Characteristics of the main element of a prefabricated foundation

The main component of such a foundation is reinforced concrete blocks. To make them, it is necessary to use special equipment, so this process is carried out in factories.

The use of such blocks is quite universal:

- Civil and low-rise construction.

- Construction of basement walls.

- Creation of the basement of the building.

If heavy grade concrete was used to create the block, it can withstand enormous loads.

The characteristics of the main elements of a prefabricated base (weight, dimensions, volume) are determined using markings - this greatly simplifies the selection of equipment necessary for work on a construction site.

Installation of a prefabricated base is possible from blocks, the width of which varies between 0.3 - 0.6 m. This thickness allows the base to be used when constructing buildings from materials of different weights.

Choosing a prefabricated foundation: what to look for

If Westerners prefer a monolithic strip foundation to a prefabricated foundation, then in the Republic of Belarus things are a little different. The prefabricated structure allows you to significantly speed up construction: minimal work time and ease of installation. Also, there is no need to look for highly qualified specialists for work.

The installation of a strip base can guarantee a long service life of the structure, but subject to all construction aspects. This can only be achieved if you have a drawing drawn up by a specialist - this will allow you to complete the work taking into account every detail. The problem is that it is rational to use a prefabricated foundation only on soils with a minimum moisture content - if it is present, dampness will form at the joints of the blocks.

A prefabricated foundation cannot be built on clay or loamy soils, which are characterized by swelling or flooding - this will lead to subsidence of the foundation with all the ensuing circumstances.

When constructing a prefabricated foundation, it is necessary to take into account that, regardless of who drew up the drawing and what level of its execution, a gap may form in the foundation structure into which the block will not fit. Ways to solve the problem:

- Cut the reinforced concrete element to a size that will allow it to be installed in an empty space.

- The gap can be filled with another building material (for example, brick) and poured with concrete.

Before you begin installing a block base, you need to determine its type, based on the specific situation. You can choose recessed or shallow, with a support pad or prefabricated.

The installation of a buried foundation is carried out at a depth below freezing of the soil, while a cushion is installed to support it and each block is lubricated with cement before laying. The installation of a shallow foundation is similar to a buried one, except for the depth - it is located above the soil freezing level.

Advantages and disadvantages

Formwork diagram for strip foundation.

Speaking about the advantages of a reinforced concrete foundation, it should be noted such a quality as the high speed of construction of the building, which immediately affects the overall construction period of the house. Another important parameter of the blocks is high quality, meeting all GOST standards.

At the same time, the cost of such a foundation is higher than a conventional strip foundation, especially if the foundation is poured with your own hands. In addition, during construction it will not be possible to do without special equipment, since the weight of the blocks is considerable.

Nevertheless, the past shortcomings of reinforced concrete blocks have been practically eliminated. An example would be the following: a small layer of concrete mortar is applied to the foundation pad, which is necessary to level the surface and prevent possible ruptures. Previously, this was a big problem as the concrete layer often broke, thereby creating leaky areas between the blocks. But today the situation has been corrected by adding special additives to concrete solutions.

Types of foundations.

And now regarding the large weight of the blocks. The use of new materials has made it possible to lighten the weight; now there are blocks that do not exceed a weight of 30 kg. Nevertheless, the only problem with reinforced concrete blocks is still their price. But even in this case there is a way out. Many of the developers began to use a technology called intermittent precast foundation. This allows you to reduce the number of blocks and other materials used, but even in this case there is no fear of reducing the strength of the building.

While Western countries prefer monolithic strip foundations, prefabricated structures have gained popularity in the former USSR. Elementary construction technology allows construction to be carried out by people who do not have any construction skills, which is why this type is well suited for DIY construction. But it is worth mentioning an important drawback: a prefabricated reinforced concrete foundation cannot be built on every soil. The blocks are suitable for construction on dry soil, which is due to its high moisture permeability, and for construction on bulk soil, which is also devoid of moisture. In this regard, the installation of a prefabricated reinforced concrete structure requires waterproofing.

Construction of a prefabricated strip base

Such a foundation is built in 2 stages: preparation and installation of blocks.

Preparation

The correct construction process is impossible if a drawing or diagram is not first drawn up, which will indicate all the details of the work being carried out. It is necessary to pay attention to ensure that the drawing is drawn up correctly and that all information is clear - it is necessary to accurately observe important points. You also need to accurately determine the parameters of the trench for the foundation: width, length, depth.

After the drawing and the necessary parameters of the trench have been studied, marking work is carried out, and then the soil is excavated. We must try to ensure that after this process is completed, the bottom of the pit has maximum strength. When the trench is ready, wooden pegs are placed to help determine the depth of the foundation.

