Our services for fire protection of concrete and reinforced concrete structures

We carry out fire protection of all types of reinforced concrete structures using modern technology!

We offer the following work:

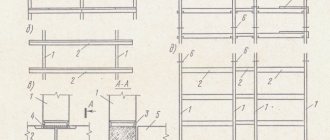

- use of slab or sheet cladding,

- installation of protective screens,

- plastering (or applying an additional layer of concrete) to the surface,

- painting with special fire-retardant paints,

- technical selection of the required sections of elements.

We calculate fire resistance based on the type, grade, moisture content of concrete, reinforcement thickness, geometry of supports and floors, load limit and designed fire protection thickness. And depending on these indicators, we select the best option - plaster, paint, sheet or roll material, etc.

The TechStroyGarant company offers fire protection services for concrete and reinforced concrete structures in Moscow and the Moscow region

Our fire protection work, carried out at a high level, provides long-term fire protection (from 120 minutes) for concrete and reinforced concrete structures

Always during or after a fire, concrete and reinforcing elements quickly heat up, as a result of which it loses its integrity.

For this reason, fire protection of reinforced concrete structures is of great importance - it ensures complete safety of the structure from the consequences of a fire and minimizes the cost of its restoration.

Thanks to the work of our specialists, you will reduce the possibility of fires to a minimum.

We have already protected more than 70 objects and guarantee increased durability of load-bearing structures under direct exposure to fire and high temperatures

Call 8 (495) 150-5-987 and consult for free!

We test the effectiveness of the chosen protection in laboratory conditions: we heat a concrete fragment covered with fireproof material to temperatures comparable to those in a fire.

We protect any buildings from fire: those under construction (at the design stage), recently built or in operation.

For small volumes of work, in order not to disturb the geometric shapes of the building surfaces, we are ready to apply fire retardant materials using hand tools.

For large volumes, plastering of protected structures is carried out using the wet shotcrete method, making it possible to create fire-retardant coatings that accurately replicate the shape of the building structure being protected.

Fire protection of reinforced concrete structures

Fire protection of reinforced concrete structures

Reinforced concrete is a composite material used in the construction of buildings for a wide variety of purposes.

It consists of reinforcement filled with concrete. Under normal operating conditions, reinforced concrete is durable, can withstand enormous weight and last for many decades. But in the event of a fire, both concrete and reinforcement warm up very quickly, losing their original qualities. Under the influence of high temperatures, the density of a reinforced concrete structure decreases, irreversible processes begin, as a result of which the very geometry of the building is disrupted. Without high-quality and effective fire protection, it can simply collapse due to a fire.

How to ensure proper fire protection of reinforced concrete structures

There are many ways to improve the fire resistance of reinforced concrete. Among the main ones we can highlight the following:

- special fire-retardant paints;

- fire-resistant plaster compositions based on basalt fillers;

- protective screens made of special plates;

- roll materials.

The purpose of fire protection is to prevent a decrease in the load-bearing capacity of reinforced concrete under the influence of high temperatures, to maintain thermal insulation properties, and to prevent deformation and destruction of the structure. The most effective means of fire protection for reinforced concrete are fire retardant paints.

Such protective compositions have several significant advantages over analogues:

- They provide a high degree of protection against overheating and at the same time prevent the spread of fire.

- They can be applied using the usual methods - brushes and rollers. The main thing is to make the coating as uniform as possible and without gaps.

- Even when exposed to direct fire, fire-retardant paints can protect reinforced concrete from extreme heat for an hour and a half or even longer.

Operating principles of fire retardants

These paints contain special flame retardants, due to which, when the temperature rises, the composition begins to swell and forms a dense insulating shell on the surface that protects from high temperatures. This process starts when the temperature exceeds 200°C. The protective shell does not allow fire to heat reinforced concrete and can withstand temperatures up to 700°C. At the same time, its decorative properties are preserved (if the temperature does not exceed 400°C).

To ensure that the fire retardant is as effective as possible, we recommend thoroughly degreasing and sanding the surface before applying it. It is important to ensure the highest possible adhesion - this will increase the effectiveness of the composition.

Fire retardant compounds for reinforced concrete structures SPECTRUM

One of the most common fire retardant compounds is SPECTRUM paints. These compositions have certificates of compliance with the Technical Regulations on fire safety requirements (Federal Law No. 123 of July 22, 2008). Production of the composition is strictly in accordance with GOST R 53295-2009.

