In all premises, be it a residential apartment building or a one-story private house, except for one-story commercial cabins, it is necessary to waterproof the floor under the screed only so that dampness and moisture do not accumulate in the coating. This is especially true for private buildings without basements, since excess moisture can cause cracks in the concrete foundation. Waterproofing is divided into several types: coating, roll, dry mixture. The most important point is the integrity of the finished result; any coating is applied in one go. If you apply it over time, it won't do any good. Now let’s look at an example with an ordinary residential apartment building.

Waterproofing the floor in an apartment before screeding in the event of a force majeure situation will solve a whole bunch of headaches for you, and to install it you will not need to call a specialist and pay money for it. The materials for its manufacture are not that expensive, and to install it yourself you just need to know a few basic points and know the technology itself.

Waterproofing the floor before screed

Well, are you ready? Then let's go!

What is it for?

Why do you need waterproofing in an apartment?

- Many people probably know that waterproofing first of all helps to avoid water leaks when pouring screed, of course, if wet technology is used. Here it will retain excess moisture that will flow from the concrete and rush through various cracks and joints, through the ceilings to the neighbor, to the floor below.

- Whatever one may say, no one is safe from floods. In order not to spoil relations with neighbors on the lower floors, in rooms with high water intake (bathroom, bathroom and kitchen), first of all, after accepting the apartment, it is recommended to waterproof the floor. Since it will take some time for it to dry and the smell to disappear.

- And it will naturally be that the rooms located down the riser with excess humidity emit water vapor, which also has a detrimental effect on the concrete floors and foundation in your apartment. The same risk factor can be attributed to apartments above basements, in which the atmosphere is constantly humid. That is, the first floors.

Some people argue that waterproofing is only necessary in the bathroom or bathroom. But this opinion is wrong, since they probably simply forgot that heating pipes were laid throughout the apartment. Maybe you shouldn’t do this in the corridor, but also, anything can happen, as they say. It’s better to play it safe once again and spend an extra 200-300 rubles on the same corridor and seal it properly, so as not to spoil relations with neighbors and not pay for expensive repairs to their apartment, if something happens.

Features of floor waterproofing in a private house

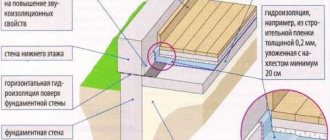

Most experts say that in this case, waterproofing under the floor screed and on top of it is mandatory. In general, the process of waterproofing a house before screeding looks like this:

- The first step is to create a so-called air cushion, which is made using materials of varying degrees of strength.

- Crushed stone is laid in a layer of at least 10 cm.

- Add sand to the required level on top of the crushed stone. This air cushion does not allow the process of capillary rise of moisture from the soil to the screed to occur, since the size of the air pockets remaining in the crushed stone is significantly higher than those necessary for moisture penetration.

- If there is a high groundwater level under the house, additional waterproofing is required before screeding the floor. For this purpose, a polyethylene film is often used, which is placed between a concrete screed and an air cushion. It will be an excellent barrier to moisture entering the room, while serving as the easiest to install and inexpensive solution. There are alternative options - more expensive and durable. These are mainly rolled materials that are produced using polymer components.

What is better to make it from?

After we have found out why floor waterproofing is needed, let's take a closer look at each type separately. Because you need to choose the type you need. And when choosing, you can save money and not overpay for unnecessary options.

Sand

Bulk waterproofing

If you do not live in an apartment but in a cottage and you did not have a basement included in the project, then it would be best to make a gravel bed and fill it with sand. Thanks to this layer cake, the rising bubbly vapors will seep out less from the soil. This method is considered the simplest and easiest to do independently.

Of the minuses, it is worth noting that such a layer will not completely stop moisture. For this reason, an additional layer of film should be used.

Rolled

Rolled waterproofing is ready for pouring screed

For rolled or pasted materials, as they are also called, it is not necessary to use roofing felt for waterproofing a concrete floor, as was done in ancient times. The market now offers many substitutes. They are divided only by thickness, width and composition. These criteria are selected for a specific application. After high-quality laying, they are a kind of membrane that can hold back a huge amount of water in case of leaks.

Among the advantages of these materials, it is worth noting their low cost and ease of use.

There is only one minus: if this type of material is used in a large room, then it will be necessary to carefully seal the joining seams.

The best materials for this role are isoplast, filizol, and hydroisol.

Important!

The use of conventional roofing felt is strictly not recommended. No matter what beautiful people say in colorful advertisements from a zombie box, no matter what new technologies they describe, its basis is still cardboard! Based on this, its service life is minimized several times and is no more than two years in rooms with high humidity.

A few words about the material:

Waterproofing the floor in an apartment with film

- In production, a special waterproofing polyethylene film is used.

