Everyone understands that the basis of any building is the foundation, and as long as the foundation is reliable and strong, the building will serve its owner reliably and for a long time. To date, several foundation technologies have been developed and are successfully used in construction. A successful and frequently used technology can rightfully be attributed to the technology of creating a columnar foundation.

According to their structure, foundations can be divided into:

- Solid wall structures - strip foundation.

- The foundation is made of free-standing pillars.

It is better to use a strip foundation for a log house if you are going to build a basement or cellar; strip foundation is also warmer, which allows you to save on floor insulation.

Comparing these types of foundations, it should be noted that a columnar foundation is erected for the construction of buildings that do not have a basement; such buildings mainly include wooden houses and wooden baths and log cabins. A do-it-yourself columnar foundation with a grillage is really simple and effective. The main task assigned to this foundation is to uniformly reduce the amount of settlement of the structure. This task will be successfully completed only if the foundation is made with strict adherence to the drawings and accurate consideration of all marks. The construction of a columnar foundation is several times cheaper due to less material consumption and less labor costs, in contrast to a strip foundation.

The pillars must be in the corners of the log house and under the load-bearing walls.

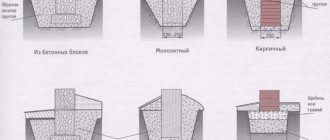

Depending on the type of soil, the type of columnar foundation is selected. The main difference in a columnar foundation is the method of its construction; therefore, this foundation is divided into:

- — prefabricated foundation;

- - monolithic foundation.

A prefabricated columnar foundation is erected in places with groundwater and on highly frozen soils. The time period required for the construction of a prefabricated columnar foundation is much less than that of a monolithic columnar foundation. Considering the strength characteristics, it is worth noting that they are much higher for a monolithic foundation than for a columnar foundation.

According to the degree of penetration into the ground, columnar foundations can be divided into:

- - recessed columnar foundation;

- — shallow columnar foundation;

- - non-buried columnar foundation.

In this article, we will look at the principle of constructing a non-buried columnar foundation.

We calculate a columnar foundation with a grillage

The reliability of the structure largely depends on how well the foundation calculations are performed.

At the preliminary stage, the bearing capacity of the soil on your site is determined. This will allow you to calculate what the support area should be, that is, the sum of the areas of all the pillars. When calculating, not only the weight of the foundation itself is taken into account, but also the weight of the structure being built on it, which includes the weight of building materials, loads, both domestic and natural.

To compensate for possible errors, the resulting value (weight divided by support area) needs to be increased by approximately 30%. After this, we calculate the required number of support pillars. The maximum side length of a support column usually does not exceed 60 centimeters. Support pillars must be placed at the corners of the house and at the junction of load-bearing internal walls. Otherwise, the frequency of placement of pillars is calculated individually, but on one section of the foundation the step between pillars cannot exceed 3.5 meters.

We carry out excavation work

At the initial stage, we mark the future foundation, especially carefully checking the right angles. To do this, measure the diagonals of the rectangle. We make the markings from a stretched cord. We remove the plant layer and transfer the fertile soil layer.

In the places where the pillars are placed, we dig or drill holes to a depth of at least half a meter exceeding the freezing level of the soil in your area.

When using wooden formwork, the cross-section of the pit must be increased by 20 cm in each direction.

The bottom of the post hole is covered with a sand cushion approximately 10 cm thick. It is watered and thoroughly compacted. The sand cushion should extend beyond the edges of the future pillar. We lay sheet roofing material on top of the sand, preventing the soil from absorbing moisture from the concrete solution.

We build formwork for foundation pillars

Typically, wooden formwork is made from boards 2 cm thick. You can also use sheets and trimmings of chipboards.

The boards are used to form boards, and then boxes, which are lowered into the prepared pit. The wooden surface of the formwork can be lined with polyethylene from the inside or moistened with plenty of water.

In addition to wooden formwork, concrete mortar can be poured into other structures. For example, you can use pipes made of any material of large diameter, or even form the formwork in the form of a cylinder from roofing felt.

In some cases, formwork may not be built at all, for example, when a hole is made in dense, dry soil. In this case, you can limit yourself to polyethylene.

