In modern construction, massive products—reinforced concrete trays—have become widespread. Thanks to high quality and advanced manufacturing technology, building materials have found application in various fields: in the construction of private and multi-storey houses, terraces and garage complexes, arrangement of ditches, highways, laying heating networks.

Concrete trays are a necessary thing during construction.

Classification of trays

Reinforced concrete structures differ in shape. They come in the form of a square, rectangle, trapezoid and semicircle.

According to their purpose, reinforced concrete trays are divided into the following types:

- Drainage

- Road.

- Drainage.

- For heating mains.

- Impassable channels.

- Inter-track, inter-sleeper.

- Cable, energy.

According to the method of laying they are divided:

- For the edges. Installed to divert water flows from roads to slopes.

- To telescopic ones. Used in the construction of garages and buildings.

According to the production method, building materials are classified into reinforced concrete concrete, manufactured by vibration casting and vibrocompression.

Screened reinforced concrete tray

Screened reinforced concrete tray

Screened reinforced concrete trays for improved cable ducting at electrical substations were developed in accordance with the technical specifications of JSC FGC UES. The terms of reference were approved on October 15, 2004. Since 2010, trays have been used in the construction and reconstruction of substations. Power and control cables are laid in them. The trays have internal reinforcement - a screen made of steel reinforcing bar with a diameter of 5 mm in the form of a mesh with concrete leads for connecting the screens of adjacent trays and covers. The trays are made of concrete with increased wear resistance. Transition of a series of small trays through existing trays. Made using standard small trays.

Transition of large trays through existing trays. Made using small trays. In this case, a pair of small trays are joined to one large tray. At such a transition, the screens are connected using jumpers 400 mm long. Since 2012, a special large tray 1 meter long has been produced for the installation of such transitions.

The universal cover for the branching tray can be installed on branching trays of all sizes. The cutouts of the trays and covers contain contact elements - steel strips with holes. These strips are connected to each other using plates.

The experience of using trays at the first facilities showed that there is a rather long interval between the operation “Laying trays with connecting screens” and the operation “Installing covers on trays with connecting screens.” First, the trays are laid, the screens of adjacent trays are immediately connected with steel plates. And, immediately, the screen jumpers are connected to them. After laying all the trays, the cables are laid in them. And only then the covers are installed to connect all the screens.

For each substation during new construction or reconstruction, several hundred trays and more than a thousand covers of various types are supplied. Therefore, since 2012, parts for connecting tray screens and lids are supplied separately in group packaging. The number of parts for connecting screens is determined by the number of trays and covers supplied to a specific substation. One set of KSE-L (set for connecting tray screens) is supplied for each tray (of any type). For each cover (of any type) one set of KSE-K (set for connecting cover screens) is supplied.

| product name | Tray dimensions, mm | ||||

| A | B | C | D | E | |

| Large screened feed-through tray (LEPB) | 2000 | 1000 | — | 1200 | 400 |

| Large, shortened screened passage tray for transitions (LEPBU) | 1000 | 1000 | — | 700 | 150 |

| Small screened feed-through tray (SPL) | 1000 | 500 | — | 600 | 200 |

| Small extended screened walk-through tray (LEPMU) | 2000 | 500 | — | 1200 | 400 |

| Large shielded branching tray for 3 directions (LERB-3) | 2000 | 1000 | 880 | 1200 | 400 |

| Small shielded branching tray for 3 directions (LERM-3) | 1000 | 500 | 380 | 600 | 200 |

| Large shielded branching tray for 4 directions (LERB-4) | 2000 | 1000 | 880 | 1200 | 400 |

| Small shielded branching tray for 4 directions (LERM-4) | 1000 | 500 | 380 | 600 | 200 |

What are trays for heating mains?

Trays for heating mains are structures made of concrete and designed to protect hot water pipes from external damage, liquid ingress, corrosion, leakage of thermally insulating air, and soil displacements. They serve as a channel for laying underground communications and the main element in the construction of sewers, hydraulic structures, treatment systems and walls of the collector block.

Concrete products are suitable for any terrain. They are installed in 9-point seismic zones, in areas with high groundwater levels or large subsidence.

Varieties

Telescopic trays have low moisture absorption, which increases their service life.

