A concrete pump is a unit that supplies freshly prepared mortar from the point where it is unloaded from a concrete mixer truck to the working area. Modern craftsmen cannot imagine carrying out repair and construction work without a concrete pump, which greatly simplifies and speeds up all stages where concrete and other mixtures are involved.

Most often, concrete pumps are used in the process of monolithic construction. Industrially produced units are quite expensive, but if you have the drawings and all the necessary materials, tools, as well as the necessary patience to strictly follow the instructions and standards, you can make a concrete pump yourself.

Externally, it will differ from the factory models, but the quality of work and the performance of all necessary functions will be identical. Subject to significant cost savings, a homemade concrete pump becomes the most preferable option for many.

What types of concrete pump designs exist?

Depending on the type of drive, concrete pumps can be hydraulic or mechanical. According to the design, pistonless and piston ones are poured. Depending on the method of movement, concrete pumps are either stationary or mobile. Despite the apparent diversity, today two types of concrete pumps are used in construction: piston (with hydraulic drive) and rotary (with mechanical drive).

In a rotary unit, the mixture is supplied by rollers equipped with the rotor housing: during the process of rotation, they press on the supply hose and the concrete is thrown out from there. But it is very difficult to make such a concrete pump yourself, since the design of the rotary type is complex, so usually piston units are assembled with your own hands.

The piston installation includes three main parts:

- Piston – powers the cylinder

- Cylinder - the part responsible for taking the mixture from the hopper and pumping it

- Drive – usually choose hydraulic or electromechanical

Single-piston units are most often used, since double-piston units require a complex design. Operation of two-piston units is carried out thanks to an electric or diesel engine, which converts hydraulic energy into mechanical energy.

Classification of concrete pumps

The classification of concrete pumps varies. The first type of classification depends on the type of autonomy. They can be either mobile or landline.

- stationary concrete pumps - the main advantages of this type of equipment are higher productivity, power, reliability and at the same time the equipment can operate under fairly heavy loads and in difficult conditions;

- mobile concrete pumps are preferable for those who do not want to buy equipment, but rent it. This type of pump is compact and easy to transport; it can pump concrete mortar both vertically and horizontally.

Also, the classification may depend on the size, engine performance, and type of power supply. Concrete pumps can be classified according to the type of solution supplied and, accordingly, they are of vacuum type and piston type.

- vacuum concrete pump – concrete is supplied by squeezing the solution out of the tray using a vacuum;

- piston concrete pump – concrete is supplied using a working piston.

Piston

Diagram of a single-acting piston concrete pump.

A homemade piston concrete pump includes several large parts such as: drive, cylinder, piston. In turn, each of these parts includes a certain number of smaller spare parts. The cylinder is a vessel containing 2 check valves. They are entrusted with the task of distilling the concrete solution from the receiver to the concrete pipeline. The process itself occurs thanks to the coordinated functioning of the cylinder and piston.

When the concrete pump starts operating, the piston starts working first. After starting work, the piston creates a discharge inside the cylinder, which pushes the mixture into the successor. The piston moves to the end, and then returns to the starting position. Thanks to this operation, pressure is generated that pushes the concrete mixture into the concrete pipe.

An industrial concrete pump has two pistons, which increases power and makes technological processes more complex. However, this is only beneficial for large-scale construction projects, where the rather high price of such a device will quickly pay for itself. But for small-scale construction, buying an industrial type of equipment is too wasteful, especially since it is quite possible to make a homemade pump with your own hands.

Principle of operation

Most of the main components of the concrete pump are equipped with auxiliary devices and mechanisms.

Unit action:

- The cylindrical base of the mechanism is equipped with two installation valves, through which the mixture is suctioned and pumped into the concrete pipeline.

- The piston head performs a reciprocating movement in the cylinder, thereby creating atmospheric vacuum. Thanks to this, the concrete is sucked in.

- When the piston head is in its extreme position, the working (reverse) stroke starts.

- The piston returns to its original position, creating excess pressure, due to which the mixture is drained into the concrete pipeline, and then begins to supply concrete mixture to the zone.

When making a manual concrete pump with your own hands, a piston mechanism is usually chosen. In civil and industrial construction, equipment with two piston heads is used, which guarantees uninterrupted operation of the device and significantly increases performance. They usually make single-piston concrete pumps with their own hands.

