Probably, not a single suburban area is complete without at least a small gazebo, since on summer evenings it becomes simply indispensable for relaxing in the fresh air. If the gazebo has not yet been built, but is only planned to be built, then the design begins with choosing a foundation for it.

DIY gazebo foundation

It is not so difficult to build a foundation for a gazebo with your own hands; the main thing is to choose the appropriate option, since there are several types of such a foundation for further construction. A gazebo is a lightweight house building, therefore, even if its lower part is made of brick, the foundation for it should not be made deep and with a complex structure. One person can easily handle this work, no matter what type of base is chosen.

In order for the structure to be erected to stand firmly, without deformation, it is necessary to take into account the characteristics of the soil layers and the depth of groundwater in the area allocated for construction. Clay soil is considered to be the most problematic for foundation construction, not without reason, since with a sharp drop in temperature, uneven swelling often occurs, which, of course, leads to deformation of the foundation. As a result of the skew of the base, walls and doors suffer, and if there is still glazing, then cracks may appear there too.

The most optimal soil for constructing a foundation for a gazebo is sandy and rocky. In such soils there is no need to make a deep pit - it is quite enough if the foundation lies only 500 ÷ 400 mm.

Types of foundations

There are several types of foundations, and any of them is quite suitable for a gazebo. They differ in their design and the amount of materials required for its construction. To know what they are, you need to take a closer look at each of them.

Columnar foundation

A columnar foundation consists of square or round pillars buried in the ground at a certain distance from each other - this step depends on the area of the future gazebo. The depth of the foundation is calculated taking into account the characteristics of the soil and the characteristics of the material from which the structure will be built. For example, wooden lightweight gazebos will simply not have a significant weight impact on the foundation, so it does not need to be made very massive.

A classic example of a small columnar foundation

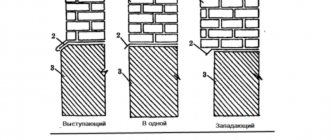

The foundation columns are cast from concrete using reinforcement, laid out from brick, or these materials are combined, that is, the underground part of the support is made monolithic from reinforced concrete, and the above-ground part is made in the form of brickwork.

You can install a wooden or brick gazebo structure on a columnar foundation, but for the latter you will have to additionally connect the pillars with a concrete belt. For concrete lining, you will have to make formwork from boards, but this task will be feasible for one master, especially if the size of the gazebo is not too large.

how to build a columnar foundation step by step by following the provided link to the corresponding page of our portal.

And here read how to make formwork for the foundation, because... it will be useful for creating a high-quality foundation for a gazebo.

Strip foundation

The strip foundation version is more complex in its design and will require significantly more labor for its construction and financial resources for purchasing materials. This base is perfect for building a gazebo from any material - both wood and brick. If you plan to build the lower part of the walls from stone or brick, then it is better to choose this type of foundation, since the ready-made necessary concrete belt will already be included in the structure of the gazebo.

Strip foundation for gazebo

To create a strip foundation, a trench is dug - its average depth should be about 500 mm. The trench is framed by formwork, into which a reinforcement structure made of metal rods will be installed. Then concrete is poured, and after the belt has hardened (after about a month), the walls of the gazebo are laid on it from brick or stone (or another, lighter structure is built).

How to carry out work on arranging a strip foundation in accordance with all the rules, and what materials are required for this, can be found in the corresponding article on the portal by clicking on the link.

In addition, be sure to read about foundation waterproofing and why it is done.

Monolithic foundation

A monolithic foundation is mainly used for “solid”, massive buildings, since it is designed for a large load. However, we must not forget that there are two types of such foundations - deep and shallow. Just the second option is perfect for installing a gazebo, that is. A concrete platform will be equipped, on which it will be possible to install a light wooden or brick structure without any problems. Moreover, in the future building the foundation for installing any type of floor is already ready!

Monolithic foundation - the future building already has a ready-made base for the floor

The work of installing a monolithic platform is quite labor-intensive, and it is better to carry it out with assistants. This is especially true for the stage of manufacturing and pouring concrete into the formwork, since it is recommended to carry out this process in one approach.

This type of foundation can be called universal, because it is suitable for construction on any type of soil. Due to the fact that the monolithic slab has a large supporting area, the load on the soil is reduced and the risk of deformation of the structure during soil subsidence is reduced. This ensures reliability for the building that will be erected on it.

