Frame-braced frame with elastic-plastic nodes.

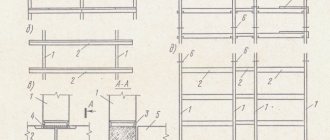

A frame-braced frame

with elastoplastic nodes, in contrast to frame-braced (rigid) frames, has elastoplastic nodes for connecting the crossbar with the column, which is achieved by a special design of the upper mounting connecting part (“fish”). The perception of horizontal loads and the overall stability of the supporting system are ensured by flat frames in one direction and stiffening diaphragms or metal braces in the other direction.

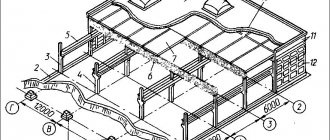

A frame of this type is used to form the load-bearing system of civil and industrial buildings with large spans and significant loads on the floors (up to 270 kPa), in which, in addition, technological conditions require the presence of spaces free from structures. The frame can also be used in industrial construction.

The structural elements of the frame are the same as in the braced frame, but with some differences in the design of the elements. Thus, the columns have higher (300 mm) consoles, which is due to the need for the console to absorb large loads from the crossbar; the crossbars also have a greater height (900 mm) with the same width at the bottom (400 mm) and at the top (200 mm). Crossbars have two modifications: prefabricated and prefabricated monolithic. In a prefabricated monolithic crossbar, the transverse reinforcement and the upper longitudinal reinforcement are exposed. Consolidation of the upper part of the crossbar is carried out under construction conditions after laying the flooring.

The design of the connection between the crossbar and the column is externally similar to the similar design of the braced frame, however, a significant increase in the design forces in the supporting section of the crossbar and a more diverse nature of the joint operation (including the reverse moment when unloading the crossbar), various methods of attaching the “fish” to the top crossbar reinforcement lead to significant differences in the operation of the unit.

In the initial period, connecting parts perform the function of elastoplastic elements. Depending on the cross-section of the working area and the yield strength of the steel, the magnitude of the forces in them is limited.

The connecting parts are made of mild construction steel VStZsp5, the length of the working sections of the parts is determined based on the condition of limiting residual deformations by a relative elongation of no more than 3%, which prevents the formation of cracks and tears.

There are two types of floor panels: hollow-core panels with a height of 220 mm and ribbed panels with a height of 400 mm. They are designed for standardized loads of 12.5 and 16 kN/m2 and are prestressed. Reinforcement made of steel classes A-1; A-1U, AtLL Other elements of the structural system are identical to those of the braced frame (stiffening diaphragms, stairs, external enclosing structures, internal fittings, etc.).

The products are produced in the same factories as the elements of the braced frame, and according to the same technological scheme. A typical technical solution provides for the possibility of creating a frame frame, for which the range of industrial products includes crossbars of the second direction, placed on metal tables welded to the columns. In the frame frame, the crossbars of the second direction do not carry a vertical load.

Due to the increased material consumption (in frames that provide the perception of horizontal loads and general stability, the load-bearing capacity of columns in compression is underutilized) and the labor intensity of constructing frame frames, this scheme is used in exceptional cases when the installation of stiffening diaphragms (for the second direction) or metal connections is impossible. Frames of the second direction (second type) are placed along the internal axes of the building (frames along the façade axes are not recommended).

Steel tables welded to columns are designed to support crossbars with vertical loads of no more than 50% of the design loads on reinforced concrete column consoles. Therefore, crossbars of longitudinal frames can be used to support floor panels with partial loads.

In buildings that are extended in plan, as a rule, frames of the first type are located in the transverse direction, and diaphragms, connections or frames of the second type are located in the longitudinal direction. In this case, metal connections are recommended of portal or semi-braced types.

RDP 6.56

Double-flange crossbars for flat slabs RDP 6.56

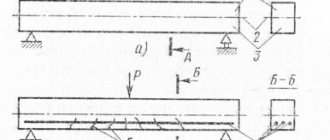

Crossbar beams are one of the most necessary reinforced concrete products, without which it is difficult to imagine the construction of multi-storey buildings today. Single-flange and double-flange crossbars are used together as supports for a certain type of slab. Pairs of crossbars RDP and ROP are used to support flat hollow-core slabs and floor slabs of multi-storey buildings.