- To avoid thermal deformation of the screed, it is necessary to walk along the edges with damper tape

- During installation, it is necessary to properly impregnate the slabs (if the base is monolithic or reinforced concrete) with waterproofing impregnation

- When joining, it is necessary to very thoroughly seal the seams. Craftsmen usually lay them with an overlap of 15-20 cm. Construction tape is perfect for this job

- To fully guarantee safety, roll materials are cut off in excess and overlaps are made on the walls along the entire perimeter of the room. After laying the finishing coating they will be hidden by the baseboard

Liquid materials

Waterproofing with bitumen

In rooms with high humidity, be it a bathroom, toilet or even a kitchen, insulation work must be carried out before pouring the screed. For this, bitumen materials or similar mastics are best suited. We recommend applying them in several layers with a regular floor brush.

An important point before using them is to thoroughly prepare the surface to be treated so that the debris collected with the brush does not form lumps and violate the integrity of the coating.

Liquid rubber-based mixtures do not require heating before use, unlike simple bitumen, which must be melted, but will not last long.

Polymer compositions containing polymer resins have proven themselves to be long-lived when used as insulation.

Waterproofing with liquid materials - finished floor

This type of insulation copes well with all the flaws left after construction work. This type is also called coating insulation. One of the advantages is that the degree of protection is the highest among similar materials. The downside is its cost, which is achieved by using “several layers”.

Among the proven new products on the market, we can offer you: water stop, aqua shield.

A few words about the materials:

- If waterproofing is carried out not in the house, but in a garage box, be sure to remove all stains from fuels and lubricants from the floor. Otherwise, the composition simply will not stick to the base.

- You need to select a primer based on the compatibility factor. Any one won't do. The protective layer will foam and break down over time.

- Liquid insulation is best applied in several layers. And the next one only after the previous one has completely dried. The direction of painting should be changed by 90° with each new layer

Dry plaster mixtures

Plaster floor waterproofing

In addition to the above, dry, ready-made mixtures are sometimes used to insulate a concrete base, which can simply be diluted with water. In this case, it is recommended to apply the mixtures in 2-3 layers, allowing them to dry completely. Also, do not forget that each layer must be uniform and solid.

It is recommended to apply about 1.5-2 kg of the mixture per square meter of room. But this type of waterproofing easily eliminates all the flaws of builders. The only negative point is that applying this coating will take a little longer due to the layering.

Waterproofing materials

The market for construction and finishing materials is vast and actively developing. In such an area as the formation of a hydraulic barrier, both old, time-tested and new unique developments of domestic or foreign production are used.

In residential construction, floor waterproofing is carried out using the following types of building and finishing materials:

Liquid formulations

This is a huge class of products, including a variety of bitumen-polymer, polymer-rubber, polymer and other compositions. Including:

- intermediate primers for floors based on synthetic elastomers (polyurethane, epoxy, acrylic). They are applied to the prepared base, in some cases sprinkled with quartz sand to create an “adhesive bridge”;

- mastics based on bitumen, bitumen-polymer or polymer compositions. These are classic and modified compositions that paint the screed in 1-2 layers;

- rubber-like polymer materials (liquid rubber, hybrid MS polymers). For floors, waterproofing from such compositions is practically not used, since their purpose is non-loaded surfaces. The exception is narrow-profile mixtures from Bostik (Aqua Blocker), Isonem (MS Polymer) and some others;

- impregnations on a polymer, organic or solvent basis with a water-repellent effect. These are special compounds that, after application, penetrate into the wood or mineral base, forming a waterproof barrier.

Insulating films

Made from polyethylene (HDPE or LDPE), polyvinyl chloride or polyolefin (TPO). For waterproofing under the screed, film products with a thickness of at least 150 microns are recommended. When installing, the canvas must be laid with an overlap, and the seams must be tightly glued or welded. You can get acquainted with the types of polyethylene films on the Izolux website.

Membranes and geomembranes

This is a modern class of materials made from dense polyethylene, PVC or EPDM rubber. The product can be standard or reinforced, and the surface may have slight embossing or special profiling. Depending on the manufacturer, after installation, the joints must be welded, glued or connected using special locks.

The products are flexible, characterized by a high-density and tensile structure, resistance to chemically aggressive liquids, sudden temperature changes and frost.

Roll materials

This category includes all bitumen or resin containing products. The basis of the finished product can be different:

- Cardboard (glassine, roofing felt);

- Polyester non-woven fabric – polyester, polypropylene (TechnoNIKOL self-adhesive waterproofing, Icopal Ultranap);

- Fiberglass (TechnoNIKOL Gidrostekloizol, KRZ Rubemast).

The waterproofing is self-adhesive.

Some of the materials may have an external mineral coating on one or both sides. They are fixed by fusing or gluing with subsequent sealing of seams and junctions.

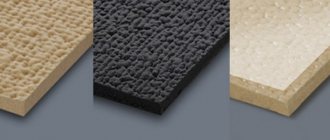

Dry mixes

There are two types of products in this group:

Rigid or semi-rigid coating mineral compositions made of cement, quartz sand, plasticizers and special chemically active additives (Ceresit CR 65, Sika-101A, Bergauf Hydrostop, Ivsil Vodostop).

Designed for the formation of waterproof coatings on non-deformable mineral substrates inside and outside buildings.

