Next, pressure is created by pumping air with a compressor, after which the concrete mixture is transported under pressure to the place where it will be distributed into molds.

Foam block refers to materials made from cellular concrete, that is, it is characterized by a porous structure with closed cells.

Characteristics of foam blocks

Advantages

- Low price. Even in comparison with aerated concrete, which also belongs to cellular concrete, the cost of this material is on average 20% cheaper.

- Easy to install. If you are familiar with the features of brickwork, then without much difficulty you can build walls made of foam concrete with your own hands, which have several working nuances, which we will discuss below.

- Fire resistance.

- Relatively light weight, which allows it to be used for erecting such buildings (for example, columnar). The low weight also makes the installation process much easier.

- The material is resistant to various chemical influences, as well as biological factors (rotting, damage by rodents, etc.).

- Moisture resistance.

- Easy to process. The material is perfectly cut and polished, which is another advantage over aerated concrete.

The following instructions will help you with implementation:

- First, we clean the blocks from dust, dirt, snow, etc.

- All types of bases are suitable for this material due to its low weight. The only requirement for the foundation is that it must be strong and level.

Advice! A columnar foundation is suitable for relatively small structures made of foam blocks with a maximum of two floors.

- we start from any angle. The optimal wall thickness is 2 blocks + a facing layer of half a brick.

- The first row is placed on a layer of waterproofing. In this case, you can use sheets of roofing felt, laying them in two layers.

- Masonry can be carried out using a cement-sand composition. The ratio of cement and sand is 1:3. The thickness of the seam should not exceed 30 mm.

- All subsequent rows are laid on a light mortar with a joint thickness of about 15 mm.

- If you are working in hot and dry weather, wet the blocks with water immediately before laying.

- After laying the first row, you need to check its horizontalness with a level. This is the starting point for all subsequent work, therefore, if even minor irregularities are detected, they should be removed using a grinding tool.

- Check for voids at seams. It is necessary to fill horizontal, vertical and inter-row joints with cement mortar so that there are no cavities left. The remaining mortar should be removed during the laying process.

- Blocks can be set with light blows of a rubber hammer.

- To achieve greater strength, the walls are reinforced with metal mesh or reinforcing bars laid in each row or across a row.

- For partitions, formwork is installed above windows and doors, into which a reinforced frame is laid and concrete is poured.

We carry out façade cladding

Now let's look at how to properly insulate a house made of foam blocks.

Thermal insulation of walls comes in two types:

- Internal, in which insulation is applied to the walls from the inside. On top of the thermal insulation layer, sheets of plasterboard are most often installed, which can be painted, covered with wallpaper, tiles, etc. Less commonly, lining is used as internal cladding.

- External or facade. There are several types of finishing with insulation possible:

- Creating a plaster facade, when a layer of plaster is laid on top of the insulation.

- Ventilated façade using sheathing and siding panels as cladding.

- A brick facade, which is built in half a brick using face blocks.

For buildings made of foam blocks, the best option is to create a brick facade.

Creating a brick facade

When facing a building with brick, a layer of insulation is almost always laid, which allows not only to make the building attractive, but also to answer the question: “how to properly insulate a house made of foam block?”

Today, three methods are used for cladding walls made of foam blocks with bricks:

- Cladding without air gap. It is an excellent solution for unheated facilities. At the same time, the brick perfectly protects the porous structure of the foam block from precipitation.

Advice! It is advisable to provide for brick cladding at the design stage, since this material requires a wider and more powerful foundation.

- Cladding with an air gap without ventilation. This method is applicable both when arranging “cold” buildings and those that are in operation throughout the year. In this case, moisture, being on the surface of the foam block, is released into the air layer, from where it is gradually removed through the body of the brick. The thickness of such a layer should be 3–4 cm. For such systems, it is necessary to additionally install ventilation, which will help regulate the humidity in the rooms.

- Facing with a ventilated gap device. The best option for residential buildings where people live all year round. The brick screen does not serve as a heat insulator, since a flow of cold air constantly moves between the load-bearing and facing walls, which slides over the surface of the foam blocks. Air intake occurs through special ventilation slots located at the bottom of the wall. The air flow exits from above. It also provides for the removal of condensate, which is carried out through drainage holes.

Choosing insulation

Mineral wool is insulation for foam blocks.

If you decide to install insulation between a foam block and a brick, then you should have an idea about the most popular thermal insulators and their main properties.

