Reinforced concrete cable trays: used for laying communications

Reinforced concrete cable tray is a structure that is used quite widely. Typically, such products are used for their intended purpose - for laying electrical wiring and communication cables, but in some cases small-diameter pipes are also placed in them.

In the article we will talk about the main types of reinforced concrete trays, and also specifically focus on those that are best suited for solving our problem.

To protect conductors, structures made of durable concrete are used

Main types of tray products

When carrying out construction work, as well as when laying roads, it is often necessary to allocate areas through which communications will pass - wires, pipes, etc. At the same time, an important task is to preserve the integrity of the objects being laid, and therefore a variety of structures are used to protect them (find out here how to lay concrete in the cold).

Prefabricated channel elements

The most common product in this case is a reinforced concrete tray.

Today, the following varieties are used in industry and construction:

- Products for prefabricated channels. They are distinguished by their largest dimensions and are used for the construction of drainage and storm sewer systems. These structures are characterized by high strength and resistance to corrosion.

Note! When purchasing such products, it is important to pay attention to such a parameter as price. Factory-produced trays are more expensive, but higher quality heavy concrete is used for their manufacture, and they fit together much better due to their precise dimensions.

- Telescopic structures. They are trapezoidal products that are installed in series of several pieces on roadsides to ensure maximum efficient drainage. The material is characterized by low water absorption, which significantly increases the service life of trays of this type.

Photo of the telescopic structure

- Culverts. Mounted for effective drainage along the edge of the asphalt pavement. They are usually installed with a slope so as not to impede the flow of drainage. For production, the technique of prestressing reinforcement and high-temperature drying is used, which significantly improves the mechanical parameters.

Most of the varieties listed above are used exclusively by professional builders. But above-ground and underground boxes for cable products can be installed with your own hands. They are smaller in size compared to culvert trays, but at the same time they are not inferior to them in strength.

In the next section we will look at this type of reinforced concrete products in detail.

Cable channels

Design and dimensions

Gutters for wiring installation are made in the form of open U-shaped containers.

For their manufacture we use:

- Concrete grades B15, B20 or B25.

- Steel reinforcement class A1 or A2.

These products are able to withstand significant temperature changes due to the fact that during their manufacture components are added to the solution that prevent cracking.

The tray itself and the lid

As a rule, when installing communication channels, entire products are used; fortunately, most manufacturers have a significant number of additional elements in their assortment.

The sizes of reinforced concrete cable trays that are most often used are given in the table below:

| Name | Weight, kg | Length, mm | Width, mm | Height, mm |

| LK3 | 270 | 1990 | 1100 | 150 |

| LK4 | 220 | 1990 | 850 | 150 |

| LK5 | 170 | 1990 | 600 | 150 |

| UBK1A | 275 | 1990 | 1000 | 160 |

| UBK2A | 175 | 1990 | 500 | 160 |

| L 20-5 | 125 | 1990 | 500 | 160 |

| L 20-10 | 275 | 1990 | 1000 | 160 |

However, in some situations it becomes necessary to adjust the product to a specific size. In this case, cutting reinforced concrete with diamond wheels is used, since the gutter material is highly durable, and attempts to process it with other tools lead to rapid wear.

Features of use

Model with polymer cover

As the name suggests, the instructions recommend using such products for above-ground installation of communication wires.

This provides the following benefits:

- The cables are housed in a housing that reliably protects them from damage due to both mechanical stress and the influence of weather factors.

Note! The design of the case does not provide for the presence of locking elements, so the risk of theft remains. It is for this reason that the external installation of gutters is justified only within protected areas.

- If you need access to the conductors, simply open the trench. Of course, the slabs themselves are quite heavy, but it will still be much less expensive than in the case of placing wires in a trench covered with earth.

- Finally, in areas with difficult soils (permafrost, quicksand, stone monolith) this is the only option for placing cables.

Burying into the ground

However, in some cases, such structures are buried in the ground.

At the same time, we receive the following advantages:

- Firstly, all communications are located in a relatively dry space without contact with soil moisture. This allows you to save money by using cables with a lower moisture protection class.

- Secondly, the connection of several cable routes is facilitated. To insert additional wire into the tray, diamond drilling of holes in concrete is used.

Note! The drilled holes through which the wire is passed should be carefully sealed.

- Finally, with proper organization of the internal space (separating wires by voltage and purpose using partitions and wall mounting systems), sorting is greatly simplified. Agree, it is much easier to remove the cover from a concrete tray and look for the required cable than to dig a hole, risking cutting the conductor with a shovel or excavator bucket.

Schemes for placing conductors in the trench cavity

In principle, both installation options are acceptable and are actively used in modern construction.

Conclusion

Reinforced concrete cable trays, despite their bulkiness, are very useful. Their use makes it possible to keep the wires intact, and also facilitates manipulations after installation (see also the article “Plasticizers for concrete and other modifying additives”).

The video in this article contains additional information about these products.

Page 2

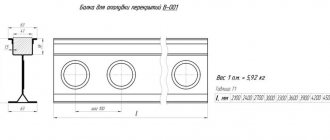

A reinforced concrete tray is a factory-produced building element made of reinforced concrete and intended for the construction of various technical structures: communication and water supply channels, gutters of storm sewer systems, drainage systems, heating mains and various elements of underground and surface communications. We will tell you what types and sizes of reinforced concrete trays exist, what are their characteristics and scope of application.

Reinforced concrete trays for heating mains and cables are needed for laying communications and draining water.

Main characteristics of trays

Dimensions and shape

The photo shows the most common type of product.

To understand what reinforced concrete trays are, you should consider them in detail. If we do not take into account the nuances, we can say that these products have a U-shaped cross section and resemble gutters.

The products have a U-shaped cross-section and an oblong shape like a gutter.

In this case, the geometric section can be either rectangular, trapezoidal, triangular, elliptical or parabolic. For various purposes, one or another form is used depending on the tasks set, for example, reinforced concrete culverts of rectangular cross-section are used in drainage systems, and triangular ones are used for storm drainage along highways.

The section profile may be different.

Special coverings are also produced for the trays. These are reinforced concrete or metal slabs that serve to protect communications from the ingress of unwanted substances and objects, as well as to prevent clogging of drainage channels and drainage gutters.

The sizes of parts vary not only depending on the type, but also within the same group.

Tray sizes may vary. Depending on the purpose and brand of the product, its length, width, wall thickness, height and, accordingly, volume may vary. Length and width can vary from 25 - 50 cm to three to six meters, height - from 6 to 160 cm, weight - from 25 kg to 3 tons or more.

Important! According to GOST for the production of reinforced concrete products, products can have both standard sizes and rarer fractional sizes. The way the tray is attached to the lifting cables or cleats may also vary.

Composition and properties

Products are available in large sizes.

As already mentioned, trays are made from reinforced concrete. According to GOST 23009-78, for the production of these reinforced concrete products, cement concrete based on Portland cement grade M400 and higher should be used. The concrete must be heavy, dense, made with dense aggregates and have a grade of at least M300.

In the production process, injection molding or vibration pressing technology is used. These methods make it possible to create a material of high strength, fairly accurate geometry, good water resistance and frost resistance, since compacting concrete significantly improves its quality.

