Construction is a process of meticulous planning and selection of materials, selection of decor and creation of comfort. It is very important to be clear about your wishes at the very beginning of the construction process. Now, when buying a house or apartment, you can easily find an option with an open plan.

This type of property is gaining more and more popularity due to the buyer’s freedom of action to remodel and decorate the home. To create your own housing plan, you need to build interior partitions yourself. Often, foam blocks are used to connect interior partitions.

Main characteristics of foam blocks

The undeniable advantage of foam blocks is their price.

But they also have other strengths:

high strength. With a fairly light weight, the foam block can withstand pressure from 3.5 to 5 MPa. They are able to withstand the weight of a structure of up to three floors built from blocks. Widespread use can be seen in the construction of high-rise buildings, but in this case, blocks are used to create walls, and the supporting structure is made by pouring concrete monolithically into the building forms.

ease of use. A standard size foam block weighs only 11 kg, which makes it easier to work with, especially with a large area of wall construction, and also allows you to save on delivery, because carriers often pay attention to weight rather than volume. thermal insulation.

Thermal insulation qualities are 3-3.5 times higher than those of ordinary bricks, which, taking into account the low weight, is an undeniable advantage over other materials. environmentally friendly and bioresistant. The composition of the foam block guarantees safety to humans, and at the same time it is not characterized by aging and is resistant to rotting. frost-resistant and fire-resistant. The block is able to withstand the influence of direct fire for a duration of 5 to 7 hours, and the porous structure maintains the frost resistance of the material.

simplicity. Due to its composition and structure, the foam block is susceptible to any influence, which is used when it is necessary to give a certain shape to products by drilling and cutting. different densities.

Depending on the provision of the required qualities, the required density is selected. Low-density foam blocks are used for thermal insulation purposes, and high-density foam blocks are used for design purposes. Average density is used to meet these two parameters.

We offer to buy ECO tongue-and-groove silicate slabs from us.

There are two types of ECO tongue-and-groove slabs: ordinary and ordinary porous with expanded clay inclusions. Each variety is available in two sizes: 498x70x248 mm and 498x115x248 mm. Plates 70 mm thick are solid , without internal cavities. thick slabs are hollow and have cylindrical voids inside to reduce weight and provide better sound insulation.

How we are working

- We deliver building materials throughout Moscow and the Moscow region, in the Vladimir, Kostroma, Tver and Kaluga regions.

- We accept applications seven days a week and ship materials at any time convenient for you. Phone +7-495-105-97-59 is available daily from 9 am to 8 pm. Requesting a call back is free.

- We help you choose the appropriate type and size of slabs, calculate the required minimum amount of material, and give recommendations for construction. If necessary, a specialist travels to the site for on-site consultation. Consultation on building materials is free .

- If a shipment is found to be defective, we will replace it immediately.

- You can buy any number of slabs from us , even one piece .

- We provide construction services. We will quickly and efficiently build any structures at your site.

Project as a gift . All buyers are provided with free design documentation for the construction of a cottage. You can choose a ready-made private house project for yourself.

Purpose of tongue-and-groove slabs

Tongue-and-groove silicate slabs (PSP) are a type of tongue-and-groove blocks. They are used for interior and inter-apartment partitions during construction or redevelopment of housing.

70 mm thick slabs are intended for interior partitions that do not serve as a load-bearing structure. Thin partitions are lighter in weight, take up less space, and will help save up to 30% of usable space.

If you need greater wall strength, for example, between apartments, it is better to take thick 115 mm row slabs. Porous slabs weigh less and provide better sound insulation compared to conventional slabs.

Advantages of PSP

A wall made of tongue-and-groove blocks is erected quickly and reliably : the groove of one slab fits into the ridge of another. For strength, a layer of glue is applied to the joint between the plates. The assembly of partitions from PGP is so simple that you can do it yourself without the involvement of professional builders.

The slabs are cut with a regular hacksaw ; it is easy to drill holes in them for plumbing and electrical wiring. The wall surface is smooth and does not require plaster, which allows you to save on painter services.

