When creating a well, it is important to remember that it should be as protected as possible from leaks and groundwater penetration. Waterproofing of a structure can be carried out both at the construction stage and during the process of repairing the structure. If you waterproof a well from concrete rings yourself, you need to learn more about this process and the materials used. It is also worth watching a video that shows the entire process of waterproofing a structure.

Features of additional well treatment

Wells from concrete rings are created in many areas, as this method allows you to obtain clean drinking water. But it is worth remembering that if even a small leak occurs, groundwater can spoil the water.

Sealing the drinking source is important because groundwater contains fine sand and microorganisms that significantly degrade the quality of the water. The entry of small amounts of groundwater into the water supply system installed on the site can lead to deterioration in the health of the people using it.

In the case where the wastewater disposal system is sealed, it is also important to properly waterproof the well. This is due to the fact that wastewater is a source of pathogenic bacteria and can negatively affect human health and the growth of plants located near the well.

When is it necessary to update waterproofing?

The insulating layer deteriorates over time, so it must be renewed periodically. During the construction phase, concrete is waterproof, but over time its properties deteriorate. The waterproofing layer should be updated if you notice the following signs:

- rapid filling of the sewer well or its overflow;

- displacement of concrete rings;

- appearance of lime in drinking water.

Once these signs are detected, the well should be repaired and waterproofed.

Materials used to process well walls

The choice of a specific material depends on the design features and properties of the concrete rings. Treatment can be divided into sealing seams between well elements and waterproofing joints with the pipeline.

In the first case, mastics and coating waterproofing materials are selected. In the second, construction adhesives are used. Increasingly, concrete spraying is being used to seal wells and sewer systems. This method allows you to evenly apply the material to the surface and reliably protect the system from leaks. In addition, membranes are often used that can prevent moisture penetration.

It is worth noting that it does not matter whether the well is repaired from concrete rings or the insulation is carried out at the construction stage - the rules for performing the work are the same.

Repair work

How you will repair wells with your own hands depends on the design of the structure and, first of all, on the material from which it is made.

Important: All repair work is carried out in special clothing, with insurance and a partner.

Wooden wells and their features

Repairing a wooden well with your own hands can, without exaggeration, be considered one of the most difficult. It will require the installation and use of auxiliary structures:

- a securely fastened working platform (in the manner of a construction “cradle”),

- a structure that will fix and hold the well crowns above the area being repaired so that the entire wall does not collapse, losing support.

When performing repair work, it is necessary to secure part of the structure above the repaired area.

The main reason for repairing wooden structures is putrefactive processes that occur in wood under the influence of water. In this case, the organic pollution is not the organic matter brought into the well from the outside, but its own walls. The only way to eliminate this phenomenon is to replace rotting logs with new ones .

Wooden well made of logs

The procedure is performed in a certain sequence.

- The constructed working platform is secured using reliable cables on beams that are installed above the well. It is important that the platform can move up and down safely.

- Moving in such an area along the wall (assistants will be needed; it is almost impossible to cope with such a task alone), they accurately determine the boundaries of the damage zone.

- Logs higher than those to be replaced are secured on both sides, eliminating the possibility of collapse.

- The area where the logs are rotten is being dismantled. All damaged elements rise to the surface.

- Elements for replacement are selected (the availability of the necessary building materials should be taken care of in advance).

- Selected whole logs are installed in place of the removed ones and driven in. The achieved strength is checked.

- Self-repair of a wooden well ends with dismantling and removing auxiliary structures from the well shaft.

- The mine is being cleaned.

Concrete structures

In order to decide how to repair the well with your own hands in this case, you should assess the degree of damage.

The main problems of concrete wells are:

- damage to the surface layer (plaster, sealant),

- formation of cracks in the structure,

- depressurization of seams,

- displacement of elements.

The reasons for the destruction of concrete wells can be:

- materials (primarily concrete) of low quality,

- soil mobility,

- activity of ground or flood waters that destroy joints.

