Sometimes during construction, at the stage of laying the foundation, it is discovered that it is not possible to use standard materials that are usually used for pouring the foundation, such as sand, cement and crushed stone. What could be an alternative material for laying a foundation?

These are, of course, railway sleepers - a very inexpensive and accessible material. The good thing about a sleeper foundation is that the consumables for it are quite easy to get. The second indisputable advantage is the low price, and if sleepers are delivered directly to your home, then you simply cannot find a better material for laying the foundation of a future home.

Many people speak out against the use of sleepers in laying the foundation for a house, because such sleepers probably already have a long history of working as a railway track.

We hasten to dispel this myth and assert that sleepers, the material of which is thoroughly impregnated with creosote, have a truly unlimited service life and can serve faithfully for many years to come as a reliable foundation for a residential building.

How to build a foundation from reinforced concrete sleepers correctly?

Strip foundation made of sleepers for permanent buildings.

Most of the opponents of the use of sleepers as a material for the manufacture of foundations accuse the impregnation that is used in the production of railway tracks - creosote.

It is known that this substance, which has a characteristic odor that is quite difficult to tolerate, contains components that are toxic to humans. Some people express concern when it is recommended that they build a foundation for a private home using sleepers that are impregnated with creosote.

You should know that this is actually true. New sleepers that have just been manufactured are not recommended for construction. However, this does not apply to sleepers, the operational period of which as a railway track has come to an end.

Such sleepers spent quite a long time in the open air, therefore, the sun's rays and numerous precipitation managed to remove most of the harmful impregnation from their surface. Therefore, a foundation made of sleepers with a long service life is absolutely safe to use as the basis for the construction of private houses, which are made using frame technology. Such houses are much lighter than their analogues, which are built from materials such as blocks or bricks.

To work you will need the following elements:

- reinforced concrete sleepers;

- cement;

- crushed stone;

- sand;

- special equipment for lifting reinforced concrete sleepers;

- metal staples;

- metal pins;

- bitumen;

- composition with antiseptic properties.

Nuances of creating a foundation

Before work, you need to carefully check all materials for quality.

Many newcomers to the construction trade consider the use of sleepers to create a foundation unsafe, citing the impregnation of this material - creosote. The fact is that this substance has a rather pungent odor and contains components that can harm human health. But all these fears are not justified, since only recently made sleepers cannot be used for the construction of houses, and products that are exposed to the open air for a long time are quite suitable. Precipitation and sunlight have removed the harmful substance from the surface of the material, and now it is safe for humans.

It is recommended to use sleeper foundations for the construction of frame houses. Such a building will be much lighter than its counterparts built using standard materials.

Before you begin, you will need to prepare the following tools and materials:

- reinforced concrete products;

- cement;

- crushed stone and sand of fine or medium fraction;

- equipment for lifting sleepers;

- metal staples and pins;

- bitumen;

- antiseptic solution.

Sleepers can also be used to construct garages or sheds.

Areas of application of sleepers in the construction of foundations

Before making a decision to use such material for the construction of the foundation, the developer must take into account certain features that can play an important role in the construction of the foundation:

- purchasing sleepers that have reached the end of their intended service life at an affordable cost;

- possibility of transporting purchased material to the construction site. The fact is that transportation costs and payment for loading and unloading operations can “eat up” all your savings;

- the structure proposed for construction must be light in weight;

- performing all the work on building a foundation from sleepers with your own hands, without involving a construction team.

Using sleepers, you can build a classic version of the foundation, characterized by reliability and a long operational period, but the technological conditions of the work must be observed.

In addition, the developer has a choice - to use reinforced concrete sleepers for construction or opt for wooden analogues. Everything here is determined by your financial budget.

Some are wary of using sleepers made of wood material impregnated with creosote, which gives the wood a long service life and protects it from rotting. This impregnation has an unpleasant odor and is considered poisonous. But all the fears are in vain - over the entire period of operation on the railway track, the sleepers have long been weathered of creosote, and its dangerous properties have disappeared.

