We often store some old things, valuable and not so valuable tools, spare parts for the “iron horse” and other equipment in the garage. To secure all these treasures, you need to choose the right gate.

A modern development for the garage - roller shutters. Their main purpose is to provide the highest level of safety and the need for an aesthetic component.

It is also possible to make your own garage shutters and save some money.

What are roller shutters?

If it is necessary to protect the premises, you will need a high-quality product with an easy installation and use procedure. This type of product can be called roller shutters for the garage.

Steel or aluminum profiles with varying degrees of thickness are the basis for the production of roller shutters.

Aluminum products are characterized by increased strength, do not rust, and the service life of such material is longer than that of other products.

The slats are pulled together tightly in order to enhance the anti-vandal effect , and additional rigid ribs are installed for the holding function.

This manufacturing procedure requires a product thickness of 0.5 to 1 millimeter, which places a large load on the electric drive.

Products made from steel alloy profiles are the most reliable and durable . To ensure that the structure is not exposed to moisture, it is made from galvanized steel sheets.

Thermal cumulation in the garage is achieved by additional insulation of roller shutters. To do this, the entire perimeter of the gate is covered with special insulation. Such insulation will help to obtain a comfortable temperature in the room even with sub-zero temperatures outside the window.

Roller shutters designed for garages are available in two types : with vertical and horizontal opening and closing of the gate. Gate structures can be opened manually or automatically.

Rolling gates are easy to install and operate. Such products can be installed both inside and outside the garage opening.

An extensive selection of slats allows you to choose a door for any garage opening.

Types and features

Roller shutters have long been a popular material capable of protecting windows, doors, garage doors and other spaces.

They not only cope with protection, but also tightly hide the room from sunlight and noise produced from the street.

The market offers a variety of roller shutters, differing in production technique, material used to create the product, installation method and operational purpose.

Based on the installation method, such products are divided into built-in and overhead . Overhead products are installed on top of the opening that needs protection, and built-in products are installed in the inside of the opening.

Experts recommend using roller shutters with internal installation because they are resistant to mechanical stress, hold tightly, are not subject to bending, and are more attractive from an aesthetic point of view than the second type.

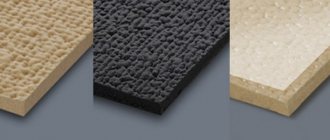

According to the material added to production, roller shutters are divided into :

- plastic.

They are not used in openings with large spaces, but have excellent decorative properties. Such shutters protect the room from noise interference and direct rays of the sun, but they cannot save the owner’s property from burglary;

steel.

Such roller shutters are made from a metal profile with a painted or galvanized surface. They protect property from the penetration of ill-intentioned persons into the owner’s territory.

This type of product is most often found in modern construction;

aluminum.

This type of roller shutter is similar to steel in its properties and the nature of room protection, but has less weight and is distinguished by an affordable price. Such shutters are used by shop owners and residents of the first floors in apartment buildings;

armored.

Typically, such products are made from high-strength aluminum or metal profiles. It is these roller shutters that are used in rooms that need to be protected as much as possible from intruders.

Installation of such roller shutters is carried out in institutions related to finance and institutions with increased security. Manufacturers often equip these products with an electric drive and remote control;

wooden.

Wooden roller shutters are used as a decorative material, made without the addition of artificial components and characterized by high environmental safety.

Such shutters protect the room from sunlight and serve as a heat-insulating material;

perforated.

Such roller shutters are made from a profile using durable metal, with plastic inserts. Such inserts can be produced in any form. This type of construction is distinguished by its high price, but at the same time, by the quality of production.

Craftsmen prefer to install such structures in rooms where control over another room is required, and regular ventilation must also be carried out.

The perforated type of roller shutters is often used in the installation of store windows.

According to their purpose, roller shutters are divided into sanitary, window and garage.

- The purpose of sanitary roller shutters is to provide reliable protection and visual concealment of pieces of technological equipment, such as meters, valves or metal pipes.

- Window roller shutters are installed in the openings of the room and reliably protect against the entry of unauthorized persons and daylight.

