There are open and closed types. They are used for the purpose of separating sewage waste; with their help, heavy fractions and large debris are separated from water. These open-type structures are a reservoir that is assembled from perforated concrete blocks. In them, the liquid goes into the ground on its own through special holes. Heavy fractions remain in the mine and are removed using special equipment for further disposal.

Closed-type installations are a special sealed container that has technological outlets located at different heights. When wastewater enters the mine, floating particles are discharged using the upper channels, and sediment layers are discharged using the lower channels.

The structure must be installed in a place where groundwater lies below the station bottom level. Additionally, a 0.5 m cushion of crushed stone is poured in. The base should rise 1 m above the soil.

Conclusion

Before you start setting up a sewage disposal network, be sure to read all the provisions of SNiP, start planning, marking, and then selecting a mine that suits you. You will definitely need an estimate for the installation of a sewer well in order to correctly calculate in advance all the costs of arranging the entire highway network.

1. 2. 3.

The sewerage system has a very ancient history, so its design and technology have been brought to a very high quality state. This article will discuss the main issues related to the use of sewer wells in the sewerage system.

The regulatory act regulating the requirements for sewer wells and the procedure for their installation is SNiP 2.04.03-85 “Sewerage. External networks and structures." The document displays all the factors relating to sewer wells, including their location, classification, dimensions and operational characteristics.

To install a sewer system on a private property, it is necessary to use inspection wells, placing them on the section of the pipeline between the building and the wastewater receiver. In addition, one of the possible options for disposing of wastewater after it has passed through a septic tank is a filter sewer well.

Inspection wells must be installed not only in private households, but also on local sewer systems.

The installation site must be located behind the so-called red building line, which is a conditional boundary dividing the target area into certain segments. SNiP states that sewer wells must be installed every 35 meters if the pipeline diameter is up to 150 mm, or every 50 meters for a pipeline with a cross-section of 200 mm. In addition, inspection wells are installed if the system contains:

- turns and bends;

- changes in pipe diameter or slope;

- branches of the structure.

Requirements for the operational characteristics of reinforced concrete wells are reflected in GOST 2080-90, and for polymer wells - in GOST-R No. 0260760.

Most plastic structures are also supplied with manufacturer’s instructions, which outline the conditions for using the well. Brick, concrete or reinforced concrete are used to make stone sewer wells, and rubble stone is used to create filter wells. Polymer wells can be made of polyvinyl chloride, polypropylene or polyethylene. In addition to structures made from a single material, there are structures on the market made from compounds of various resources.

According to SNiP, the dimensions of sewer wells vary as follows:

- when using pipelines with a diameter of up to 150 mm - at least 700 mm;

- up to 600 mm – 1000 mm;

- up to 700 mm – 1250 mm;

- from 800 to 1000 mm – 1500 mm;

- from 1200 – 2000 mm;

- from 1500 mm with a system laying depth of 3 m.

The volume of the structure is not indicated anywhere, but knowing the initial depth and diameter, you can calculate this indicator yourself.

The order of actions will look like this:

- first, the exact location on the site where the well will be located is determined;

- then the selected area is cleared of any plants (bushes, trees, etc.);

- if necessary, buildings located on the construction site are demolished or moved;

- It is very important to ensure unobstructed access to the site.

Next, the preparation of the pit for the sewer well begins.

As a rule, a pit is created according to the following principle:

- first of all, a hole of the required dimensions is dug;

- then the bottom is cleaned;

- a check must be made to ensure compliance with the laying depth of the structure and the slope angles of the pit walls;

- in the case of stone structures, a 20-cm waterproofing layer must be laid at the bottom of the pit, compacting it as tightly as possible.

Types of wells

SNIP regulates specifically and precisely where and how sewer wells should be installed. It is also important to take into account the Building Codes and Rules because the inspecting authorities are required to check structures for compliance with the requirements, and if violations are detected, they may issue an order requiring changes to be made to the sewerage system, which will require additional costs and will significantly increase construction time.