Modern equipment allows you to effectively compact concrete.

Steel of class AI - AIII, as well as BP-I is used as reinforcement, and the cross-sectional diameter should be taken at least 6 mm for longitudinal and at least 5 mm for transverse reinforcement. The production of trays is regulated by regulatory documents, the main one of which is GOST 21509-85; the instructions do not suggest making them yourself.

Important! The materials and technologies used make it possible to call these products high-strength, waterproof and frost-resistant elements of utility networks, hydraulic engineering and building structures.

Types and purpose

There are many types of JBL.

To begin with, it should be said that JBL is divided into three main groups:

- Drainage concrete trays. They are used for the construction of drainage, sewer and collector systems, as well as for the installation of various elements of hydraulic structures and systems for draining water from transport routes;

- Cable trays. Designed for installation of cable channels, laying utilities, protection of busbars and various electrical, communication, information networks and communication channels;

- Concrete trays for heating mains. Used to protect pipes with steam and hot water from contact with melt and groundwater, sedimentary flows, soil and aggressive chemicals. They are characterized by increased strength and resistance to destructive environmental influences.

Laying cables in reinforced concrete structures.

In addition, there is a classification by purpose:

- Road. Serve to collect and drain water from highways, pedestrian sidewalks, city roadways and parking lots;

- Railway. There are inter-track and inter-sleeper (MPL and MSHL), designed for drainage of water from railway tracks;

- Drainage They are used in the construction of storm sewers, as well as for draining water from the foundations and plinths of buildings, transferring and discharging it into designated areas;

- Drainage. They are used to drain water from household plots and farm plots, organize the collection and drainage of storm and melt water, discharge water from embankments, slopes, bridges, etc. There is a separate type here - telescopic trays, which are used to drain liquid from embankments and slopes, including on roads and highways;

- Rain. They are small in size and are used to construct gutters to collect water in areas around houses, along roads and streets, sidewalks, etc. They are an integral part of storm sewers and landscaping systems;

- Cable. As already mentioned, they are used for installation of utility networks;

- Heat mains. They protect pipes from corrosion, soil pressure, ground displacements, as well as from contact with the external environment and heat loss.

Application of products for laying heating mains.

The price of products depends on their size, purpose, type and shape. It can range from several hundred to several thousand rubles per piece.

Important! For convenience, additional elements are produced that are designed to select the length of the channel, otherwise cutting of reinforced concrete with diamond wheels will be required. Also, parts can have various technological holes in the walls or bottom, which makes it possible not to use diamond drilling of holes in concrete during installation work.

Conclusion

Culvert reinforced concrete trays and cable products are irreplaceable elements of water disposal and drainage systems, storm and street sewers, hot water supply systems and utilities. The use of these products reduces construction costs of the listed facilities and speeds up their installation.

The video in this article will help you better understand the features of the JBL.

masterabetona.ru

Floor slabs for channels and trays

Ask a Question

Checkout

The floor slabs of the trays are flat reinforced concrete structures that serve to cover the upper part of the reinforced concrete tray from negative environmental factors. Depending on the size of the trays, our company is ready to provide floor slabs for trays of any size and shape. In modern construction, tray floor slabs are most often used for heat supply networks. Channel trays with utility lines also need protection, so floor slabs for them are also in great demand. If you look at the floor slabs of utility trays, you will notice the unusual shape of the slab. It is cut on both sides in such a way as to create a support platform for the channel. The cover is tightly fixed on the channel due to its weight. This prevents the lid from subsequently sliding on the concrete. Floor slabs for heating mains are reinforced concrete products with a strength of at least class B20 and frost resistance F300, made of heavy concrete. Precast concrete slabs are reinforced with wire or reinforcement with a metal class of at least A-2. This allows you to fully rely on their strength and durability. Floor slabs for heating main trays can be solid or with holes. The latter are used to control the heating main and its technical condition. Blind lids completely cover the tray, both in length and width. Our company produces fully compatible trays and covers to ensure maximum protection of communications. Floor slabs for cable duct trays are made using technology similar to slabs for other types of trays. Unlike heat-conducting networks, which are located at a fairly large depth, the floor slabs of cable channel trays protect the channels from mechanical influences close to the surface. However, the requirements for them are the most stringent. Such trays are made of reinforced concrete grade no lower than B20 and reinforced with wire of steel class A-II or higher. The security of cable communications will be maximum. To securely fix the cover on the channel, either special compounds or the cover’s own weight are used. As a rule, no additional fixation is required. If you want to buy floor slabs for channels and trays, reinforced concrete rings, FBS blocks, to clarify prices and characteristics, please contact our sales department in Moscow by phone.

| P-17-3 Dimensions (L x W x H in mm): 2990x2160x120 Weight (in kg): 1940 |

| P-18-5 Dimensions (L x W x H in mm): 2990x2160x150 Weight (in kg): 2420 |

| P-18-8 Dimensions (L x W x H in mm): 2990x2160x150 Weight (in kg): 2420 |

| P-21-5 Dimensions (L x W x H in mm): 2990x2460x160 Weight (in kg): 2940 |

| P-21-8/2 Dimensions (L x W x H in mm): 1495x2460x160 Weight (in kg): 1480 |

| P-24-8/2 Dimensions (L x W x H in mm): 1495x2780x180 Weight (in kg): 1880 |

| VP 16-6 Dimensions (L x W x H in mm): 1610x600x160 Weight (in kg): 380 |

| VP 16-12 Dimensions (L x W x H in mm): 1610x1200x160 Weight (in kg): 775 |

| VP 16-18 Dimensions (L x W x H in mm): 1610x1800x160 Weight (in kg): 875 |

| VP 16-18 with hole Dimensions (L x W x H in mm): 1610x1800x160 Weight (in kg): 980 |

| VP 19-6 Dimensions (L x W x H in mm): 1910x600x160 Weight (in kg): 430 |

| VP 19-18 with hole Dimensions (L x W x H in mm): 1910x1800x160 Weight (in kg): 1180 |

| VP 22-6 Dimensions (L x W x H in mm): 2210x600x160 Weight (in kg): 525 |

| VP 22-12 Dimensions (L x W x H in mm): 2210x1200x160 Weight (in kg): 1050 |

| VP 22-18 Dimensions (L x W x H in mm): 2210x1800x160 Weight (in kg): 1575 |

| VP 22-18 with hole Dimensions (L x W x H in mm): 2210x1800x160 Weight (in kg): 1400 |

| VP 25-12 Dimensions (L x W x H in mm): 2520x1200x220 Weight (in kg): 1820 |

| VP 25-18 Dimensions (L x W x H in mm): 2520x1800x220 Weight (in kg): 2495 |

| VP 25-18 with hole Dimensions (L x W x H in mm): 2520x1800x220 Weight (in kg): 2220 |

| VP 28-12 Dimensions (L x W x H in mm): 2820x1200x220 Weight (in kg): 1820 |

| VP 28-18 Dimensions (L x W x H in mm): 2820x1800x220 Weight (in kg): 2800 |

| VP 28-18 with hole Dimensions (L x W x H in mm): 2820x1800x220 Weight (in kg): 2520 |

