The main element of attic and interfloor floors in many private houses is a wooden beam. The service life of wood floors is limited due to the properties of the wood, especially if it has been poorly processed or has been subjected to stress and moisture.

As a result of such factors, the beam ceases to cope with the function assigned to it (sagging, deflection, curvature is possible) and reinforcement of the wooden floor beams will be required.

In addition to damage and loss of load-bearing capacity of floor and ceiling beams (joists, purlins), strengthening may be dictated by an increase in the load on the floor.

When to strengthen wooden floor beams

- poor condition of the beam structure

. The result is wood damage. High humidity, temperature changes, the activity of various pests (bark beetles), cracking - all this leads to deformation of the floor beam;

- reduction in load-bearing capacity

. Under their own weight, constant and variable load, floor beams can bend. According to the standards, if the deflection is within 1:300, then there is nothing to worry about. For example, if a beam is 2500 mm long. bent by 10 mm. this corresponds to the normal deflection value. If the deflection is greater, it should be strengthened;

- the need to increase the load-bearing capacity of the beam

. Associated, for example, with the reconstruction of an attic into an attic or living space. Such a restructuring will lead to an increase in constant and variable loads on the floors of the second floor, which automatically requires a change in the cross-section of the installed wooden beams.

Within the article, several common methods of strengthening the ceiling (repair, reconstruction) will be given. But only a professional can accurately answer the question of how to strengthen wooden floor beams and only after analyzing the condition of the structure. After all, in each case the decision will be individual.

Using the table, you can get an idea of what cross-section a beam should have under a certain load.

Permissible cross-section of beams under load

Material prepared for the site moydomik.net

Reinforcement samples and diagrams

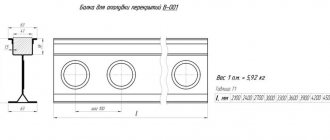

For testing, more than 30 beams of laminated wood measuring 3000x110x330 mm (LxWxH) were manufactured.

Structural reinforcement schemes:

- Control samples (without enhancement);

- Reinforcement along the bottom edge with carbon tape FibArm Tape 530/300 size 3000×100mm in 3 layers:

- Reinforcement of the bottom edge with carbon tape FibArm Tape 530/300 size 3000×100mm in 3 layers with inclined clamps:

Ways to strengthen wooden floor beams

The main types and methods of strengthening wooden floors are given in order of increasing labor costs and duration of work.

Type of amplification without changing operating conditions

Reinforcement with wooden overlays

The method is used when the tree is damaged. The pads are installed on both sides of the timber beam (on the sides or top and bottom), as tightly as possible to it and are fastened (tightened) through with a bolt. It is important to treat the damaged area and pads with an antifungal solution. In critical cases, if the area is severely damaged, it is better to remove it. To strengthen the beam, you need to attach an overlay along its entire length.

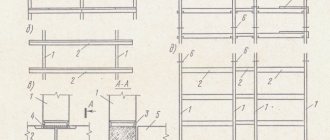

Reinforcement of spans with metal plates (plates) or rod prostheses

Steel plates are used instead of the wooden ones described above. The metal also needs to be treated with an anti-corrosion solution. The device diagram is shown in the figure.

Reinforcement of beam spans with metal plates and rod prostheses

Reinforcement of flooring with carbon fiber (carbon fiber reinforced plastic)

Modern reinforcement technology (carbon fiber reinforcement). Carbon fiber (strips, sheets, plates, threads, fabric) is glued in several layers until the required beam stiffness is achieved. The ease of use and lightness of the material lead to the fact that carbon fiber is gaining popularity as an effective means for restoring beams and building structures.

Below is a diagram of reinforcement (strengthening) of floor beams with carbon fiber.

Reinforcement of beams with carbon fiber

Reinforcement of beams with carbon fiber - diagram

Carbon fiber reinforced beams

Reinforcement at the ends with wooden or metal prostheses

The technology allows you to strengthen the beam at the junction with the load-bearing wall. This is exactly the place where, due to temperature changes, wood damage occurs faster.

The diagram below shows the technology of reinforcement with prostheses made of channel, rolled profile

Reinforcement with prostheses made of channel bars and rolled profiles

Reinforcement with prostheses made of channel, rolled profile – 2

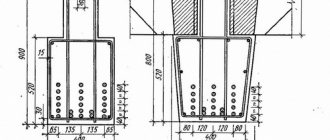

Installation of a rod prosthesis

The bar prosthesis of the Deidbekov system is made of two paired trusses, which are made from scraps of reinforcing steel with a cross-section (diameter) of 10-25 mm. The length of the prosthesis should be 10% greater than twice the length of the rotted end of the beam, but not more than 1.2 m.

Device of a rod prosthesis

- Install temporary supports under the ceiling at a distance of 1-1.5 m from the load-bearing wall, consisting of racks and purlins.

- Disassemble the ceiling from below to a width of 75 cm and from above - 1.5 m from the wall.

- Cut off the damaged section of the beam (0.5 m)

- Insert the prosthesis blank vertically into the interfloor ceiling and turn it to a horizontal position, first pushing it onto the beam, then pushing it into the wall niche in the opposite direction.

- Move and nail the sliding strip.

Installation of a rod prosthesis

Reinforcing beams with truss ties

Strengthening floors - installing trusses

Type of amplification with changing operating conditions

Strengthening wooden floors using these methods requires a significant restructuring of the supporting structure of the beam spans.

Changing operating conditions of structures

Changing the work pattern

Non-standard solutions

If it is not possible to strengthen the wooden floor beams, you can try to unload them, i.e., distribute the load from the existing beams to additionally installed elements.

Strengthening floors by installing supports under load-bearing beams

Supports supporting beams from below are a good way to redistribute the load from the beam to the support.

Strengthening floors - installing supports

Strengthening floors by installing additional beams

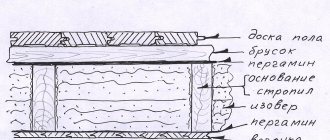

If the existing logs are intact and intact, their load-bearing capacity can be increased by increasing their number. Installing additional wooden beams will increase the load on the structure. When installing new logs, it is imperative to protect their ends with roofing felt to avoid damage.

Strengthening floors - installing additional beams

We hope that from the above methods of strengthening wooden floor beams, you will choose the one that will solve your problem in the best way and at minimal cost.

A number of defects allowed during the installation of beams (crossbars) and trusses

Like any other type of construction work, installation of reinforced concrete beams and crossbars can

Embedding the ceiling into the outer wall: a - supporting the beam on the wall; b - sealing of floor slabs: 1 - wall, 2 - lining, 3 - end of the beam to be sealed, 4 - floor slab.

be made with various defects. The most common are:

- displacement of the axis of the beam (crossbar) from the axis of the column;

- displacement of the beam (crossbar) in the plane of the transverse frames;

- incorrect connection of the beam (crossbar) with the column;

- laying a beam (crossbar) on a brick wall without providing a special support pad;

- the existing deviation of the crossbar (its plane) from the vertical;

- performing installation work using a beam (crossbar) with obvious defects.