The double-flange transom has a T-shape with two recessed shelves for supporting the floor slabs. The crossbar itself is mounted on columns, racks and other supports, where it is rigidly built into the frames, transferring loads from the floors and maintaining the shape of the building. Single-shelf crossbars are installed near load-bearing walls, and double-shelf products are needed to support two slabs in the middle of buildings.

Like other frame products for the construction of multi-storey buildings of various profiles (public, residential, civil), concrete crossbars are produced reinforced, this can be either simple reinforcement with non-prestressing reinforcement (grids and frames), or complex rope reinforcement and the use of prestressing reinforcement. You can find specific drawings of crossbars in standard series in our “Reinforced Concrete Products Directory”. The most common are series 1.020.1/87, series 1.020.1-2с/89, series 1.020.1-4, series 1.420.1-4, series 1.420.1-20 с and others. Requirements for the shape and dimensions, materials and properties of transom beams include GOST 18980-90. This is a valid document that you can download for free in the “GOSTs and SNiPs” section of the website.

Crossbar dimensions

GOST 18980-90 divides transom concrete products into seven types, depending on design, endurance and standard size. The most popular are double-flange RDP and single-flange ROP transom beams for the construction of multi-story public buildings. They have a length from 2 to 11 meters, cross-section 565x450, 595x600, 550x800 mm. The cross-section of the crossbar is selected based on the design operational loads, scale and number of floors of the building. The parameters of concrete strength and density, frost resistance and water resistance also dictate the requirements of specific projects. You can order reinforced concrete products for use in Krasnodar and Kemerovo, Vladivostok and Moscow - we will ensure the production of crossbars with optimal climatic and chemical resistance. Double-flange RDP crossbars certified according to GOST 18980-90 are produced from heavy concrete of special density, which can withstand any operational loads. This is concrete M300-M500, which has high compressive strength B20-B40.

RDR and RDP crossbars produced according to modern standards (for ribbed and flat slabs P, PK) are necessary for supporting the internal horizontal parts of the building. In particular, ribbed and flat PC slabs are supported on the shelves. The crossbar beam transmits loads from flooring and coverings to columns and racks. Flights of stairs and landings also rest on crossbars (such crossbars are called RLP). Crossbars are divided according to their load-bearing capacity, size, shape and purpose. In our catalog you will find all transom products produced in accordance with GOST 18980-90.

Naturally, the crossbar requires impeccable performance - strength, rigidity, crack resistance, the necessary load-bearing capacity and fire resistance. Therefore, only factory-made beams that are produced at flagship reinforced concrete structures are used in construction. Only professionals who produce RDP crossbars using modern equipment and with thoughtful reinforcement can guarantee the endurance and durability of beam products. Today, the production of reinforced concrete products uses the latest vibration equipment and special additives to increase the performance characteristics of crossbar products.

Marking of reinforced concrete crossbars

Modern requirements of GOST 18980-90 require encryption of the brand of reinforced concrete products; this alphanumeric combination includes the type of cross-bar, the cross-sectional size of the product, the length of the cross-section beam in decimeters, and the load-bearing capacity in kN/m is also indicated. Additionally, the types of embedded products are indicated. It is also customary to indicate on the end of the crossbar the brand, weight, date of production of the beam and a QC stamp.

As a sample, consider the RDP 4.52 crossbar (5240x565x450 mm), where:

- RDP – double-flange crossbar for flat slabs;

- 4 – cross-section of the crossbar;

- 52 – product length 5240 mm;

Double-shelf type crossbars are the most popular and in demand horizontal structural elements of multi-storey buildings. In Russia, many companies in Moscow, Yekaterinburg, Kazan, Rostov-on-Don, and Novosibirsk often seek to buy them. Specialists are ready to provide a wide range of transom beams at affordable prices. Beams with special recesses-shelves are used to support the flooring and landings and flights, so they must withstand high operational loads. In addition, the crossbar connects the columns and racks of the building to each other, so the choice of beam length determines the pitch of the columns, and the height - the format of the building and the expected loads. The connection between the structures in the frame can be rigid or hinged, but most often the rigid type of connection is used.