A good advantage is that decommissioned sleepers for foundation construction can be obtained almost free of charge during repair work on railway tracks. In addition, construction of the base is possible on your own, because the material does not require special processing and does not cause installation difficulties. You just need to have an assistant on hand to help move the sleeper to the right place and lay it in the foundation trench.

Sleepers can be used to build a bathhouse or outbuilding, for a garage and gazebo, for a barn or a light country house. But most often, a foundation made of sleepers is in demand for a greenhouse. As a rule, a foundation is erected for such a structure in the following cases:

- installation of a greenhouse close to a residential building and its year-round operation;

- its location in an unguarded place;

- penetration into the soil below the freezing point of the soil;

- use for lumber construction;

- construction on a site with unstable soil composition or uneven terrain;

- construction of greenhouses of non-standard sizes.

Laying waterproofing and insulation

Waterproofing is applied over the foundation, only after this should sleepers be laid. The concrete must be treated with resin and roofing felt applied. Later, the first layer of sleepers is laid. To build the first layer, it is best to choose sleepers that are large in size and heavy in weight. The shawls are connected to each other with a tenon joint.

Foundation waterproofing device

The gap between the equipped foundation and the laid sleepers must be insulated from

We suggest you familiarize yourself with How to install a door closer on a wooden or metal door with your own hands

moisture. This is achieved by pouring molten bitumen onto the foundation base and then laying roofing felt. Another layer is laid in a similar way after the bitumen has completely hardened.

Construction of bathhouse windows and doors from sleepers

Doorways can be made both during the construction of a building and after its completion. Due to lower labor costs, you should give preference to the second method: you just need to cut out the necessary holes in the finished log house using a chainsaw.

When deciding to install door frames during construction, prepare for a complex process and take into account possible shrinkage of the finished structure. At the same time, built-in boxes can cause its unevenness, and this in turn may require additional repairs.

What should you pay attention to when laying a foundation with your own hands?

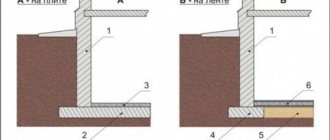

Columnar foundation made of wooden sleepers: 1 - Sleeper; 2 - Waterproofing, which should already be present on the sleeper; 3 - Concrete shoe (option 1), brackets (option 2); 4 - sand cushion (option 1), wooden support (option 2); 5 - sand cushion.

We suggest you read: What kind of foundation for loamy soil?

The construction of the foundation of a private house must be approached with special responsibility. This is due to the fact that today the market for construction-related services is rapidly developing, while some contractors do not quite correctly prioritize the construction of private houses, ignoring basic safety rules. An unscrupulous attitude towards laying the foundation in the future can easily turn into a disaster for all residents of the house.

In the process of selecting railway sleepers for the manufacture of a foundation, it is quite important to control the purchase of material and carefully analyze the road surface that will be used for the construction of the foundation of a private house.

If the sleepers are too worn out, they may result in a poor-quality foundation that will need to be restored over time, spending quite a lot of money. The savings that were achieved at the beginning may come to naught in the event of such a sad ending. It is necessary to carefully monitor the activities of an organization that plans to build a foundation from sleepers.

Sleepers must be additionally impregnated with moisture-repellent agents before laying.

Some people mistakenly begin organizing all construction processes by designing the foundation of the future building. However, you should know that this is not the most rational approach, because first of all it is recommended to determine the territory of the site. Once a suitable choice has been made, you can save some money for further construction.

If you carefully approach the design and laying of the foundation of a future building, you can achieve maximum reliability and a long period of operation of a residential structure.

It is preferable to lay such a foundation on soils with a high degree of hardness, otherwise it will not be possible to avoid settlement under the pressure of the total weight of the building. Foundations that can be constructed using sleepers come in different types:

- columnar;

- tape;

- pile;

- slab;

- foundation on sand cushions.

The sleepers can be laid on a gravel bed; moisture will not linger on it, and the sleepers will not rot.