| VP 31-12 Dimensions (L x W x H in mm): 3130x1200x260 Weight (in kg): 2380 |

| VP 34-12 Dimensions (L x W x H in mm): 3430x1200x260 Weight (in kg): 2600 |

| VP 34-18 Dimensions (L x W x H in mm): 3430x1800x260 Weight (in kg): 3720 |

| VP 34-18 with hole Dimensions (L x W x H in mm): 3430x1800x260 Weight (in kg): 3680 |

| VP 37-12 Dimensions (L x W x H in mm): 3740x1200x320 Weight (in kg): 3480 |

| VP 40-12 Dimensions (L x W x H in mm): 4040x1200x320 Weight (in kg): 3780 |

| VP 40-18 with hole Dimensions (L x W x H in mm): 4040x1800x320 Weight (in kg): 5350 |

| VP 43-12 Dimensions (L x W x H in mm): 4300x1200x360 Weight (in kg): 4560 |

| VP 46-12 Dimensions (L x W x H in mm): 4600x1200x360 Weight (in kg): 4880 |

| VP 49-6 Dimensions (L x W x H in mm): 4900x600x360 Weight (in kg): 2520 |

| VP 55-6 Dimensions (L x W x H in mm): 5500x600x400 Weight (in kg): 3180 |

| P-1-5/8 Dimensions (L x W x H in mm): 740x420x50 Weight (in kg): 40 |

| P-3-8 Dimensions (L x W x H in mm): 740x570x50 Weight (in kg): 50 |

| P-4-15 Dimensions (L x W x H in mm): 740x570x100 Weight (in kg): 110 |

| P-5-8 Dimensions (L x W x H in mm): 2990x780x70 Weight (in kg): 410 |

| P-6-15 Dimensions (L x W x H in mm): 2990x780x120 Weight (in kg): 700 |

| P-6-15a Dimensions (L x W x H in mm): 2990x780x120 Weight (in kg): 700 |

| P-7-3 Dimensions (L x W x H in mm): 2990x1160x70 Weight (in kg): 610 |

| P-7-5/2 Dimensions (L x W x H in mm): 2980x1160x70 Weight (in kg): 300 |

| P-8-11 Dimensions (L x W x H in mm): 2990x1160x100 Weight (in kg): 870 |

| P-8-8 Dimensions (L x W x H in mm): 2990x1160x100 Weight (in kg): 870 |

| P-9-15 Dimensions (L x W x H in mm): 2990x1160x120 Weight (in kg): 1040 |

| P-10-3/5 Dimensions (L x W x H in mm): 2990x1480x70 Weight (in kg): 770 |

| P-11-8 Dimensions (L x W x H in mm): 2990x1480x100 Weight (in kg): 1100 |

| P-12-12 Dimensions (L x W x H in mm): 2990x1480x160 Weight (in kg): 1770 |

| P-12-15 Dimensions (L x W x H in mm): 2990x1480x160 Weight (in kg): 1770 |

| P-13-11b Dimensions (L x W x H in mm): 2990x1480x120 Weight (in kg): 1330 |

| P-15-5 Dimensions (L x W x H in mm): 2990x1840x120 Weight (in kg): 1650 |

| P-15-8 Dimensions (L x W x H in mm): 2990x1840x120 Weight (in kg): 1650 |

| P-16-15 Dimensions (L x W x H in mm): 2990x1840x180 Weight (in kg): 2480 |

| PTP-8-6 Dimensions (L x W x H in mm): 800x600x80 Weight (in kg): 95 |

| PTP-11-9 Dimensions (L x W x H in mm): 1100x900x80 Weight (in kg): 195 |

| PTP-24-12 Dimensions (L x W x H in mm): 2400x1200x120 Weight (in kg): 850 |

| PTP-28-12 Dimensions (L x W x H in mm): 2800x1200x120 Weight (in kg): 990 |

| PTP-30-12 Dimensions (L x W x H in mm): 3000x1200x120 Weight (in kg): 1070 |

| PTP-32-12 Dimensions (L x W x H in mm): 3200x1200x120 Weight (in kg): 1130 |

| PTP-36-12 Dimensions (L x W x H in mm): 3600x1200x120 Weight (in kg): 1270 |

| TP-27-12 Dimensions (L x W x H in mm): 2700x1200x220 Weight (in kg): 1710 |

| TP-43-8 Dimensions (L x W x H in mm): 4300x800x220 Weight (in kg): 1780 |

| TP-43-12 Dimensions (L x W x H in mm): 4300x1200x220 Weight (in kg): 2730 |

| TP-47-8 Dimensions (L x W x H in mm): 4700x800x220 Weight (in kg): 1980 |

| TP-47-12 Dimensions (L x W x H in mm): 4700x1200x220 Weight (in kg): 3000 |

| BZ-02 Dimensions (L x W x H in mm): 600x400x50 Weight (in kg): 29 |

| BZ-04 Dimensions (L x W x H in mm): 800x400x50 Weight (in kg): 38 |

| BZ-06 Dimensions (L x W x H in mm): 1100x400x50 Weight (in kg): 58 |

| BZ-07 Dimensions (L x W x H in mm): 1300x400x50 Weight (in kg): 62 |

| В-4 Dimensions (L x W x H in mm): 750x500x60 Weight (in kg): 55 |

| В-5 Dimensions (L x W x H in mm): 850x500x70 Weight (in kg): 75 |

| В-6 Dimensions (L x W x H in mm): 950x500x70 Weight (in kg): 83 |

| В-7 Dimensions (L x W x H in mm): 1050x500x80 Weight (in kg): 106 |

| В-8 Dimensions (L x W x H in mm): 1150x1000x90 Weight (in kg): 265 |

| В-9 Dimensions (L x W x H in mm): 1300x1000x100 Weight (in kg): 333 |

| В-10 Dimensions (L x W x H in mm): 1400x1000x100 Weight (in kg): 359 |

| V-11 Dimensions (L x W x H in mm): 1500x1000x120 Weight (in kg): 460 |

| V-12 Dimensions (L x W x H in mm): 1600x500x120 Weight (in kg): 240 |

| V-13 Dimensions (L x W x H in mm): 1700x500x130 Weight (in kg): 278 |

| V-16 Dimensions (L x W x H in mm): 2000x500x160 Weight (in kg): 403 |

To order products from the ROSATOMSNAB reinforced concrete plant: floor slabs for channels and trays, complete transformer substations, FBS blocks, check prices and characteristics, contact our sales department in Moscow by phone.

Ask a Question

Checkout

Reinforced concrete cable trays: used for laying communications

Reinforced concrete cable tray is a structure that is used quite widely. Typically, such products are used for their intended purpose - for laying electrical wiring and communication cables, but in some cases small-diameter pipes are also placed in them.

In the article we will talk about the main types of reinforced concrete trays, and also specifically focus on those that are best suited for solving our problem.

To protect conductors, structures made of durable concrete are used

Main types of tray products

When carrying out construction work, as well as when laying roads, it is often necessary to allocate areas through which communications will pass - wires, pipes, etc. At the same time, an important task is to preserve the integrity of the objects being laid, and therefore a variety of structures are used to protect them (find out here how to lay concrete in the cold).

