When choosing the type of foundation for a future structure, first of all, pay attention to the characteristics of the soil.

If, due to its instability, it is impossible to use the classic “tape”, they often resort to combined designs. Similar types of foundations include columnar strip foundations.

What materials the structure is assembled from and how to build the base yourself will be discussed in detail in the article.

Design features

A column-strip foundation is the basis for buildings in which the underground part is arranged as a columnar structure. And the above-ground one is of the tape type. The belt part rests on reinforced concrete pillars.

The pillars are installed below the freezing level on a sand cushion. The strip base is erected using a reinforcing frame filled with concrete.

This design is used in the construction of light frame or wooden buildings on difficult soil:

- loose;

- mobile;

- relief;

- heaving.

Advantages:

ease of implementation;

- minimum earthworks;

- the ability to build houses on plots with highly pronounced relief;

- high thermal insulation due to the distance between the building floor and the soil;

- increased stability and structural strength;

- such a foundation provides protection against damage to the building due to ground movements and vibration influences.

Flaws:

- with this foundation option it is impossible to build a house with a basement;

- complexity of design (you need to order a project).

The main stages of constructing a column-strip foundation

Preparatory work

At the initial stage, you should properly prepare the area: clear it of debris, remove existing roots of trees and shrubs. It is imperative to cut off the top layer of soil, from 10 to 25 cm high, depending on the situation in the area. If the soil in the area is clayey, then it is recommended to remove it to a greater depth and fill it with sand instead. Next, you can begin planning the site, leveling it, sometimes even using special equipment.

The next stage is marking for future poles on the ground. It is more convenient to do this according to the plan, so before starting work, you should at least prepare a sketch design.

Marking is best done using a thread, which is stretched by two parallel lines, indicating the width of the strip part of the foundation. Be sure to use a measuring tool to check the perpendicularity of the corners. But it should be borne in mind that then the trenches under the monolithic tape should be made wider by approximately 10-15 cm on both sides in order to install removable formwork.

All intersections of load-bearing walls, including internal ones, are transferred to the terrain. To mark them, a peg is driven into their center, indicating the location of future wells and, accordingly, supports. In addition, places for pillars should be marked under all supporting structures at a distance of 1.5 to 3 m from each other, depending on the weight of the future structure.

For what occasions is it suitable?

The foundation of the columnar-strip type is suitable for the construction of cottages from light materials and all kinds of outbuildings. It is usually used in areas with high levels of soil heaving. The design of the base reduces the impact of heaving on the walls of the building.

Often such a foundation is erected during construction in regions with deep soil freezing , as well as in various cases when increased strength and at the same time lightness of the foundation is required.

Attention! Column-strip foundations cannot be used in areas with a height difference exceeding 2 meters. It is not suitable for areas with clay or marshy soil, or for the construction of any houses made of heavy building materials.

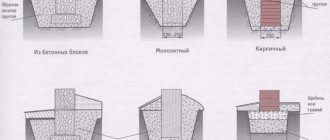

What are the pillars made of?

Before you begin to independently arrange a columnar-tape base, you must choose the optimal material for making supports. Available solutions include: wood, concrete blocks, brick, asbestos cement and metal pipes. Familiarize yourself with the features of each option and choose the most suitable solution for your situation.

Wooden supports

Wooden supports

They are used extremely rarely due to their relatively low durability. Wooden pillars are only suitable for arranging a foundation intended for installing a terrace or other similar structure.

The optimal diameter of wooden posts is 150-200 cm.

Before burying pillars of the material in question into the ground, they must be treated with antiseptic and fire-retardant impregnation. Thanks to this treatment, the resistance of the material to rot, pest damage and fire will be significantly increased.

Bitumen-based mastics are optimal for waterproofing wood.

Wooden supports

Brick supports

Iron brick is well suited for arranging a columnar-band structure. With its use, shallow columnar foundations are also erected.

Brick supports

Professionals recommend installing brick supports with a width of about 40-50 cm.

Concrete supports

Supports in the form of concrete pillars, additionally strengthened with reinforcement, are considered the most reliable. Because of this, these types of supports are the most popular.

Concrete supports

Concrete pillars can have either a solid (monolithic) structure or consist of several blocks.

It is important that the width of the pillars is at least 40 cm.

Tubular base

Tubular base

Pipes made of asbestos cement or metal are very easy to install. Installation boils down to placing hollow pipes in pre-prepared recesses, installing reinforcement rods inside the pipes and finishing filling the cavity with concrete mortar.

