sells monolithic sections UMK 1200-100 TAIII (Series 3.503.1-81. Issue 1-2. Span structures made of entirely transportable beams with tension on stops for bridges and overpasses located on public roads. Monolithic sections. Working drawings) at wholesale price, with delivery throughout Russia. You can also order from us the production of reinforced concrete products of any complexity according to individual drawings. Our products are of high quality and fully comply with all technical requirements of GOST standards.

Materials and tools needed for work

For each stage of work, you need to prepare your own set of materials and tools. Their list may differ only due to some factors, for example, the distance between the slabs that needs to be poured. However, there is still a standard list that includes the following materials:

The area between the floor slabs is filled with concrete and pre-reinforced.

- boards that will be used to create side formwork and surface;

- wooden beams or metal channels that will serve as support for plywood or a plank pallet;

- timber for creating load-bearing supports for the formwork platform;

- reinforcement rods, wire with which the bundle will be made, metal chairs;

- concrete solution, which is made from sand, M400 cement, crushed stone and water;

- concrete mixer;

- circular saw, shovel, trowel, bayonet tool and protective film.

As for the amount of material, it depends on the area of overlap that needs to be made, as well as on the area of overlap itself. If we talk about a private house, then in such buildings it is, as a rule, not very large, so it will not be difficult to cope with the work yourself.

Installation of formwork

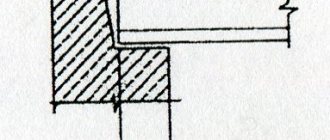

Formwork installation diagram.

To complete this stage of work, a team of 3-4 people will be required.

To make assembly easier, we place one shield as a base. We install a spacer under each bolt so that nothing bends under load.

We attach the ribs to the base of the formwork. We fasten the ribs taking into account how wide we need the beam. Beams of three sizes are allowed: 35, 40, 45 cm. With the required width of 35 cm, both side ribs are placed flush. With a required width of 40 cm, only one edge of two prefabricated panels is placed flush. If you need a beam 45 cm wide, the ribs are attached without using this technique. Everything is fastened with self-tapping screws.

As a result, we ended up with a box of three prefabricated panels in the place where the future beam will be located.

Figure 4. Types of attachment of ribs to the base. A – 35 cm, B – 40 cm, C – 45 cm.

Now we prepare spacers from the reinforcement. They will be needed in order to maintain the required size of the beam and prevent bevels. We simply cut the reinforcement into pieces of the required length (35 cm).

After this, we proceed to upholstering the resulting box with film from the inside, using a carpenter's stapler with staples. This is necessary in order to prevent unnecessary water loss from the concrete and to avoid the appearance of sinkholes. If this is not done, the concrete will lose a lot of moisture along with sand and cement. After drying, gravel will appear heavily on the outer edges of the beam. The surface of the beam will be completely covered with strong roughness and irregularities, bumps and depressions, the so-called shells. Such a beam will be of poor quality and will have to be redone.

Stages of formation of a monolithic floor section

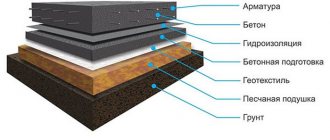

The formation of the area between the slabs is no different from the creation of any other monolithic floor. Despite the fact that the area of work is relatively small, it is still worth adhering to construction rules, so all stages of the work must be completed carefully. This is what determines how reliable the monolithic structure will be.

The first thing that needs to be done is to form the formwork for the monolithic section. In this case, it is necessary to take into account that the concrete solution weighs quite a lot, moreover, it takes a long time to dry, so the strength and mechanical characteristics of the formwork must be such as to hold it for a fairly long period of time.

How to install formwork:

Installation of formwork for a monolithic section between slabs

- The bottom is made, for which a sheet of plywood is taken, and beams are placed on it, which will act as load-bearing elements. Since the distance between the slabs in a private house is not so large, it is not difficult to make the bottom of the formwork. Before forming the reinforcement grid, we cover the bottom with roofing felt or construction film.

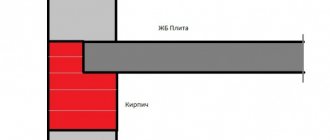

- The borders of the monolithic section on the sides will be the floor slabs. As a rule, there is a wall on the third side.