Prefabricated channel elements

The most common product in this case is a reinforced concrete tray.

Today, the following varieties are used in industry and construction:

- Products for prefabricated channels. They are distinguished by their largest dimensions and are used for the construction of drainage and storm sewer systems. These structures are characterized by high strength and resistance to corrosion.

Note! When purchasing such products, it is important to pay attention to such a parameter as price. Factory-produced trays are more expensive, but higher quality heavy concrete is used for their manufacture, and they fit together much better due to their precise dimensions.

- Telescopic structures. They are trapezoidal products that are installed in series of several pieces on roadsides to ensure maximum efficient drainage. The material is characterized by low water absorption, which significantly increases the service life of trays of this type.

Photo of the telescopic structure

- Culverts. Mounted for effective drainage along the edge of the asphalt pavement. They are usually installed with a slope so as not to impede the flow of drainage. For production, the technique of prestressing reinforcement and high-temperature drying is used, which significantly improves the mechanical parameters.

Most of the varieties listed above are used exclusively by professional builders. But above-ground and underground boxes for cable products can be installed with your own hands. They are smaller in size compared to culvert trays, but at the same time they are not inferior to them in strength.

In the next section we will look at this type of reinforced concrete products in detail.

Cable channels Design and dimensions

Gutters for wiring installation are made in the form of open U-shaped containers.

For their manufacture we use:

- Concrete grades B15, B20 or B25.

- Steel reinforcement class A1 or A2.

These products are able to withstand significant temperature changes due to the fact that during their manufacture components are added to the solution that prevent cracking.

The tray itself and the lid

As a rule, when installing communication channels, entire products are used; fortunately, most manufacturers have a significant number of additional elements in their assortment.

The sizes of reinforced concrete cable trays that are most often used are given in the table below:

| Name | Weight, kg | Length, mm | Width, mm | Height, mm |

| LK3 | 270 | 1990 | 1100 | 150 |

| LK4 | 220 | 1990 | 850 | 150 |

| LK5 | 170 | 1990 | 600 | 150 |

| UBK1A | 275 | 1990 | 1000 | 160 |

| UBK2A | 175 | 1990 | 500 | 160 |

| L 20-5 | 125 | 1990 | 500 | 160 |

| L 20-10 | 275 | 1990 | 1000 | 160 |

However, in some situations it becomes necessary to adjust the product to a specific size. In this case, cutting reinforced concrete with diamond wheels is used, since the gutter material is highly durable, and attempts to process it with other tools lead to rapid wear.

Features of use

Model with polymer cover

As the name suggests, the instructions recommend using such products for above-ground installation of communication wires.

This provides the following benefits:

- The cables are housed in a housing that reliably protects them from damage due to both mechanical stress and the influence of weather factors.

Note! The design of the case does not provide for the presence of locking elements, so the risk of theft remains. It is for this reason that the external installation of gutters is justified only within protected areas.

- If you need access to the conductors, simply open the trench. Of course, the slabs themselves are quite heavy, but it will still be much less expensive than in the case of placing wires in a trench covered with earth.

- Finally, in areas with difficult soils (permafrost, quicksand, stone monolith) this is the only option for placing cables.

Burying into the ground

However, in some cases, such structures are buried in the ground.

At the same time, we receive the following advantages:

- Firstly, all communications are located in a relatively dry space without contact with soil moisture. This allows you to save money by using cables with a lower moisture protection class.

- Secondly, the connection of several cable routes is facilitated. To insert additional wire into the tray, diamond drilling of holes in concrete is used.

Note! The drilled holes through which the wire is passed should be carefully sealed.

- Finally, with proper organization of the internal space (separating wires by voltage and purpose using partitions and wall mounting systems), sorting is greatly simplified. Agree, it is much easier to remove the cover from a concrete tray and look for the required cable than to dig a hole, risking cutting the conductor with a shovel or excavator bucket.

Schemes for placing conductors in the trench cavity

In principle, both installation options are acceptable and are actively used in modern construction.

Conclusion

Reinforced concrete cable trays, despite their bulkiness, are very useful. Their use makes it possible to keep the wires intact, and also facilitates manipulations after installation (see also the article “Plasticizers for concrete and other modifying additives”).

The video in this article contains additional information about these products.

rusbetonplus.ru

Cable channels

In many premises, cable communications are laid in an open way. This applies to both electrical wiring and television, telephone, Internet and other cables. But wires running along the walls are extremely vulnerable to external influences. Any careless movement can damage them and leave you, for example, without the Internet. If an electrical wire is damaged, even more serious consequences can be expected.

To protect against mechanical damage and environmental influences, open communications are laid in cable channels. However, these products also have another function. It is unlikely that bundles of wires hanging on the walls can add elegance to the decor. On the contrary, correctly selected cable channels will become its important element.

In the EKF PROxima product line you can find products for a wide variety of sections in three main colors: white, light and dark wood. But the palette of shades has no restrictions: the customer can choose a cable channel in any color he wishes, and the company will manufacture it.

An economical version of the cable channel is presented in the EKF Basic line. It is optimal for projects with a small budget. These products can only be purchased in white, but they are not inferior to the more expensive line in the choice of sections and dimensions.

Reinforced concrete drainage, channel, concrete, cable trays

Order this product

Reinforced concrete drainage and cable trays are produced and used in civil, railway, road and energy construction for the installation of underground communications and wastewater disposal.

| Reinforced concrete drainage and cable trays | ||||||

| Product name | Dimensions, mm | Unit weight, tons | Series | Carriage norm, pcs. | ||