The work is done extremely quickly and simply. The optimal pipe diameter is selected individually, taking into account the expected load on the foundation being built.

Materials

The strip part of the foundation is erected from reinforcement with concrete. Underground pillars can be made of various composite or solid materials, each of which has its own characteristics.

Tree

Wooden poles are inexpensive, easy to install , and they increase the heat-saving properties of the foundation.

But the tree is short-lived.

Even if you use oak beams, after pre-treating them with high-quality compounds that protect the wood from moisture and pests, they will last a maximum of 30 years.

Reference! The tree is ideal for arranging grillages raised above the ground and for the construction of light outbuildings. It is used for the construction of temporary residential buildings.

Brick

Brick can be used in the construction of the strip part of the structure. It is often used to construct pillars. The advantage of brick is its efficiency, durability and ease of use.

You can lay brick pillars without having the qualifications of a builder . The main thing is to mix the cement mortar correctly so that during operation the pillars do not crumble into individual bricks.

When creating an underground support for a building, you can only use bricks that do not absorb moisture. Silicate or solid ceramic is suitable.

Concrete

Concrete is the main material for the construction of the strip part.

A reinforced frame is poured with concrete as pillars. The outer wall of the concrete pillar can be a pipe made of moisture-resistant material.

Concrete pillars are the most reliable and durable. But their construction is a rather labor-intensive process that requires the use of special construction equipment.

Interesting! For the construction of very small buildings, the use of such a foundation is unjustified. It is used in the construction of fairly large houses from lightweight materials. Concrete must be of a grade not lower than M300.

Pipes

Pipes for base pillars can be from:

- plastic;

- concrete;

- asbestos;

- gland.

Plastic is only suitable for small, lightweight buildings. Asbestos pipes are quite strong, but short-lived - they last about 60 years. Metal is also strong and reliable, but requires reliable waterproofing.

Rammed and bored posts

A cast-in-place pillar is a pile obtained by pouring concrete into a pre-prepared well. Bored pillars are constructed by drilling and filling a hole.

This version of the foundation is characterized by increased strength, wear resistance, and resistance to external influences.

It is not the most economical option for constructing a columnar strip foundation.

Reference! It can withstand high loads in the form of two- or three-story cottages made of lightweight materials or one-story houses made of stone or brick.

Rubble stone

Rubble stone can be used both for the construction of pillars and for arranging the strip part. Laying out pillars from this material is not easy.

It is necessary to carefully select stones, use a reliable bond with the use of reinforcing elements. Using rubble for a strip base is more rational. It acts as a filler bound with a cement mixture.

Natural stone supports are durable and reliable. Can withstand large buildings made of lightweight materials. But if the technology is violated when creating a rubble foundation, it will not last long. The stone itself will remain intact, but the masonry will gradually deteriorate.

Block foundation and strip base

The next type is a columnar foundation made of blocks. Making such a foundation with your own hands is not very difficult.

Most often, this type of foundation is used for wooden buildings - bathhouses, verandas or houses made of timber.

For a house made of foam blocks, this option may not be very suitable due to the fact that the supports are designed for small, lightweight buildings. But a columnar foundation made of blocks is much easier to build than a columnar foundation.

Most often, a columnar block foundation is made from reinforced concrete components. Such construction can be carried out very quickly, since the construction of the base is carried out according to the type of brickwork.

First, the area is properly prepared for construction, then a sand cushion is formed.

It should be remembered that this type of base is best secured with thick concrete mortar. Under no circumstances should it be diluted with water.

To make it stand even more firmly, you need to coat the seams that were formed during the construction process with a concrete solution.

It is especially good to make such a columnar foundation with your own hands for a frame house. For a house made of timber, this type may also be suitable, but here you need to know all the possible disadvantages.

The next type is a column-and-strip foundation. This type is monolithic and is most often used to build wooden houses.

To make a columnar strip foundation with your own hands, you use TISE technology (a special drilling rig for making wells).

Video:

To build a column-and-strip foundation, reinforcement is placed into the holes and then filled with concrete mortar.

The result is a pole that can withstand heavy loads (up to 15 tons). This type is called strip, because the construction technology is similar to the construction of a simple strip foundation.

Typically, wells are made 15 cm below the freezing area of the ground. This type of construction may take longer than other types because drilling is a difficult process.

In addition, the ease of work also depends on the type of soil and what time of year the laying is carried out. In winter, such work is almost impossible to do.

Another disadvantage of this type is that the lower part of each hole will have to be further expanded in order for everything to be correct.

