There is still no clear answer to the questions of whether it is possible to pour a foundation in the rain, how justified this is and whether, in this case, the maximum quality of the frozen monolith will be achieved. The foundation is usually a multi-layer “pie” consisting of building materials with dissimilar characteristics, which manifest themselves differently in the presence of excess moisture. Therefore, one of the main factors for the long service life of an underground structure is careful adherence to the sequence of laying the base, or cushion, consisting of several layers, each of which can have its own technology. When carrying out work, you will need to take into account weather conditions, which is important.

Is it worth starting work if it's raining?

The reliability of the structure does not depend on rain, unless precipitation in summer is excessive.

When construction time is limited, and weather forecasters report showers and thunderstorms, take the following safety measures for the finished structure in the event of precipitation:

- During rain, cover the finished foundation and the container with the mortar with waterproofing material (film) in two layers to protect it from water ingress and the possibility of washing out the uncured mortar;

- Choose only high grade cement (not lower than 400);

- Eliminate voids in finished masonry using vibration equipment.

Choosing the time of year for concreting

The foundation can be poured in spring, summer and autumn. Each period has its own characteristics.

Concreting in summer

It is generally accepted that the optimal period for pouring a foundation is summer. However, in the heat, concrete dries out quite quickly, which negatively affects its quality. Rapid evaporation of moisture leads to the appearance of voids, which make the material fragile and the future structure unstable. To fill the foundation in the summer, it is advisable to adhere to the following conditions:

- the temperature during the day and night should not exceed +15-25 °C throughout the entire period of concrete hardening;

- air humidity no more than 80%;

- in hot weather, you need to care for the concrete by watering, which will prevent the formation of cracks.

The described conditions for pouring the foundation are typical for the beginning of June (depending on the region). During this period, the temperature is not too high and the humidity is most suitable. In July and August, daytime temperatures rise significantly and nights can be quite chilly. If there is a choice between these two months, then you should give preference to August.

It should also be taken into account that the maximum strength of concrete is achieved when moisture is removed from it for a long time. The solution hardens for about a month, during which the water disappears.

If work is carried out in the rain, then theoretically excess water should be drained through the crushed stone into the ground without reducing the quality of the concrete.

Spring pouring of the foundation

In spring, you can also pour the foundation, taking into account the average temperature and high humidity.

However, you will have to provide for a number of points:

- It is necessary to add anti-frost additives to the pouring mixture, since in the spring the weather takes a long time to settle and night frosts are possible, which means the foundation may suffer.

- When pouring the foundation in the spring, it is important to remember that you cannot start building a house on a fresh foundation. It must settle and undergo mandatory shrinkage.

How does rain affect concrete?

Water is a component of the finished mixture, giving concrete plasticity and stability during subsequent hardening. A slight increase in the percentage of moisture will not damage the laid mixture and will not affect the quality of the foundation.

Water is not an independent material and must be mixed well in the overall composition. A sharp increase in humidity in the form of strong jets and flows of moisture can erode the top layer and reduce the strength and appearance of the structure.

A moderate amount of moisture will contribute to a more durable hardening of the concrete, but if the flow of precipitation has increased, measures must be taken to cover the top layer of the uncured mass of concrete.

Weather for obtaining good quality concrete

The durability of concrete structures is determined by the experience of the craftsman pouring the concrete.

However, an important factor determining their service life is the weather conditions during the procedure. If you adhere to the technology, then concrete should be poured in dry, warm and stable weather, which is recommended by many experts in this field. If we delve a little deeper into the physics of the concreting process, it is worth noting that cement hardening upon contact with liquid occurs at an ambient temperature of +20°C. The strength of cement increases faster at an air humidity of 80%.

Therefore, light rain is even recommended during concreting. As a result, the concrete solution will set better and harden more efficiently. This will have a positive effect on the strength of the structure being built.

Effect of rain on concrete quality

Although additional moisture is beneficial to concrete, there is one caveat - too much water can lead to damage during hardening. Depending on the abundance of precipitation, partial washout of the mixture may occur, followed by exposure of the reinforcing elements. The concrete surface can be damaged by rain if the adhesion processes of the concrete composition have not been completed.

What to do if it's already raining

If bad weather began during the work process, then more attention should be paid to covering the mortar and foundation, as well as monitoring the quality of the placed mass during the laying process.

Severe erosion can create undesirable consequences in the form of:

- Cracking and destruction of the surface of the finished layer;

- Failure to fill corners and transitions;

- The appearance of bubbles inside the mixture being poured.