Manholes

Such structures are necessary for any sewer system, regardless of its degree of complexity. Wells provide the ability to monitor the operation of the system and are used for its maintenance (repair, cleaning, flushing, etc.). Depending on where the observation structures are located, there are several types:

- linear wells are placed on straight sections of the highway at a certain interval with a significant length of communications,

- rotary wells are installed in places where the direction of flow of wastewater changes (in order to reduce hydraulic resistance, sudden changes in “course” should be avoided; pipes must be connected at an angle of 90° or more),

Rotary manhole - nodal wells are required at the junction of the outlet pipe with several inlets (the number of the latter, according to current standards, should not exceed 3),

Design of a nodal type sewer well

- Control wells are installed when using a centralized sewer system and are installed where the local sewer connects to the central pipeline.

Important: As stipulated in SNiP, linear type sewer wells are installed on straight sections every 35 meters if the pipeline diameter is up to 150 mm, and every 50 meters if the pipe diameter is 200 mm.

Drop wells

Drop wells are used to change the flow speed or depth of pipelines. They are also used when it is necessary for the sewer line to bypass any obstacle (another pipeline, etc.). In general, such structures represent a vertical shaft (reservoir) with inlet and outlet pipes. Depending on the purpose, it may be necessary to install sewer wells of this type with additional devices, for example, with steps that dampen the flow rate.

Example of a differential polymer well

The following types of drop wells are distinguished:

- classic well design (effluent inflow through the upper pipe, discharge through the lower pipe),

- models of wells with baffle-drain surfaces of the walls to reduce the flow rate,

- channels with a significant slope, capable, on the contrary, of “accelerating” the flow, increasing its speed,

- complex designs of multi-stage drops.

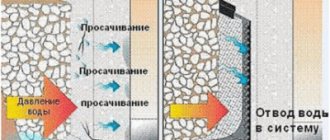

Filtration wells

Models of wells of this type are used in sewerage systems to provide soil post-treatment of partially clarified wastewater in the septic tank and drain the liquid component of the septic tank contents into the ground. Structurally, a filtration well differs from others in the absence of a sealed bottom (instead, it is backfilled with gravel or other filter material). Options for wells with holes in the walls of the tank are also possible. Through such holes, the liquid also goes into the soil, and to further clean it, filter material is also backfilled from the outside of the well at the stage of its installation.

Filtering sewer well made of concrete rings with perforation

Storage wells

The principle of operation of a storage sewer well is the same as that of a cesspool - it is a place for collecting waste. When organizing a storage facility, it is important to ensure its tightness and provide for the possibility of access by a vacuum truck to pump out the contents.

What materials may be needed?

Do-it-yourself sewerage from concrete rings is made using the following materials and tools:

- shovel;

- shovels with sides;

- buckets;

- handles with cross handles;

- products for loosening soil;

- cement grade M200 - M500;

- sifted fine sand;

- crushed stone with medium fractions;

- concrete products with a diameter of 10 cm;

- corners, asbestos pipes and tees;

- hacksaws;

- waterproofing material.

Using a shovel with sides, the earth is scooped up, and the depth of the pit is formed with a shovel and bucket. A layer of crushed stone is poured onto the bottom of the trench to strengthen the structure. The bottom is installed on a crushed stone cushion.

Materials for making wells

The construction of a sewer well provides for the possibility of using various materials.

- Brickwork is highly durable, and if you have some skills, erecting a structure will not take much time. In this case, technological holes are made during the construction stage.

- Concrete wells can be built using the pouring method (using formwork) or by installing finished products (rings of various diameters). Holes for inlet and outlet pipes in cast structures are made at the pouring stage; in ready-made reinforced concrete products, holes must be made with a hammer drill or other suitable tool.

The photo shows a linear well for sewerage made of reinforced concrete rings

Important: Brick and concrete wells require waterproofing of walls from the outside and inside and bottom, unless we are talking about filtration structures. Careful sealing is needed where pipes enter tanks.

- Plastic that is impervious to water and chemicals (for example, detergents and disinfectants) is convenient for making wells. You can make a plastic sewer well with your own hands from a Eurocube or barrels. There are also ready-made blocks available for sale, which include not only the tank itself, but trays with wiring of various types.

Installation of plastic sewer wells may require anchoring to a concrete foundation if groundwater or flood waters rise close to the surface of the earth and there is a possibility of the lightweight structure floating. Spontaneous movement of an unfixed well under the influence of water can damage other elements of the system.