| length | width | height | ||||

| Overhead cable trays | ||||||

| UBK-1A | 2020 | 1030 | 160 | 0,313 | Series 3. 407-102, issue 1 | 120 |

| UBK-2A | 2020 | 530 | 160 | 0,175 | 230 | |

| Reinforced concrete drainage trays and heating mains | ||||||

| L-1 | 2990 | 400 | 680 | 0,3 | Series 3.006.1-2/87, issue. 0, 1 | 48 |

| L2-2 | 2970 | 760 | 530 | 0,35 | 36 | |

| L3/2-8 | 2970 | 780 | 380 | 0,3 | 60 | |

| L3/2-15 | 2970 | 780 | 380 | 0,3 | 60 | |

| L4/2-8 | 2970 | 780 | 380 | 0,36 | 48 | |

| L4/2-15 | 2970 | 780 | 380 | 0,36 | 48 | |

| L5/2-8 | 2970 | 780 | 680 | 0,44 | 48 | |

| L5/2-15 | 2970 | 780 | 680 | 0,44 | 48 | |

| L6/2-5 | 2970 | 1160 | 530 | 0,45 | 32 | |

| L6/2-8 | 2970 | 1160 | 530 | 0,45 | 32 | |

| L6/2-11 | 2970 | 1160 | 530 | 0,45 | 32 | |

| L6/2-12 | 2970 | 1160 | 530 | 0,45 | 32 | |

| L6/2-15 | 2970 | 1160 | 530 | 0,45 | 32 | |

| L7/2-5 | 2970 | 1160 | 680 | 0,53 | 32 | |

| L7/2-8 | 2970 | 1160 | 680 | 0,53 | 32 | |

| L7/2-11 | 2970 | 1160 | 680 | 0,53 | 32 | |

| L7/2-15 | 2970 | 1160 | 680 | 0,53 | 32 | |

| L8/2-5 | 2970 | 1160 | 1000 | 0,78 | 24 | |

| L8/2-8 | 2970 | 1160 | 1000 | 0,78 | 24 | |

| L8/2-11 | 2970 | 1160 | 1000 | 0,78 | 24 | |

| L8/2-15 | 2970 | 1160 | 1000 | 0,78 | 24 | |

| L10/2-5 | 2970 | 1480 | 550 | 0,66 | 12 | |

| L10/2-8 | 2970 | 1480 | 550 | 0,66 | 12 | |

| L10/2-11 | 2970 | 1480 | 550 | 0,66 | 12 | |

| L10/2-15 | 2970 | 1480 | 550 | 0,66 | 12 | |

| L11/2-5 | 2970 | 1480 | 700 | 0,72 | 24 | |

| L11/2-8 | 2970 | 1480 | 700 | 0,72 | 24 | |

| L11/2-11 | 2970 | 1480 | 700 | 0,72 | 24 | |

| L11/2-15 | 2970 | 1480 | 700 | 0,72 | 24 | |

| L12/2-5 | 2970 | 1480 | 1010 | 0,96 | 20 | |

| L12/2-8 | 2970 | 1480 | 1010 | 0,96 | 20 | |

| L12/2-11 | 2970 | 1480 | 1010 | 0,96 | 20 | |

| L12/2-12 | 2970 | 1480 | 1010 | 0,96 | 20 | |

| L12/2-15 | 2970 | 1480 | 1010 | 0,96 | 20 | |

| L13/2-5 | 2970 | 1480 | 1320 | 1,25 | 16 | |

| L13/2-8 | 2970 | 1480 | 1320 | 1,25 | 16 | |

| L13/2-11 | 2970 | 1480 | 1320 | 1,25 | 16 | |

| L13/2-15 | 2970 | 1480 | 1320 | 1,25 | 16 | |

| L14/2-5 | 2970 | 1840 | 570 | 0,93 | 24 | |

| L14/2-8 | 2970 | 1840 | 570 | 0,93 | 24 | |

| L14/2-11 | 2970 | 1840 | 570 | 0,93 | 24 | |

| L14/2-12 | 2970 | 1840 | 570 | 0,93 | 24 | |

| L14/2-15 | 2970 | 1840 | 570 | 0,93 | 24 | |

| L15/2-5 | 2970 | 1840 | 720 | 0,99 | 24 | |

| L15/2-8 | 2970 | 1840 | 720 | 0,99 | 24 | |

| L15/2-11 | 2970 | 1840 | 720 | 0,99 | 24 | |

| L15/2-12 | 2970 | 1840 | 720 | 0,99 | 24 | |

| L15/2-15 | 2970 | 1840 | 720 | 0,99 | 24 | |

| L16/2-5 | 2970 | 1840 | 1030 | 1,25 | 16 | |

| L16/2-8 | 2970 | 1840 | 1030 | 1,25 | 16 | |

| L16/2-11 | 2970 | 1840 | 1030 | 1,25 | 16 | |

| L16/2-12 | 2970 | 1840 | 1030 | 1,25 | 16 | |

| L16/2-15 | 2970 | 1840 | 1030 | 1,25 | 16 | |

| L3-8 | 5970 | 780 | 380 | 0,6 | ||

| L3-15 | 5970 | 780 | 380 | 0,6 | ||

| L3d-8 | 720 | 780 | 380 | 0,08 | ||

| L3d-15 | 720 | 780 | 380 | 0,08 | ||

| L5-8 | 5970 | 780 | 680 | 0,88 | ||

| L5-15 | 5970 | 780 | 680 | 0,88 | ||

| L5d-8 | 720 | 780 | 680 | 0,11 | ||

| L5d-15 | 720 | 780 | 680 | 0,11 | ||

| L7-5 | 5970 | 1160 | 680 | 1,06 | ||

| L7-8 | 5970 | 1160 | 680 | 1,06 | ||

| L7-11 | 5970 | 1160 | 680 | 1,06 | ||

| L7-15 | 5970 | 1160 | 680 | 1,06 | ||

| L7d-5 | 720 | 1160 | 680 | 0,14 | ||

| L7d-8 | 720 | 1160 | 680 | 0,14 | ||

| L7d-11 | 720 | 1160 | 680 | 0,14 | ||

| L7d-15 | 720 | 1160 | 680 | 0,14 | ||

| L8-5 | 5970 | 1160 | 1000 | 1,56 | ||

| L8-8 | 5970 | 1160 | 1000 | 1,56 | ||

| L8-11 | 5970 | 1160 | 1000 | 1,56 | ||

| L8-15 | 5970 | 1160 | 1000 | 1,56 | ||