Of all these types of load-bearing structures, strip and column bases are best suited for using sleepers.

During the construction of the strip foundation, logs will be joined along the entire perimeter. If sleepers are planned to be laid horizontally, the markings should be carried out according to plan, after which you will need to make 2-3 rows under the base. These rows should be connected to each other.

A layer of sand and crushed stone, well compacted and moistened, should be placed under the foundation from below. Next, sleepers are laid on top, which are placed with overlapping joints, as in brickwork. Metal staples should be used to secure the end joints. Metal pins should be used to tighten the bottom and top layers.

If you plan to lay a columnar foundation, the logs will need to be placed vertically at a certain distance from each other. During the preparatory work, sleepers must be treated with a special compound with antiseptic properties and coated with bitumen. This type of foundation has a long service life, which can be up to 50 years.

Making a foundation from wooden sleepers

This material is not only used to build the foundation, but also to construct the bottom row of the frame. It is advisable to use sleepers that have not been treated with creosote, otherwise they should be completely immersed in the soil.

Before use, the surface of the wood is coated several times with antiseptic compounds to prevent rotting, exposure to moisture and insects. Before processing, the material is carefully inspected for defects that could cause weakening of the entire structure.

When construction is planned on support pillars, the sleepers are placed vertically and tied. This installation option is suitable for small rooms whose load-bearing walls do not create a large load.

The sleeper foundation for the greenhouse is mounted using the method of installation on the surface of the earth. This base is easy to adjust in height, installation work does not take much time. The same method is used to build foundations for light garages and country houses. A foundation made of wooden sleepers for a barn laid on the surface of the earth is also reliable and can last for several decades.

We suggest you familiarize yourself with: Do-it-yourself jug - installing a jug

Under walls constructed from heavy materials, railway sleepers are laid horizontally in a prepared foundation trench. A cushion of crushed stone or sand is first placed at the bottom.

A layer of waterproofing material is laid between the foundation base and the walls of the facility, which at the same time creates protection from the creosote odor. The depth of laying sleepers is determined taking into account the characteristics of the soil composition on which construction work is being carried out.

Let's take a closer look at the vertical installation of sleepers.

Installation work is carried out as follows:

- The position of the supports is noted at intervals of two to two and a half meters. The installation step depends on the expected loads on the foundation and can be reduced;

- pits of the required depth are formed;

- the bars are placed vertically;

- the pits are filled with rubble stone, compacted and concreted. To add additional strength, you can use reinforcement from metal rods.

A foundation made of reinforced concrete sleepers is considered a more expensive option than its counterpart made of wood material. However, its range of applications is wider. You can even build a foundation for a frame house from reinforced concrete sleepers, if the number of floors in it does not exceed two levels.

Transportation of structures is more labor-intensive than transportation of wooden sleepers, and this is explained by the difference in the weight of the elements.

To lay a strip foundation made of railway sleepers, a foundation trench is first prepared, the depth of which is determined taking into account the weather conditions of the region. If the soil composition is prone to crumbling, then a formwork structure made of wooden panels is placed at the height of the foundation and the plinth.

Due to the solid soil composition, it is allowed to install formwork only for the base, the height of which is approximately one and a half meters from the surface of the earth. At the bottom of the trench, a sand cushion is placed in a layer of fifteen to twenty centimeters.

The sleepers are laid in rows, and the staggered order of their placement should be observed, without joining the rows of structures with the previous ones. With this installation option, the base has a high reliability indicator and resists movements of the soil composition. It is recommended to pour a layer of mortar fifty centimeters deep after each row. The distance between adjacent elements of the same row should be within seventy centimeters, and the foundation will serve you for a long time.

A column foundation made of reinforced concrete sleepers is considered a more economical option, since its construction requires less building materials.

Unfortunately, the installation work on its construction is characterized by certain difficulties, since vertical installation of heavy reinforced concrete sleepers by hand is impossible. We will have to involve a working team and install special lifting devices.