Silicate is stronger than drywall and lighter than brick. Silicate tongue-and-groove slabs are harmless to health , fire-resistant, breathe and retain heat, and do not change shape with fluctuations in temperature and humidity. The partition will not crack or swell over time.

It is cheap to build from silicate slabs . This is explained not only by the low price of the material, but also by the economical consumption of glue and the reduction in the cost of construction and finishing work.

Characteristics

Thickness: from 7.0 to 11.5 cm Length x height: 49.8 x 24.8 cm Types: ordinary and ordinary porous with expanded clay Color: white resistance: EI 90 Composition: sand, lime Sound insulation: from 48 to 52 dB

Prices

| Dimensions, mm (length*width*height) | Appearance | Type | Weight, kg/piece | Price, rub/piece (pickup from Yaroslavl) | Price, rub/piece (delivery within Moscow) |

| 498*70*248 | private | 15,3 | 44,50 | 55 | |

| 498*70*248 | ordinary porous | 14,5 | 53,0 | 62,5 | |

| 498*115*248 | private | 19,5 | 63,0 | 77,1 | |

| 498*115*248 | ordinary porous | 18,5 | 66,8 | 80,6 |

Partitions in an apartment: disadvantages of plasterboard structures

For the construction of partitions from plasterboard sheets, it should be understood that, along with obvious advantages, such as:

speed of construction.

The material is quite light and transportable, easy to cut and modify. space occupied. Designs using plasterboard structures are mounted on a frame, and the thickness of the walls can be only 5 cm. Sound insulation.

The level of noise insulation is quite high for such a thin material. practicality. Wiring cables or water pipes can be placed in empty cavities.

There are also a number of disadvantages:

mechanical strength. Even with a small physical impact, deformation of the sheet is possible. It is possible to break it even just by leaning on it.

moisture resistance. Plasterboard sheets are very susceptible to moisture, so flooding of neighbors from above will inevitably lead to renovation renovations. density.

It should be understood that drywall is a rather fragile material, and you cannot hang, say, a shelf on it. From such an impact, the sheet may burst and the shelf may fall. But it will withstand things like paintings and photographs.

In general, it should be understood that using only plasterboard sheets as partitions may be a budget solution, but the issue of practicality and durability remains.

When choosing partitions, pay attention to the strength of the material, installation features, noise insulation, and price.

Now the market offers three solutions to the issue of interior partitions.

The first is the use of drywall. The second is brick, and the third is tongue-and-groove blocks.

Interior partitions made of ceramic blocks

For interior partitions, you should choose ceramic blocks of minimum thickness:

Porotherm 8 , Porotherm 12, Porotherm 20 .

They are used both in standard apartments in residential high-rise buildings and in country houses.

Most prestigious premium residential complexes in Moscow choose Porotherm ceramic blocks for the construction of interior partitions, since future residents have high demands on the quality of materials on which comfort and quality of life depend.

Tongue-and-groove blocks as an option for interior partitions

The option of tongue-and-groove blocks is the most economical. The blocks are equally well suited for the construction of single partitions and for creating partitions in box format, where you can additionally hide various types of communications, such as water pipes or electrical wires.

Tongue-and-groove blocks are distinguished by a high level of hydrophobicity, and have already found wide application in the arrangement of bathrooms. Along with this, blocks of this type are characterized by low thermal conductivity, which makes them attractive for the construction of partitions in commercial buildings.

The presence of a protrusion on top and a groove on the bottom improves grip and simplifies their installation. The invariable advantage of tongue-and-groove blocks is the ease of finishing after their installation, since it is not even necessary to plaster the surface; you can immediately glue the wallpaper, having previously applied a layer of primer.

Comparison options

Basic indicators for comparison of wall materials.

Comparison of building wall blocks must be carried out according to a number of parameters that have a direct impact on the durability and strength of the structure.

- The concept of strength refers to the possible load that can be placed on a block.

- Volumetric weight is the conditional density of building blocks taking into account voids.

- The thermal conductivity indicators of the blocks show the amount of heat that will escape through a wall with an area of 1 m? with a temperature difference of 1°C.