Under the influence of high temperature, the SPECTRUM composition forms a porous foam material and protects reinforced concrete structures from heating. The manufacturer offers compositions with different fire resistance limits: REI 60, 90, 120, 150 minutes. They are suitable for all types of reinforced concrete structures.

Fire retardant paints SPECTRUM have the following properties:

- weather resistance - more than 25 years;

- resistance to chemicals;

- one hundred percent moisture resistance;

- adhesion – no more than 1 point;

- frost resistance – up to -60°C;

- impact strength – more than 50 cm;

- drying time to the third degree according to GOST – from 30 minutes.

SPECTRUM paints are presented in an assortment of RAL colors, which allows you to choose the color solutions that suit you. We also note that before applying SPECTRUM paint there is no need to prime the surface. Finishing is also not required, which greatly simplifies and speeds up the process of providing fire protection.

Where are modern methods of fire protection of reinforced concrete used?

Fire retardant compounds can be used in almost any reinforced concrete building, be it a production facility, an industrial facility, a warehouse, a parking lot or a residential building.

Important: there is a myth that the use of reinforced concrete in construction automatically solves fire protection issues. Actually this is not true. When exposed to ultra-high temperatures, the structure loses its properties within the first half hour and may collapse. Therefore, taking measures to improve fire protection is mandatory.

It is especially important to ensure a high level of protection in production and other facilities with an increased fire hazard. If you own such properties and they do not have adequate fire protection, be sure to consider using fire retardant paints. This is one of the best options today in terms of combination of price, quality and efficiency. If you have any questions about the use and specifics of such compositions, contact our representative for a free consultation.

Prices for fire protection of reinforced concrete

We understand that the customer should under no circumstances refuse fire protection because of the high price, therefore we try to offer affordable prices for fire protection of reinforced concrete structures.

| Fire resistance limit | Price |

| R30 | from 440 rub/m2 |

| R45 | from 540 rub/m2 |

| R60 | from 790 rub/m2 |

| R90 | from 1,000 rub/m2 |

| Protection with plaster compounds | from 800 rub/m2 |

*R - loss of bearing capacity after a specified number of minutes.

The cost of installing fire protection is affected by:

- features of the object - purpose, geometry, presence of problem areas, grade of concrete, type of reinforcement, etc.;

- surface condition – wear, need for preliminary cleaning;

- remoteness of the object – the delivery price depends on it;

- volume of work and its complexity;

- required fire protection limit.

Many of these factors influence the choice of material, which is the largest component of the price. In addition: we use lightweight materials, but in some cases a reinforcing frame is still required. Installation work is also included in the total cost.

is a certified dealer of the best domestic and foreign manufacturers of fireproof materials.

Concrete fire protection technology

What kind of fire protection the concrete structures will have is thought out at the early stages of designing a building under construction. The main goal of comprehensive measures to protect components is to increase the time during which signs of maximum loads will be reached. Namely:

- Reduced load-bearing capacity (R)

- Loss of thermal insulation properties (I)

- Fracture and deformation (E)

Fire retardant treatment of concrete is primarily aimed at preventing a rapid decrease in bearing capacity, destruction and deformation of the most important components. Transformations begin to occur when the surface is heated to 350° degrees.

When determining fire resistance, the following are taken into account:

- Type of concrete and degree of its moisture content.

- Class and thickness of reinforcement.

- Thickness of fire retardant treatment of concrete surfaces.

- Geometry and design of supports.

- Maximum load level.

Based on the audit results, the degree of fire resistance is calculated. Additional measures are being thought out to increase resistance, solutions are being checked against GOST for fire protection of reinforced concrete structures.

Depending on the situation, the following types of concrete fire protection can be used as an additional measure:

- Fire retardant paints and compositions for reinforced concrete.

- Plaster composition for increasing the fire resistance of concrete based on vermiculite and other basalt fillers.

- Plates for creating a protective screen.

- Roll materials.

In addition, special design solutions are being developed for reinforced concrete floors and ceilings to reduce heat and fire loads and prevent the rapid occurrence of a fire.