We reinforce foundation pillars

The thickness of the reinforcing rod is usually selected no more than 14 mm. The design of the reinforcing mesh should be 50 mm away from all edges of the concrete casting, with the exception of the upper edge, in which the reinforcing rods must be brought out in order to subsequently connect them with the reinforcing mesh of the grillage.

Mesh nodes can be welded if the reinforcement is marked with the letter “C”. Otherwise, the reinforcement is either tied with wire or fixed with plastic clamps.

We assemble the frame on the ground, select its configuration depending on the cross-section of the pillar and lower it into the formwork.

Pour the concrete solution and fill the soil

The grade of concrete for pouring is selected depending on the planned load on the support pillars. Each layer of poured concrete, 30 cm thick, after being placed in the formwork, is processed with a vibrator or bayonet shovel. Air must escape from the concrete mass.

After processing with a vibrator, the next layer is poured and so on until the top of the formwork. It is not recommended to take long breaks in pouring layers in the column - this will reduce the strength of the structure.

The concrete sets in about four days, after which the removable formwork can be removed. The concrete solution will mature only after a month, but its upper surface can already be waterproofed by treating it with bitumen mastic or placing roofing material on it.

If you are installing a foundation in heaving soil, it is recommended to create a sand cushion around the pillars to compensate for soil movements. The sand poured around the pillars must be thoroughly compacted.

We arrange a grillage for a columnar foundation

A grillage is a horizontal element that connects the foundation base into a single rigid structure. Typically, monolithic reinforced concrete or ready-made foundation blocks are used for production.

In the case of building a foundation on soils with strong heaving, it is advisable to raise the grillage above the ground so as to eliminate the impact of rising soil.

Installation of grillage - photo

To create a hanging grillage, continuous formwork is installed between the manufactured pillars. In order not to create the bottom of such formwork from wood, you can create its walls from the ground itself, and simply fill the space for the gap with sand.

Inside the formwork, a load-bearing metal frame is created from rods approximately 14 mm in diameter. The required amount of reinforcement is calculated in the same way as in the case of a strip concrete foundation. Since we left the rods of the internal frame of the pillars sticking out, we connect the frame of the grillage with the reinforcement of the already cast pillars.

Also, as in the case of pillars, the internal metal frame should not touch the walls of the casting and should be 50 mm away from them. When pouring, the air that gets into it during mixing must be removed from the concrete solution. A vibrator is used for this. After the concrete has matured, the formwork and sand cushion are simply removed.

The formwork for the grillage can also be installed hanging. To do this, a U-shaped structure is knocked together from boards.

Video - Columnar foundation with grillage

Almost every person understands that the foundation is the basis of a strong and durable building, and therefore the service life and operation of the building will depend on the quality of the work performed. Today, during their construction, a number of advanced technologies are used, which make it possible to create a full-fledged structure as quickly as possible without loss of quality. These include the creation of a columnar foundation using a grillage.

How to pour a columnar foundation

The great popularity and widespread use in the construction of columnar foundations is explained by the ease of construction and strength. In addition to these advantages, a columnar foundation also has a number of disadvantages that must be taken into account when building a foundation with your own hands. This foundation cannot be erected on moving soils, in areas with groundwater and in areas with large differences in elevation. Having calculated the cost of a columnar foundation, you will be pleasantly surprised, because its cost is one and a half times less than the cost of any other foundation.

A columnar foundation is a system of supports that are located strictly at key points of the building:

- - at the corners of the building;

- — at the intersection of walls;

- - under load-bearing structural elements.

The foundation must be tied to the plan of the future structure and exactly correspond to all the drawings of the design documentation, only in this case the future structure can stand for a long time and reliably.

When choosing supports, it is necessary to take into account the possible load on the foundation, you need to know the approximate weight of the structure, the presence of heavy furniture in the building and the number of people capable of staying inside at the same time. The choice of material from which the supports will be made and their quantity will depend on these indicators. The pouring of a columnar foundation must be done before the onset of winter cold; it cannot be left unloaded over the winter, because by spring it may become deformed and will need to be redone.

To fill a columnar foundation you will need the following materials:

- — supports (material – concrete, brick, reinforced concrete);

- — fittings;

- — boards for formwork;

- - sand;

- — crushed stone;

- - cement.