In the construction industry, when laying roads, a special section is allocated through which various systems pass. The main task is to keep them intact. A reinforced concrete tray, which has the following varieties, can easily cope with it:

- Products for prefabricated channels. They have maximum dimensions, are durable, resistant to corrosion, and are used in water and stormwater systems.

- Telescopic structures. They have a trapezoidal appearance and a long service life due to low moisture absorption. Several pieces are installed along roads for greater drainage.

- Gutters that allow water to pass through. In order not to interfere with the flow, they are mounted on a slope; in their production, a drying technique is used under high-temperature conditions.

To install the tray, you need to dig a trench into which the channels are laid. Waterproofing is done at the joints. Then install the lid and cover it with earth.

Description

Reinforced concrete structures are produced on the basis of GOST 13015.0-83. The state standard regulates the basic parameters of reinforced concrete materials, standards for the production and operation of building materials.

According to the document, concrete products after production must have high performance and have the following qualities:

Drainage trays.

- increased thermal and waterproofing;

- frost resistance;

- high level of resistance to any load;

- waterproof;

- resistance to aggressive factors and groundwater;

- reliability.

The concrete from which the trays are made must meet the following requirements:

- Brand - at least 300.

- Tensile strength - over 70 MPa.

- The size of filler granules is up to 15 mm.

- Lack of surface-active additives in the production of the mixture.

GOST 13015.0-83 also regulates fittings. The strength of the material is guaranteed by the use of high-quality and durable steel. The steel class in the reinforcing frame is AI/A-III/Bp-I.

Heating main channels are covered with concrete covers to quickly eliminate an accident that may occur during the operation of the heat supply system.

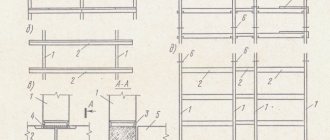

Gateways are divided into subtypes based on the installation method:

- KL. Equipped with special ceilings.

- KLp. Manufactured with lids and reinforced concrete blocks resting on them.

- KLS. A gutter system with blocks resting on each other, fastened with channels.

The blocks are installed in a ditch on a sand bed. Products must be in close contact with the ground, this affects the reliability of the structure. The joints are filled with mortar. On structurally unstable soil, bitumen or other plastic waterproofing is used.

To ensure load uniformity and to avoid distortions, the earth is filled on both sides at the same time. When using blocks in areas with aggressive factors, the façade should be covered with a protective layer of a special solution.

Concrete tray for utilities.

Reinforced concrete cable trays used for laying cables in the ground

Did you like the video? Subscribe to our channel!

Reinforced concrete cable tray is widely used in construction for the purpose of laying utility lines. Their use ensures the most reliable protection of communications from any damaging effects, both natural and man-made. It is permissible to use trays for laying cables with voltages up to 35 kilovolts.

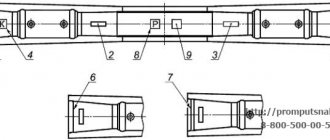

A reinforced concrete cable tray (Fig. 1), the scope of which is quite wide, is a hollow reinforced concrete product in the form of a channel. The main advantages are that they allow the most efficient use of the site area, and also help reduce overall construction costs.

If we talk about savings, they are visible to the naked eye, because using a concrete cable tray is 2-3 times cheaper than laying cables using other structures to realize the internal space.

Production of

reinforced concrete trays

Reinforced concrete cable trays have different sizes and are made from heavy concrete, and steel reinforcement is used as a frame. The production of this product is carried out in accordance with GOST No. 23009-78, using Portland cement as a base, the grade of which should not be lower than M400, as well as reinforcement that was made from steel of classes A3 or A1. The following materials can be used as filler:

- selected sand,

- granite,

- gravel.

This product must be produced in accordance with all technological requirements, otherwise it simply will not have the necessary characteristics. One of the most basic characteristics can easily be called increased strength, which can only be achieved if high-quality concrete is used. In addition, the properties of concrete will determine frost resistance, as well as resistance to cracking. It is worth noting that if the production technology is violated, the trays may lose their ability to impermeable to moisture, which is unacceptable. If all production procedures were carried out efficiently, your cables will be reliably protected from harmful influences.

Reinforced concrete cable trays can be used in any type of soil, with the exception of those that are aggressive to materials such as concrete. To avoid clogging, it is permissible to use special floor slabs (Fig. 2), which must be made of the same material as the reinforced concrete cable trays .