Photos on fire protection

Fire protection at the Skolkovo Tambov Innovation School

In a short time, TechStroyGarant specialists completed a large amount of fire protection for load-bearing metal structures of the Skolkovo-Tambov Educational Complex. This is a school with 2,425 places and 97 classes.

Read more >>

Fire retardant and anti-corrosion treatment in the elite residential complex Polyanka 44

Fire protection of load-bearing metal structures and anti-corrosion treatment of the construction site of a residential complex with an underground parking lot “Polyanka 44” has been completed. The reconstruction of the residential complex is being carried out by a large general contractor "CODEST". The most modern and reliable fireproof materials Promat were used.

Read more >>

Fire protection of metal structures of GAZPROM Boiler House in Tikhvin

Work was carried out to bring the fire resistance limits of the metal structures of the Boiler House and Administration Buildings to the required level by applying the fire retardant composition “Terma” and the foil fire retardant material “Bison” for metal structures with a total area of 5953.39. The VMP anti-corrosion system is used.

Read more >>

Fire protection of wooden structures in the Serebryany Bor complex in the Klinsky district

Checking the quality of fire retardant treatment of air ducts Types of fire protection of metal structures Checking the fire protection of metal structures Degree of fire protection of metal structures

TekhStroyGarant carried out fire protection of wooden structures in the Sports and Recreation Complex (PHC) and Congress. A large volume of laminated wood structures were treated with fire retardant compounds from the manufacturer NORT, which were coated with fire retardant varnish.

Read more >>

Fire protection and anti-corrosion treatment of non-residential premises of the Zvezda film studio

"TehStroyGarant" carried out fire protection and anti-corrosion treatment of load-bearing metal structures and engineering systems in the premises of the TV and film studio of the Zvezda TV channel with a total area of 2421.9 sq.m. The work was carried out in difficult access conditions.

Read more >>

Anti-corrosion treatment in the Boiler House on the territory of the military-patriotic park in Kubinka

We completed anti-corrosion treatment of a total area of 3000 m of the boiler room for the heat supply system of the Military-Patriotic Park of Culture and Recreation of the RF Armed Forces “PATRIOT” in the city of Kubinka, Moscow region.

Read more >>

VIEW ALL PROPERTIES

How to order fire protection for concrete structures from our company

- You can order fire protection work in Moscow or another region by phone or on the website.

- Our specialist accepts the application and discusses with you the details of ensuring the security of the facility.

- We coordinate with you a visit to the site and examine the scope of work: we select a fire protection method and materials, draw up a plan, determine the deadlines, and agree on the estimate.

- We clean, degrease, level and prime surfaces, preparing them for the application of paints or compounds.

- We apply protective coatings and install fireproof screens.

- We hand over the work of the fire laboratory, after which you receive a certificate of completion, a license from the Ministry of Emergency Situations, a certificate for the fire resistance of materials, and a conclusion from a fire laboratory expert.

- We monitor the quality of fire-resistant coatings annually.

You can obtain more detailed information about the fire protection of concrete and reinforced concrete structures by calling us at 8 (495) 150-5-987 or through the feedback form.

Structural fire protection

Structural fire protection is understood as increasing the fire resistance of structures by cladding with fire-resistant panels, special plaster, as well as by filling voids and gaps with heat-insulating elements.

- MONOLITH The structural fire protection system “Monolith” is designed to increase the fire resistance limit of load-bearing reinforced concrete structures. Special development for the protection and finishing of vaults and walls of automobile and railway tunnels in conditions of “hydrocarbon” fire.

- MONOLITH OB The structural fire protection system “Monolit OB” is designed to increase the fire resistance limit of load-bearing reinforced concrete structures. Special development for the protection and finishing of vaults and walls of automobile and railway tunnels in conditions of “hydrocarbon” fire.

- SMP-01 Mineral wool boards made of modified fire-resistant fibers are designed to increase the fire resistance of load-bearing metal and concrete structures, as well as air ducts.

- Miropan-PRO-Tunnel Calcium-silicate fire-resistant fiber panels for the protection of vaults and walls of railway and road tunnels. Increases the fire resistance of reinforced concrete structures. R(EI) 240.

- Miropan-PRO-wall Calcium-silicate fiber panels for protecting internal walls and constructing fire partitions. R(EI) 240.