After drying the concrete well, the degree of destruction is assessed.

- If only the surface layer is damaged, it can be restored from inside the mine. In preparation for work, you will need to remove all the coating that is not holding well, leaving only guaranteed reliable areas untouched. To do this, carefully tap the crack in the coating or at the seam site. Having removed the old coating, it is replaced with a new waterproofing layer.

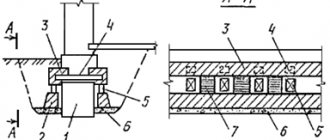

Sealing well joints - If the crack is through, you will have to work from the outside, for which the concrete structure is dug around the perimeter, forming a shaft into which a person can fit and move relatively freely while performing repairs. Otherwise, the repair technology is almost the same. The wall is cleaned of earth and dirt, the crack is sealed with mastic or cement and covered with waterproofing for greater reliability.

How to repair a well made of concrete rings when they are displaced? In this case, it is impossible to do without lifting equipment - the structure will have to be partially dismantled and reassembled in accordance with all the rules, restoring the geometry, ensuring the strength of the seams and the tightness of the shaft as a whole.

Important: To avoid repeated displacement, the rings are fastened together with special staples.

Fastening rings with staples

Brick mines

Repairing brick wells is technically simpler than others. If cracks appear in the brick or the seams are washed out by groundwater, a brick from the damaged area is selected, and a new one is laid in its place using mortar. After the seams have hardened, the plaster layer and waterproofing are restored.

Brick well

Rolled and coating waterproofing materials

Often, bitumen mastics and polymer compounds are used to waterproof various surfaces. They are usually used for external waterproofing. It is worth remembering that if the well is drinking, it is not worth treating it from the inside with such materials. This is due to the fact that when using a well for a long time, elements that are harmful to the body can penetrate into the water.

Waterproofing using such compounds is carried out in several layers. Moreover, during such work, reinforcing meshes consisting of polyester fibers are used.

It is worth noting that mastic, compositions based on liquid rubber and paint contribute to additional sealing of concrete rings. The use of such materials prevents the gradual penetration of moisture through the concrete.

You can also use rolled materials on a soft frame to process the well. They can be used separately or together with mastics. It is quite simple to secure such materials, which is why many owners of suburban areas choose them.

Features of polymer membranes

Increasingly, land owners are purchasing various film materials. The use of such products is facilitated by the presence of an adhesive layer, thanks to which they can be secured quite simply. The described films reliably protect the well from moisture. It is also worth noting that they can also be used to seal seams between concrete rings.

It is important to remember that the described compositions should not be used as a waterproofing agent. It is best to use them in conjunction with mastics. This will allow the joints to be closed more securely and prevent leaks.

Repair of inspection wells of sewer and drainage networks

Sewerage maintenance, cleaning and repair are the most important activities that must be carried out regularly to ensure efficient operation of the system and to avoid emergency situations. The consequences of untimely repair of sewer wells are very unpleasant: sewage, escaping into the environment, can poison the soil and groundwater, as it is a rather aggressive environment. If drainage networks are not repaired in a timely manner, emergency situations occur that lead to flooding of areas, from highways to basements of buildings. Timely preventive maintenance will allow you to avoid emergency situations and help you save valuable time and money.

Types of repair of sewer wells and drainage networks:

- Routine sewer repair

is the elimination of minor damage that disrupts the normal operation of the system (sealing fistulas, repairing moving parts of dampers, valves, replacing brackets and hatches, etc.); - Major sewerage repairs

- includes the elimination of serious violations of the system (subsidence of wells, emergency blockages, destruction of trays in the wells of large collectors, etc.), as well as dismantling of pipes, their relocation and installation of additional inspection wells.

When is it necessary to repair the sewer?

- During planned system repairs (for example, replacing old sewer pipes with new ones);

- During emergency work (for example, leakage and damage to sewer pipes ).

What well repair services do we offer?