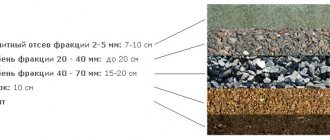

The support cushion is being installed. It should be a twenty-centimeter layer of compacted sand, on which a reinforced concrete block will be placed on top.

Installation of blocks

When constructing a strip base, blocks are installed perpendicular to the alignment axes in two directions. To do everything correctly, you need to have a drawing and carry out all the processes, creating a result of the work that is as close as possible to the requirements specified in it.

The axial risks of the foundations must be combined with fixed landmarks. To do this, before the installation of supporting elements begins, beacon blocks are installed at the corners of the structure being built and at the intersection of the axes. To install them exactly, it is necessary to use special equipment for geodetic calculations. Only after this can the foundation be constructed by laying the blocks.

A number of blocks are laid only on a dry surface. If there is precipitation, work cannot be carried out. Also, each element is lubricated with a solution before installation.

When installing the block, focus on the edge of the previous row (bottom) and the alignment axis (top). The free vertical space between the elements is filled with a solution compacted with reinforcing rods with a diameter of about 0.2 cm. It is necessary to ensure that excess cement is removed before hardening - this will simplify the installation of waterproofing material.

The blocks are protected from the outside using waterproofing. If this is not done, groundwater will destroy them and moisture will penetrate into the home.

If the expected weight of the structure and the type of soil allows, you can use lightweight blocks (with a void inside). This will reduce costs, but will also reduce the load-bearing capacity of the base.

When laying communication nodes of a structure passing through foundation elements, the empty hole between them and the wall must be sealed. To do this, you can use tarred tow.

Preparatory work

Strip foundation made of prefabricated elements.

At the initial stage of work, it is necessary to clear the area for the building and mark the axes of the building. For marking, a construction cord (wire) and metal stakes driven into the ground are used. The site is usually prepared with dimensions 2 m larger on each side than the dimensions of the building. Marking is a critical step, since it is necessary to achieve rectangularity of the contours.

To control the angles (90°) of the marked rectangle, simple measurements are taken. From the points of intersection of the axes, 3 m are measured on one side, and 4 m on the other axis. Pegs are driven in at the resulting points. The distance between them (diagonal) at an angle between the axes of 90° should be 5 m. The application of the Pythagorean theorem provides fairly accurate results.

After marking, excavation work can be carried out to prepare a trench for a prefabricated foundation. If possible, excavation is carried out with an excavator, but if the estimated foundation depth is small, the work can be done with your own hands. After using earthmoving equipment, adjusting the dimensions and leveling the walls is done manually. In this case, it is necessary to constantly monitor the depth of the trench. If the deepening is excessive, add a layer of sand or crushed stone (up to 10 cm) followed by compaction.

Then a sand cushion is laid in a layer of 10-15 cm, its width should be 20-30 cm greater than the width of the block. The difference in the depth of the most distant marks of the bottom of the trench should not be more than 10°. Ideally they should be on the same level. The bedding is watered and compacted, and a waterproofing layer is laid on it. You can use plastic film. Sometimes the bottom layer for prefabricated foundations is made of reinforced concrete cushion slabs (CF), laid on top of the waterproofing.

To install a prefabricated foundation you will need:

- blocks of design size;

- reinforced concrete slabs-pillows;

- masonry mortar;

- waterproofing material;

- reinforcing bars.

Set of tools:

- container for preparing the solution;

- welding machine; USHF (Bulgarian);

- level (building level), plumb line;

- cord, tape measure, pegs for marking;

- shovels, trowel, trowel, crowbar;

- lath for leveling the solution.

Foundation using a slab

When installing the base, reinforced concrete blocks can be replaced with a monolithic slab. The algorithm for carrying out the work in this case will be slightly different:

- A pit is dug and a 10 cm cushion of crushed stone/sand is made. Formwork is installed along the pouring contour, which, together with the soil, is moistened immediately before pouring the mixture.

- Concrete is being poured. Its height: about 15 cm.

- The places where the wall blocks rest on the base are reinforced with mesh (cells 10 by 10). This can significantly increase the strength of the structure.

- The mixture is compacted and left for a couple of weeks - this is necessary for the base to harden. After this, the formwork is dismantled, the surface is dried and primed.

- Waterproofing is being carried out. After its installation is completed, it is covered with mortar - the future basement floor.

Installing a prefabricated strip foundation is a complex process that requires correct calculations and special equipment, so it is not recommended to carry it out without outside help.