- Frost resistance is a concept that shows the number of freezing/thawing cycles, after which the strength of the blocks will decrease by 10%. For central Russia, 1 cycle takes 1 year.

- Shrinkage is a value that shows how much the size of a block has decreased after construction. Water absorption is the amount of moisture that can be absorbed by a material.

The well-known brick has been replaced by a building block. Buildings made from this material are erected much faster and have a number of advantages, one of which is a high level of heat retention. After reading this article you will learn what building blocks are, types, sizes. The price of the product depends on the manufacturing method, materials and dimensions. Types of building blocks, photos, sizes, etc., we will now look at all this.

Pay attention to how you can reduce costs by using slotted expanded clay blocks.

- Artificial - those that are produced at enterprises by mixing dry mixtures in the required proportion. To make the products the required size, the mixture is poured into molds.

- Natural – those that are made by grinding natural stones. They are used mainly for decorative finishing.

Naturally, the budget ones are artificial building blocks. Kinds:

- concrete;

- expanded clay concrete;

- polystyrene concrete;

- gas silicate;

- foam concrete.

Making walls: what you need to know

When installing blocks, the first thing you should pay attention to is the floor - it should be almost flat. If the floor has flaws, it must first be leveled using special mixtures.

Before installation, the blocks must be brought into the room where the partition will be built to acclimatize them.

This step should be done at least 24 hours before construction. Next, you need to remove all kinds of debris and dust for better adhesion of the block, putty and your floor.

To lay foam blocks, a special glue is used, which is applied to the base of the floor and the junction points on the walls.

You should first mark the outline of the wall, both on the floor and on the adjacent wall. Alternatively, you can lay a metal profile that will guide the masonry.

The blocks are stacked on top of each other in such a way that the protrusion is inserted into the groove from top to bottom, so when laying the first layer, the protrusion is cut off and installed with the groove up.

When the first row is installed, you should cut one block into two parts and start installation from there. This is necessary to create a wall in the shape of a chessboard. This action will increase the strength of the wall significantly.

When laying subsequent layers, the adhesive solution must be applied to the seam, and after installing the plate, press firmly on it to make a tight, well-glued joint. Excess glue is removed with a spatula and placed in the groove of the next row.

When installing the wall, you should allow the glue to dry, and do not lay more than five rows per day - this will eliminate the possibility of tilting individual parts of the wall. If a door is planned in the wall being built, it is worth inserting several rods of reinforcement so that the part of the wall above the door does not fall from its own pressure.

Partition masonry

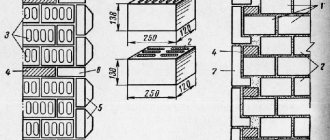

For the construction of partition walls, a special partition foam block is produced, which is distinguished by its small thickness. Its standard sizes are:

- Length – 60 cm.

- Height – 20 or 10 cm.

- Width – 10 cm.

Preparation for masonry

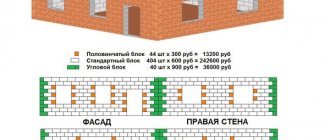

Before starting work, it is necessary to carry out preparatory work. You should draw up a project for the future wall on a piece of paper, indicating the dimensions. In accordance with it, the amount of required building material is calculated. To do this, the length and height of the partition wall are multiplied, and the area of the doorway is subtracted from the resulting product. Next, the area of the wall is divided by the area of one block.

Wall length – 5 m, height – 3 m, doorway area 2 m2, area of one foam block – 0.12 sq.m (0.6 x 0.2 m).

((5 x 3) – 2) : 0.12 = 108 blocks.

When purchasing building materials, you should always purchase with a small margin of 5-10%. During the work, various unforeseen situations may arise - from unintentional damage to a block to a simple error in calculations.

When purchasing foam blocks, you need to pay attention to their humidity level: the material must be dry without excess moisture. Along the walls to which the partition will adjoin, a vertical line is drawn using a level, indicating the location of the foam blocks. This area, the entire height and width of 15 cm, should be cleared of external finishing down to the load-bearing base - remove wallpaper, paint and a layer of plaster. In the place where the partition will be installed, the floors should also be cleared of floor coverings.