- Major and current repairs of sewerage and drainage ;

- Major and current repairs of storm sewers with repair of inspection wells;

- Replacement of sewerage outlets in high-rise and low-rise buildings;

- Major and current repairs of inspection wells

In particular, we do the following:

- lifting a manhole of any type (inspection, sewer, drainage, etc.);

- neck replacement;

- dismantling or restoration of brickwork;

- installation of base plates;

- replacing the brickwork of the well with newer reinforced concrete rings;

- complete repair of plaster with waterproofing mortar;

- restoration of asphalt-concrete coating around wells;

- removal of asphalt-concrete pavement;

- organization of sand cushion;

- waterproofing of fistulas;

- waterproofing joints;

- sewer gutter repair

- replacement of the lining and sewer hatch;

- cleaning the well from construction debris;

- replacement of base plates to prevent failures and subsidence of hatches;

- elimination of failures;

- complete replacement of rings;

We guarantee the quality of the work performed and look forward to long-term cooperation.

Use of mixtures

To waterproof a well, mixtures based on binding mineral components are often used. They are applied using a special device that creates high pressure and sprays the composition onto the surface. Thanks to the use of this method, the mixture is evenly distributed over the surface and fills all the seams and irregularities.

The use of such compositions for surface waterproofing can be carried out both outside and inside the well. It is worth noting that if the composition is applied correctly, the use of additional compounds is not required.

When creating a coating inside a well, it is best to insulate the surface with paint or a membrane. Such materials will reliably protect concrete well rings and the joints between them from leaks.

Well dismantling

Nowadays, modern people do not have any special problems with water supply; most private houses have centralized water communications that easily allow people to get water from faucets in the bathroom and kitchen. But this was not always the case. It is enough to think back 70-80 years ago to remember that the main source of water in a private house was a well.

Solving the problem of old wells

In the 20th century, most wells were made of reinforced concrete rings. Currently, the situation may develop in such a way that when purchasing a private house, such a well will still be located in the yard, but there is no longer a need for it. In general, if the well is in good condition and the water in it is still clean and potable, it can become an alternative water supply option, but it often happens that the old well has long since fallen into disrepair and is no longer of any use . This means that it needs dismantling.

Materials for well dismantling

Many in such a situation try to follow the path of least resistance, that is, they decide to simply bury the well. But a completely obvious alternative solution would be to order dismantling work from a company that provides services in this activity. It cannot be said that this is an easy task and does not pose any operational problems, but it would also be incorrect to say that dismantling the well is unrealistic. All we need for dismantling is a manual or electric winch (hoist), cables and a tripod, similar to the one used to dig modern water wells.

Well dismantling work

So, first you need to mechanically disassemble the external upper structure above the well. As a rule, it is made in the form of a gable roof with a pediment and a door on it. Surely everyone has seen such a well at least once in villages outside the city. We carry out this work using pry bars, a hacksaw, an ax, a nail puller and other simple improvised tools.

After this, we install a metal tripod with a hook on the ground above the well, on which we hang our winch. Further inside the well we cling to the holes of the reinforced concrete rings. Usually they are already there for ease of installation, but are simply then sealed with cement mortar. We hang the cable on the hook of the hoist, and we also insert its ends (of the cable) into the holes of the ring and fix it, for example, with fittings so that they do not jump back. After this, we begin to slowly pull the ring until it appears above the ground. We carry out the same operations with the remaining rings.

Read more:

Dismantling columns on the terrace of a country house

demontazh.su

Technology for applying waterproofing materials

Before carrying out waterproofing work, it must be remembered that the application method can vary greatly depending on the conditions. If waterproofing is carried out at the stage of creating a well, you only need to clean the surface from dirt and dust.

If well waterproofing work is carried out in an existing well, you must first completely clear the reservoir of water and dry it. When processing seams, you need to choose simple surface protection methods. Mastics and other coating materials are often used. Many people combine them with membranes.