After the wells are ready, reinforcement is placed in them and concrete is poured. But not completely, but by one third, in order to insert a piece of roofing felt (tar paper jacket) for greater strength of the base. When the concrete solution dries a little, you can pour the rest.

The advantages of such a base are that the supports can withstand a load of more than 10 tons, and they also tolerate low temperatures.

Photo:

After this, a grillage tape is made, it is reinforced and secured 15 cm above ground level.

In addition to these types of foundation, you can make a columnar brick foundation with your own hands. This type is not used often because it is expensive.

However, brick supports can last much longer than wooden ones. This type can be used for wooden buildings or buildings made of foam blocks. However, the structure should not have more than two floors.

A pile foundation with a shallow depth is also quite popular. Its use is most advisable on slightly heaving or non-heaving soil.

If the house is built on rocky ground, then it is better that it be made of timber. Verandas are also sometimes built using this type of foundation.

This option is not very suitable for a house made of foam blocks, but you can always consult with specialists to make the right choice.

Step-by-step instructions for DIY construction

The arrangement of a columnar-strip foundation does not require the use of complex equipment. It can be done with your own hands, if you have basic construction skills.

Project creation and cost determination

For the construction of a light structure or temporary outbuilding on a flat area with good soil, the foundation can be designed independently.

But when building a residential building, it is better to contact a designer who will take into account many important factors:

- soil characteristics;

- slope of the site;

- freezing depth.

The cost of such a foundation depends on the dimensions of the planned building, as well as on the selected material, technology for laying pillars and tape.

It is possible to independently calculate the cost of the entire structure if there is a carefully calculated project . You can use mathematical formulas for calculations.

It’s easier to use online calculators that calculate the consumption and cost of structures using the same formulas. In this case, 2 calculators will help - for calculating the pillars and for calculating the tape.

Important! When using online calculators, you must enter the parameters of the future foundation in special form windows. The calculation is carried out automatically, without errors.

Depth calculation

By planning construction on stable soil and knowing the depth of soil freezing in your area, you can calculate the depth of the pillars yourself.

They should be immersed in the ground 20-30 cm below the freezing level.

The average depth is 80 cm. You can use an online calculator, but in its form you need to enter accurate terrain data, knowing which is easier to calculate yourself.

If there are complicating factors, you should consult a specialist for calculations. For example, on a site with a pronounced slope, the depth of individual pillars relative to the ground level will differ. In case of weak soil, the pillars should be deeper and reinforced at the level of a more stable layer.

Attention! Rules for the design and construction of foundations are contained in SP 50-101-2004.

More details about the calculation of a column-strip foundation in the video:

Preparation and marking of the site

Before starting work on the construction of the foundation, it is necessary to prepare the site:

- all rubbish must be removed;

- uproot trees that may interfere with construction, the entry of special equipment or the delivery of materials;

- The building site should be leveled.

Marking is done using pegs and rope. It is necessary to mark the internal and external perimeter of the strip foundation, as well as the places for drilling wells for the pillars.

Creating trenches and recesses for pillars

Trenches and depressions can be made by hand. But if a full-fledged cottage is being built, it will be too long, difficult, and not ideal.

Advice! It is better to call modern construction equipment with small dimensions, with the help of which all land preparatory work can be completed in one day.

Installation of supports

The procedure will be as follows:

Installation begins with compacting the bottom of the pit. The soil at the bottom needs to be moistened and compacted well using a compacting tool.

- Pour a sand-crushed stone mixture onto the bottom, creating a cushion about 20 cm in height. It should also be moistened and compacted.

- Place waterproofing in the form of polyethylene or roofing felt on the pillow.

- Create formwork from boards (if the ground is dense and dry, simply line the walls of the pit with polyethylene).

- It is advisable to wet the formwork.

- Assemble the pole frame from reinforcement and place it in the formwork.

- Fill the prepared structure with concrete mixture. Pour gradually, level the layer every 20-30 cm using a vibrator.

- The formwork can be removed after 3-4 days, when the solution has hardened.

- Treat the surface of the supports with waterproofing.

- Fill the remaining hole in the hole with sand.

Tape installation

The support pillars topped out onto the strip foundation strip. Now you need to arrange the ribbon:

- Make a frame from steel wire and weld it with the protruding reinforcing bars of the pillars.

- Build a tape formwork from boards or plywood, following the markings.

- Line the inner walls of the formwork with sheet waterproofing material.