Using stationary devices if it is not possible to create a concrete pump yourself

Stationary concrete pumps

There can be two options - with a chassis and without a chassis. The first allow you to freely move equipment within the construction site. If there is a need to transport the device to another facility, you will have to use a special platform. The smallest figure is 5 cubic meters, the largest is 200.

The feed height can reach 250 meters. If the pipes for transporting concrete are in a horizontal position, the amount of concrete transportation will be more than 1 kilometer.

Creating a concrete pump with your own hands is not always advisable, because a lot of effort and money are spent, and not everyone has the skills. In such cases, you can always find a way out and take advantage of the suggestions of knowledgeable people.

Buy or do it yourself?

Making a concrete pump with your own hands is not as difficult as it seems. The main thing is to calculate everything accurately in advance and use the drawings. Many people choose this option due to the fact that buying a factory model is expensive, and rent in terms of the number of hours and days is sometimes equal to the cost of parts and labor for constructing the device yourself.

You can buy a used concrete pump, but no one knows how long it will work and whether it will be able to efficiently perform its functions. It is much more profitable to make a mini-concrete pump with your own hands, being absolutely sure of the quality of the selected mechanisms and their operation, having assembled the unit in accordance with the requirements and required indicators.

Homemade installations are not as powerful as factory ones, but they are simple to implement and can ensure smooth, proper operation. Manufacturing a pump is advisable if small-scale repair and construction work using concrete mortar is regularly carried out or if a large house is being built. In this case, the costs will be fully recouped by the opportunity to speed up construction and save on labor.

Detailed structure of piston concrete pump

The concrete pump cylinder is a hollow part with 2 valves. These valves, opening alternately, allow liquid concrete to be taken from the tank and pumped into the concrete pipeline. And this, in turn, is possible due to the movement of the piston and the change of phases of the rarefied atmosphere and ultra-high pressure. To meet the needs of private housing construction, a simple model with one piston is quite sufficient. On large construction sites, where there is a need for high productivity, two-piston models are also used, but they are too expensive and difficult to manufacture - it is almost impossible to assemble a two-piston concrete pump with your own hands.

In general, in order to make a functional concrete pump yourself, you need to pay great attention to the design and creation of drawings. Sample drawings can be found online and you can also use them. Or you can contribute your own know-how - it’s your choice.

How to make a simple concrete pump

To assemble a concrete pump with your own hands, you need to stock up on materials and tools that are indicated in the drawings. What you need: a steel pipe for the cylinder, a sheet of metal 5 millimeters thick, a lathe, round metal sheets (to make the piston and valve), a screwdriver, an electric motor, wrenches and bolts, a welded frame, a gearbox with a reduction gear, plastic or steel pipes for concrete pipeline.

Usually, for self-assembly, mechanisms with one piston are chosen.

The main stages of producing a mini-concrete pump with your own hands:

- Searching for a drawing, drawing up a plan indicating everything necessary, a design diagram.

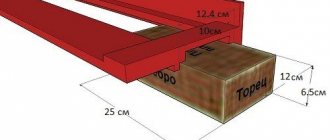

- You need to select a cylinder and a piston - these are the key parts. The cylinder diameter should be a maximum of 400 millimeters (but smaller is better), the piston stroke should be at least 0.5 meters. If the parameters do not match, the mechanism will quickly wear out. Parts must be precisely made, without roughness.

- Pump selection - it can be hydraulic or electromechanical.

- Gearbox - must include a gear ratio to reduce and convert rotational movements into translational ones.

- King pin – connected to the mechanism.

- A metal corner is used as a welded frame.

- Making check valves from steel.

All parts are checked and assembled into a single mechanism using a drawing (it is desirable that there is also a drive diagram of all structural components). Next, you need to check your work. You cannot start the unit without concrete inside or a special starting mixture. It is prepared independently from an ordinary concrete mixture diluted in water, and then machine oil is added.

testing and drive equipment

An equally important component of the installation is the drive. He is required to set the piston in motion to pump the solution.

The motor can be one of 2 types:

- Hydraulic;

- Electromechanical.