Construction of a sewer well

Sewer wells are a mandatory attribute of external sewerage; without them, its installation is impossible. They must run along the entire length of the pipeline. Their design and quantity may vary slightly, depending on the type and purpose of the structure, complexity and length of the system.

The process of constructing such a device is not complicated, the main thing is to understand the difference in types of structures, because a homemade septic tank or cesspool is also a well, and to comply with the rules and requirements. After this, it will be easier to make an efficient and trouble-free sewage system for your home.

Requirements

The requirements for sewer wells are regulated in SNiP 2.04.03-85. This act describes all aspects relating to these structures: location, classification, dimensions and characteristics. The document says that a well is installed if:

- there are turns or bends;

- pipe diameter or slope changes;

- pipeline branches occur.

Overall dimensions may vary. depending on the diameter of the pipeline:

The volume is not indicated, but knowing the depth and diameter you can calculate it yourself. The operational characteristics of concrete wells are reflected in GOST 8020-90, and plastic (polymer) wells in GOST 32972-2014.

Video: Sewerage made from concrete rings is the simplest and cheapest option

Also, when installing a well shaft, it is necessary to comply with sanitary standards, these include:

- cannot be installed near sources of drinking water and water supply systems;

- installation is carried out at a certain distance from residential buildings and neighboring areas;

- volumes must correspond to the number of users.

You can read more about sanitary standards in this article: Rules for installing a septic tank.

Types of septic tanks and their design features

When arranging a septic tank made of concrete rings, the design of each type of structure has its own nuances.

Local structure with one chamber

At the heart of a single-chamber septic tank, in a country house made of concrete rings, there is one container, which plays the role of a sewage storage tank. Its optimal volume is 16-20 times the daily water discharge. The design allows for the absence of a bottom and drainage.

Two-chamber system

The cleaning system has good functionality. The two-chamber structure for a summer cottage made of concrete rings is based on two storage tanks. The structure of the well allows the accumulation of heavy fractions in the first chamber, and the secondary one is intended for the accumulation of settled wastewater. By constructing a system that uses drainage based on sand and gravel, it is possible to obtain high-quality drainage of water into the soil.

Three-chamber septic tank

The basis of the three-chamber system is made up of three containers. This building is a perfect waste disposal device. The first two wells act as sedimentation basins for sewage, the last one performs the final filtration of wastewater. The third sewer pit has to be dug deep, right down to the occurrence of sand and clay, which will facilitate the removal of moisture.

Types of wells

To understand which and how many wells need to be installed on the site, you should understand their types. The sewer system may include the following types:

Each of them has its own specific function; sometimes they can be combined in one structure. Below we will take a closer look at each of them.

A sewer inspection well can be installed on any system, regardless of its complexity. Helps monitor the performance of the sewer pipeline and is used for maintenance - cleaning, flushing, etc. Depending on the location they are divided into:

- linear - if the highway is long, it is located on straight sections, at a certain distance;

- rotary - installed in places where the direction of the pipeline changes;

- junction - mounted at the junction of several pipes into one;

- control - used at the junction of the local sewerage system with the centralized one.

Perepadny

Serves to change pipe laying depth or flow rate. They can also be used to bypass any obstacle. The design consists of a tank with inlet and outlet pipes located at different heights, and additional devices, for example, stages for reducing speed. Just like the previous view, they may differ slightly from each other:

- classic design - wastewater enters through the upper pipe and is discharged through the lower pipe;

- with baffle and drain walls - to change the flow rate;

- channels with a slope - to increase speed;

- structures with multi-stage drops.

Filtration

These models are used as a device for soil post-treatment of wastewater coming from a septic tank. The design feature of this well is the absence of a bottom and holes in the walls. Instead, a drainage layer of crushed stone or gravel is installed at the bottom and outside of the well.

Cumulative

A place for collecting and storing wastewater, in other words, an ordinary cesspool. When arranging it, it is important that the container is sealed and cleaned regularly.

Types of sewer wells

According to their functional purpose, mines are conventionally divided into several main types:

- examination rooms;

- differential;

- rotary;

- accumulative;

- filtration.

Each of these types performs its specific function.