In heavy rain, stop the work and try to reliably cover the already poured foundation.

Pouring concrete in the fall: what you need to know and how to do it correctly?

The construction of concrete structures in the autumn has its advantages and disadvantages. If you organize the pouring process correctly, you can get high-strength, high-quality concrete.

Water-cement ratio W/C

For the chemical reaction of cement stone formation (hydration), 1/3 of the mass of cement is enough water. However, such a solution has zero mobility, plasticity, layability, air cannot escape from the mixture even when compacted with a vibrator. Therefore, in concrete, an obviously excessive amount of water is used, which is necessary to prepare a plastic mixture.

When temperatures are positive in the fall , concrete can be mixed on site, significantly reducing the construction budget. An individual developer should consider:

- the higher the water-cement ratio (maximum 0.8), the faster the structure will gain strength

- W/C can be reduced only by increasing the grade of cement, which is more expensive

- The foundation can in the fall only if the technology is strictly followed (from mixing to stripping)

- compaction with a deep vibrator is a prerequisite, since the solution has minimal plasticity even with the addition of a Superplasticizer

What grades of concrete are best to use?

The quality of the solution used has an important impact on the strength of the foundation.

When pouring in wet weather, pay attention to the brand of cement. The unifying component is taken at least 400 (M400, 500, 600). Their high cost is justified by the ability to carry out work close to water due to increased moisture resistance and the ability of the mixed solution to harden quickly.

Weather conditions for high-quality concreting

It is necessary to realize that the durability of the structure directly depends on the experience and qualifications of the craftsman who carries out the concreting. One of the main factors affecting service life is meteorological conditions during concrete pouring.

According to technology, the foundation should be poured in dry, warm and stable weather. And many experts in the field of construction insist on this opinion. But it is not so.

Delving into the physics of this process, it is important to note that the primary connecting link of the concrete mixture, cement, hardens when combined with water, but at an air temperature of about 20 ° C.

The photo shows a monolithic foundation poured in summer weather

Important! Cement is a hydraulic binder and gains strength faster at 80% air humidity. Therefore, it is even recommended to pour concrete in light rain or humid, cool weather; the concrete will set and harden better. This will certainly affect the strength of the structure under construction.

The most optimal time of year with favorable wet conditions for pouring concrete is autumn. But in autumn there is a risk of frost. In this case, the temperature regime during concrete hardening is disrupted.

Due to the temperature difference, stresses arise in the unhardened body itself, which subsequently cause cracks. To avoid this situation, you can use antifreeze additives.

They give the necessary strength to concrete. It would also be a good idea to “wrap” the freshly poured formwork with construction felt and film.

Preparing a solution with less water

In rainy weather, less water will be required to mix the solution.

Consider the important nuances of the work before you start building the foundation:

- Equip a covered canopy that protects against moisture getting into the container with the prepared solution;

- At the beginning of work, pour out one part of the cement;

- Mix with 2 parts sand;

- All components are combined with water in the ratio of one part water and half the binder;

- The mixture is fixed using 4 parts gravel.

Compliance with the composition in proportion allows you to obtain strong and reliable concrete even when mixed in wet weather.

The foundation will be poured with savings in cement due to lower consumption of the main components for preparing the mixture. The resulting structure will be resistant to temperature changes and the formation of cracks, adhere better to the reinforcement base and have a reduced risk of shrinkage.

Is it possible to pour a foundation in the rain?

The decision on whether it is possible to concrete in the rain is made by the owner of the site himself. If work is carried out correctly in the summer, this will not have any consequences. But at the end of autumn, on the eve of severe frosts, it is better not to do concreting: water that does not have time to react to hydrate the mixture inside the monolith will lead to the appearance of microcracks and reduce the strength of the casting.

Working conditions in the rain

If the process has already begun and it starts to rain, work can not be interrupted. It is enough to cover the concrete that has not had time to set from strong flows of water during rainfall. If urgent work is required, but there are prolonged rains, a polyethylene canopy is made over the construction site.

More information about the liquid component of the composition

Water is an integral part of concrete, so it does not pose a significant danger to structures made from it. However, if it is in excess, the number of air bubbles in the inner part may increase, which leads to a weakening of the load-bearing capacity.

To enter into a chemical reaction with cement, it is enough to add water in an amount of 25% of its mass, but to fully prepare the working mixture, from 40 to 70% is required. With such a dosage of liquid, the solution acquires the necessary plasticity.