Masonry mortar

For laying foam concrete blocks, you can use a variety of compositions: cement masonry mortar, ready-made adhesive mixtures on a cement or polymer basis, construction and installation adhesives, etc.

You can prepare cement-sand masonry mortar with your own hands. To do this, you will need construction sand of medium or coarse fraction, Portland cement grade M-300 or M-400, and clean water. It is better to use a small concrete mixer for mixing. But in the absence of it, it is quite possible to knead the solution manually: in a large container or stretcher. Fortunately, when laying “half a brick”, the consumption of mortar is much less than when constructing load-bearing walls of buildings.

One of the options for laying a wall made of lightweight concrete

Initially, water is poured into the concrete mixer in the required amount, after which cement is loaded. When it is thoroughly dissolved in water, construction sand is added to the solution. The ratio of sand and cement for masonry mortar is usually taken as 5 to 1. The amount of water depends on the moisture content of the sand, so you should focus on the consistency of the mortar - it should not be too liquid or too thick.

Ready-made dry mixtures can be purchased at a construction supermarket, where there is quite a large selection. For foam concrete masonry, special adhesive compositions are produced, which contain improving additives. Such mixtures were created taking into account the technical features of foam blocks, in particular the high rate of moisture absorption, as a result of which an ordinary solution can be dehydrated too quickly.

Dry mixtures will cost slightly more than cement mortar prepared by yourself. However, their quality is disproportionately higher due to precisely adjusted proportions and special chemical additives.

To prepare a solution based on dry mixtures, they should be diluted with water in the proportions indicated on the packaging and in the instructions for use. Water is poured into the container, after which the mixture in the required quantity is poured there. Everything is thoroughly mixed using a mixer attachment attached to a perforator and left for 5-10 minutes. During this time, the water will thoroughly saturate the solution, then it will need to be mixed again with a mixer. After this, the solution is ready for use.

Laying the first row

To work on the construction of the partition we will need the following tools:

- Master OK.

- Grinding machine with cutting wheel.

- Hacksaw for foam concrete.

- Hammer.

- Pins or anchor bolts.

The first step is to mark the floors: draw a straight line on them, indicating the future wall, and mark the doorway on it. Along the line, a flat metal profile is attached to the floor with self-tapping screws or dowels, along which the first row is laid out. However, you can completely do without a profile. To do this, at the junction of the future partition with the load-bearing walls, two starting blocks are installed on the mortar, between which twine is stretched. Using this cord as a guide, all other foam blocks of the first row are laid out.

Before starting laying, the floors in this area must be thoroughly cleaned of debris and treated with an adhesive primer composition. Then a layer of masonry mortar is laid on the floor, or construction adhesive is applied. The thickness of the layer should usually not exceed 1 - 2 cm, but to level out minor unevenness in the floors, deviations from this rule in one direction or another are permissible.

Laying a foam concrete partition

When the first row approaches the door openings, the blocks are cut to the required size using a grinder or a hacksaw. Foam block is a very technologically advanced material that can be processed even with carpentry tools.

Laying subsequent rows

After the first row has been laid, you can begin laying subsequent rows. The technology for their placement is similar to the laying of the first row: two starting blocks are installed at opposite ends of the partition, and the guide twine is again stretched, along which the remaining blocks of the row are placed. But in this case, the laying begins not with whole foam blocks, but with halves. This allows you to create a staggered ligation of the masonry, making it more durable.

In the areas of the doorway, after every pair of rows, the vertical position should be checked using a building level or plumb line to avoid its narrowing or expansion. When the masonry reaches the height of the door, a lintel is installed above the opening. It can be made from 2 corners installed as shelves on 2 sides of the wall, or from 2-3 pieces of reinforcement with a diameter of 10-12 mm. Foam block ceilings are laid on them, serving as support for continuing the masonry above the door. Upon reaching the ceiling wall, if the joint is too wide, you should cut the finishing foam blocks lengthwise, reducing their height.