In order for the monolithic foundation to firmly withstand the loads that will be created by the building placed on it, it is recommended to reinforce it, even if it is intended for the installation of a light gazebo.

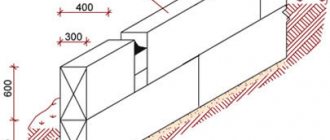

To install a gazebo, 250 ÷ 300 mm in thickness of a reinforced monolithic slab is sufficient, which will be buried 150 ÷ 200 mm into the ground, and, therefore, rise above the surface by 100 ÷ 120 mm.

It is advisable to build a gazebo on a slightly elevated area so that during rain, water does not actively absorb into the soil around the foundation slab and does not wash away the bedding layers. Better yet, make an additional drainage area of crushed stone along the entire perimeter of the foundation.

Work on the construction of a monolithic foundation

The process of arranging any foundation begins with marking and tracing the area allocated for it. For this purpose, a thin rope, a square for drawing out even angles are used, and if the foundation is round, then an improvised compass, as well as wooden pegs or pieces of reinforcement. These elements are installed along the perimeter of the marked area. And, of course, you will need measuring instruments, such as a tape measure and a folding meter.

Marking and tracing of future construction

- Marking a rectangular foundation begins with determining the location of the first corner and installing a starting peg in it. At the same time, the future object is tied to the stationary points indicated on the site plan.

- Focusing on this starting point, the remaining corners of the foundation are marked and measured. The evenness of a rectangle is determined by measuring its diagonals - their lengths must match exactly.

Foundation for a light gazebo: reeds, polycarbonate or PVC

You can use absolutely any materials, even ordinary oilcloth, which can be installed on the roof as protection from moisture. Here we mean all structures whose weight is extremely light and without wall panels: only supports and a lightweight version of the roof. Many will say that such gazebos can be made without a foundation. Theoretically, this is true, you can try, but if there is an error or shrinkage of one of the supports, you will have to redo the entire frame. It's long, expensive and unnecessary.

To do everything once and for a long time, now we will look at how to make a foundation for a gazebo made of lightweight materials. We chose the cheapest and simplest solution to the problem, but it can always be upgraded!

STEP 1: make markings on the ground . We draw the approximate dimensions of the structure and mark the places where the supports will stand in the future.

STEP 2: deepen the holes. In the marked places, using an earth drill 30-40 in diameter, we make indentations of 50-60 centimeters. Depending on the looseness of the earth, you can make 40 and 70 centimeters (clay/sand).

STEP 3: compact the landing site . It was possible to make a columnar foundation for the gazebo, but for the lightweight version this is a lot. It will be enough to make a “cushion” of concrete at the bottom of the drilled hole. Some even use slag of different fractions. If you fill it up and spill it with water, after a while it will become compacted. First, large slag is added, then fine slag.

STEP 4: installing supports . Wooden posts (or a metal profile) are installed directly on a concrete “tablet”, which is poured below. They are leveled and left for several days.

After some time, when the concrete below has hardened, you can fill everything with earth. The foundation for the gazebo made of lightweight materials is already ready, construction can continue. Important: it is advisable for the supports to stand for 24 days until the concrete has completely hardened. Then the risk of displacement will be minimal.

Polycarbonate - types and features of the material

What is it, release form

Polycarbonate is a type of plastic made from polyesters. Thanks to the peculiarities of the production technology of this material, it is flexible and lightweight, which greatly simplifies installation work and allows you to create complex structures.

Polycarbonate veranda attached to the house.

Most often, polycarbonate is used to cover canopies over the entrance to the house, awnings over car parks, and for the construction of greenhouses. It is also perfect for building gazebos. Moreover, the material is used not only as a roofing covering, but also for the construction of enclosing structures.

Visually, polycarbonate, in its transparency, resembles glass, but its characteristics differ significantly from the latter in an advantageous direction. First of all, this is clearly high strength at a much lower density, and therefore the massiveness of the fence. Polycarbonate can withstand a blow from a stone falling from a height or thrown from a short distance - in similar situations, glass will simply shatter into pieces or, at least, crack. Buildings made from polycarbonate sheets can withstand squally winds, as well as thick snow layers - it all depends only on the strength of the structure’s frame.

As a rule, metal structures are used as a frame for polycarbonate. However, in the construction of gazebos, wood has recently been increasingly used, and brick or hollow blocks are used as a base.