- The formwork is carefully filled with cement mortar. The layer should be smooth, without joints or air bubbles.

- Next, you need to wait 28 days until the cement of the tape hardens and gains strength. If the weather is hot at this time, the cement tape must be periodically moistened. In humid weather, cover with polyethylene. Otherwise, drying will be uneven, which can lead to deformation and cracking.

Monolithic columnar foundation manufacturing technology

When installing columnar foundations, you should adhere to the following recommendations:

- It is recommended to bury the pillars to a depth of ≤ 70 cm - this is required by technological calculations;

- The foundation must be erected on a flat area with non-heaving soil and a low groundwater level;

- To strengthen the base, a wooden, concrete or metal grillage is installed. Construction based on concrete significantly increases labor intensity and costs;

- A house on a columnar foundation should not be heavy, built of brick or concrete.

Columnar prefabricated and monolithic base

During the design process for a columnar foundation, its load-bearing capacity is calculated taking into account the diameter of the supports and the dimensions of the grillage. For a monolithic structure, Dmin of columnar supports should not exceed 40 cm2; construction experience shows that Dmin can start from 25 cm2 without losing the strength of the foundation and its load-bearing capacity. Horizontally, the columnar foundation is strengthened by expanding the ledges, which have the following recommended optimal dimensions:

- Ledge height ≈ 40-60 cm;

- The width of the ledge is 1.2-2 times greater than its height (depending on the type of concrete).

The recommended distance between pillars according to the technological map should be maintained within 100-200 cm on flat terrain without a slope. If the distances at the corners of the building do not match, under large and powerful junctions, the pillars must be laid in any case.

Pole location map

The columnar foundation on the site is marked as follows:

- The axles are carried out;

- Ropes or cords are stretched along the outer and inner sides of all supports;

- The length of the diagonal dimensions of the building is compared.

For error-free installation of the formwork, a free area of up to 50 cm is left around each pillar, taking into account the lower widening of the pillars.

The pillow on which the columnar monolithic foundation will rest is arranged as follows:

- Crushed stone is poured in a layer of up to 15 cm, also moistened and compacted;

- Sand is poured on top in a layer of up to 20 cm, moistened and compacted;

Substrate

In order to prevent the destruction of pillars, they must be reinforced vertically. For this we use:

- Corrugated rods that are laid in a vertical direction - 4 pieces Ø 12-16 mm;

- Smooth rods Ø 6-8 mm, laid horizontally every 30-40 cm - the calculation is carried out based on the height of the pillars.

In order for the frame to stand stably before pouring the solution, it is buried in a sand and crushed stone cushion. For a concrete grillage, the rods should protrude 40-60 cm beyond the monolithic supports so that they can be bent into the body of the grillage tape. When arranging a wooden or iron grillage, the rods should not reach 3-5 cm to the edge of the pillar.

To fill the base, formwork is installed from scrap materials:

- Four wooden, plywood, metal panels;

- The shields are reinforced with jibs that are installed from the walls of the pit.

Formwork for foundation pillars

When assembling removable formwork, the panels are placed vertically and fastened to each other with steel plates, clamps or staples.

Common mistakes and ways to avoid them

Laying a sand cushion without compaction. This leads to uneven subsidence of the pillars and deformation of the strip part. It is necessary to compact the soil under the pillow and the pillow itself.

- Unevenness of the trench bottom is allowed. As a result, the thickness of the concrete pour is uneven and it dries unevenly. To avoid this, you should use construction laser levels when laying a trench.

- Dig trenches and leave them for several days . As a result, the earth crumbles from the walls and creates differences at the bottom. You need to dig and fill the holes in one day.

Foundation on stilts

It is quite clear that for the construction of foundations of this type, piles are used, which act as the main supports. Consideration of the pros and cons of this foundation for a house should begin with the very definition of piles. So what are screw piles and what do they represent?

The popularity of pile foundations has recently increased significantly because they have a high load-bearing capacity. Many specialized factories have recently begun to produce pile supports of increased strength.

For example, a standard screw pile has a metal wall thickness of 4 mm. This is quite enough to withstand the effects of problematic soils. Today you can already purchase supports with a wall of 6.5 mm. Thanks to this, the range of use of such foundations for structures has become much wider, especially in industrial construction.

It is most advisable to arrange pile foundations on problematic soils. These include clayey, loamy, peat and marshy soils. If, under such conditions, you build a reinforced concrete foundation, it will be very expensive. And it is the pile-screw foundations that can provide high strength indicators in such conditions, as well as low cost.