To make the formwork, a board 20 millimeters thick is used as material. Such a board is lightweight and less expensive compared to metal plates or chipboards. Shields are assembled from boards, and boxes are made from shields, which in turn are inserted into a prepared hole in the ground at the site where the supports are installed. The inner surface of the box is thoroughly wetted with water, this will prevent the wood from absorbing water from the concrete and will greatly facilitate dismantling the box after the concrete mixture has dried.

The foundation is reinforced with reinforcement having a diameter of 14 millimeters. The reinforcement is located inside the box so that its edges do not reach the wall of the box by 5 millimeters. Reinforcement with a diameter of 6 millimeters is used as longitudinal rods, which are welded to the horizontal ones every 30-40 centimeters. The longitudinal rods are 50 centimeters longer than the box; subsequently, the grillage frame will be attached to them. After completing the grillage frame, excess rods can be easily removed.

Video of pouring concrete grillage:

At the final stage, concrete is poured, which is poured in layers of 20-40 millimeters with mandatory breaking with a vibrator, to prevent the formation of air pockets, which can significantly weaken the foundation as a whole. It is recommended to perform the pouring at one time; pour a layer of concrete, break it with a vibrator, and so on until the very top of the support. If you fill the support at intervals of a day, a seam will form at the junction of the layers, which negatively affects the load-bearing features of the foundation.

What is a grillage and a foundation with a grillage?

A grillage is a part of a columnar foundation, which is located on its top and distributes the load between all the pillars, and also serves as a support for all elements of the building. The grillage has the form of beams, the design of which combines the heads of the pillars. Usually the grillage is made of wood, less often of metal, but modern construction uses reinforced concrete or concrete.

A foundation with a grillage is already a structure that has a reinforced upper part that combines the heads of the pillars. It comes in two types:

- tape;

- solid.

The type of foundation used depends on the following indicators:

- soil;

- material;

- device method.

The columnar foundation can be of the following types:

1. Depending on the material used in manufacturing:

— prefabricated, this type is made of natural stone, concrete blocks, bricks;

- monolithic.

2. Depending on the method of foundation construction:

— shallowly buried – the support is buried into the ground up to 70 cm and is mounted on solid foundations, for example, on rocky or sandy soils;

- strongly buried - the support is located at a depth of up to 2 m. The use of such a depth is justified by the presence of heaving soils.

Advantages and disadvantages

The main advantages of a columnar foundation with a grillage are:

- The scope is unlimited. Can be built on clayey, rocky, hard and unstable soils. The terrain of the site also does not matter, which saves the architect from standard solutions and high construction costs;

- Proper installation will ensure the building's durability (more than 70 years);

- Relatively low price;

- It is possible to select the type and type of foundation and its grillage, which makes it possible to save on the price and timing of the work;

- The simplicity of the technology makes it possible to build the foundation yourself.

But, in addition to the above advantages, there are also several disadvantages:

- inability to build a basement or cellar;

- low resistance to soil deformation during the heaving process.

For which buildings is a columnar foundation suitable?

It is advisable to use such a foundation if the building is sufficiently light; if you decide to build a house from stone or brick materials, then it is better not to use it.

It is ideal for the now popular wooden and frame houses, as well as for a variety of outbuildings, garages and country-type buildings.

The advantage of a columnar foundation is its suitability for any type of soil.

Even if the area is swampy or peaty, the structure will reliably strengthen and protect the building. It will not be able to be pushed out by the force of frost heaving, which is a big problem for some areas where the soil is too mobile.

However, it is worth saying that any building erected using such a foundation, by definition, cannot have a basement.

Calculations of a columnar foundation with a grillage

Undoubtedly, it would be better to entrust the first calculation stage of constructing the foundation to specialists, but if the budget is limited, you can try to figure it out yourself using technical literature and the Internet.

The calculation stage includes the following steps:

- geological surveys. They are required to determine the load per unit area of soil, which, therefore, will determine the support area of the future columnar foundation, which must support the entire weight of the constructed building. Existing load per 1 sq. cm of soil can be found in technical literature;

- calculation of the weight of the building. This indicator depends on the material used during construction, as well as the existing load from wind and snow;

- calculation of the base area of a columnar foundation. This indicator can be obtained by dividing the approximate weight of the building by the weight that 1 square meter can withstand. cm of soil. To equalize the calculations, we increase the resulting figure by 25−30%;

- number of pillars. This indicator is obtained by dividing the area of the base of the foundation by the area of the base of one pillar.