Gazebos made of this material can have different dimensions and represent a great variety of design solutions. However, they always fit perfectly into the landscape design, without overloading the appearance of the site, but as if “dissolving” in it.

There are two types of polycarbonate, differing in their structure. But both varieties can be used in the construction of gazebos.

Cellular polycarbonate - so named because of the pronounced cellular hollow structure of the sheets.

Cellular polycarbonate is the most popular option, as it has the greatest flexibility and affordable cost. Sheets of this type consist of two or three horizontal layers connected by vertical ribs. They impart rigidity to the structure without interfering with the light transmission of the material. For installation on the roof and walls of the gazebo, cellular polycarbonate with a thickness of at least 8 mm is suitable.

Cellular polycarbonate is divided into primary and secondary, depending on the raw materials used for its manufacture. For installation on a gazebo, it is recommended to use only primary type material, otherwise exposure to temperatures and ultraviolet radiation will make it fragile and short-lived.

The standard dimensions of a cellular polycarbonate sheet are 2100×6000 mm, but many companies involved in the sale of this material also practice cutting into more “down-to-earth” dimensions, including according to customer drawings.

Monolithic version of polycarbonate - very similar to conventional glass

Monolithic polycarbonate sheets are more like glass and look much more impressive than honeycomb material. At the same time, as already mentioned, they differ from quartz glass in their strength and lighter weight.

We recommend: Do-it-yourself fence for your dacha - cheap and high quality

Monolithic polycarbonate is produced in solid and perforated versions, colored or transparent. The cost of the “monolith” is significantly higher than the price of cellular sheets. For the construction of gazebos, sheets of monolithic polycarbonate with a thickness of at least 4 mm are used, but it is better to choose the six-millimeter version.

The standard size of a monolithic polycarbonate sheet is 2050×3050 mm.

Advantages and disadvantages of polycarbonate

Polycarbonate gazebos look light and airy, however, they have a fairly reliable and solid design. This applies not only to the frame, the strength of which depends on its correct installation and the selected material, but also to the characteristics of its cladding.

Despite the apparent “airiness”, such a gazebo is a very durable structure, designed for long-term use.

So, polycarbonate, made from primary raw materials, has the following positive qualities :

High strength characteristics. Polycarbonate does not deform under high loads, even in winter under a thick layer of snow, as well as under the influence of strong winds. Resistance to high and low temperatures. The material does not become brittle in severe frosts and does not melt under the influence of sunlight in summer. Light transmission. Polycarbonate perfectly transmits light, but at the same time prevents the penetration of ultraviolet rays into the space under the roof. Water resistance of polycarbonate. Polycarbonate is completely waterproof. Well, if the joining of individual sheets of material is done properly, then the seams between them will not let water through. The material is inert to biological influences - it never becomes a breeding ground for mold or mildew, and is not susceptible to putrefactive processes. Fire safety. Polycarbonate is classified as a highly flammable and self-extinguishing material. It does not release toxic substances into the environment even when ignited. Thermal insulation abilities. This applies to a greater extent to the cellular variety of polycarbonate. Due to its cellular air-filled structure, it is able to retain accumulated heat, for example, in a greenhouse. The flexibility of the material allows it to be used to create gazebos and canopies of various shapes. Easy to install. The low weight of polycarbonate allows you to create structures from it that do not require massive foundations and reinforced frames. In addition, you can even make a “mobile” gazebo from it, which can be moved to any convenient place at any time. Durability of polycarbonate - its service life is estimated at 10–15 years without the need for repairs. Material safety. If glass can break when hit or dropped, then polycarbonate will only crack. In any case, it will not produce sharp cutting fragments.

However, polycarbonate also has a number of disadvantages that you should be aware of when purchasing it to create a particular design:

Cellular polycarbonate, made from recycled materials, is not resistant to ultraviolet rays, so it is recommended to purchase high-quality material that has a special protective coating applied using co-extrusion technology.

High-quality polycarbonate with a protective coating is able to reflect ultraviolet rays and significantly inhibit the penetration of “hot” infrared rays, transmitting mainly only the visible part of the spectrum.

If the protective layer in any area is damaged, the entire polycarbonate sheet may be damaged by UV radiation (the appearance of brittleness, the formation of a network of cracks, etc.). Damaged material cannot be repaired; the sheet will have to be replaced.