- Garage roller shutters protect the owner's property from theft. This type of roller shutter serves as a well-deserved alternative to heavy metal gates.

Today, the range of roller shutters is huge, and is available in various types and colors.

Horizontal roller shutters are the most popular ; they are widely used to protect financial institutions, in private homes, apartments and to protect shops. Craftsmen recommend installing vandal-proof shutters - protective roller shutters.

Types of profiles

The main materials for the manufacture of roller shutters are aluminum and steel. Aluminum profiles are lighter in weight, highly resistant to corrosion and are more expensive than steel ones. Steel lamellas must be protected from mechanical damage, because scratches on the coating lead to corrosion. Such a canvas has significant weight and requires the installation of a powerful engine. According to the manufacturing method, profiles are divided into two types:

With ventilated insertsroller strips that can be filled with polyurethane foam;

- extruded profiles with stiffeners, characterized by larger wall thickness.

Note! The type of profile affects the resistance to wind loads and burglary resistance; the maximum permissible width of the door depends on it. When installed in an unheated garage, roller shutters with vented or viewing inserts are used to provide natural light and ventilation.

What material to choose for the garage?

When choosing roller shutters that are most suitable for a garage, experienced craftsmen advise to be guided not only by appearance and ease of installation, but also to pay attention to the degree of protection against thefts and adverse weather conditions.

Garage roller shutters vary in the materials they are made from. as the main and most stable type of structure.

It can be an alloy made of steel or non-ferrous metal, but the parameters of the opening for mounting the structure do not always allow the installation of such a heavy fence.

Therefore, in such structures, products made of composite, plastic or aluminum material are sometimes used.

If you need lightweight roller shutters that are durable, you can use products made from aluminum.

Such materials are filled with polyurethane. If the garage owner does not have great financial resources, he can afford roller shutters made of plastic fabric.

In addition, this material is wear-resistant and amenable to wet cleaning.

Roller shutters made of polycarbonate material optimize the lighting required for the room. This design includes a roller shutter base made of lamellas, a cylinder, guides and a box.

A design of this type allows you to install a system with closing and opening of the canvas in all directions and at different slopes. These roller shutters are ideal for garages and for dividing walls between two sections of a room.

Polycarbonate products will appeal to those garage owners who do not want to be separated from the outside world by a dense fence.

Such systems do not separate the garage from the yard with a dense coating, but only slightly muffle the entry of sunlight into the room.

Roller shutters made of wooden elements are rarely used , and most often serve only as a decorative component. This type is popular only for indoor use or window openings.

It is not advisable to use such roller shutters to protect a garage, since the material from which they are made is not durable, and if you try to break into the garage, it will be damaged by mechanical damage caused by intruders.

Roller shutters in bright colors differ in cost from plain products to a greater extent. However, it is not necessary to focus on purchasing expensive models; it is enough that the gate protects the garage and the property in it.

How to make roller shutters yourself?

Roller shutters can be purchased in a store or at the construction market, but many craftsmen want to make such products themselves. Before making the structure yourself, it is important to decide on the technology for installing the future fence.

It can be internal, external or built-in.

Most often, self-taught craftsmen use an external installation method, which involves fixing the box above the opening.

This method is good because it does not require additional preparatory work.

All work on the production of roller shutters will be divided into three stages :

- preparatory – taking the necessary measurements, checking the quality of the slopes and level;

- choosing the right material, taking into account the quality of the garage walls and the depth of the fasteners;

- installation and installation of the structure.

You might be interested in an article on how to make inexpensive garage doors from corrugated sheets with your own hands.

Design and drawing

In the preparatory stage, the geometric parameters of the entire roller shutter, as well as its components, are calculated, which are obtained by cutting lengths of blanks.

Then you need to draw up a detailed drawing , which will clearly indicate the overall dimensions of the homemade roller shutter (width and height), the size of which depends on the size of the opening covered by the roller shutter and the installation type (internal, external or built-in).

Also in the drawing, the necessary parameters are the length of the roller shutter, the length of the guide rail, the length of the protective box and the octagonal shaft.