The formation of air pores is the result of the evaporation of excess water that has not reacted with the binder during the hardening process of concrete.

Although there is a risk of reduced load-bearing capacity, it is still possible to pour a foundation in inclement weather, especially if the rain is not very heavy, and certain precautions were taken during laying.

Effect of humidity and temperature on hardening

The strength gain of the poured mixture largely depends on the temperature and humidity conditions. In rainy weather, there is no need for additional care, since the concrete is not exposed to sunlight and maintains a high level of humidity. As a result, water does not evaporate from the surface of the molded structure. After watching the video, you will learn how else to protect concrete from water.

A different situation occurs in hot weather. The solution dries unevenly, which can cause cracks and more serious defects to appear. In this regard, constant care is necessary. The surface of the foundation is regularly moistened with water and covered with burlap.

The full strength gain of concrete occurs within 28 days, but the initial reserve is 5-7 days. It is during this period that optimal temperature and humidity conditions must be maintained.

What damage can rain cause to concrete?

The main damage from flowing jets is caused to the above-ground part, if it has not yet frozen. Part of the mixture may be washed out of the formwork, and large fractions will not bind into a monolith. Because of this, the surface of the foundation also suffers, but it is still recommended to level it horizontally before construction.

The main danger is the high water content in the monolith when it freezes. This often leads to the destruction of the foundation, so the finished above-ground plinth is protected with a finishing layer, a blind area is made and reinforced concrete rain gutters are installed, and rainwater inlets are attached to the roof.

How to deal with the cold

At the same time, you can carry out concrete work in winter, if you know how to pour concrete in cold weather. The main thing is to follow certain rules, and the filling will turn out no worse than on the most favorable days. The first condition is to correctly deliver good, correct concrete. Experienced builders advise not to be greedy and use a concrete pump. The second is caring for already poured concrete. At a minimum, when pouring it, it is necessary to add frost-resistant additives and take care of the formwork with insulation. In the future, we can recommend heating the concrete area. If you try hard enough, you won't care at what temperature you can pour concrete. You can always!

At what temperature can concrete be poured and should work be stopped in winter?

The most favorable time for constructing a load-bearing structure is considered to be the period from April to November. However, the situation may turn out to be such that filling will need to be done in winter, because in some regions of Russia there is practically no summer. Modern construction technologies make it possible to create durable foundations even in cold weather.

Building a foundation in winter is especially important on shaky soils. After waiting for them to freeze, you can dig an excellent pit. In addition, you can save a certain amount on purchasing building materials out of season. Most often in winter, strip foundations are erected using concrete blocks and structures made of concrete piles intended for light wooden objects.

When planning winter work, it is worth remembering that ordinary concrete is not suitable for it. In cold weather, it is permissible to use only cement with special additives and modifying additives. The latter reduce water consumption by about 10–15%. When air humidity is 60% or higher, it is not recommended to use modifiers; moreover, it is worth remembering that they can react with some metals.

- thermal guns;

- special heating wire laid when pouring concrete;

- electrodes (reinforcing bars) to which voltage is applied.

There is also a method of heating the concrete mixture using a welding machine, but it essentially boils down to the use of electrodes and is applicable only for small volumes of pouring.

Only water and fillers are allowed to be heated, but not cement, otherwise it will lose its qualities.

For winter work, concrete with special additives is required.

Typically, in regions of the Russian Federation, a solution with a temperature above 21 ºC is not used, taking into account the fact that 4.5–5 ºC will be released into the atmosphere. Therefore, for the working composition, the liquid is heated to 32 ºC. Hotter water is first mixed with fillers, and then portionwise with cement.

Whether it is possible to pour a foundation in cold weather without heating should be discussed separately. Even temperature fluctuations from 5 to 0 °C for concrete mortar are considered winter. During the cold season, when concreting, it is important to ensure smooth hardening of the solution by at least 60%. This guarantees the preservation of the structure of the base and its ripening when the thaw arrives.

However, the foundation will gain strength only when the temperature of the solution is above zero, so without artificial heating, you need to choose a fine winter day for construction work. The composition of the cement is also important: the so-called cold concrete contains antifreeze additives that lower the freezing point of water.

The likelihood of pouring a foundation in winter will raise doubts among most developers, and they are justified. Everyone knows that water, one of the main components of concrete, tends to freeze at low temperatures.