To increase strength, reinforcement is passed every 3-4 rows of masonry. You can use steel wire with a diameter of 6-8 mm or fiberglass reinforcement. Reinforcement makes it possible to connect individual elements of a row with each other, increasing the rigidity of the entire structure.

Calculating the number of blocks

To calculate the number of blocks, it is necessary to take into account the thickness of the partition and the volume of masonry. The dimensions of the blocks should be selected to match the required thickness of the partitions, if it is monolithic. The volume of the masonry is the derivative of the width of the wall by the height.

If the wall is hollow, then the volume must be multiplied by two, and also add the volume of the wall, which will be between the two components of the hollow wall.

Next, the volume should be divided by the volume of the block (height multiplied by width) and get the required quantity.

To this figure it is necessary to add another 10 percent of the resulting figure, based on trimmed parts and damaged blocks during delivery.

In order to accurately calculate these quantities, you can go to the Internet and find a calculator for the calculation. You can additionally check yourself by calling a specialized company, indicating the dimensions of the wall.

The use of blocks for installing partitions

The following types of foam blocks are available on the building materials market:. Technical characteristics of foam concrete and ordinary concrete. Based on the type of production technology, blocks can be divided into the following types: For the construction of partition walls, a special partition foam block is produced, which is distinguished by its small thickness.

Interior partitions - choice of material

Its standard sizes are:. Before starting work, it is necessary to carry out preparatory work. You should draw up a project for the future wall on a piece of paper, indicating the dimensions. In accordance with it, the amount of required building material is calculated. To do this, the length and height of the partition wall are multiplied, and the area of the doorway is subtracted from the resulting product.

Laying blocks

We discussed the beginning and preparation of masonry earlier, but we will go into more detail. Having prepared the place and laid the first block, the next one must be placed on the reverse side, and a fishing line must be stretched between them, which will serve as a guide when laying the entire row. When laying each paired row, you should start with half a block to create a checkerboard grid.

You should not allow the seam thickness to exceed 3-5 mm, as this affects the strength of the structure.

If possible, the rows should be laid with a gap of 3 hours, then there is a maximum probability that the wall will not have a slope.

After laying each row, you need to check yourself using a building level. Every third row requires reinforcement, and every third row must be checked with a vertical level. It is better to apply the solution or adhesive material using a comb - this will create an even layer and improve the adhesion of the two blocks.

Material selection

When choosing a material, you should carefully consider the markings of the blocks. It indicates its technical characteristics and scope of application.

By density

The following types of foam blocks are available on the building materials market:

- D-400 and D-500 – thermal insulation materials. Typically, such blocks are used to insulate the external walls of a building. Due to their low density, they have low thermal conductivity and low strength. It is unacceptable to build load-bearing walls from them, but it is quite possible to use such blocks for partitions in an apartment or house.

- D-600...D-900. A denser raw material that can be used both as insulation and as a structural material for load-bearing walls under light floors. Ideal for laying internal partition walls.

- D-1000 and D-1100. Structural blocks used to construct load-bearing structures. In terms of their technical characteristics, they are similar to ceramic bricks: they are heavy and have high strength. Due to their large mass, foam blocks of the D-1000 and D-1100 brands are not recommended for the construction of partitions on light floors and foundations.

According to production technology

Based on the type of production technology, blocks can be divided into the following types:

- Rifled. In the manufacture of such blocks, cutting using a steel string is used. This allows you to obtain blocks with smooth edges and a clear geometric shape.

- Molding. In this case, special molds are used for casting. Such foam blocks have complex geometry with grooves and protruding edges.

- Reinforced. To increase strength, reinforcing material – polypropylene or fiberglass – is added to the concrete mixture.

Preparing the openings

When the main masonry comes to an end, the guide frame can be disassembled and the openings can be prepared. The locations of the openings need to be thought out in advance, and at the end of construction, just trim the protrusions of the outline.

If the location of the opening suddenly changes, or there is a need to make an additional one, a reciprocating saw is an excellent tool for this. First you need to outline the outline of the opening using a tape measure and a level, and the opening should be made larger than the finished door or window.