In order to make a concrete pump with your own hands, they often opt for an electromechanical model. If, for example, we consider the prostate and economy, then it is much superior to the original form.

Video instruction:

This driving device consists of the following ingredients:

- Asynchronous three-phase motor;

- Gearbox;

- A mechanism that converts rotational motion into translational motion;

- Kingpin.

Putting the entire system together shouldn't be too difficult. First you need to weld a frame from a metal profile to which the previously assembled concrete pump will be attached.

Again, an electric motor with a connected starter is screwed onto it.

The gearbox is attached to the shaft of the electric motor using bolted connections. Then you need to make and install a conversion mechanism.

Its main purpose is to convert the circular movements of the shaft into translational ones (back and forth).

In order for the entire structure to properly serve its purpose, the piston and the converting mechanism are connected to each other using a pin.

Now that the assembled concrete pump is ready for operation with your own hands, all that remains is to combine the electric motor with the power cable and begin testing.

In order to make the unit more mobile, it is installed on a single-axle trailer.

This way it can be freely moved around the site where construction is taking place or completely transported to other construction sites.

To ensure that the assembled installation operates correctly and safely, you need to conduct the first test.

Video:

Before the initial start-up, the pump must be filled with a mixture of concrete, albeit with a large water content - checking at idle is unacceptable.

To lubricate all moving and wearing components, add a little automobile oil to the test solution. After any use, the device must be dismantled and cleaned.

Following all the recommendations given, the assembled concrete pump with your own hands should serve for a very long time.

But before you start working, you need to carefully calculate everything. If, for example, all the components of the device need to be purchased on the market, their price can reach 60 thousand rubles.

But when installation is necessary only for a one-time use, renting will be a more reliable and profitable solution.

We think you liked the article - Do-it-yourself concrete pump

The content of the article

- Types of concrete pumps and preparation for work

- testing and drive equipment

Trans Mix concrete pump, floor screed, liquid floors

Pump assembly highlights:

- A lathe is used to create some items, usually small round parts that, once created, need to be cleaned and finished to the desired size.

- The body is made of sheet iron.

- When choosing a drive, you need to take into account the features of different designs: it must be economical and simple.

- Starting a concrete pump requires the presence of the following basic parts: a gearbox that reduces the gear ratio, an asynchronous electric motor with a 3-phase feed, and a reciprocating piston converter. There are special requirements for the quality of these parts, since the correctness and efficiency of the concrete pump will directly depend on them.

- Everything is assembled easily: a frame is welded from metal profiles, all elements are attached to it according to the diagram, and the electric motor is connected to the switch. The gearbox is bolted to the engine, the converter is mounted, and the cable is connected to the engine.

- After checking, the concrete pump must be disassembled and cleaned - the same as after each time the building mixture is prepared.

- If you need to make a mobile concrete pump with your own hands, you can install it on a single-axle trailer.

Materials and preparation of main parts

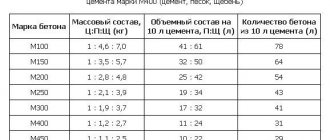

You will need a scaled drawing, as well as a diagram of the movement of working parts. The latter will help determine the required rod length, crank size and piston stroke (usually taken to be 60-90 cm). After this, you need to purchase or make all the elements of the mechanism yourself:

1. For a hydraulic cup you will need a thick-walled pipe with a diameter of 350-400 mm.

2. It is better to make check valves and the piston head from alloy steel that is resistant to alkaline environments.

3. An asynchronous motor and a reduction gearbox are used as a drive - for viscous concrete, the rotation speed of the rotor shaft is too high.

The characteristics of the concrete pump must correspond to the transportation conditions: the delivery height and the length of the pipeline to which the unit is connected. Depending on the engine power and gear ratio, as well as the useful volume of the hydraulic chamber, you can get a productivity of up to 100-150 m 3 / h with pumping the solution over a distance of up to 40 m.

Special attention should be paid to gate valves, since there are several suitable options:

- The C-valve (BRF) is the easiest gate to operate and maintain, but also the least durable.

- S-valve (BSF) - considered optimal in price and at the same time quite reliable.

- Rock valve (RL) is the rarest type of gate valve, but it is best suited for working with heavy and coarse-grained concrete, since it is less clogged with thick mixtures.

