3481

Many people do not realize that even an ordinary cement screed is subject to a lot of requirements according to GOST. Professional builders follow all regulations and carry out a specific project to ensure that they adhere to them. What are the main requirements that concrete floors must meet when laying them themselves?

Concrete floors have structural requirements, including minimum thickness and finishing quality

Requirements for floor screed

Standards and requirements do not come out of thin air; it is important to comply with them, especially if repairs are being carried out in an apartment building. For example, you can’t just remove walls. The same standards apply to floor structures.

The requirements apply to all levels of the floor - from the rough to the finishing coating. In order for flooring materials to last a long time, they must be observed. Therefore, you should not reject SNiP. A brief study of its requirements will help you avoid mistakes that are so easy to make. The regulatory documents stipulate absolutely all standards, from waterproofing the subfloor to the proportions and components of the cement-sand mortar.

When arranging a cement-sand screed, the following technical characteristics are taken into account:

- minimum thickness;

- structural strength;

- waterproofing;

- minimum layer above the heated floor system;

- reinforcing layer;

- presence and location of expansion joints.

Minimum layer

They are guided not by how much mixture is needed, but by the requirements for the minimum thickness of the screed.

When choosing the minimum layer, they are guided by the type of mixture. But despite the composition, according to SNiP, the minimum thickness of the floors cannot be less than 3 cm. When adding reinforcing fibers, the thickness of the screed is allowed to be at least 1.5 cm. If pipes pass through the floor screed, the screed is poured no thinner than 4 cm.

Attention! Determining the strength of a coating is a difficult matter, because this requires special technical means. Of course, you need to be guided by GOST requirements, but in this matter the assessment is carried out only indirectly. It can be argued that the coating will be durable if you follow the proportions and recommendations of the manufacturer, as well as other requirements for arranging the screed.

Waterproofing

Lubricant waterproofing on concrete floors

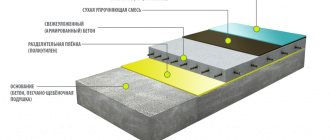

The use of a waterproofing layer is mandatory, because if the screed becomes waterlogged, water will flow to the lower floors. For this reason, SNiP establishes requirements for the waterproofing layer.

If waterproofing is performed above a room, the following types of waterproofing material are used:

- On bitumen mastic (Brizol, hydrostekloizol).

- On polymer adhesive (PVC, fiberglass, polyisobutylene).

If screeding is carried out on the ground: SNiP obliges the soil to be compacted with black crushed stone with additional impregnation from bitumen or poured concrete composition.

Reinforcement

To reinforce or not depends on specific situations.

The reinforcing layer is used in cases where the thickness of the screed exceeds 5 cm. For this, any technology can be used. This standard applies to premises with an average degree of load, that is, residential.

When reinforcing, according to the standards, it is recommended to use the following materials:

- Wire to create a mesh with cells 10 x 10 cm.

- Polymer mesh.

- Metal rods.

- Fiber fiber.

Reinforcement of a concrete screed strengthens it and prevents the risk of cracks, maintaining integrity and reducing deformation loads. Reinforcement of a screed whose thickness is less than 5 cm may be necessary if a water heating system is installed. Moreover, the reinforcing layer is not used with a rough screed, since almost the entire load falls on the finishing layer.

Expansion joints

Floors in different rooms are separated by expansion joints.

With a large area of the room, the risk of cracks increases. Therefore, a screed technological map is being designed. It indicates the sequence of work, the materials used and the location of expansion joints, including the distance between them and other technical information.

Solution

When pouring a cement screed yourself, all these norms can be ignored due to ignorance or reluctance. Many people believe that the entire technological effectiveness of the process lies only in the preparation of the solution. Although this is not incorrect, as has already become clear from the material presented above, it is still worth noting the features of preparing the solution. The proportions vary depending on the brand of cement, layer thickness and other criteria, but all solutions consist of the following components:

- Sifted river sand;

- Cement. Brand M300-M400 is suitable for residential premises; M500 is used in industrial premises;

- Gravel or crushed stone. The size of the fractions should be 5-15 mm and withstand pressure from 20 MPa.

If you use ready-made mixtures for filling, then you don’t have to worry too much about the composition, because manufacturers prepare mixtures that meet the standards.

Choosing a solution

There are certain conditions that affect the thickness of the floor screed. This is not only the technology itself, but also:

- Characteristics of the operation of the room where work on the construction of the subfloor is carried out. The greatest loads on the floor are in the corridors, kitchen and living room. So you should not think about the minimum indicators in such premises, but do a little more than required.