- Monolith-tunnel Fireproof plaster system for finishing and protecting walls and vaults of transport tunnels. The kit includes a fire retardant mixture, a covering layer, a galvanized steel reinforcing mesh with fasteners. EI 240.

- AK-strong Fire protection system for concrete and reinforced concrete structures using external reinforcement. R(EI) 180.

- Shov-AK-1 Innovative system for filling expansion joints of any width. Increases the fire resistance of objects made of concrete and reinforced concrete structures, including those built in seismic zones. R(EI) 240.

Consequences of fire on reinforced concrete structures

Concrete does not burn, reinforced concrete structure (concrete + metal reinforcement) also does not burn and does not support combustion. It may seem that in a fire in a concrete building, only the finishing and interior are damaged. But this is a big mistake. Four factors that cause catastrophic consequences in a concrete structure during a fire:

- deformation and violation of the structure of concrete. Any material has its own temperature limit. This applies to both the concrete itself and the steel rods with which it is reinforced. Damage to the structure leads to loss of load-bearing capacity, and this can lead to the collapse of the building;

- water in the structure. Like any porous material, concrete contains some amount of moisture. When exposed to heat, it boils, expands and produces an explosive effect. The wetter the concrete, the faster this happens. In raw material - after 5-20 minutes, and the amplitude of the scattering of fragments during an “explosion” reaches several meters;

- Fire extinguishing water, which is present in any building in use, has a negative effect when used: due to the temperature contrast, the structure cracks;

- expansion joints between panels in buildings are filled with sealants that burn and melt. As a result, the joint is exposed, and smoke, flame, and oxygen spread through it to maintain combustion. Once the fire is over, this joint is no longer functional and must be resealed. Otherwise, it is susceptible to atmospheric influences, which changes the microclimate inside the building and again the concrete suffers.

That is why fire protection of concrete and reinforced concrete structures is necessary.

Our licenses

License No. 50-B/00378

SRO extract N0000627

More details

Fire protection of reinforced concrete and concrete structures

Fire retardant coating based on high molecular weight rubber for metal structures

Fire retardant efficiency: up to R120 Permissible relative humidity during operation: up to 100% Service life: at least 30 years

Concrete and reinforced concrete structures are widely used in the construction of buildings and structures for various purposes: residential, industrial, public, administrative. They need effective fire protection. This is not only a fire safety requirement, but also a guarantee of the reliability of the facility. Thanks to them, concrete walls, floors, and frame elements can resist thermal effects longer without deforming and, accordingly, without becoming a source of threat to residents and staff. When exposed to high temperatures, structures become brittle and pieces break off, which can lead to complete destruction of the object. This is due to various reasons:

the properties of the concrete itself change - at temperatures above 250-300 °C, the cement binder is destroyed, and when it reaches 550 °C, the quartz grains contained in sand and crushed stone change into another modification, and their volume increases;

- due to thermal effects, the dimensions of the reinforcement located inside it change;

the moisture contained in the material boils due to intense heat and provokes the explosive breaking off of individual pieces;

When extinguishing a fire with water, large cracks form, caused by differences in thermal deformation of one or another element.

This state of affairs must be avoided.

Requirements for fire protection of concrete structures in accordance with SNiP and GOST

The fire resistance of individual structures and buildings as a whole has a numerical and alphabetic expression. The numbers indicate the number of minutes during which the structure resists flame and thermal effects before critical conditions occur. There are 11 fire resistance limits in total - 15 minutes, 30, etc.

The letters indicate what kind of damage occurs at the end of the above period:

- R – loss of bearing capacity;

- E – destruction

- I – loss of functionality of heat shields.

In accordance with the 01/21/97 edition of SNiP, all buildings are assigned a fire resistance category from I to V. And this is how the minimum regulatory fire resistance limits of individual structures relate to their functionality in buildings from the first to third categories:

- load-bearing elements – R from 45 minutes (third) to 3 hours (first);

- external walls – E from 15 min to 30;

- interfloor ceilings – REI 45 – 180;

- roofless floors, decking – RE 15 – 30;

- roof purlins, trusses and beams – R 15 – 30;

- internal walls and partitions REI 60 – 180;

- landings and flights – R 45 – 60.