How the surface is prepared

Surface preparation is carried out as follows:

- After the well is drained, the walls are cleaned of old waterproofing material. It is also necessary to remove dirt, sand and dust.

- To improve the adhesion of the material to concrete, it is worth using a primer.

- After this, the distance between the rings is cleared of the solution and primed. It is in these places that leaks often appear.

Surface preparation should be done very carefully, since if there is contamination, the waterproofing material may not bond securely to the concrete.

Application of insulating materials

Before using composite compounds, it is worth remembering that they must be applied in 2-3 layers. For reinforcement you need to use polyester fiber. Materials should be applied using a roller or brush.

After application, you must wait about 4 hours. The composition is not diluted before applying the second layer. To carry out the work, just heat it and apply it using a spatula. After carrying out such work, the second layer will begin to penetrate the first, resulting in a reliable connection.

Then you need to wait about 2 hours for the composite to harden. After this, you need to walk over the surface with a special roller with spikes, which allows you to remove trapped air.

It is worth noting that membranes and other film materials are produced with an adhesive surface, so they only need to be pressed to remove air bubbles. But it is worth noting that they can be fixed only after the applied mastic has completely hardened. This usually happens within 24 hours. Typically, membranes are used to protect the inner surface of wells.

When and how should repairs be made? ↑

Evidence that a well needs repair can be a deterioration in water quality. Violation of the tightness of the structure leads to the penetration of soil and perched water into the product. The water becomes cloudy and undrinkable. This is especially noticeable during the spring snow melt.

Having discovered the cause of the deterioration of the water condition, it is necessary to act immediately. Even if you've never done a DIY well repair, it's never too late to learn. Before repairing a well, it is advisable to pump out the water from it. And after carrying out the work, carry out sanitary treatment of the structure.

Wooden well repair ↑

Violation of the tightness of wooden wells is most often associated with rotting of wooden structures. Having identified the defective area, it is removed and replaced with a new one. To carry out repair work, a platform made of thick boards is knocked down. It should fall freely into the well. Beams are placed on the head, to which the platform is attached using a cable. It is lowered into the well manually or using a gate. It is from this that the wooden well is repaired.

Securing the well frame above the rotten area

To perform the replacement, it is necessary to secure a part of the frame located above the rotten area. To do this, two “goats” are placed on both sides of the well. Four short logs are secured to them on each side of the well. A pair of strong boards are nailed to the logs, to which the crowns of the log house are attached.

This way, removing rotten logs will not cause the structure to collapse. Instead of boards, the crowns can be hung on a cable or ropes with hooks. After removing the defective area, new logs are selected according to its size and installed in place of the old ones. To do this, the prepared log is driven in and wedged.

Concrete well repair ↑

The need to repair a concrete well arises when cracks form or the rings are displaced. Gaps in the seams occur due to the fault of unscrupulous craftsmen who used low-quality cement in construction. Or the reason for this is the peculiarities of the soil surrounding the well. With this option, during the spring melting of snow, the soil is saturated with water and erodes the seam between the rings.

Repair of such defects depends on the degree of destruction of the putty. If they are insignificant and were noticed in time, you can seal the cracks from inside the structure. Any moisture-proof material intended for concrete products is suitable for this.

Sealing the seams of a concrete well

Before caulking, remove all weak points in the seam. Then carefully seal the crack, making it impermeable to water. More extensive damage should be repaired not only from the inside, but also from the outside of the structure. To do this, dig a ditch around the perimeter of the well, down to the depth of the defective seam. It should be wide enough to make it convenient to carry out repair work.

Having thoroughly cleaned the defective seam, it is covered on both sides with a viscous composition for concrete products. It is advisable to protect the outside of the well rings with waterproofing material. This will prevent the seams from eroding and water from entering the well. After completion of the repair work, the canvas is covered with viscous clay and compacted.

Inserting new concrete rings for deepening/repairing a well

Displacement of well rings

A much worse option is displacement of well rings. To eliminate this problem, it is necessary to dig out and disassemble the entire defective area. And then reassemble it as during the initial installation of the well. It wouldn't hurt to secure each ring with additional staples. After carefully sealing all the seams, it is necessary to waterproof the well and make a new blind area.