- Floor covering that will be laid after the prepared base has dried.

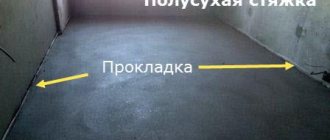

- The material into which the semi-dry screed is poured, as well as the very condition of this coating. The more unevenness there is, the more it will be necessary to arrange a layer of semi-dry screed. If you pay attention to building codes and regulations, then the minimum thickness is set at 20 mm. With such a thin layer, it is very important to think about reinforcement so that it does not crack over time.

- Materials for semi-dry floor screed used in the process.

Each of these factors adds or decreases the overall thickness and creates conditions for the use of additional moments in installation. But this does not mean that a very thin or very thick base will be more effective, unlike each other. At the same time, there are subtleties and nuances. Each specific case should be approached individually.

First, you should inspect the base of the subfloor itself. We will proceed from this when determining the thickness of the semi-dry screed. It will be enough to carefully examine the exterior. It’s a good idea to run a metal strip about a meter long. It will indicate existing uneven parts, as well as significant protrusions. Such defects appear not only in old buildings, but also in newly built houses. The precision of the work will allow you to perform the laser level.

Calculation of the thickness of semi-dry screed

Cement semi-dry floor screed begins with the preparation of the base. The smoother the surface, the less amount of solution will have to be spent during work.

When deciding on a coating device, make an economically sound, technically competent decision, taking into account the points specified in the standards:

- service life and structural strength;

- rational use of materials taking into account characteristics;

- the possibility of mechanizing work, reducing labor costs;

- the influence of negative aspects, the ability to violate the integrity of the flooring;

- hygiene and fire resistance.

How to check the quality of the finished screed

You can check the quality using the rule.

There are many masters. Only the lazy today do not fill the screed themselves, and not everyone follows the norms. At the same time, it is not difficult to determine the quality of the poured screed.

Important! If the screed does not become cracked after a month of drying, then we can safely say that the proportions of the mixture are correct and it is strong enough.

In addition to strength, the evenness of the coating is also important. Many types of flooring are demanding on this parameter. For laminate and parquet, the maximum height difference reaches 2 mm per 2 linear meters.

To check this value, you can use a long rule and level. If the rule leaves a gap of more than 2 millimeters, then you will have to use a finishing leveler. The strength of the screed is not so important in residential premises, because it does not experience heavy loads. The evenness of the coating is much more important.

Document structure

Building codes and regulations contain requirements for the design of floors intended for public premises, administrative facilities, industrial enterprises, and private homes. The document structure contains:

- general requirements for floor design features and its development;

- classification of coatings depending on strength and material thickness;

Today there are many ways to perform work related to leveling the subfloor for further laying of floor coverings

- interlayer requirements;

- list of measures to protect against water penetration;

- recommendations on the area of application and thickness of the screed;

- litter characteristics;

- requirements for the bases on which floors are installed.

Subfloors should be designed according to special regulatory documents. Previously, SNiP 2.03.13-88 was considered the main document on rough concrete foundations. However, despite the fact that floor installation techniques in residential buildings have not changed, new materials and construction technologies began to appear, and therefore the standards have changed.

Today the document SP 29-13330-2011 is in force. It updates the edition of the standards for flooring.

Surface reinforcement

When a semi-dry floor screed is performed, the thickness will depend, among other things, on the reinforcing layer. In this case, everything familiar is a steel mesh with a cell size of 10*10 mm. But this begins to go away due to the increase in the weight of the finished structure on the floor.

A semi-dry screed with fiber comes as a replacement. This component is easily “introduced” into all components of the mixture and a single whole is obtained. The coating ultimately becomes more durable, stronger and harder, able to withstand any load and flooring without exception.

The steel mesh also increases the overall thickness of the subfloor. The installation process will look somewhat drawn out due to the creation of additional stages of work: filling the mixture, laying the reinforcing element, finishing work. With fiberglass everything is much simpler and more convenient.

Floor screed reinforcement is used to give the structure greater strength. SNiP recommends the following materials:

- Wire mesh with a cell of 100×100 or 150 mm;

- Mesh made of polymer materials;

- Frame made of twigs;

- Fiber reinforcement – fibers of steel, polypropylene, basalt.

This procedure is necessary where the height of the screed is more than 40 mm. For residential premises where there is no high load on the floors, screeds up to 70 mm are not reinforced.