GOSTs regulating fire protection rules for concrete:

- 12.1.004-91 – fire safety;

- 30247.0-94 – methods for testing the fire resistance of building structures;

- R 52293-2009 – fire classification of materials, fire protection means.

structural fire protection

Materials for the protection of concrete structures

Ensuring the standard fire resistance limit of a structure is achieved through the installation of fire retardant materials. They are divided into several groups:

- boards made of foamed vermiculite and other fire-resistant substances;

- thermal insulation plaster;

- LMB;

- roll materials.

The lightest coatings are paint and varnish. Their advantages:

- ease of application, even in hard-to-reach areas;

- the smallest weight and volume. Because of this, additional supports and frame elements are never required for installation of paintwork materials.

Fireproof paints can be intumescent or non-intumescent (based on silicate materials). The former, under the influence of high temperatures, increase in volume, depending on the brand, by 10-40 times. Following this, chemical decomposition begins, which occurs with the absorption of heat and the release of non-flammable gas. Ultimately, a coked layer of foam forms on the structure, which can protect the concrete from thermal effects for quite a long time.

There are paints for interior and exterior (weather-resistant). The latter can also be used inside - for unheated rooms, in conditions of high humidity. In addition, the compositions are one-component and two-component, transparent and tinted. The fire resistance limit of paintwork materials, depending on the brand, is 2.5 hours.

Another popular material is fire-resistant plasters. In their manufacture, quartz sand and lime (calcium hydroxide) are not used since the fire resistance of these substances is below 550 degrees. Heat-resistant plasters are made on the basis of liquid glass, gypsum, pozzolanic Portland cement + vermiculite, diatomaceous earth, mineral fiber and other components.

We offer not only protective treatment for reinforced concrete, but also metal and wooden structures.

Call 8 (495) 150-5-987

Fireproof paints for concrete

Intumescent compounds are a popular fire protection option that increases the fire resistance limit of reinforced concrete to 150 minutes. Such paints are water-based with the addition of gas- and foam-forming heat-resistant fillers. After being applied to the surface and drying, the paint creates a decorative effect, but when heated it expands 10–40 times its original thickness. In addition to a thick physical barrier, the fire retardant composition for concrete releases inert gas and water, that is, three factors at once reduce the negative effects of open flames and extremely high temperatures.

Depending on the composition, fire-resistant paints for concrete can be used for interior and exterior work. Outdoor weather-resistant materials do not deteriorate under the influence of precipitation and are suitable for internal treatment of unheated wet rooms.

Fire protection work for reinforced concrete and concrete

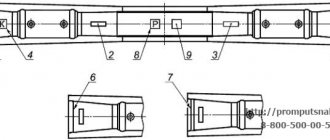

To install slab protection, we most often use products from one of the most famous manufacturers in the industry - Promat. Slabs for concrete cladding are represented by the Promatect H brand. This is a large-format product manufactured according to the international standard ISO 9001.

The slab is silicate, the binder is Portland cement. It can be used for fire protection of reinforced concrete floors, walls, partitions, as well as for fire cladding of wooden and metal surfaces. Fire resistance limit – up to 3 hours. Dimensions:

- thickness – from 6 to 25 mm;

- length and width – 250 by 125 cm;

- weight per square meter depending on thickness from 5.6 to 23.2 kg;

- density 870 kg per cubic meter.

Main characteristics:

- non-flammability;

- moisture resistance;

- high strength;

- ease of processing.

The material can be cut, drilled, milled with ordinary wood tools. Some difficulty is created by the dust that arises during processing - it is harmful to the respiratory organs and mucous membranes. It is better to entrust installation to professionals equipped with personal protective equipment.

The main thing that simplifies installation is that Promatek-N slabs are self-supporting, i.e. a frame is not required for their installation. Mounted end-to-end, without overlaps, fixed with self-tapping screws or staples. Finishing – decorative plasters, ceramic or clinker tiles.

For your information

Non-flammable fire-retardant plasters for reinforced concrete and metal structures from the manufacturer Promat are represented by the Promat Fendolight and Promat Neosprey brands.

Their composition:

- Portland cement;

- expanded vermiculite;

- modifiers.

Main characteristics of Fendolight:

- density – 775 kg per cubic meter;

- consumption per layer 1 cm thick – 6.45 kg per square meter;

- seismic resistance 9 points;

- resistance to cryogenic liquids;

- fire resistance limit – up to 4 hours;

- service life - up to half a century.