The blocks above the opening should be strengthened by laying reinforcement: in the blocks, parallel to the line of the opening, an incision is made up to 10 cm deep and a rod from the reinforcement is laid, which is then plastered. Before finishing the walls, electrical wiring is laid.

Types of interior wall blocks

In addition, wall blocks can be differentiated based on production technology. In this case, they are divided into the following types:

- Rifling block . It is obtained by cutting raw materials using a steel string. This material is characterized by improved geometry and edge integrity.

- Molded material . To obtain it, forms with partitions are used. With reduced accuracy, it is possible to increase the economics of the product.

- Reinforced block . During production, polypropylene fiber is added to the mixture. This product is characterized by high strength. However, during any construction it is necessary to know the characteristics of the aerated concrete block, which you can read about here in the article.

If we talk about the purpose of blocks, they can be of the following types:

- wall;

- septal (semi-block);

- non-standard (customer’s wishes are taken into account here).

How to strengthen walls made of foam blocks?

Strengthening a block wall can be done internally or externally. Internal strengthening involves laying reinforcement every 3-4 rows of wall laying.

Externally, the wall can be strengthened:

plaster. This option is quite simple, but not very reliable, since at the slightest impact it can crumble. drywall.

Installing plasterboard sheets on a block wall will certainly strengthen the structure and make it more resistant to physical impact. tree. The blocks can be sheathed with wooden clapboard, and the issue of decorating the wall can be immediately resolved, or they can be sheathed with chipboard, but it will not be possible to hang wallpaper on such material.

The most practical option is to use drywall, since you can easily hang wallpaper or install tiles.

Partitions in a studio apartment: possible options and their features

The studio apartment is characterized by a large amount of space, not limited in its division into rooms.

In the interior it is only possible to highlight certain zones. To separate these zones, the owners install partitions. For a studio apartment, a stationary partition or a sliding one can be used.

As a rule, this type of apartment is quite small in area and it is unwise to reduce it further with massive partitions, which is why sliding partitions are very popular.

Sliding partitions are made according to the principle of a sliding wardrobe, and are produced in glass or plastic versions, which allows you to choose the desired pattern and color scheme.

Glass partitions have many advantages:

versatility. A glass partition will add freshness and space to any interior.

The ability to create partial drawings and the purity of the material will satisfy any esthete. compactness. Glass is definitely thinner than any partitions, and therefore is so in demand in apartments with a small area. The use of glass partitions is perhaps the most successful solution in terms of saving space.

reliability. Glass for partitions is pre-tempered, which significantly increases its strength and practically equates it to unbreakable materials. ease of installation.

The material is complete and therefore does not require additional preparation before installation. A glass partition can be installed in an apartment that is ready for renovation. increase in space.

The use of glass gives the feeling of increasing the amount of space, which is so important in a small apartment. creativity. Glass in the interior, combined with designer prints, will please the eye.

Along with a lot of advantages, it is worth saying that the material is quite expensive, and installation can only be done by professionals, and you will need to pay extra for creativity.

Often, the bedroom area is separated from the rest of the apartment, and if we talk about a stationary option, it does not have to be a wall: it can be a bamboo wall with large gaps, a bookcase installed in such a way that it covers the intimate area from prying eyes.

The installation of partitions in an apartment or house is designed to divide the space into certain zones, so before choosing a material you should clearly define the purpose of their installation.

We will advise on the choice of brand and volume of concrete for your construction site. We will make calculations and offer the best commercial offer.

Durable and lightweight YTONG blocks in thin formats are ideal for repairing and furnishing your home.

Walls made from YTONG blocks simultaneously combine both light weight and a reliable structure that will withstand the tasks assigned to it.

Blocks for the construction of non-load-bearing walls (partitions) have the following dimensions: height 250 mm, length 625 mm and a wide selection of thicknesses: 50, 75, 100, 150, 175, 200 mm - this will allow you to use them to solve any difficulties that arise during redevelopment time:

- Creation of interior partitionsDesign of bathroomsConstruction of podiumsUse for the implementation of complex design ideasDesign of loggias

Since the material is easy to process: it is easy to saw, drill, groove and cut out elements of complex shapes, working with it will not be difficult, and you will be satisfied with the end result.