Today, several types of insulation are known, each of which has advantages and disadvantages.

- Mineral wool. It is the most popular insulation material, which is used for thermal insulation of walls, ceilings, roofs, floors, loggias, etc. If you do not know how and how to insulate a bathhouse made of foam blocks, then this heat insulator will be the best option.

Mineral wool has the following advantages:

- High heat and sound insulation characteristics.

- Durability.

- Easy to install with your own hands without the use of special equipment.

- Acceptable price.

- Flexibility and ease of use.

Perhaps the only drawback of this material is its low moisture resistance. Even if 3% of the insulation gets wet, it can lose half of its thermal insulation characteristics.

- Styrofoam. The material has long been a leader in the insulation market because it is very easy to install and cheap. With the advent of mineral wool, foam plastic faded into the background, but continues to enjoy some popularity. Its slabs are lightweight and not afraid of water.

Unfortunately, foam plastic has as many disadvantages as advantages:

- It is flammable, so it is not advisable to use it for insulating baths.

- Poor sound insulation.

- Fragility.

- For some reason, mice are not indifferent to polystyrene foam.

- Extruded polystyrene foam is an excellent option if you need to create a foam block with cladding and insulation. It is perhaps the best insulation for floors, especially when used under a screed for heated floors. The material does not have the disadvantages of polystyrene foam; it is stronger and denser, and therefore more convenient to install and allows you to achieve higher thermal insulation results. Extruded polystyrene foam, in addition to its high characteristics, is characterized by a rather high cost.

The second method of external insulation is layered (well) masonry

Quite often, in low-rise construction, the so-called layered masonry or “three-layer system” is used. In accordance with the name, the masonry is made in three layers:

- bearing wall;

- thermal insulation layer;

- cladding on the outside.

One brick is the front layer; it is quite enough to not only protect the insulation, but also perform decorative functions. Extruded polystyrene foam or high-density mineral wool, which are resistant to deformation and are well resistant to moisture, are used as insulation.

Three-layer “well” system of external insulation

Layered masonry is also used for reconstruction of houses. The undoubted advantage of this method is the ease of the resulting structure. But the resulting wall is quite thick, and this requires the construction of a wide foundation. And the biggest disadvantage is the fact that after some time condensation begins to form inside, and the tightness of the outer shell does not allow the evaporation of excess moisture even in dry and warm weather. And the high consumption of material during well masonry, which leads to an increase in construction time and an increase in the cost of houses, is hardly in favor of this method.

Carrying out thermal insulation work

Let's look at how to insulate a house made of foam blocks step by step:

- We will use mineral wool as insulation. To secure its sheets, it is necessary to create a sheathing.

Advice! Due to the porosity of foam concrete, ordinary screws or nails are not suitable for it. Therefore, to fasten the sheathing and thermal insulation panels, you should use chemical anchors or twist-on dowels, which are more affordable. The insulation can also be applied to glue.

- We create the sheathing. The pitch of the sheathing should be equal to the width of the mineral wool slabs. They should fit tightly between the profiles.

- To create a vertical frame, metal hangers are attached to the wall.

- We strengthen wooden or metal profiles on hangers. The profiles should be 5 cm thicker than the insulation boards.

Advice! Wooden sheathing beams must be treated with protective compounds that prevent rotting.

- We lay mineral wool boards between the profiles.

- A layer of waterproofing should be installed on top of the insulation. Foil or any material with a foil layer, for example, penofol, is suitable as a waterproofing material. Penofol is a thin insulation with a waterproofing membrane that will create an additional layer of thermal insulation.

- We stuff the waterproofing membrane onto the frame profiles with an overlap of 10 cm.

We seal the joints with metal tape.

- Now you can start laying bricks. The masonry is carried out in half a brick at a distance of about 5 cm from the sheathing profiles. This gap is necessary to create an air gap, which is needed for additional thermal insulation.

Block containers made of sandwich panels

As an office, the container block has a beautiful appearance and creates a pleasant impression on clients and visitors.

As a home or warehouse, a block container made of sandwich panels is protected from all influences of the external environment, and insulation allows you to maintain the desired temperature inside the room and easily maintain it.

Block containers made from sandwich panels are easy and simple to operate in any climatic, geographical and weather conditions.

All-season and weather-resistant properties have made block containers made from sandwich panels very popular among office businesses, manufacturing, the raw materials industry, and the manufacturing and construction industries.