Manufacturing process

The manufacturing procedure can be divided into certain points:

- cutting roller shutter lamellas with grinding of cutting areas to remove burrs;

- installation of a sealing insert in the end profile, installation of a lock and locking strips;

- cutting guide tires with subsequent grinding, and installing seals in the tires;

- flanging in tires if necessary;

- cutting boxes for protection, making windows for control elements;

- cutting of the octagonal shaft with grinding of the cutting points;

- assembly of the roller shutter fabric;

- assembly of a protection box with additional drives.

To make roller shutters, even with your own hands, you need certain equipment , including:

- tables for workpieces;

- machines for cutting roller shutter components;

- miter saw;

- workbench for mechanics;

- compressor.

How to assemble and install correctly?

To successfully install roller shutters, you will need some construction tools: tape measure, level, screwdriver, pliers, hammer, drill with perforation function, nut wrenches and scissors.

Before installation, it is important to properly prepare the opening. This includes removing defects and uneven walls to create a good seal on the guide rails, with no signs of play.

The most time-consuming work is preparing and using holes and fasteners. The holes are made using a hammer drill at a distance of half a meter. Fastening accessories are selected according to the wall material.

For concrete, you need to attach steel anchors with plastic dowels; metal will require self-tapping screws; for a brick opening, steel anchors with a spacer are created. Wooden structures will require screws or studs.

After the drilling work has been completed, you need to secure the frame , guide rails and drive mechanism. The master should check the box and tires with a level to prevent distortion. Electrical elements are connected to the drive mechanism.

Preparing for installation

In order for roller shutters to completely cover a window or doorway, it is necessary to correctly calculate the dimensions of the finished structure. Using a construction tape, you need to measure the width and height of the window or door. If the width is more than 2 m, additional amplifiers will be required. If the width of the window opening exceeds 5 m, you cannot do without installing reinforcing aluminum profiles.

When taking measurements, you need to take into account the dimensions of the protective box. Depending on the degree of protection and the type of roller shutter control mechanism, the width of the box can vary from 15 to 30 cm. The design with an electric drive looks more voluminous.

During installation you will need the following set of tools:

- measuring tape or construction tape;

- marking pen;

- sharpened knife;

- screwdriver;

- fasteners;

- perforator;

- drill with a set of drills.

Before installing roller shutters, you need to calculate the ratio of the size of the window and the shutter design itself

How to install roller shutters with your own hands

Before starting work, you need to prepare the necessary tools and components that cannot be made yourself. The set of tools depends on the method of fastening the roller shutters. This type of protection is installed on window and door openings, gates, etc. Roller shutters come in steel and aluminum. When installing, it is necessary to take into account that the former are much heavier than the latter.

Selecting the type of installation

High-quality installation of roller shutters with your own hands will not take much time if you take into account all the installation nuances in advance and choose the type of fastening correctly. Shutters are installed in an overhead or built-in manner outside or inside the room.

Most often, the choice falls on the external invoice installation method. In this case, the roller shutter is installed above the doorway. The convenience of this method is that it can be used after the building has been put into operation. Installing roller shutters with your own hands requires special care, because... Re-installing blinds is problematic.

Necessary tool

List of tools that will be required: drill, drills adapted for working with metal and stone, wrench, hammer, screwdriver, screwdriver, metal scissors, pliers.

At the last stage of work, cracks and crevices will have to be sealed. A mounting gun will help you do this kind of work better. Assembling a roller shutter with your own hands requires a competent choice of fittings.

Before purchasing fittings, you need to find out what the walls are made of. If they are made of concrete and monolith, for fastening you will have to use dowels with a screw-in screw. They will have to be screwed in to a depth of at least 3 cm.

For less dense walls, steel anchors can be used. For a more durable fastening, they will have to be screwed in not by 3 cm, but by 6 cm. When installing roller shutters on a steel wall, you can limit yourself to self-tapping screws. Screws are purchased for wooden walls.

Marking and preparing the opening

Before starting work, a number of necessary measurements are carried out. First, the size of the opening is determined diagonally. The measurement error should be minimal. A large error cannot be corrected even with finishing. At the next stage, it is checked how accurately the walls of the openings are installed horizontally and vertically. If they are crooked, applying the necessary layer of plaster to level the walls will help correct the situation.