- Vertical supports are placed under the bottom holding elements, which are beams. They must be secured so that the bottom of the formwork does not slip off the vertical supports, which are load-bearing. A unifork is used for this, although not always. As a rule, when building a private house, there is no special supporting equipment, so parts of the formwork can be fixed using nails or staples.

- An important point in this process is the support of the formwork in the floor plane, which should be as strong as possible. This can be achieved by compacting the soil and lining it with some kind of board or tile material.

After the formwork is ready, and there is no doubt about its strength, we move on to the next stage.

Monolith between floor slabs

Greetings! The distance between the parallel slabs PK-51.12.8AtVta and PK-51.18.8AtVta is 1.3 m; they rest with their short sides on load-bearing walls. It is necessary to monolith this gap, leaving 1 m to the wall on one side. Is it possible to do this? If yes, then how (how many materials, technology)?

Why such a long distance? The slab would fit 1.2m wide. What will you have there?

Behind Baikal he wrote: Why such a long distance? The slab would fit 1.2m wide. What will you have there?

There will be a 1.3x1m hatch to the 2nd floor. The slab will fit, but there is nothing to support one end of it.

Hurry to the attic. in the house.

Behind Baikal he wrote: Why such a long distance? The slab would fit 1.2m wide. What will you have there?

*There will be a 1.3x1m hatch to the 2nd floor. The slab will fit, but there is nothing to support one end of it.

You can put a suitable channel(s) below or on top of the side slabs, and place/hang the central slab on it.

* * * In addition to the fact that there are questions about the load-bearing capacity of the side plates, which will additionally have to bear their own weight and the payloads of the central plate, there is another problem.

The central slab must not be cut to shorten, since destruction of the steel frame is likely to dramatically reduce the load-bearing capacity and integrity of the slab. The protruding end, if permissible, can be designed as a useful or decorative balcony.

KoshakBehemoth wrote: There will be a 1.3x1m hatch to the 2nd floor. The slab will fit, but there is nothing to support one end of it.

You can close up the space. Such technology exists. The reinforcement is bent trough-shaped so that the ends extend 15-20 cm from above onto the side slabs. The frame is welded and rests on this reinforcement, which, as often as possible, rests on the adjacent slabs. (30-40cm.). The weight from the monolith will be transferred to these slabs. Your distance is very large. A monolith with a volume of almost two cubes. I have never filled such distances with concrete. Maximum 60-80cm. You need to know the load-bearing capacity of the slabs and the weight of the monolith. Concrete can squeeze out reinforcement the size of a finger. If you just fill the space with expanded clay concrete... It is three times lighter than concrete. You can probably use foam concrete. Because of the frame, it will not fall to the bottom. Only one frame with reinforcement will weigh 300 kilograms.

Hyperborey wrote: The protruding end, if permissible, can be designed as a useful or decorative balcony.

It cannot be used as a useful balcony; the floor slab is not designed for this.

Behind Baikal he wrote: You can close up the space. Such technology exists. The reinforcement is bent trough-shaped so that the ends extend 15-20 cm from above onto the side slabs. The frame is welded and rests on this reinforcement, which, as often as possible, rests on the adjacent slabs. (30-40cm.). The weight from the monolith will be transferred to these slabs. Your distance is very large. A monolith with a volume of almost two cubes. I have never filled such distances with concrete. Maximum 60-80cm. You need to know the load-bearing capacity of the slabs and the weight of the monolith. Concrete can squeeze out reinforcement the size of a finger. If you just fill the space with expanded clay concrete... It is three times lighter than concrete. You can probably use foam concrete. Because of the frame, it will not fall to the bottom. Only one frame with reinforcement will weigh 300 kilograms.

What if you don’t load the slabs, but lean them on a column? All the same, there will be some kind of staircase, so the column will just fit into the interior. Of course, if it is a hatch from the first floor to the second. And please explain your phrase about squeezing out the reinforcement: where can it be squeezed out from?

MrGalaxy wrote: And please explain your phrase about squeezing out the reinforcement: where can it be squeezed out from?

The ends of the trough-shaped reinforcement-stand under the frame will rise. After all, it is 1.2 meters long and the formwork will not help if the space between the slabs is filled with concrete.

Are the boards already installed? Then it's too late to advise. According to the mind, it was necessary to strengthen the free side ends of the slabs (non-supported long sides) with an I-beam along the entire length, in this metal frame already weld a jumper under the hatch and fill the resulting space with reinforcement supported by an I-beam and pour it in. Or put a piece of the slab there. The iron structure would distribute all the loads.