Construction work begins with marking. After this, a hole is dug under each sleeper, observing the installation step determined by the calculated data.

The depth of the pit should be one and a half to two meters, its width is determined by the cross-section of the structure, taking into account the need for a space around the sleeper to be filled with cement mortar.

Before installing the support, sand and crushed stone are poured into layers at the bottom of the pit, everything is thoroughly compacted. As soon as the place for installing the sleeper is prepared, a reinforced concrete product supported by a winch is lowered into the hole. The pillars are adjusted vertically, after which all free space is concreted.

The use of such sleepers can be considered using the example of a foundation for a greenhouse. To make a foundation from wooden sleepers for a greenhouse, you need to start by preparing the base. You will need to dig shallow trenches around the entire perimeter of the greenhouse. Sleepers are laid in trenches so that their upper edges are flush with the ground. In case of unstable, moving soils, the foundation will need to be made deeper and the sleepers will need to be laid in several pieces next to each other.

- Using construction staples.

- Overlapping with additional fastening using nails. For such a connection, it is necessary to make a sample at the end of each of the sleepers to half their thickness, 20 cm long.

The structure will be connected vertically using reinforcing bars or crutches, which are pre-inserted into the drilled holes.

The base for the bathhouse is made in the same way, but you will need to be more careful about the issue of its deepening. On soils that are subject to heaving, it is necessary to lower it to the entire freezing depth. If the groundwater is deep and the soil is stable, it may be possible to get by with a shallow foundation.

We invite you to read: Foundation made of blocks, step-by-step instructions on how to make it yourself

Making a foundation using sleepers is quite simple if you follow all the rules and have the necessary tools. The only thing you should take care of is special equipment for moving sleepers.

Final Steps

How to caulk a bathhouse from sleepers

At the final stage of construction, lay boards with a thickness of 55 cm on the beams, and then lay slate or roofing felt on the structure. Leave the bath for 6 months without touching it for the necessary shrinkage.

We invite you to familiarize yourself with the DIY pool pump with filter

As soon as the structure has given the necessary shrinkage, you can begin to caulk it. To do this, stock up on a hammer and caulk made of wood or metal. If you are unable to find this tool in the store, make it yourself using an electric jigsaw.

The bathhouse is caulked as follows: the insulation is twisted into a tight bundle and pushed between the sleepers of the crowns. The result should be a perfectly even and dense insulating seam. This step does not need to be carried out when initially using jute fibers as an insulating material, since this insulation itself is quite dense.

To give the building an external appeal, you can cover it with siding or other material of your choice.

At this point, the construction of a bathhouse from sleepers is considered complete, and if you carefully study the technology, it should not present you with insurmountable difficulties in the process. The main thing is to be patient, which will pay off in the end.

Strip foundation made of reinforced concrete sleepers

For a two-story frame, wooden house or a one-story structure made of brick or concrete blocks, in most cases a strip foundation is made. Concrete sleepers are laid in wooden formwork, which can significantly reduce the cost of cement for pouring.

It is important to note that it is not recommended to lay sleepers directly on top of each other. The height distance between them should be about 50 cm. In this case, the distance between the edges is 50-70 cm.

A foundation made of reinforced concrete sleepers, which is made in this way, can be quite strong and last a long time.

Foundation construction procedure

The construction of the base must be treated with great responsibility. It is necessary to carefully analyze the condition of the products that will be used for such work. If they are damaged, the created foundation may turn out to be of poor quality and after a certain time it will be necessary to carry out restoration procedures.

Before laying sleepers, they must be thoroughly treated with special water-repellent solutions.

It is best to create such foundations on soil with high hardness to prevent the possibility of settlement under the load of the house. The foundation made of reinforced concrete sleepers can be of different types:

- Columnar;

- tape;

- pile;

- slab.

The optimal solution for using such material are tape and columnar varieties. For a strip base, logs must be laid around the entire perimeter. A layer of sand and crushed stone is preliminarily laid under the foundation, which will need to be thoroughly compacted and moistened. Then sleepers are placed on top, which are placed with overlapping joints. For fastening you need to use metal staples and pins.