Penetrating waterproofing compounds of mineral type (Penetron, Isonem, Kalmatron, Gidrotex). These are complex mixtures with an interesting mode of action. After application, the product reacts with the base: polymer or organosilicon additives that penetrate deep into the concrete transform the metal oxides and salts contained in the concrete into more complex compounds - the so-called insoluble crystalline hydrates. A network of such crystals fills capillaries, microcracks, and multiple pores of the base. Due to the surface tension of water, such an obstacle becomes an insurmountable barrier to liquids of any type.

The first type of waterproofing mineral compositions is available in the range of almost all manufacturers of dry building mixtures. The latter are highly specialized products, preferable in cases where, in addition to the water barrier function, it is necessary to strengthen the concrete (in compression) and increase the degree of its frost resistance.

To summarize, we note that rigid coating, liquid and penetrating waterproofing are excellent for both apartments and private houses. But according to membrane manufacturers, it is film and roll materials that, when installed correctly, provide a 100% guarantee of the absolute water resistance of the structure.

Preparing the base

What to use to waterproof the floor in an apartment before screeding, I think you have already decided after reading about each method. Do not forget that insulation directly affects the safety of the future finishing coating. Now let's look in detail at how to prepare the base for its installation.

Preparing the concrete base for waterproofing

First of all, the concrete base, no matter what kind, should be thoroughly cleaned. And not by sweeping, but by washing specifically. Let's just say, scrub it off with a rag. This is not a joke and I am not forcing you to do anything unnecessary. This is required to fully familiarize yourself with the condition of the foundation in your apartment. With this procedure, it will be possible to detect all existing defects, such as cracks, poor-quality slab joints, etc.

If you find any defects or damage to the rough coating, they should all be completely eliminated. The material for this should be selected based on the specifics of the defect. Cement, gypsum putty or tile adhesive can easily help you with this.

Primer and impregnation of concrete base

Also, do not forget about the floor below your apartment, unless you live on the first one. There, lower down the riser, there is exactly the same room in which moisture will rise to the ceiling in the same way, and therefore, before applying waterproofing to the floor, it is recommended to apply impregnation to the base, which over time will not allow mold fungus to develop from excess moisture.

And to strengthen the adhesion of the waterproofing coating to the concrete base, it is recommended to apply a layer of primer. Some people think that this is not necessary, but we recommend that you take care of it, especially if coating waterproofing is used. The primer will kill all remaining dust and applying it with a brush will not be difficult.

Important!

If you are planning to move partitions or remodel, then it is recommended to do this first, since applying waterproofing to the floor is recommended as a solid coating, otherwise it will be of no use!

Preparatory work before laying waterproofing under the screed

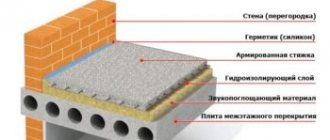

The base must be prepared before laying the waterproof layer. In the case of reinforced concrete floors, preliminary measures include cleaning from dirt and debris, sealing cracks and eliminating other significant defects, drying (except for the penetrating insulation option).

Preparing a wood subfloor can be quite complicated:

- First of all, it is necessary to ensure the reliability of the joist system - the supporting structure of the floor.

- The covering boards should not sag or move. If there are deficiencies, the wooden base is repaired or its individual elements are replaced.

- Experts recommend the option of laying cement particle boards on the subfloor, which ensure the rigidity of the base. The sheets are fixed with self-tapping screws, the joints are puttied with cement-sand mortar.

Waterproofing can be laid on the prepared base.

Let's consider the materials most often used to install a waterproof layer under the screed.

Prices for materials and labor

The price for waterproofing floors in apartments depends on the area of the premises. Because of this, we cannot give you an exact answer to this question. On average, this figure is 750-800 rubles/m2. There is nothing complicated here, you can easily save a tidy sum on carrying out this work and get away with just spending money on materials.

| Material | Price |

| p/e film | from 310 rubles (10 x 3m, 200 microns) |

| waterproofing membrane | from 365 RUR/m2 |

| lubricants | from 680 (25 kg) |

| impregnation | from 150r |

Waterproofing with screed

Floor waterproofing can also be done with liquid mastic material based on bitumen. As a rule, it is applied with a roller or brush, after first clearing the surface of dust and debris.

You can take regular bitumen and heat it to a liquid consistency, but such waterproofing is less durable and not convenient to use. It is still rational to use bitumen-rubber materials, which are more expensive, but durable and unpretentious in use.

A good alternative is bitumen-polymer waterproofing, since the synthetic resins from which it consists are capable of providing the material with the required durability. In addition, this insulation is not afraid of negative temperatures and can be used not only in the bathroom.

Conclusion

In order for the waterproofing of the floor in the apartment before the screed to last its intended service life, everything must be done correctly and according to the instructions. Its quality directly depends on the materials used. Laying is necessary in all rooms, without exception. Some people forget that heating pipes run in all rooms.

A thorough study of the base surface and determination of the permissible load will help determine the material for its manufacture.

Floor waterproofing: types of materials

With high-quality insulation, conflicts with neighbors from the lower floor are completely excluded, since in case of unforeseen situations, it will retain all the water!