In some cases, experts recommend installing linings on these products. Although it is believed that they spoil the appearance of the building and increase the cost of work. Also, before starting work on installing these structures, it is necessary to determine how well the slopes of the openings are made. They should not have any deformations, cracks or chips. All detected defects must be eliminated in advance; during the final assembly of the roller shutter structure, this will be quite difficult to do.

Drilling holes

When starting to install roller shutters, the first step is to prepare the frame for installation. This part of the roller shutter consists of a frame and guides. The shutters are mounted to the holes, which are made at the first stage of work using a drill. To do this, you need to step back 10 cm from the edge, and drill holes every 50 cm. Taking into account the dimensions of the fasteners, the diameter of the holes is about 8 mm. If the roller shutter control is automatic, then the size of the holes for the automatic control systems and the location of their attachment depend on the size of this mechanism.

We assemble tires with a box

The product is applied to the opening. If the installation is carried out using the overhead method, then this product will be located above the window opening. With built-in installation, shutters are placed on the top and side slopes.

Before installation, use a level to check how horizontally the box will be installed. The tires on the edges must be installed vertically. It is also necessary to determine the diagonal difference between the extreme points of the entire structure. The resulting value should be no more than 0.2 cm. Lastly, use a marker to mark the locations of the holes on the wall, depending on their location on the frame.

Fastening the frame

The box is then temporarily removed. Holes are made in the tires at the marked points. Dowels are installed in the resulting holes. Make a hole for the wire. Its diameter is about 2 cm, but it is better to clarify this parameter in the instructions. A spring is installed in the place prepared for the wire.

If the design provides for external locks, their holes are prepared at the bottom of the opening. The frame is attached. Remove the film located on the back of the structure. The box is installed so that the holes on it and the wall completely coincide. Then they check that the tires and frame are installed correctly. And only after that the screws are tightened with a screwdriver.

The time has come to install fasteners on the inside of the opening. To do this, mark the connection points for the control system. All received marks are checked to ensure their compliance with the dimensions of the elements of a given structure using a building level. After this, holes are made according to the markings. Then you need to connect the guides to the tape stacker.

Installation of canvas

The canvas is mounted as follows:

- First, rings are placed on the shaft.

- Crossbars are inserted on the sides.

- The shaft is wrapped with protective material.

- The blade is installed through the shaft into the control mechanism - guide bars.

- Then springs are installed on top of the canvas.

- The springs are connected to holes located on the shaft.

Connecting the roller shutter system drive

Connecting the drive consists of installing a switch. For motor installation, a cable with double insulation is used. The cross-sectional diameter of such a wire is 0.75 mm. If there are several electric drives in the system, you will have to calculate the total power of the wires that are connected in the junction box.

Components of roller shutters

Structurally, roller shutters consist of the following components:

- Protective boxdesigned to protect the control mechanism and blade. It includes the following elements:

- box body with shaft;

- side plugs;

- mounting plates;

- restrictor plates;

- shaft;

- spring-inertial mechanism.

- Protective cloth . It consists of aluminum or steel lamellas, movably fastened together. The lower lamella may have a locking mechanism.

- Guide rails along which the web moves. They are a metal profile covered inside with fleecy material.

- End profile.

In addition, the design of roller shutters includes a manual or electric control mechanism .

Rules for the care and maintenance of the roller shutter system

Caring for the product involves regularly cleaning it from dirt. In winter, adhered snow and ice must be removed from the canvas. System parts must be lubricated in a timely manner with machine oil or special lubricant. If there are problems with the operation of the roller shutter mechanisms, the roller shutters cannot be used.

The mechanism and guide bars should be regularly inspected and checked for any damage. If a fault is noticed in time, it can be easily fixed.

Today everyone knows about roller shutters. Complex roller shutter systems provide maximum security for your home or office. And that is why they can often be found not only in residential buildings and apartments, but also in offices, enterprises, shopping centers and banks. But the most important thing is that you can make roller shutters with your own hands without any outside help.