If it was decided to use a columnar base, the logs should be placed vertically with a certain interval from each other. During preparation, it is necessary to treat the sleepers with a special antiseptic and bitumen. This type of foundation has a fairly long service life, which can last up to 50 years. The sleepers are laid on a concrete base and gradually covered. They are then connected to other sleepers installed in a similar pattern.

The following video will help you learn in more detail about the procedure for creating a foundation from sleepers with your own hands.

Tape base made from sleepers

For two-story wooden houses, it is best to create a strip base. In this case, concrete sleepers are laid in a special formwork made of wood, which allows you to save a lot on pouring cement. The whole procedure consists of the following steps:

- First, a trench is dug. Its depth must exceed the soil freezing level.

- The formwork is being created. Often boards are used for manufacturing. It must be securely fastened from the bottom of the pit to the top of the basement.

- A layer of sand is added to a height of up to 20 cm. This will help prevent damage to the foundation.

- A cement mixture or concrete is prepared.

- Concrete is poured along the entire perimeter of the pit to the required height, after which the sleepers are installed. They will be used as buta. Then a new layer of concrete is poured and the sleepers are laid again. They need to be installed not on top of each other, but in a checkerboard pattern. According to this scheme, the base is poured to the top of the formwork. This will prevent the tape from cracking. The height interval between sleepers should be about 50 cm. The distance between the edges can vary from 50 to 70 cm.

Columnar base made of sleepers

To install such material you will need to use special equipment.

This type of basis is the most economical. It can be used for frame or wooden buildings, as well as buildings made of foam concrete blocks.

A foundation made of reinforced concrete sleepers allows you to save a lot of money, but you need to take into account that such material has a fairly large mass. Not every master will be able to place it in the formwork or pit with his own hands. For these purposes, you will need to use special equipment, which will greatly simplify the work. Creating a columnar foundation consists of the following steps:

- The first step is to dig a hole for each post. The interval of their installation depends on the design of the building. The depth of the hole can vary from 1.5 to 2 m. The width should allow you to install the material and pour cement mortar around it.

- At the bottom of each pit you will need to create a cushion based on sand and fine crushed stone.

- After which the installation of reinforced concrete products is carried out.

- Each hole is filled with cement mortar.

Creating a columnar base from non-standard materials is not so difficult, the main thing is to carefully follow the work technology.

Using sleepers for bases is a good solution. Thanks to this material, you can save a lot on building a house. The main thing is to carefully select products to ensure a long service life.

Columnar foundation made of reinforced concrete sleepers

Drawing of a reinforced concrete sleeper.

This type of foundation for buildings is the most economical. It may be suitable for frame, wooden buildings, houses made of foam concrete blocks on damp soils, especially if they are subject to heaving.

A sleeper foundation can save quite a large amount of money at the initial stage of construction work. However, do not forget that this material has considerable weight. Not everyone alone will be able to lay it in formwork or install it in a hole. In this regard, additional equipment may be needed that is intended for installation.

There is nothing difficult in constructing this type of foundation if you follow the technology and have all the necessary materials for the work.

Positive and negative properties of sleeper baths

First of all, you need to figure out what a sleeper is. Sleepers are inexpensive lumber that is treated with creosote, a special anti-corrosion compound that protects the wood. Creosote is a rather toxic antiseptic that extends the service life of sleepers and prevents the inevitable damage to the material by mold, fungi and parasites.

What are the main advantages of a bathhouse made from old sleepers:

- Very low price of lumber, as it is sold at residual value.

- Quite simple and convenient installation.

- Short installation times.

Of course, unlike other buildings, the bathhouse has a rather specific function. The temperature inside it is very high, which causes the creosote to release an unpleasant odor. It’s quite difficult to be in such a steam room. This is the main disadvantage of a bathhouse made from old sleepers. Nevertheless, many summer residents use sleepers to build such structures, despite the inconvenience and discomfort.