Repair of a brick well ↑

Repair of brick wells comes down to replacing fallen bricks and plastering defective areas. Before starting repairs, the masonry is cleaned with a steel brush. In this case, defects that are not visible to the eye are detected. The crumbled bricks are removed, and new ones are fixed in their place using cement mortar. Then the surface of the well is plastered.

Plastering defects in a brick well

Deepening the well ↑

If the well loses water, it has to be deepened. For structures built less than six months ago, this process is performed by digging up soil under the lower rings. As soil is removed, the well gradually settles and deepens. If the structure is many years old, this method will not work.

To deepen old structures, rings of smaller diameter or thick plastic pipe are used. Before installation, holes are made in the product, which are subsequently covered with a stainless steel mesh. Having lowered the pipe to the bottom of the well, soil is selected underneath it. As the soil is removed, the pipe lowers to the desired level. The connection between the old rings and the new pipe is sealed with mortar.

Proper operation of the well is necessary so as not to create big problems associated with its repair. This includes annual sanitization. Inspect joints and seams every three years. Clean the well as needed, but at least once every five years.

Joint protection

Before carrying out work, it is important to remember several rules:

- The seams must be treated before waterproofing is applied to the entire surface of the well walls.

- The seams are sealed with a mixture of one part cement, 3 parts sand and 1% liquid glass. Treatment with this composition contributes to additional protection of the joints of the concrete well.

- Holes for water pipes must be processed at the last stage. Waterproofing of these places is carried out after installing the couplings.

By following these rules, you can reliably protect the well from leaks for a long time. It is worth remembering that before carrying out the work described, it is necessary to repair the well made of concrete rings if its elements have shifted relative to each other. Otherwise, the applied insulation may eventually cease to perform its functions due to the rings moving to the side.

Cleaning and repair of concrete wells

It is impossible to do without a well in private homes, because it can be the only source of water or forms the basis of an independent water supply system. But in order for the water in it to be clean and tasty, the well pit should be kept clean from time to time, cleaned and, if necessary, repaired. Specialists are called in for this work, but if this is not possible, then cleaning or repairs are carried out independently, while observing safety precautions.

When is cleaning needed?

The well is cleaned when there is obvious contamination in the water, an unpleasant odor appears, the reasons for this are different. Here are a few of them:

- In the well rings, there is a loss of tightness of the seams.

- The bottom of the well has risen, which contributes to the accumulation of sand.

- Getting animals, garbage, plants into the water.

- Oil leaking from the pump.

- If you do not protect the well pit from sunlight, the walls will turn green, and along with them the liquid.

- As a result of breaking the clay lock, clay got into the well.

- Sewage fluid has penetrated into the well and contaminates the water, resulting in an unpleasant odor and taste.

- The liquid level in the concrete structure has decreased.

If the cause of contamination of well waters is sewage, then to eliminate it, they look for cesspools that are nearby and begin repairs from them.

Cleaning Methods

There are two methods to clean a concrete pit:

- Drainage pump. This method makes the job easier and reduces cleaning time.

- Manual method. Although it is a complicated method, cleaning and repair is not always possible without it.

In addition to basic methods, it is important to perform preventive and disinfectant well shaft care methods.

Manual

The process of cleaning a well manually.

Cleaning a well made of concrete rings with your own hands begins with pumping out the water. Liquid is taken out from the well pit in buckets. This method is not easy and takes a lot of time, so it is recommended to use pumps. We clean the well using the following devices:

- rubber high boots;

- sponge;

- ladder;

- buckets;

- a brush designed for working on metal.