| L8d-5 | 720 | 1160 | 1000 | 0,2 | ||

| L8d-8 | 720 | 1160 | 1000 | 0,2 | ||

| L8d-11 | 720 | 1160 | 1000 | 0,2 | ||

| L8d-15 | 720 | 1160 | 1000 | 0,2 | ||

| L10-5 | 5970 | 1480 | 550 | 1,32 | ||

| L10-8 | 5970 | 1480 | 550 | 1,32 | ||

| L10-11 | 5970 | 1480 | 550 | 1,32 | ||

| L10-15 | 5970 | 1480 | 550 | 1,32 | ||

| L10d-5 | 720 | 1480 | 550 | 0,17 | ||

| L10d-8 | 720 | 1480(1420) | 550 | 0,17 | ||

| L10d-11 | 720 | 1480 | 550 | 0,17 | ||

| L10d-15 | 720 | 1480 | 550 | 0,17 | ||

| L11-5 | 5970 | 1480 | 700 | 1,44 | ||

| L11-8 | 5970 | 1480 | 700 | 1,44 | ||

| L11-11 | 5970 | 1480 | 700 | 1,44 | ||

| L11-15 | 5970 | 1480 | 700 | 1,44 | ||

| L11d-5 | 720 | 1480 | 700 | 0,18 | ||

| L11d-8 | 720 | 1480 | 700 | 0,18 | ||

| L11d-11 | 720 | 1480 | 700 | 0,18 | ||

| L11d-15 | 720 | 1480 | 700 | 0,18 | ||

| L12-5 | 5970 | 1480 | 1010 | 1,92 | ||

| L12-8 | 5970 | 1480 | 1010 | 1,92 | ||

| L12-11 | 5970 | 1480 | 1010 | 1,92 | ||

| L12-12 | 5970 | 1480 | 1010 | 1,92 | ||

| L12-15 | 5970 | 1480 | 1010 | 1,92 | ||

| L12d-5 | 720 | 1480 | 1010 | 0,24 | ||

| L12d-8 | 720 | 1480 | 1010 | 0,24 | ||

| L12d-11 | 720 | 1480 | 1010 | 0,24 | ||

| L12d-12 | 720 | 1480 | 1010 | 0,24 | ||

| L12d-15 | 720 | 1480 | 1010 | 0,24 | ||

| L13-5 | 5970 | 1480 | 1320 | 2,52 | ||

| L13-8 | 5970 | 1480 | 1320 | 2,52 | ||

| L13-11 | 5970 | 1480 | 1320 | 2,52 | ||

| L13-15 | 5970 | 1480 | 1320 | 2,52 | ||

| L13d-5 | 720 | 1480 | 1320 | 0,32 | ||

| L13d-8 | 720 | 1480 | 1320 | 0,32 | ||

| L13d-11 | 720 | 1480 | 1320 | 0,32 | ||

| L13d-15 | 720 | 1480 | 1320 | 0,32 | ||

| L16-5 | 5970 | 1840 | 1010 | 2,52 | ||

| L16-8 | 5970 | 1840 | 1030 | 2,52 | ||

| L16-11 | 5970 | 1840 | 1030 | 2,52 | ||

| L16-12 | 5970 | 1840 | 1030 | 2,52 | ||

| L16-15 | 5970 | 1840 | 1030 | 2,52 | ||

| L16d-5 | 720 | 1840 | 1030 | 0,32 | ||

| L16d-8 | 720 | 1840 | 1030 | 0,32 | ||

| L16d-11 | 720 | 1840 | 1030 | 0,32 | ||

| L16d-12 | 720 | 1840 | 1030 | 0,32 | ||

| L16d-15 | 720 | 1840 | 1030 | 0,32 | ||

| L4-8 | 5970 | 780 | 530 | 0,72 | ||

| L4-15 | 5970 | 780 | 530 | 0,72 | ||

| L4d-8 | 720 | 780 | 530 | 0,09 | ||

| L4d-15 | 720 | 780 | 530 | 0,09 | ||

| L6-5 | 5970 | 1160 | 530 | 0,9 | ||

| L6-8 | 5970 | 1160 | 530 | 0,9 | ||

| L6-11 | 5970 | 1160 | 530 | 0,9 | ||

| L6-12 | 5970 | 1160 | 530 | 0,9 | ||

| L6-15 | 5970 | 1160 | 530 | 0,9 | ||

| L6d-5 | 720 | 1160 | 530 | 0,11 | ||

| L6d-8 | 720 | 1160 | 530 | 0,11 | ||

| L6d-11 | 720 | 1160 | 530 | 0,11 | ||

| L6d-12 | 720 | 1160 | 530 | 0,11 | ||

| L6d-15 | 720 | 1160 | 530 | 0,11 | ||

| L14-5 | 5970 | 1840 | 570 | 1,86 | ||

| L14-8 | 5970 | 1840 | 570 | 1,86 | ||

| L14-11 | 5970 | 1840 | 570 | 1,86 | ||

| L14-12 | 5970 | 1840 | 570 | 1,86 | ||

| L14-15 | 5970 | 1840 | 570 | 1,86 | ||

| L14d-5 | 720 | 1840 | 570 | 0,23 | ||

| L14d-8 | 720 | 1840 | 570 | 0,23 | ||

| L14d-11 | 720 | 1840 | 570 | 0,23 | ||

| L14d-12 | 720 | 1840 | 570 | 0,23 | ||

| L14d-15 | 720 | 1840 | 570 | 0,23 | ||

| L15-5 | 5970 | 1840 | 720 | 1,98 | ||

| L15-8 | 5970 | 1840 | 720 | 1,98 | ||

| L15-11 | 5970 | 1840 | 720 | 1,98 | ||

| L15-12 | 5970 | 1840 | 720 | 1,98 | ||

| L15-15 | 5970 | 1840 | 720 | 1,98 | ||

| L15d-5 | 720 | 1840 | 720 | 0,25 | ||

| L15d-8 | 720 | 1840 | 720 | 0,25 | ||

| L15d-11 | 720 | 1840 | 720 | 0,25 | ||

| L15d-12 | 720 | 1840 | 720 | 0,25 | ||

| L15d-15 | 720 | 1840 | 720 | 0,25 | ||

| Channel, cable, reinforced concrete trays | ||||||

| LK300.45.30-1 | 2990 | 430 | 280 | 0,45 | Series 3.006.1-2. 87, no. 1,2,3,4,5 | |