Inspection well

An inspection well (photo) is a shaft that is located above the main drainage line. Such a shaft makes it possible to conduct a visual inspection of the system’s performance and, if necessary, carry out its flushing or mechanical cleaning during operation.

In most cases, such shafts are installed on straight sections of drainage at a certain distance, however, shafts installed at turns or intersections of communications can also be called inspection shafts.

Inspection shafts can be of several types:

- linear

, installed on straight sections;

- rotary

, installed in places where the direction of the highway changes. In order to avoid hydraulic resistance, the angle between the incoming and outgoing lines must be at least 90 degrees;

- nodal

, installed at the junction of several highways. Such chambers connect one outlet pipe with several incoming pipes, but there can be no more than three incoming pipes;

- control systems

are installed at the points where the private system is connected to the main one.

Note! The distance between inspection shafts is determined by the diameter of the pipe. For example, with a pipe diameter of 15 cm, the distance between wells is set to no more than 35 meters. With a pipe diameter of 50 - 70 cm, the distance between the shafts is 75 meters.

Drop well

The construction of a differential sewer well is a simple structure (see photo), which is installed in the following cases:

- when reducing the depth of the ditch under the drainage main;

- when bypassing other underground pipes or communications;

- to prevent high fluid velocity.

According to the type of design and functions, drop wells are divided into several types:

- a conventional shaft with a liquid supply in the upper part and an outlet in the lower part;

- difference with the baffle-drain wall to reduce the flow rate;

- short channels with a large degree of slope to increase flow speed;

- a mine with multi-stage drops.

Rotary well

Such shafts are installed in those sections of the highway where sharp turns of the channel are necessary, since it is in these places that blockages of the system most often occur.

Storage well

Storage shafts or wells (photo) are designed for collecting and storing waste liquid with its subsequent pumping using a pump or special vacuum trucks.

For private homes, installing sewer wells of this type can be an advantageous solution if the nearest central system is far away or non-existent. Depending on the volume, such shafts can be made of reinforced concrete rings, monolithic concrete or large plastic containers.

With a small amount of wastewater, installing a plastic tank is most justified, since the price of such a tank is low and the installation process can be done with your own hands, without the involvement of equipment or professional construction teams.

Filtration well

Filtration shafts or wells can be open or closed. Both types of wells are designed to separate wastewater and separate large debris and heavy substances from the liquid.

Open-type structures are mines made of perforated concrete blocks, where liquid goes through special holes into the ground, and heavy substances remain within the mine and are subsequently removed by special equipment for burial or disposal.

Closed wells are sealed containers with technological outlets, which are located at different heights. As wastewater enters, floating particles are removed by the upper channels, sedimentary layers are removed by the lower ones.

Installation of a concrete well

Sewage wells made of concrete and brick practically do not differ in the stages and progress of installation work. In any case, installation proceeds as follows:

- A pit of the required size is dug.

- The foundation is being laid - pouring the foundation or a finished slab.

- Construction of walls - pouring or installing rings.

- Waterproofing walls and seams.

- Backfilling and compaction.

- Cover device.

In order to lower the finished rings into the pit, you will need to use special equipment.

Installation of a plastic well

Ready-made containers made of plastic or other polymeric materials make it possible to complete all work without the involvement of lifting equipment and save time. The main thing is to choose the right location for the structure and its size. Installation is carried out in several stages:

- Digging and preparing a pit.

- The foundation is a cushion of sand and crushed stone or a poured base.

- Installation of the tank, if necessary, fastening to the foundation.

- Inclusion in the system.

To avoid filling a well of any type, it is recommended to make a concrete blind area around it along the entire perimeter of the neck, 1.5 m wide.

Video: Installation of a sewer well made of concrete rings

Optimal septic tank sizes

When calculating the effective and working volume of sewerage in a private house made of concrete rings, it is necessary to proceed from:

- three times the amount of water discharged per day. As a rule, there are about 200 liters per person.

- To determine the optimal volume of the septic tank, taking into account everyone living in the house, you need to multiply the indicator by 3 and by the number of users of the drainage system.

The dimensions of concrete rings for sewerage play an important role. In the single-chamber version, the entire volume of water is contained in one container. The two-chamber design takes on ¾ of the total volume in the storage tank, and ¼ goes to the second chamber. A three-chamber septic tank will distribute the entire volume of wastewater equally across all storage tanks.