The laying of reinforcing materials is carried out at the preparatory stage. To ensure that the reinforcement fits correctly, special plastic supports are used.

The need to determine the minimum

The minimum thickness of a semi-dry screed should be determined in the case where there are installed communications or a heated floor system. By making a very large layer of subfloor, the distance from the floor to the ceiling is reduced. This is especially noticeable in low rooms.

Above the heated floor level, the minimum thickness should be 35 mm. This level is established immediately after the completion of all its elements. A thick floor increases the cost of heating the room, since the screed itself is saturated with heat for a long time, not to mention another obstacle - the floor covering.

The large thickness of the floor puts pressure on the ceiling. It appears most often on balconies. And the drying time will immediately increase. The material tends to expand over time. This can subsequently cause pressure on the walls if the layer is too massive.

If the mixture does not include any additional reinforcing substances, then its minimum thickness should be 40-50 mm. You can tell a lot about thickness by looking at the packaging for the mixture. Recommended parameters are always displayed there. Manufacturers always worry about the bottom line.

According to SNiP, when laying a semi-dry screed immediately on the floor slab, it must be at least 20 mm thick. If there is an additional layer of waterproofing - 40 mm.

Maximum performance

There are no maximum limits for the screed. Everything will depend on the need to hide communications or any surface irregularities. But you should be careful not to put a strong load on the floor.

Experts recommend not starting with minimal layers of semi-dry screed, but taking a slightly larger one. A small value will lead to the appearance of cracks and chips on the surface, which will lead to repeated work.

Since almost every base for a subfloor has unevenness of several centimeters, the screed, in general, will be about 50-60 mm. At each level above the ceiling it should be at least 30-35 mm. Some places will be larger, some will be at minimum limits. This is also necessary to ensure that the water evaporates evenly before drying.

The laying of slabs is not always carried out to a decent standard. It even happens that the differences are more than 60 mm. In this case, it is best to use sand concrete made from a coarse sand fraction for the solution. In this case, the thickness of the semi-dry screed can reach up to 15 cm. If you have to make it even larger, then expanded clay will come to the rescue, which can reduce costs.

SNiP cement-sand screed

As for the most common capital method of organizing a coating, the characteristics here are virtually the same as those made using the semi-dry method. And the point, of course, is that the same cement and sand are used here and the addition of the same impurities is allowed. So:

- the thickness of the cement-sand floor screed should not be less than 2-2.5 centimeters (the larger limit can vary to significant values from 100 mm or more if reinforcement or plasticizers are used);

- the weight of cement-sand screed per 1 m2 with a minimum layer is 40-50 kg (higher ones can be lightened with various additives, for example, polystyrene foam granules);

- the strength of the cement-sand floor screed is enviable, like that of any other capital structure (the tabular indicators of a conventional mortar after hardening are from M150 to M180 - this is quite enough even for moving heavy equipment);

- the density of the cement-sand screed (thermal conductivity) is on average 2000 kg/m3 (if everything is done in compliance with the necessary details).

All of the above indicators are completely optional for people whose professional activities are far from construction.

Cost of work with materials: from 390 rub./m2

Order by phone:

8

Contact us and entrust all calculations to our specialists. You can be sure that they will offer the most profitable and technologically advanced solutions in any specific case. Everyone who contacts us will always have the opportunity to take advantage of:

- attractive prices;

- prompt execution of work;

- many years of experience of employees;

- professional consultations;

- official quality guarantee.

Call! You will like our conditions!

Minimum screed thickness

The current legislation considers the minimum thickness of semi-dry floor screed according to SNiP, although in practice the indicator depends on many nuances. The most significant influencing factors include:

- presence or absence of communications;

- changes in height and presence of unevenness;

- installation of heavy furniture and use of equipment;

- floor covering used.

As a result, the minimum thickness of a semi-dry floor screed is often the optimal solution. We help customers understand the features they are interested in so that the purchase brings the most positive experience.

Let's start our acquaintance with the physical properties of the structure in question with the fact that the thickness of the floor screed in an apartment is not allowed to be less than 20 mm. Otherwise, its destruction is inevitable due to poor wear resistance. That is, you should calculate it at the lowest point so that it is even thicker.

A completely different matter is the thickness of the screed for a water heated floor. There should be enough here to hide the pipes. In addition, it is recommended to make a heat-insulating pillow from expanded clay. Accordingly, the level increases significantly.