A perfectly flat surface of the finished wall will speed up the final finishing process, be it plastering, tiling or any other finishing work.

YTONG is a moisture-resistant wall material that is not at risk of deformation when used in rooms with high humidity, so YTONG is without any restrictions suitable for use in showers and bathrooms, as well as in kitchens. Ceramic tiles can be glued directly to the blocks without any additional processing, which significantly reduces construction time.

Structures made of cellular concrete do not require preliminary installation of embedded elements for fastening heavy elements of furniture and plumbing equipment. Any shelves, kitchen cabinets, mirrors, radiators, etc.

etc. are easily mounted using special dowels for aerated concrete, which can withstand very significant loads. For hanging interior items (paintings, photographs, etc.), ordinary nails are used, which are recommended to be driven in at an angle of 45o (from top to bottom). We strongly recommend We recommend using the adhesive mixture and YTONG tools in your work, which will significantly simplify and speed up your work, and the result will be different. Dimensions of blocks, mm Average density [kg/m³] D 500 Length 625 Height 250 Concrete strength class B 3.5 Width 50, 75, 100, 150 Deviation of geometric dimensions, mmCoefficient of thermal conductivity in dry condition, [W/m °C]0.099 Height+0.7 Length+1.2 Frost resistance [cycle] F 100 Width+0.8 Date: 12/30/2014 Views: 445 Comments: Rating: 25 For the manufacture of interior partitions You can use various materials, but blocks are in demand today.

Modern and easy-to-use foam blocks, special gypsum boards, and traditional bricks can be used. But it is more practical to purchase glass blocks for these purposes. Several decades ago they were popular, but now they are returning to construction. When working with blocks, it is necessary to take into account the properties of the products and laying technology. Scheme of a partition made of glass blocks.

Main types of blocks for partitions

Partitions made of blocks are not always built. Some people still prefer brick. This is a traditional building material that is great for any room. Such partitions are easy and quick to erect; they can take exactly the shape that is needed; it is easier to make openings from brick. It should also be noted that such partitions are extremely durable; cabinets and shelves can be hung on them; they can withstand loads very well.

To construct an interior partition, half-brick masonry is used, which is quite enough. The total thickness after plastering the surface in this case will be approximately 140-160 mm, which is quite enough. Edge masonry is used much less frequently. You need to immediately decide what thickness will be - one-and-a-half or single.

Scheme of a brick partition.

To build a wall, you can use different types of bricks; they can be solid or hollow, ordinary ceramic or silicate. It should be remembered that sand-lime brick is not always suitable. It is not recommended to make such partitions in bathrooms and kitchens, as it absorbs moisture well. During work, it is necessary to take into account that the brick has significant weight: 1 m² of such masonry made of solid red brick with a layer of already applied plaster is approximately 300 kg. For a partition with a height of 3 m, a linear meter will already weigh 900 kg. Floors must be able to withstand this load. Therefore, to reduce weight, hollow brick is used; it provides high strength, but its weight is much less. Some experts advise using special porous ceramic blocks.

The characteristics of the material impose restrictions on the length of the partitions, usually no more than 5 m. If longer partitions are required, then it is best to replace the brick with another, lighter material. Otherwise, the base may simply not withstand such a heavy load. Clay or lime mortar is used for masonry, and the rows are reinforced to give the wall additional strength and stability. The diameter of such fittings is 4-6 mm.

Diagram of a partition made of foam blocks.

You can also use a simpler metal mesh, the cells of which have dimensions of 50 * 50 mm. After laying, the surface of the brick must be covered with a layer of plaster and then primed. As soon as all the preparatory layers have dried, you can begin decorative finishing.

But there is another option. To work on the construction of an interior partition, you can use special colored decorative bricks. You can create solid walls from them, they will look beautiful. The weight of such a wall is less, it does not require decorative finishing after construction, which significantly reduces weight and construction costs.

Return to contents