If you purchase cheap sheets of low quality, you cannot expect durability from them. The only way to somehow extend its service life is to install the gazebo exclusively in the dense shade of trees.

During installation work, the surface of the sheets can be accidentally scratched. This affects not only the appearance, but also the integrity of the protective coating, the importance of which was just mentioned. Therefore, work must be done very carefully.

Based on the totality of characteristics, it is clear that the advantages of polycarbonate significantly outweigh its disadvantages.

Foundation for a “medium-heavy” gazebo: metal or wood

This option is already intended for those who decided to do everything more thoroughly - from metal. This means not only metal supports, but also a roof made of corrugated sheets or even bitumen. Here, the depth of the foundation for the gazebo remains basically the same: from 50 to 70 centimeters. A lot depends on the soil, because if the clay is shallow, you can do 50 centimeters. If the soil is sandy, then you can go deeper up to 70 centimeters. The difference is in the massiveness of the concrete part. Let's take a closer look at how to make a foundation for a gazebo of this type.

STEP 1: marking and drawing of the installation location of the supports . Everything is similar to the first option; you need to decide where the pillars of the structure will be.

STEP 2: drill the ground for the supports . It is advisable to take a drill with a diameter of 45 cm so that the concrete mass has more weight and volume. We go deeper approximately 50 cm.

STEP 3: installing posts . Here we will have profiled pipes of approximately 80x80 mm under a roof of considerable weight. Pour 10-20 liters of solution, install a support, and level it a little. Add the solution completely level with the ground.

STEP 4: Finish leveling . So that the gazebo was level and the construction did not go wrong, you need to use a level and guy wires. We level everything, secure it with a stretcher, and leave it for several days.

After several days of concrete hardening, the guy wires can be safely removed. Let it sit for another 2-3 weeks until it is completely strengthened - the foundation of a wooden or metal gazebo is ready. This option is suitable for most structures, except for brick buildings. A slightly different type of work is provided for them, now we will look at it!

Types of gazebos

Classifying gazebos in your home according to any parameters does not make sense, because in our time the variety in construction has reached unprecedented proportions. This is caused not only by the imagination of modern masters, but also by the abundance of materials. Combinations of plastic, concrete, wood, metal and brick are just the tip of the iceberg. In particular, plastic can help you inexpensively, but very beautifully decorate both the interior and exterior of your building, regardless of its design.

After reading the guide on how to make a hexagonal gazebo with your own hands, you have all the necessary knowledge to build any shape or design. All you need to do is apply this knowledge in practice

If you wish, you can build a closed gazebo. To do this, you will need additional means - insulation, windows and a door. Also, the floor in such a gazebo can be made of ceramic. And inside, a fireplace or barbecue with a hood built into the wall will add coziness.

Such a gazebo can easily turn into a summer kitchen, if you have the necessary household appliances. In this case, a portable gas cylinder will not be superfluous; it can be connected to both the barbecue and the burner.

All of the above applies to rectangular or square gazebos. Shapes can be with many angles or round. It all depends only on your imagination. Also, for a quadrangular shape you will need additional supports, one in the middle of each side.

A gable roof for such gazebos is made in the same way as a multi-pitched roof, only with different shapes. Rafter structures are made in the shape of the letter “A”.

Interestingly, quadrangular gazebos accommodate fewer people than rounded versions.

In addition to experimenting with shape, you can try different types of wall cladding or roofing for a building. You can make the roof semicircular and use polycarbonate or corrugated sheeting. It will look very original.

Don't forget about additional exterior elements. They may include a barbecue, street benches, tables, hanging flowers and anything else that comes to your mind. When building, keep in mind the main thing, the purpose of the gazebo is to provide you with the most comfortable stay possible.

Foundation for a brick gazebo with barbecue or barbecue

This is the most difficult option. Some brick gazebos are not inferior in weight to an ordinary garage or even a small private house. That is why we will make a strip foundation for the gazebo. It will distribute the load and support significant weight, preventing cracking of the walls.

It is advisable to build a separate foundation for the barbecue in the gazebo, since its weight is significant. The trench must be deepened 1/3 more than during the construction of the gazebo itself. Let's take a closer look at the process in step-by-step instructions:

STEP 1: thoroughly clear the space for the gazebo . We mark the area along the thread, add soil in the right places.

STEP 2: dig a deep trench . The width of the trench can be the width of a shovel, but it cannot be made less than 25 centimeters. The recommended foundation depth is 60-70 centimeters if the structure has brick walls.