NoNe wrote: Then it's too late to advise.

Why? A way out can always be found, especially in construction.

NoNe wrote: it was necessary to strengthen the free side ends of the slabs (non-supported long sides) with an I-beam along the entire length

It could have been so, but apparently construction is being carried out without a plan, by gravity.

Behind Baikal he wrote: You can close up the space. Such technology exists. The reinforcement is bent trough-shaped so that the ends extend 15-20 cm from above onto the side slabs. The frame is welded and rests on this reinforcement, which, as often as possible, rests on the adjacent slabs. (30-40cm.). The weight from the monolith will be transferred to these slabs. Your distance is very large. A monolith with a volume of almost two cubes. I have never filled such distances with concrete. Maximum 60-80cm. You need to know the load-bearing capacity of the slabs and the weight of the monolith. Concrete can squeeze out reinforcement the size of a finger. If you just fill the space with expanded clay concrete... It is three times lighter than concrete. You can probably use foam concrete. Because of the frame, it will not fall to the bottom. Only one frame with reinforcement will weigh 300 kilograms.

Where did the 2 cubes of the monolith come from? If you fill the entire thickness of the slab, I thought it was 1.3*3.6*0.22=

1.03 cu. The load-bearing capacity is indicated in the brand of slabs, 800 kg/m2. Are monolithic floors generally made from expanded clay concrete? Will it have enough compressive strength? What other options are there? The slabs have not yet been laid, but they need to be laid in the coming days.

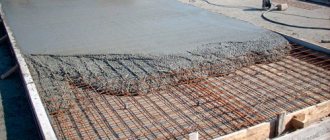

Making a reinforcement grid

Regardless of the size of the area, it must be reinforced between the floor slabs.

When the distance between the slabs is from 1.5 m, in addition to reinforcing bars, it is best to use reinforced mesh. If the distance is small, you can limit yourself to two layers of lattice made of rods.

The process of forming a reinforcement grid:

The reinforcement grid is laid 5 cm above the bottom of the formwork, the reinforcement is tied together with wire.

- The rods must be sawed off to a certain length, taking into account the step, which should be about 15-20 cm. Next, the prepared rods are tied together with wire. The result should be two layers of lattice.

- When installing the first layer, the reinforcing lattice must be laid 5 cm above the bottom of the formwork, for which the “glasses” are intended. After this, laying a mesh on top, lay the second layer of lattice.

- If the area between the floor slabs is not so large, reinforcement can be done with rods without mesh. In this case, the frame is formed in two layers, and each of them must be 5 cm away from the edge of the slab. It is worth noting that it is not necessary to use a welding machine in this process, since all connections can be made using metal wire.

Some people advise inserting reinforcing bars into pre-drilled holes in the slabs, but this should not be done. The monolith section will rest on the notches that are present on any floor slab model. They can be either longitudinal or round, resembling a glass.

Making and pouring concrete

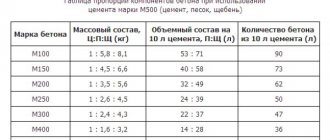

Table of proportions of components for the manufacture of concrete.

Before you start mixing the concrete solution, you need to prepare all the necessary components. Since the monolithic section looks like a rectangular parallelepiped, it will not be so difficult to calculate the required amount of solution in cubic meters.

After all the components are prepared, you can proceed to making the solution in a concrete mixer, following certain rules:

- adhere to loading standards;

- the concrete mixer must be installed on a perfectly horizontal surface;

- the solution must be unloaded into a special container, and after that - to the required place.

As for the last rule, it can only be broken if the concrete mixer is installed next to the formwork and the prepared solution is unloaded directly into it. Re-filling should be carried out no later than after 2-3 hours. You can make one fill, this is important if the area is not wide. After this, the surface needs to be leveled, for which a trowel or rule is used.

In addition, after pouring concrete into a container, it needs to be well pinned, and sometimes, if a fairly large area is being formed, vibrated.

Another important point is the drying mode of concrete. So, when it rains, the surface will need to be covered with polyethylene, and in the heat, on the contrary, moistened with water to avoid cracking.

As a rule, the formwork is removed after 3-4 weeks. If you follow all the above recommendations, the monolithic section will be reliable and durable.