To work, you will need to collect the necessary tools and materials, as well as order components for roller shutters. Installation can be carried out on any opening:

If you want to make roller shutters yourself, you must first decide how the installation will be carried out. It can be overhead or built-in, external or internal. The most common is external, overhead installation, when the box is installed from the street side above the opening. It does not require preparatory work and can be completed after construction is completed.

Preparatory stage

First you need to take some measurements. First of all, using a tape measure, measure the diagonals of the opening. The difference between them should not exceed 5 mm. If it is larger, then this should be corrected with finishing. Even if you don’t know how to make roller shutters with your own hands, you don’t need any special knowledge. It is enough to carry out all work carefully and follow the instructions.

Now you will need a construction slope and level. They check the horizontality of the wall above the opening and the verticality of the side walls. In case of unevenness, they should also be removed. You can use plaster or install special overlays. The latter will cost more, and may also slightly spoil the appearance of the structure. To reliably install roller shutters with your own hands, you need to check the quality of the slopes. They must be intact, without cracks or chips. Only in this case will the structure last a long time. If there are any defects, they should be eliminated before work begins.

To clearly demonstrate the preparation process, we invite you to watch a video on how to assemble roller shutters yourself. By following our recommendations, you will be able to cope with all stages of the work yourself. Be sure to check the availability of the tools you will need:

- drill;

- drills for metal and stone;

- screwdriver;

- metal scissors;

- pliers;

- riveter;

- spanners;

- screwdrivers;

- hammer.

If you plan to install automation, you will need an indicator screwdriver and a multimeter. At the end of the work on installing homemade roller shutters, you will need sealant and a mounting gun to seal existing joints and cracks.

Instructions for making and installing roller shutters for a garage with your own hands

We often store some old things, valuable and not so valuable tools, spare parts for the iron horse and other equipment in the garage. To secure all these treasures, you need to choose the right gate.

A modern development for the garage - roller shutters. Their main purpose is to provide the highest level of safety and the need for an aesthetic component.

It is also possible to make your own garage shutters and save some money.

Choosing accessories for roller shutters

For successful fastening of the structure, it is very important to choose the right fittings and secure them correctly. Often from the photo it seems that roller shutters are easy to make with your own hands without any help. But it is important to be careful when performing all stages. Determine what material the walls are made of. If the walls are built of dense material (concrete, stone, monolithic brick), then use plastic dowels with a screw or nail screw. In this case, the depth of penetration into the wall should be at least 3 cm.

But for walls with voids it is necessary to use steel expansion anchors. In this case, the depth of insertion of the anchor must be at least 6.5 cm. To reliably assemble roller shutters installed on a metal wall, use self-tapping screws, and for wooden houses - screws or through tie rods.

Stages of installation of the structure

First of all, the frame is assembled, which includes a box and guides. To attach roller shutters, holes are made in the frame. They retreat 10 cm from the edge, and then every 50 cm they cut another hole for fasteners with a diameter of 8 mm. Don't forget to make a hole for the drive. Its diameter will depend on the selected control system.

Now we attach the frame to the opening and, through the holes made, mark the places for installing the dowels. After this, we attach the structure to the opening. The canvas is assembled from existing lamellas and attached to the shaft. To properly make roller shutters yourself, you need to correctly secure the clamps in the open and closed positions. At the end, they install a lock and configure the drive system.

It is very important to check the operation of homemade roller shutters. To do this, you need to open and close the canvas up to ten times and make sure that nothing interferes with its movement. No extraneous sounds should be heard during operation of the structure. If the work is set up correctly, the canvas will move easily. And you can enjoy a reliable and practical design that will protect your property.

Selection of fasteners

To fasten roller shutters, you should use fasteners that correspond to the characteristics of the materials from which the walls or slopes are made. If it is a brick or concrete wall, then the most rational would be to use dowels with self-tapping screws or metal anchor bolts .

The length of the fasteners is selected taking into account the presence of cavities inside the walls.

On walls made of porous bricks, the length of the fasteners must be at least 65 mm . For concrete, 35 mm .

The easiest way to install roller shutters on metal structures is with self-tapping screws; in wooden buildings, with wood self-tapping screws and through tie rods.