STEP 3: partial filling of the trench . To save mortar, you can place bricks, granite rubble or remains of blocks in the trench - all this is quite suitable.

Choosing a site for a concrete gazebo

A concrete gazebo for a garden belongs to small architectural forms (SAF) and most often represents a rotunda - a round building with a dome. However, it can be an open gazebo on a hill, a “stone” cave, or even a glass pavilion with a fireplace.

Before you start making a cement gazebo, you need to choose the right location for it. It is usually installed in a quiet, secluded corner of the garden, surrounded by greenery and flowers. The ideal place for it is where the building will be protected from the wind and sun by nearby trees. In this case, it is worthwhile to provide in advance a space nearby for planting low shrubs and climbing plants.

For construction, you should select a flat area, otherwise you will have to build a retaining wall. The soil underneath must be dense so that the concrete structure stands stable and secure.

Stages of building a garden gazebo

No matter how small a cement building may be, it weighs a lot, so work must begin with the construction of the foundation.

Laying a strong foundation

The foundation for a cement gazebo will have to be made in the form of a shallowly buried strip or a monolithic slab of reinforced concrete. Only these two options are able to withstand the weight of the structure being built. In the first case, it will be necessary to additionally lay a wooden floor, and in the second, it is enough to cover the slab with frost-resistant tiles or stone.

For a shallow tape base:

- A trench is dug along the perimeter of the MAF, 30–40 cm deep and 30–35 cm wide.

- A 10 cm sand cushion is compacted at its bottom.

- Sheets of roofing material are laid out on top of the sand.

- Reinforcement made of steel rods with a cross section of 6–8 mm is laid in two horizontal rows connected by vertical rods.

- Using boards and bars, the formwork is prepared so that the future foundation rises 15–20 cm above the ground.

- Vertical rods are installed in the corners and under the columns to connect the base to the walls.

- Everything is filled with a solution of M300 cement and sand in a ratio of 1:3.

The monolithic foundation is done in the same way, only it is not a trench that is dug, but a shallow pit 10–15 cm in size on each side larger than the pavilion being built. The reinforcement in it is laid over the entire area along the perimeter and with an intersection in the middle.

Construction of walls and roof

Filling vertical flat walls is done in the same way as a strip foundation. Formwork of the required height is formed, reinforcement is placed there and everything is filled with concrete. Due to the large weight of the resulting structure, most often the walls made of concrete mortar for a garden pavilion are made low - at waist level. And above there is open space or a wooden or forged lattice is installed.

For the columns, a frame is erected from parallel vertically installed reinforcement rods, which are wrapped in sheets of galvanized steel as formwork. There should be an equal distance from the edges to the steel elements and from them to the center of the future pillar. Only in this way will the bearing capacity of the columns be sufficient to withstand the weight of the roof.

A more complex version of a cement mortar gazebo is to create figured walls or statues supporting a canopy. In this case, you must first make a reinforcing frame from a chain-link mesh. Here it is enough to give free rein to your imagination and a truly unique masterpiece will appear in your garden plot.

After installing the frame in place, a thick solution of cement and sand (1:3) is prepared and gradually applied to the reinforcement structure. Further, without allowing complete setting, the intended shapes are formed from it. You can imitate tree trunks, boulders or intricate interweaving of roots.

Unlike columns, where you will still need to make a roof from corrugated sheets, when creating a reinforcing frame for a shaped gazebo, you can immediately provide a concrete roof vault.

Peculiarities

Polycarbonate is a modern material for construction, including gazebos. This is a lightweight, soft and flexible material that allows you to create structures of unusual shape, simplifies and reduces costs for transporting the material and its installation.

Polycarbonate is a type of plastic based on polyesters. Features of the composition and production ensure the lightness and plasticity of the material, as well as its good thermal insulation qualities.

Visually, the material is similar to glass (transparent, attractive), but it is much lighter and stronger. The polycarbonate sheet can withstand being hit by a stone thrown at close range. Objects made from it will withstand even strong winds and under a layer of snow. As a rule, polycarbonate is combined with a metal frame . Among modern projects, you can increasingly see wood, hollow stone and brick as a base . This gazebo can have different dimensions and designs.

A special feature of the material is its light transmittance, so the gazebos do not visually clutter the area, but seem to dissolve in it.