| LK75.45.30-1 | 740 | 430 | 280 | 0,12 | ||

| LK300.45.45-1 | 2990 | 430 | 430 | 0,6 | ||

| LK75.45.45-1 | 740 | 430 | 430 | 0,15 | ||

| LK300.45.60-1 | 2990 | 430 | 580 | 0,8 | ||

| LK300.45.60-2 | 2990 | 430 | 580 | 0,8 | ||

| LK300.45.60-3 | 2990 | 430 | 580 | 0,8 | ||

| LK300.45.60-4 | 2990 | 430 | 580 | 0,8 | ||

| LK75.45.60-1 | 740 | 430 | 580 | 0,2 | ||

| LK75.45.60-2 | 740 | 430 | 580 | 0,2 | ||

| LK75.45.60-3 | 740 | 430 | 580 | 0,2 | ||

| LK75.45.60-4 | 740 | 430 | 580 | 0,2 | ||

| LK300.60.30-1 | 2990 | 580 | 280 | 0,53 | ||

| LK300.60.30-2 | 2990 | 580 | 280 | 0,53 | ||

| LK300.60.30-3 | 2990 | 580 | 280 | 0,53 | ||

| LK75.60.30-1 | 740 | 580 | 280 | 0,13 | ||

| LK75.60.30-2 | 740 | 580 | 280 | 0,13 | ||

| LK75.60.30-3 | 740 | 580 | 280 | 0,13 | ||

| LK300.60.45-1 | 2990 | 580 | 430 | 0,68 | ||

| LK300.60.45-2 | 2990 | 580 | 430 | 0,68 | ||

| LK300.60.45-3 | 2990 | 580 | 430 | 0,68 | ||

| LK75.60.45-1 | 740 | 580 | 430 | 0,18 | ||

| LK75.60.45-2 | 740 | 580 | 430 | 0,18 | ||

| LK75.60.45-3 | 740 | 580 | 430 | 0,18 | ||

| LK300.60.60-1 | 2990 | 580 | 580 | 0,88 | ||

| LK300.60.60-2 | 2990 | 580 | 580 | 0,88 | ||

| LK300.60.60-3 | 2990 | 580 | 580 | 0,88 | ||

| LK300.60.60-4 | 2990 | 580 | 580 | 0,88 | ||

| LK75.60.60-1 | 740 | 580 | 580 | 0,23 | ||

| LK75.60.60-2 | 740 | 580 | 580 | 0,23 | ||

| LK75.60.60-3 | 740 | 580 | 580 | 0,23 | ||

| LK75.60.60-4 | 740 | 580 | 580 | 0,23 | ||

| LK300.60.90-1 | 2990 | 580 | 880 | 1,48 | ||

| LK300.60.90-2 | 2990 | 580 | 880 | 1,48 | ||

| LK300.60.90-3 | 2990 | 580 | 880 | 1,48 | ||

| LK300.60.90-4 | 2990 | 580 | 880 | 1,48 | ||

| LK75.60.90-1 | 740 | 580 | 880 | 0,38 | ||

| LK75.60.90-2 | 740 | 580 | 880 | 0,38 | ||

| LK75.60.90-3 | 740 | 580 | 880 | 0,38 | ||

| LK75.60.90-4 | 740 | 580 | 880 | 0,38 | ||

| LK300.90.45-1 | 2990 | 880 | 430 | 0,9 | ||

| LK300.90.45-2 | 2990 | 880 | 430 | 0,9 | ||

| LK300.90.45-3 | 2990 | 880 | 430 | 9 | ||

| LK300.90.45-4 | 2990 | 880 | 430 | 0,9 | ||

| LK300.90.45-5 | 2990 | 880 | 430 | 0,9 | ||

| LK300.90.45-6 | 2990 | 880 | 430 | 0,9 | ||

| LK300.90.45-7 | 2990 | 880 | 430 | 0,9 | ||

| LK300.90.45-8 | 2990 | 880 | 430 | 0,9 | ||

| LK300.90.45-9 | 2990 | 880 | 430 | 0,9 | ||

| LK300.90.45-10 | 2990 | 880 | 430 | 0,9 | ||

| LK75.90.45-1 | 740 | 880 | 430 | 0,23 | ||

| LK75.90.45-2 | 740 | 880 | 430 | 0,23 | ||

| LK75.90.45-3 | 740 | 880 | 430 | 0,23 | ||

| LK75.90.45-4 | 740 | 880 | 430 | 0,23 | ||

| LK75.90.45-5 | 740 | 880 | 430 | 0,23 | ||

| LK75.90.45-6 | 740 | 880 | 430 | 0,23 | ||

| LK75.90.45-7 | 740 | 880 | 430 | 0,23 | ||

| LK75.90.45-8 | 740 | 880 | 430 | 0,23 | ||

| LK75.90.45-9 | 740 | 880 | 430 | 0,23 | ||

| LK75.90.45-10 | 740 | 880 | 430 | 0,23 | ||

| LK300.90.60-1 | 2990 | 880 | 580 | 1,13 | ||

| LK300.90.60-2 | 2990 | 880 | 580 | 1,13 | ||

| LK300.90.60-3 | 2990 | 880 | 580 | 1,13 | ||

| LK300.90.60-4 | 2990 | 880 | 580 | 1,13 | ||

| LK75.90.60-1 | 740 | 880 | 580 | 0,28 | ||

| LK75.90.60-2 | 740 | 880 | 580 | 0,28 | ||

| LK75.90.60-3 | 740 | 880 | 580 | 0,28 | ||

| LK75.90.60-4 | 740 | 880 | 580 | 0,28 | ||

| LK300.120.60-1 | 2990 | 1180 | 580 | 1,55 | ||

| LK300.120.60-2 | 2990 | 1180 | 580 | 1,55 | ||

| LK300.120.60-3 | 2990 | 1180 | 580 | 1,55 | ||

| LK300.120.60-4 | 2990 | 1180 | 580 | 1,55 | ||

| LK300.120.60-5 | 2990 | 1180 | 580 | 1,55 | ||

| LK300.120.60-6 | 2990 | 1180 | 580 | 1,55 | ||

| LK300.120.60-7 | 2990 | 1180 | 580 | 1,55 | ||

| LK300.120.60-8 | 2990 | 1180 | 580 | 1,55 | ||

| LK300.120.60-9 | 2990 | 1180 | 580 | 1,55 | ||

| LK300.120.60-10 | 2990 | 1180 | 580 | 1,55 | ||

| LK75.120.60-1 | 740 | 1180 | 580 | 0,4 | ||

| LK75.120.60-2 | 740 | 1180 | 580 | 0,4 | ||

| LK75.120.60-3 | 740 | 1180 | 580 | 0,4 | ||

| LK75.120.60-4 | 740 | 1180 | 580 | 0,4 | ||

| LK75.120.60-5 | 740 | 1180 | 580 | 0,4 | ||

| LK75.120.60-6 | 740 | 1180 | 580 | 0,4 | ||

| LK75.120.60-7 | 740 | 1180 | 580 | 0,4 | ||

| LK75.120.60-8 | 740 | 1180 | 580 | 0,4 | ||

| LK75.120.60-9 | 740 | 1180 | 580 | 0,4 | ||

| LK75.120.60-10 | 740 | 1180 | 580 | 0,4 | ||

| LK300.120.90-1 | 2990 | 1180 | 880 | 1,98 | ||

| LK300.120.90-2 | 2990 | 1180 | 880 | 1,98 | ||

| LK300.120.90-3 | 2990 | 1180 | 880 | 1,98 | ||

| LK300.120.90-4 | 2990 | 1180 | 880 | 1,98 | ||

| LK300.120.90-5 | 2990 | 1180 | 880 | 1,98 | ||

| LK300.120.90-6 | 2990 | 1180 | 880 | 1,98 | ||

| LK300.120.90-7 | 2990 | 1180 | 880 | 1,98 | ||

| LK300.120.90-8 | 2990 | 1180 | 880 | 1,98 | ||

| LK300.120.90-9 | 2990 | 1180 | 880 | 1,98 | ||

| LK300.120.90-10 | 2990 | 1180 | 880 | 1,98 | ||

| LK75.120.90-1 | 740 | 1180 | 880 | 0,5 | ||

| LK75.120.90-2 | 740 | 1180 | 880 | 0,5 | ||

| LK75.120.90-3 | 740 | 1180 | 880 | 0,5 | ||

| LK75.120.90-4 | 740 | 1180 | 880 | 0,5 | ||

| LK75.120.90-5 | 740 | 1180 | 880 | 0,5 | ||

| LK75.120.90-6 | 740 | 1180 | 880 | 0,5 | ||

| LK75.120.90-7 | 740 | 1180 | 880 | 0,5 | ||

| LK75.120.90-8 | 740 | 1180 | 880 | 0,5 | ||

| LK75.120.90-9 | 740 | 1180 | 880 | 0,5 | ||

| LK75.120.90-10 | 740 | 1180 | 880 | 0,5 | ||

| LK300.120.120-1 | 2990 | 1180 | 1180 | 2,7 | ||

| LK300.120.120-2 | 2990 | 1180 | 1180 | 2,7 | ||

| LK300.120.120-3 | 2990 | 1180 | 1180 | 2,7 | ||

| LK300.120.120-4 | 2990 | 1180 | 1180 | 2,7 | ||

| LK300.120.120-5 | 2990 | 1180 | 1180 | 2,7 | ||

| LK75.120.120-1 | 740 | 1180 | 1180 | 0,68 | ||

| LK75.120.120-2 | 740 | 1180 | 1180 | 0,68 | ||

| LK75.120.120-3 | 740 | 1180 | 1180 | 0,68 | ||

| LK75.120.120-4 | 740 | 1180 | 1180 | 0,68 | ||

| LK75.120.120-5 | 740 | 1180 | 1180 | 0,68 | ||

| LK300.150.45-9 | 2990 | 1480 | 430 | 1,63 | ||

| LK300.150.45-11 | 2990 | 1480 | 430 | 1,63 | ||

| LK300.150.60-1 | 2990 | 1480 | 580 | 1,85 | ||

| LK300.150.60-2 | 2990 | 1480 | 580 | 1,85 | ||

| LK300.150.60-3 | 2990 | 1480 | 580 | 1,85 | ||

| LK300.150.60-4 | 2990 | 1480 | 580 | 1,85 | ||

| LK300.150.60-5 | 2990 | 1480 | 580 | 1,85 | ||

| LK300.150.60-6 | 2990 | 1480 | 580 | 1,85 | ||

| LK300.150.60-7 | 2990 | 1480 | 580 | 1,85 | ||

| LK300.150.60-8 | 2990 | 1480 | 580 | 1,85 | ||

| LK300.150.60-9 | 2990 | 1480 | 580 | 1,85 | ||

| LK75.150.60-1 | 740 | 1480 | 580 | 0,45 | ||

| LK75.150.60-2 | 740 | 1480 | 580 | 0,45 | ||

| LK75.150.60-3 | 740 | 1480 | 580 | 0,45 | ||

| LK75.150.60-4 | 740 | 1480 | 580 | 0,45 | ||

| LK75.150.60-5 | 740 | 1480 | 580 | 0,45 | ||

| LK75.150.60-6 | 740 | 1480 | 580 | 0,45 | ||

| LK75.150.60-7 | 740 | 1480 | 580 | 0,45 | ||

| LK75.150.60-8 | 740 | 1480 | 580 | 0,45 |

smetsnab.ru

Cable trays

Cable trays are reinforced concrete products designed to provide reliable protection and insulation of laid cables, pipelines and communication systems from various environmental influences. Such designs, due to their versatility, are also quite widely used in various areas of domestic or industrial construction. For example, when laying pipelines, heating mains, tunnels and canals, hot and cold water supply pipes, in the construction of drainage structures and drainage systems, various engineering systems, drainage and irrigation canals.