Also, the girders of buildings can rest on the crossbar. It is the transom structures on each floor of the building that distribute and transfer loads to columns and racks. Therefore, without a specific set of crossbars, it is impossible to build a modern frame building with optimal durability. For the construction of residential high-rises, public and commercial facilities, large-scale industrial buildings, crossbars certified according to GOST 18980-90 are required. These are reinforced concrete products that will undergo multiple stages of control - from input raw materials (quality and composition of concrete, its density, frost resistance and water resistance, evaluation of reinforcing steel) to final tests for load-bearing capacity, rigidity, crack resistance.

The purpose of the transom beam is to serve for many years as a support for decking made of flat floor slabs and coverings. The production of crossbars, as a rule, is carried out at large enterprises that can provide a decent level of production and control of finished concrete products. Concrete M300-M500 must meet the highest requirements for climatic resistance, resistance to cracks, etc. Optimally high resistance of crossbar beams to open fire is also required - at least 2 hours.

Making crossbars

According to GOST 18980-90, reinforced concrete crossbars must be made of concrete with a compressive strength of at least B22.5. Products are reinforced with steel frames and meshes made from steels A-III, A-IV, AV and others. The thickness of the protective concrete layer up to the reinforcement is strictly controlled - at least 20-25 mm. To produce crossbars that are resistant to any conditions, thermomechanically hardened steel and hot-rolled steel, as well as periodic wires, are used. The embedded products of the crossbars are determined depending on the type of fastening of the products and drawings. To facilitate installation and manipulation, the crossbars are equipped with steel mounting loops. The weight of the RDP 6-56 crossbar is 3775 kg; experienced drivers are ready to deliver large and oversized cargo.

Quality control of beam products

To guarantee the consumer the supply of high-quality frame reinforced concrete products, factories conduct a series of acceptance tests, which include checking the strength and endurance of beams. Also, the RDP crossbars provided to the site must be inspected for defects. If there is exposed reinforcement and wide cracks, the reinforced concrete products are immediately rejected and must be returned.

GOST 18980-90 defines permissible deviations from the design dimensions as undesirable, therefore the maximum deviation along the length of the RDP T-beam can be +/- 6 mm, and across the cross-section +/- 5 mm. Deviations in the straightness of the crossbar for multi-storey buildings are no more than 6 mm. As with other reinforced concrete load-bearing structures, crossbars should never have cracks in their concrete. Only cracks from compression and shrinkage of concrete, the width of which is not more than 0.15 mm, are allowed.

During acceptance tests, crossbars are tested according to the following indicators:

- class or grade of concrete in terms of compressive strength,

- transfer and tempering strength of crossbar concrete;

- compliance of reinforcement and embedded products;

- strength of welded joints;

- accuracy of geometric parameters;

- thickness of the concrete layer to the reinforcement;

- the possible presence and opening width of possible cracks;

Our specialists provide with each batch of transom beams a technical passport certifying the quality of reinforced concrete transoms. It informs the consumer about the number of reinforced concrete products in the batch, the date of manufacture of the crossbar, the weight of reinforced concrete products, and also provides the grade of concrete for frost resistance and water resistance (if necessary).

Transportation and storage

Beam products are transported and stored horizontally, in stacks no more than 2.5 meters high. Wooden spacers are placed under the bottom row of reinforced concrete crossbars, and the locations of the sling holes and lifting loops of the product are laid. Trust the delivery of reinforced concrete products only to specialists; our company has been supplying crossbars and columns throughout Russia for more than 15 years. We use only qualified drivers who deliver beams quickly and carefully. You can buy dimensional and oversized reinforced concrete products with delivery through our catalog or by phone.

www.complexs.ru