After pumping out the liquid, a ladder is lowered into the well and fixed well. Work with the concrete well begins from the top, and gradually cleaning each ring of the shaft, they go down to the bottom. To clean the bottom, remove gravel and silt from containers and lift them to the ground. After the bottom is cleaned, a filter is made from a new layer of gravel, crushed stone, and sand. If there is depressurization of the seams, they are sealed with concrete mortar. Upon completion of the repair work, they begin preventative measures - disinfection of the well.

Using a drain pump

Cleaning the well using a drainage pump.

A drainage pump will allow you to easily deal with contaminants in wells. Start work by selecting the pump power. Then begin cleaning in a certain sequence:

- The pump is placed at the bottom of the well on a pre-constructed stand, which will prevent the unit from falling into the silt.

- The hose is lowered to supply liquid into the water-filled container.

- Then pressure is applied, which pumps out the liquid.

- Using the liquid in the container, the walls of the shaft will be cleaned.

Finish cleaning the wells as soon as the water becomes clear and the unpleasant odor goes away.

Carrying out repair work

When starting to clean the well shaft, they may discover that the seams of the rings have become depressurized and need to be strengthened with concrete mortar. There are also problems with the wooden structures of the structure, these too are excluded without delay. Repair work also includes cleaning the filters that are located at the bottom of the shaft.

Sealing seams

Sealing well seams.

The seams lose their tightness as a result of displacement of concrete rings in the well structure due to excessive melting of snowdrifts. Depressurization manifests itself in the form of void formations between the rings into which soil falls. To avoid cracks, use a sealant that is resistant to exposure to water.

They also cover the cracks with a solution of cement and sand, only before doing this they protect the surface from crumbling material. Today, more modern methods are used to combat the loss of tightness of seams. To restore the concrete surface, use Fasi RM solution. Working with this material is no different from working with cement mortar.

Strengthening concrete rings

When concrete rings are frequently displaced to the side, the following methods are used:

- Dig a trench around the well.

- Find the location of the damage and dismantle it.

- Next, the displaced concrete rings are installed in place and secured with metal brackets.

- Cover the seams and seal them.

They also stabilize the well using a clay castle. To do this, dig a trench around the well and fill it with clay, compacting it well.

Rising water level

You can increase the amount of liquid in the well by deepening the shaft. Drilling methods depend on the service life of the structure. If the well has served for about 6 months, the soil is removed from under the lower ring, then the entire structure will smoothly go down. Metal rings are added on top along the entire perimeter of the shaft. The old well is deepened by digging a hole at the bottom of the shaft, into which rings of smaller diameter are placed. In this case, it is important to seal the seams between the new and previous ring.

Water disinfection

Disinfection of water in a well can be carried out with potassium permanganate or bleach.

After the cleaning and repair work is completed, water disinfection begins. To do this, a specially prepared solution of bleach and water is applied to the walls of the mine with a wide brush. When the liquid fills the concrete well, use another stronger solution of the same components only in larger proportions. It is poured into wells and covered with a lid for 24 hours. A day later, the disinfected liquid is pumped out and the well is waited for to be refilled. The liquid is no longer pumped out and filled until the taste of chlorine is no longer felt in it. But you still can’t drink raw water from a well for two weeks. And for your own peace of mind, it is better to submit a water sample for analysis to a laboratory.

If potassium permanganate was used as a cleaning solution, the pumped out liquid can be poured into the garden, which is not recommended to do with water after cleaning it with chlorine.

It is important to disinfect water not only after cleaning procedures or repairs, but also for preventive purposes, because human health directly depends on the quality of the liquid consumed.

Installation of bottom filters

To prevent turbidity of well water, crushed stone is immersed at the bottom of the structure, which itself is a bottom filter and does not dissolve in the liquid. If liquid is supplied to the well by sediment, then the filter is installed without hesitation. Since small particles can damage the unit. I place crushed stone at the bottom of the structure with a thickness of about 15 cm, but the value may increase if the soil of the well pit is saturated with water and has a mobile structure.

To prevent damage to the well, a preventive inspection of the mine is carried out and the liquid is checked for the presence of foreign odors and turbidity.

kladembeton.ru