.

Reinforced concrete cable tray :

advantages

What is the advantage of using a product such as a reinforced concrete cable tray? It is worth noting the following:

- Excellent ventilation of the laid cable route.

- The ability to use unarmored cables and also save money on their installation.

- Relatively easy access to communications, which is achieved by removing the protective cover.

- Increased service life of communications.

- A wide range of products that allows you to solve issues related to laying cable lines of any type.

Installation of

trays

Installation of these products must be carried out in accordance with SNiP 16-80, concerning prefabricated reinforced concrete and concrete structures. You should also remember SNiP 4-80, which describes safety precautions in construction.

You should proceed directly with the installation only after the trench slopes and elevations have been checked. The seams that will be formed after laying the trays should be filled with cement (M-50), and expansion joints should be filled with bitumen. The soil should be covered in an even layer and compacted according to SNiP 8-76.

Tray marking

The marking of reinforced concrete for heating mains is represented by an alphanumeric designation.

The letter indicates the type of building material:

- L - tray;

- P - plate.

The numbers indicate:

- standard size;

- permissible design load;

- length of the locks.

If the marking contains a fractional value, the model is shortened. Actual length is half the standard rating. When manufacturing a product with a length of no more than 750 mm, the letter D is written in the designation. Additionally, information about the date of manufacture and manufacturer is provided.

Table of sizes and prices of tray for heating mains

Technical characteristics of reinforced concrete products for thermal routes and their prices are given in the table:

| Brand | External dimensions, mm | Internal dimensions, mm | Weight, kg | Volume, m³ | Cost, rub./pcs. |

| L-1-8/2 | 2985x360x420 | 300x340 | 450 | 0,17 | 3170 |

| L-2-8/4 | 1498x360x570 | 300x450 | 240 | 0,1 | 1550 |

| L-2D-15 | 720x360x570 | 300x450 | 110 | 0,048 | 795 |

| L-3D-8 | 720x380x780 | 300x620 | 190 | 0,075 | 1150 |

| L-4-8/2 | 2985x530x780 | 450x620 | 900 | 0,36 | 4450 |

| L-4D-8 | 720x530x780 | 450x620 | 230 | 0,09 | 1160 |

| L-5-8/2 | 2985x680x780 | 600x600 | 1250 | 0,44 | 6190 |

| L-5D-8 | 720x680x780 | 600x600 | 1280 | 0,11 | 1540 |

| L-6-8/2 | 2985x530x1160 | 450x1000 | 1130 | 0,45 | 6325 |

| L-6D-8 | 720x530x1160 | 450x1000 | 280 | 0,11 | 1530 |

| L-7-8/4 | 1490x680x1160 | 600x980 | 680 | 0,272 | 3070 |

| L-7-15/2 | 2985x680x1160 | 600x980 | 1350 | 0,53 | 9440 |

| L-8-5/2 | 2985x1000x1160 | 900x900 | 1950 | 0,78 | 8550 |

| L-8D-8 | 720x1000x1160 | 900x940 | 500 | 0,2 | 2415 |

| L-9D-15 | 720x1310x1160 | 1200x900 | 650 | 0,26 | 3100 |

| L-10D-5 | 720x550x1480 | 450x1280 | 430 | 0,17 | 2290 |

| L-10D-15 | 720x550x1480 | 450x1280 | 430 | 0,17 | 3180 |

| L-11D-11 | 720x700x1480 | 600x1280 | 450 | 0,18 | 3000 |

| L-11D-8 | 720x700x1480 | 600x1280 | 450 | 0,18 | 2680 |

| L-12-8/2 | 2985x1010x1480 | 900x1280 | 2400 | 0,96 | 11910 |

| L-12D-8 | 720x1010x1480 | 900x1280 | 600 | 0,24 | 4380 |

| L-15-8/2 | 2985x720x1840 | 600x1600 | 2480 | 0,99 | 17080 |

| L-15D-5 | 720x720x1840 | 600x1600 | 630 | 0,25 | 4420 |

| L-16D-8 | 720x1030x1840 | 900x1580 | 800 | 0,32 | 4810 |

Prices in Russia for reinforced concrete concrete depend on the dimensions, weight of the structure, and consumption of materials for manufacturing.