Why is waterproofing needed?

Waterproofing a sewer well made of concrete rings is carried out for several reasons:

- All reinforced concrete structures are reinforced with metal reinforcement. Without protection from moisture, these elements are easily affected by rust. As a result, the bearing capacity of the reinforced concrete ring is reduced, and the mine may collapse under soil pressure.

- Under the influence of aggressive substances that are always present in groundwater, the structure of concrete can be destroyed. Waterproofing a sewer well extends the life of a concrete structure.

- The waterproofing layer prevents runoff from penetrating into the ground through concrete walls with cracks or other damage.

- Connections between concrete rings without waterproofing can also allow wastewater to pass through, violating environmental requirements.

- When the soil freezes seasonally, the binders of the concrete solution may freeze out, which significantly reduces the service life of the structure.

- Lack of protection will affect the rate at which the septic tank fills. This issue is especially relevant during spring floods, when groundwater penetrates into the wastewater reservoir.

How does a septic tank system work?

A durable concrete well, designed for the quality of sewerage, ensures consistent movement of wastewater:

- water with contaminants enters the first container and is divided into elements of different densities. Heavy fractions remain at the bottom, and light fractions rise to the surface;

- the purified liquid is fed into the second tank, where the organic matter is broken down;

- the third container without a bottom discharges purified water into the ground. The liquid is pre-filtered in a drainage well.

Three-level filtration eliminates soil contamination.

Sewage wells: installation requirements and SNiP

The content of the article:

When planning to install an autonomous sewer system on a private plot, it is important to understand that before starting work directly, you need to draw up a design and diagram of the sewer system.

To do this, you need to use the standards specified in the relevant paragraphs of SNiP.

Only then will the system work correctly and the likelihood of any malfunctions occurring soon can be eliminated.

Construction of a sewer well according to SNiP

Calculation of well volume and diameter

Before starting work on constructing a sewer well, you need to determine its overall dimensions. A well intended for home use should generally be approximately 2-2.5 meters high. First you need to find out the volume of the well in order to obtain the diameter of the rings using the calculation method.

Design parameters of the well: height and diameter of the rings

It must be remembered that the volume of the well should be greater than necessary - with a reserve of 1-1.5 months. Calculation example:

- The volume of the well is calculated using this formula: V=L x 3.14 x R2.

- Let's assume that you spend an average of 7 cubic meters of water per month (V), and let's take the height of the future well to be 2 meters (L).

- Then, the radius of the well R = root of V / 3.14 / L, which will be equal to 1 meter (R = 7 / 3.14 / 2.2 = 1m).

- Thus, the diameter of the ring should be D = R x 2 = 2 (meters).

Types of wells

Initially, you should consider the installation of sewer wells in accordance with SNiP. First of all, let's study their types.

Wells can be as follows:

- inspection rooms - they are needed to inspect sewer pipes, maintain them and clean them in case of clogging;

It must necessarily include the following elements:

Manhole diagram according to SNiP

- mine;

- working chamber;

- neck;

- top protective cover.

It should also be equipped with a special staircase.

What requirements exist in SNiP for sewer wells?

First of all, you should consider the requirements for sewer wells, which affect the choice of material for their manufacture.

Structures must have high levels of tightness and strength.

SNiP allows the use of the following materials in the construction of wells:

- ready-made structures made of plastic or polyethylene. They are initially manufactured by specialized factories in full compliance with GOSTs, so the question here will only be in determining the appropriate dimensions of the structure;

Well made of rubble stone

The following relationship is observed:

Diameter of sewer well, drawing

- for pipes with a diameter of less than 300 mm, the diameter of the well must be at least 1000 mm;

- for pipes with a diameter of 300 mm or more, the diameter of the well must be 1500 mm or more. You can install square wells. Here the length of one side should not be less than 1 meter.

Well made of reinforced concrete rings

Requirements for a septic tank made of rings

The construction of a sewer well-septic tank (the simplest option) can be carried out by installing it from ready-made reinforced concrete rings with a diameter of 1.5 to 2 m. When choosing a location on the site where the septic tank will be located, it is necessary to take into account the requirements of sanitary standards. According to them, the septic tank must be located at a distance of at least 5 meters from the residential building. Since the same standards require a laying depth of sewer pipes of at least 0.7 m, then to determine the volume of the septic tank it is necessary to take into account that the part of the septic tank capacity lying above this mark will not be in demand.