Neosprey:

- density – 500 kg per cubic meter;

- consumption per centimeter layer - 4 kg per square meter;

- fire resistance limit – up to 4 hours;

- service life – up to 25 years.

Both compositions are suitable for both indoor and outdoor use. We apply them using special equipment approved by the manufacturer - periodic or continuous plastering stations (Putmeister, etc.). Application technology – wet shotcrete. Requirements for working conditions:

- prepared clean, dry surface;

- air and surface temperature – not less than + 2, not more than + 45.

Upon completion, we apply a weather-resistant paint coating to the treated surface.

fire protection from experts

Protection methods

Methods of fire protection for concrete include the use of materials that can become an effective anti-thermal screen. For this use:

- special paint and varnish products;

- different types of thermal insulating plaster;

- lightweight non-combustible slabs made of expanded vermiculite;

- roll protection.

The most in demand due to the simplicity and ease of work are paints and plasters.

Paintwork

Fire protection of reinforced concrete structures is often ensured by applying special paints to them. Their main advantage is the absence of additional load on the elements, ease of application, and treatment of hard-to-reach areas. Based on chemical and physical characteristics, they are divided into two categories:

- Intumescent. When such paint is exposed to an open flame, it “grows” in volume ten to forty times (the indicator depends on the properties of the composition). In addition, during fires, such a coating decomposes, strongly absorbing heat. At the same time, non-flammable gases are released, due to which coked foam is formed, which protects concrete surfaces from heating for a period sufficient to eliminate fires.

- Non-intumescent. Do not expand under high temperatures. Usually made on the basis of vermiculite (a mineral from the silicate class). Apply to floors, walls, beams, concrete columns, etc.

Such products are divided depending on what kind of work - external or internal - they will be used for. In the first case, the paint is weather-resistant; it is often applied inside unheated rooms with high humidity levels. The compositions can be transparent (preserve the texture of the material), colored (for floors, walls). For floors, in order to increase the wear resistance of the coating, it is practiced to apply two-component paint. Special paint and varnish products are a fairly inexpensive solution. It can protect structures for 150 minutes.

Thermal insulating plaster

An equally popular solution in the fire protection of reinforced concrete products is the use of special plaster compositions and pastes applied to reinforced concrete floors using manual tools or by shotcreting (layer-by-layer “spraying” using compressed air). They are capable of providing fire resistance to structures for up to 4 hours.

In such mixtures, the use of quartz sand as a cement binder is not allowed. The fact is that at a temperature of 550, slaked lime (calcium hydroxide) is released from the cement, which causes the surface of the coating to crack, and the plaster can no longer effectively withstand the flame.

In modern pastes and mixtures, gypsum, liquid silicate glass, and pozzolanic Portland cements are used as binders. Manufacturers prefer heat-resistant vermiculite, mountain flour (diatomaceous earth), and similar materials as fillers. The main disadvantage of plasters is their low moisture resistance (this applies to light mixtures with perlite and vermiculite, the binder component is gypsum). Compositions with mineral fibers have the best characteristics (plus, they do not carry additional structural load).

Note. When applied, the layer of plaster should not be more than four centimeters, and the paste should not be thicker than one centimeter.

14+ years experience

Only correct installation will eliminate the risk of destruction of supporting structures and, accordingly, collapse of the structure in the event of a fire.

ORDER

Promat Phoenix STV paint for reinforced concrete and metal structures is a one-component, ready-to-use, water-based composition. The finished coating is opaque white. Designed for use in warm, dry rooms, with an additional weather-resistant coating for outdoor use. Advantages:

- quick drying (one layer dries in 2-4 hours at humidity up to 65%);

- environmentally friendly (can also be used in food industry enterprises);

- compatibility with many soils;

- European certificate EN 13381-8.

Characteristics:

- density - 1.25 grams per cubic centimeter;

- consumption per layer 1 mm thick – 1.7 kg per square meter;

- service life – up to 30 years;

- fire resistance limit – up to 2.5 hours.

We apply paint using airless spraying at temperatures from +5 to +35 (humidity no more than 80%) in the absence of precipitation. Application by hand, roller or brush is also allowed.

In addition to Promat brand materials, we use products from other well-known manufacturers for installation of fire protection:

- Armacell;

- Buffalo;

- Defender;

- Terma.