Additionally, you will need a sheet of stainless steel or ordinary iron up to 6 mm thick, as well as a metal profile (angle, channel) for the body. If the concrete pump will be transported from place to place, it is installed on a wheelbase.

Application in construction

A concrete pump is needed to supply the mixture to the place of its use, and also to perform work in hard-to-reach places. The unit significantly speeds up the work process, therefore it is used wherever concrete is used: the construction of residential and industrial buildings, private and multi-storey buildings, bridges, tunnels, etc.

The output of a concrete pump can be 20-150 m3/hour. Operation of the device is simple: concrete is delivered from the container to the site, automatically pumped in the required mode. The equipment can be used all year round - for this there is a diesel fuel heating system, and thermal insulation can be provided.

Maintenance of concrete pumps is simple: after each preparation of the mixture, it is enough to use a flushing pump with a water gun. The unit can operate around the clock.

Advantages of automatic pumps for pumping concrete:

- A special electronic control unit ensures uninterrupted and correct operation of the concrete pump. It is possible to select the desired mode and carry out constant monitoring.

- An autonomous system for washing the concrete pump and concrete pipeline is built in, which reduces the time spent on servicing the unit.

- There is lighting for working in the dark (the concrete pump itself and the working area).

- A sound alarm has been installed - the warning system is working.

- The ability to regulate the concrete distribution unit has been implemented.

- A typical concrete pump kit includes: a concrete pipeline (up to 80 meters long), software, and a flushing system.

- It is possible to add a concrete distribution boom to facilitate delivery of the mixture to the site.

- The engines comply with all international standards (EURO-4 inclusive).

- In the creation of concrete pumps, components from the world's best manufacturers are used, guaranteeing high quality work, reduced repair and maintenance costs, and increased service life.

A concrete pump is a very important unit on a construction site, greatly facilitating and speeding up the execution of a lot of labor-intensive tasks. It can be purchased ready-made or assembled yourself from simple parts and mechanisms. Self-assembly of a mini-concrete pump will result in a simple and effective unit that will become an indispensable assistant in construction.

Operating principle of a concrete pump

A concrete pump is a device with the sole task of preparing and delivering concrete from the mixing point to the target area. The installation is based on pipelines or concrete pipes that transfer the solution to any location. The greatest need arises in monolithic construction and when creating reinforced concrete structures.

Mobile concrete pump with high productivity on a crawler chassis

To understand the method of constructing the installation, you should know how a concrete pump works. The operating principle of a concrete pump is based on the properties of the liquid - it displaces and fills the changing volume of the system. If the volume is completely filled with the mixture, the solution is discharged into the concrete pipeline and then to the target area.

The design and principle of operation of a concrete pump is divided into several groups:

- piston Perform a constant feed at various distances. Modern devices are capable of displacing liquid to a height of 6-65 m. The volume of the supplied mixture reaches 180 m3/h. It is not durable due to the risk of small elements of cement getting in. Has a jerky delivery principle.

- hose (screw). Provide continuous transportation. The gerotor pump for concrete provides a large volume of transported material. The installation is characterized by silent operation when pumping compounds of any consistency. If a blockage occurs, it is broken through by reversing the engine. A gerotor pump for pumping concrete has one significant drawback - the hose has a short service life, but the structure can easily be repaired independently;

- with hydraulics. If there are hydraulic units for working with concrete, the devices become more durable and smoothly transfer the solution (without jerking or changing speed). Hydraulics help pump liquid to heights and long distances. The hydraulic drive is made as simple as possible; the device results in low energy consumption. Hydraulic pumps help pump mortar containing lightweight aggregates and are easy to operate and maintain.

Design of a piston concrete pump

Drawings of concrete pumps for DIY production differ significantly depending on the type. All models differ in design, but have similar disadvantages to a greater or lesser extent:

- the use of rolling stock is mandatory;

- limited transportation range;

- demands on the composition of the solution.

The price of a homemade concrete pump directly depends on the required power and pipe diameter. For larger pipes the pressure decreases. Recently, concrete pumps (the ability to supply concrete to a target area of various distances) and concrete pumps (smaller dimensions and mobility) have become very popular.