Choosing the location of the future septic well

So, before making a sewer well, you need to understand the features of choosing its location:

- The well must be located so that a sewage disposal truck can easily drive up to it to pump out sewage, that is, convenient access roads must be arranged.

- It is especially important to keep the sewer well as far as possible from the drinking well if you have one in your yard. The distance between these two wells can be at least 30 m according to the standards.

- The distance from the point where the sewer pipe exits from a residential building to the well should be minimal.

- There cannot be any turns in the section between the sewer pipe exiting the house and the well. If it is still impossible to do without this, then their number should be as small as possible, and the turning angles must be made obtuse, i.e. equal to 120°. In this case, the angle of inclination of the pipe after turning should not decrease.

Having figured out the choice of location, you can proceed directly to studying the installation technology, especially since it is not at all complicated.

Requirements for installing sewer wells

Before installing sewer wells according to SNiP, you need to determine the location of the structures.

If we are talking about inspection wells, then they are installed in increments of 40 meters if the diameter of the sewer pipes is 150 mm and in increments of 50-60 meters if the diameter of the pipes is 200 mm.

As for storage and filtration wells, SNiP gives completely different location standards.

They are based on the distance of the well to a certain object:

Requirements for the location of the well according to SNiP

- at least 5 meters from a residential building;

- 1 or more meters to outbuildings;

- 3 meters to the fence of the site or highway;

- 30 meters to drinking water wells or reservoirs;

- 20 meters to the garden or vegetable garden.

There are also some requirements for the technology of constructing sewer wells.

They consist of the following points:

Requirements for SNiP device technology

- the depth of the pit dug for a well cannot exceed 2.5 meters;

- the bottom of the filtration well should be at a distance of 1 meter from the maximum possible groundwater level;

- when the groundwater level is high, waterproofing must be installed;

- the diameter of the pit should be 50 cm larger than the diameter of the well;

- a sand cushion 10 cm high must be placed at the bottom of the pit;

- There should be a distance of 0.6 meters between the bottom of the well and the bottom of the sewer pipe.

Installation of a well according to SNiP

- digging a pit of the required size;

- compacting the bottom of the pit;

- laying a sand cushion;

- installation of the bottom of a sewer well;

- installing a concrete ring on the bottom;

- joint sealing;

- installation of the next ring with subsequent sealing of the seam;

- supply of sewer pipes;

- arrangement of waterproofing and thermal insulation;

- installation of ceiling;

- installation of an inspection hatch.

Installation of a plastic well

If we talk about installing a plastic well, then after immersion on a sand cushion, it must be securely fastened to it using special belts.

Then the container is filled with water, and the space between it and the walls of the pit is backfilled.

For this purpose, a mixture of sand and crushed stone is used.

A layer of thermal insulation is placed on top of the plastic container to prevent freezing of the drains in the winter.

Related Posts

How to make water supply for a private house from a well

Plastic wells for communication sewers: purpose, types, characteristics, price

Repair of faulty sewer wells

Laying the main elements

It is easier to install concrete rings in a ready-made pit using special equipment. Before laying, crushed stone and sand (10–15 cm) are poured onto the bottom of the pit. The first part must be installed as evenly as possible, clearly in the middle. To do this, one worker goes down into the pit, and the second controls the process from above.

After installation, H-shaped guides are placed on the edge of each part. Their number is calculated separately for each radius, but not less than 4 pieces. We arrange them evenly in a circle and insert the second ring. The seam is coated with liquid mastic and cemented.

So, all subsequent elements are installed. It is easier to connect parts with a groove. Like a construction set, they easily fit on top of each other. The height of the last part should be 40–50 cm above the soil level. We recommend using a narrowed part with a finished lid as the final link. The well will be safer.

A pipe for water supply is inserted into the finished well from below. The hole for it is made in the second or third element. The pipe is connected using a special coupling. The joints are coated with sealant and waterproofing. The hole for it in the well must have a larger diameter than the pipe, otherwise damage to the external water supply may occur when the soil moves.