If you mix and leave the concrete mixture at subzero temperatures, the result will be a brittle material in which frozen water crystals will break all connections

Modern construction technologies have made it possible to avoid this result. Now you can produce high-quality concrete and use it at temperatures down to minus fifteen degrees. For high-speed construction, different methods are used, which are worth talking about in more detail.

The concrete mixture gains most of its strength in the first 48 hours. At this time, it is especially important to protect the solution from freezing. You can place construction heat guns around the perimeter of the foundation and heat the air until the mixture hardens.

The larger the heated area, the larger and more powerful the guns should be

Pouring the foundation without warming up in winter is impossible. It can be provided by electric current supplied directly to the reinforcing metal mesh. In this way, the concrete itself is heated in its thickness, which is more efficient than heating the entire building area.

Three hundred eighty volts connected to the reinforcement grid will create the temperature necessary for the normal formation of the concrete mixture

To fill the foundation in spring, autumn or winter, you can use special additives that act on the water in concrete, preventing it from turning into ice crystals. A concrete mixture with such additives is called “cold”.

Salt compounds are added in strict proportions.

Why is there such a need to pour the foundation for a house in winter? Is it possible to start construction in the fall and why make such difficulties for yourself?

There are several good reasons that push developers to take such risks:

- The fragile soil on the site does not allow making a high-quality pit for filling; the earth is constantly crumbling. In a frozen state, everything becomes much simpler;

- construction is carried out in the northern region, where it is difficult to wait for the required temperature, and the thaw periods are so short that it is impossible to meet the required deadlines;

- cheaper construction. From autumn to mid-spring, prices for building materials and construction services fall;

- seasonality of the developer's work schedule. For some professions, employment is seasonal, and it is from autumn to spring that some people have free time to engage in construction.

The foundation poured in winter needs to be additionally insulated.

But every coin has two sides. And good reasons can lead to unpleasant consequences:

- Instead of saving, winter pouring of the foundation can result in additional costs. The task of digging a pit in frozen ground is impossible without special equipment, as is the kneading procedure in the cold;

- discounted concrete in winter may not contain the necessary additives. When buying a ready-made solution, you should make sure of its “winter” quality;

- Workers' work in the cold season must be paid additionally due to harsh weather conditions.

Everyone decides for himself whether it is possible or not to pour the foundation in the fall. At what temperature will the work be successful? Professionals say that even at minus fifteen it is possible to make a full-fledged reinforced concrete structure. If the work is carried out on your own, you should not wait for such frosts. A more or less safe option is down to minus five degrees, that is, the first frosts of late autumn.

Using special additives, you can achieve high-quality results without much risk

Preparing the filling

Before preparing and pouring the solution, you need to carefully calculate the volume of the required mixture. It is especially important to make competent calculations if you plan to order ready-made concrete.

Otherwise, you will have to decide on the fly where to apply the excess solution or send the concrete mixer back with the excess and say goodbye to wasted funds

If there is not enough mixture, that is also bad. The structure will not gain the necessary strength, which will subsequently lead to deformation of the walls or their collapse.

The shrinkage coefficient of concrete depends on the brand of cement and the composition of the mixture. The higher the shrinkage, the more solution will be needed.

A regular rectangular foundation of a strip structure is calculated as follows: length x width x height x shrinkage coefficient. The resulting value is divided by 1.05 (this is how much the reinforcing elements occupy).

Calculating the amount of cement for a concrete mixture

It is more difficult to calculate the volume of foundations with complex shapes. A school geometry course will come in handy. The calculation principle is the same, using the shrinkage coefficient and dividing by 1.05.

Why does the foundation collapse?

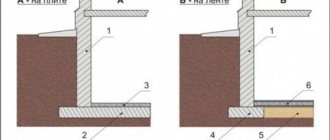

Not all developers realize that they themselves determine the service life of the foundation laid for a house. The foundation is usually a multi-layer “pie” consisting of building materials with dissimilar characteristics, which manifest themselves differently in the presence of excess moisture. Therefore, one of the main factors for the long service life of an underground structure is careful adherence to the sequence of laying the base, or cushion, consisting of several layers, each of which can have its own technology. When carrying out work, you will need to take into account weather conditions, which is important.

How to care for your winter foundation

- When formwork is formed, insulation is used - polystyrene foam or mineral wool. Such protection will preserve the temperature of the mixture from external influences of the soil.

It is better to mix the solution with heated water

- During the formation of the foundation, it is necessary to protect it from mechanical stress and monitor the integrity of the formwork.

- If small cracks have formed, but the solution has not yet hardened, they can be eliminated by vibration.