Cable trays according to their intended purpose can be divided into the following groups:

- for hermetically sealed installation of various engineering and electrical communications, pipelines;

- for laying heating mains;

- for drainage ditches intended for drainage of wastewater;

- for arrangement of drainage systems;

- for improvement of hydraulic engineering and wastewater treatment facilities.

- ease of installation of products, allowing to reduce the time for laying utility lines and repairing them in case of accidents;

- durability and strength, providing reliable protection of various pipelines and communication systems from the negative effects of environmental factors for more than a dozen years;

- versatility and simplicity of design, which allows the use of cable trays for arranging various communications, both in industrial and residential construction;

- low cost - both the product itself and its installation are characterized by relatively low prices.

The fairly widespread use of cable trays is explained by a number of advantages:

Also, it is worth noting the high performance characteristics of reinforced concrete cable trays. In addition to time-tested strength and load-bearing capacity, the smooth surface of concrete structures increases their throughput and improves self-cleaning - smooth walls do not allow debris to cling to them, and they are not covered with dirt build-up, which contributes to long-term and safe storage of pipelines inside the structure.

The obvious advantage of these trays is also expressed in their form - at the end of production these are structures completely ready for installation, which allows you to significantly save installation time, and, subsequently, maintenance or repair time. The technology of laying, for example, cable in trays is the simplest, but at the same time, effective and fast method in providing communications with electricity. The cables are distributed and laid in prepared cable trays of suitable size. Then a floor slab is installed on top of the tray, for which lifting devices are used.

When laying electrical cables, trays are produced with embedded parts on the inner sides of the walls. Embedded parts are designed for strong fastening of electrical cables and cable structures, placement of power cables and couplings on their shelves. The most important function of reinforced concrete cable trays is to protect electrical cables from the harmful effects of moisture, which can cause corrosion of the most important communication elements or completely damage the power supply system, and, as a result, there will be a need for lengthy repairs.

A cable tray is an open prefabricated structure with a bottom and sides, into which cables and wires are laid, and a floor slab is installed on top. There may be technological holes in the trays. The tray is manufactured in accordance with the requirements of GOST 23009-78 “Concrete and reinforced concrete prefabricated structures and products, symbols (brands)”, GOST 13015.0-83 “Concrete and prefabricated reinforced concrete structures and products, technical requirements”, series 3.407.1-157 " Unified reinforced concrete products for 35-500 kV substations" issue 1, 3.006.1-8 "Prefabricated reinforced concrete channels and tunnels from tray elements" issue 1-1.

To ensure the required level of compressive strength, stable frost resistance and durability, cable trays are made of heavy concrete of classes B15, B20, B25, frost resistance class F300, water resistance class not lower than W4. The reinforced elements are construction reinforcing steel of classes A-1 and A-3.

To increase strength characteristics and obtain a smoother surface, the concrete mixture is subjected to a vibration compaction process. This method is as follows: the prepared semi-dry or rigid concrete mixture is placed in a mold, where, under the action of a press, it is subjected to pressure from above simultaneously with the influence of a vibrating force from below or on the sides of the mold. Thanks to this, the concrete acquires a more dense structure, without bubbles and voids that naturally appear when preparing a concrete mixture. It is this method that makes it possible to obtain smooth-walled products with unsurpassed waterproof and strength characteristics.

Concrete cable trays are marked with alphanumeric values. The letters determine the type of product (L - cable tray; or UBK - universal concrete channel, KN - non-passable channel). Next, indicate the numerical values: the first digit means the length, the second the height of the LK tray in dm. Also, the load that the product can withstand must be indicated (from 1 to 10) - the calculated vertical load (in tf/m²). The type of load on the cable tray affects its reinforcement with steel elements. If the letter “a” appears after the numerical values, this indicates that the product is equipped with additional embedded elements. The letter “d” indicates an additional tray.

produces cable trays, observing all standards, both for the production and storage of reinforced concrete cable trays, in accordance with the quality standards described above. Therefore, we can guarantee that you receive high-quality products that allow you to take care of the provision of electricity to any corner of our country, and contribute to the uninterrupted operation of any engineering solutions in various areas of the construction business.

www.zbi-osnova.ru

Advantages of purchasing on

Strict quality control is practiced in the manufacture of power cable products. Each product unit must pass certain tests and only based on their results is it allowed to be sold. During acceptance, special attention is paid to the following points:

- Compliance of height, width, length with the required parameters. The maximum error can be no more than 1 cm in length, width, no more than 0.7 cm in height;

- Presence of cracks. Only shrinkage errors are allowed, but also no more than 0.1 mm;

- Straight profile. This parameter is responsible for the joint density, the permissible error is no more than 1 cm;

- Product unit weight. It cannot be more or less than the standard mass by more than 7%.

We produce and sell cable trays series 3.407.1-157. This means that the product is a unified reinforced concrete element, manufactured on the basis of approved drawings, using materials that meet quality requirements in their characteristics.

Order reinforced concrete cable trays from our factory. We will load and transport them to the place of electrical installation work in compliance with transportation technology. Install a reliable cable channel!