After the calculations have been carried out, the stage of marking the foundation with a grillage begins, where an important point is marking the place where the holes for the piles will be located. There are recommendations for installing supports:

- presence of support at every corner of the building;

- the presence of support at the intersection of walls;

- if there are no corners or intersected walls along the foundation line, the distance between the supports is 2.5-3.5 meters. If supports are installed more often, this will increase the cost of building material; if less often than every 3.5 meters, then the building may deform, which will lead to cracks.

Regulatory documents on columnar foundations

The number of rods, grades of reinforcement, and diameter values are obtained as a result of the calculation of a columnar foundation by a professional civil engineer. As well as drawings for its reinforcement.

For this purpose, the following regulatory documents are used:

- SP 20.13330.2011 (SNiP 2.01.07-85*) “Loads and impacts” - terminology and loads on a columnar foundation;

- SP 50-101-2004 (updating SNiPs 2.02.01-83 and 3.02.01-87) - Code of Rules for foundations of buildings and structures, clauses 12.1 - to 12.8 - general requirements for calculations, calculation of columnar foundations - clause 12.3 ;

- SP 22.13330.2011 (updated SNiP 2.02.01-83) “Foundations of buildings and structures” - loads, depth, groundwater accounting, features of design stages;

- SP 63.13330.2012 (updating SNiP 52-01-2003) “Concrete and reinforced concrete structures”, design requirements in clauses 5, 7, 10.

Calculation based on documents allows you to more accurately determine the price of reinforcement for a columnar foundation.

How is a columnar grillage foundation constructed?

The construction of a columnar grillage foundation is not that complicated. The main elements of the foundation are load-bearing supports (pillars), which can be made of various materials: concrete, rubble stone, brick, metal pipes.

As mentioned above, the pillars are installed in the corners and at the intersections of walls, and the step of their installation depends on the design and expected load of the building.

Calculations of the diameter of each support are made for each building individually. The burial depth should be below the soil freezing level, and the lower support point should be placed in a stable layer of soil. A prerequisite is the presence of grillages for connecting pillars to distribute the load on all existing structural elements of the building.

Formwork for grillage

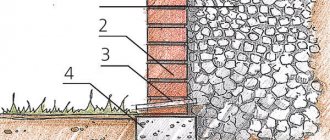

After all the pillars are installed, the formwork for the tape is prepared. Two parallel rows of boards, installed on an edge, are fastened along the width of the grillage and installed along the entire perimeter of the foundation. They form the side walls of the formwork.

Important!

If the foundation is being built on heaving soil, there must be a gap of at least 15 cm between the concrete and the soil.

Then the soil, which expands when freezing, will rise freely within the gap. Without a gap, the connection between the grillage and pillars may be destroyed or cracks may form in the tape.

If a gap is not needed, the formwork is installed on the ground.

If the grillage is arranged with a gap, its lower surface is limited by plank flooring. The flooring is supported from below with boards placed on edge. You can also pour a layer of soil or sand under the formwork and compact it. After stripping, this layer must be removed.

Construction of a columnar grillage foundation

If you want to do without specialists (engineers, architects) and start building a house or structure on your own, then you should consider several main aspects:

- grillage type. It depends on the type of soil and the properties of its movement;

- design of the future building. Area, number of floors, building material affect the pressure level;

- location relative to the ground.

Stages of construction of a columnar foundation with a grillage:

- Settlement. The theoretical part was presented above.

- Preparatory. Includes clearing the site of all uneven areas, as well as planning the site according to your project. To check the correctness of the layout, you need to measure the diagonals and angles. Vertical holes for mounting posts can be dug manually or using a drilling rig. It is important not to miss the moment and arrange formwork at a depth of one meter to prevent the soil from collapsing. The width of the hole dug should include the dimensions of the post, formwork and spacers.

- Installation of formwork. Usually they use wooden boards, less often plywood with moisture-resistant properties, wood boards, and metal sheets.

- Reinforcement. It is carried out using a metal rod up to 1.5 cm thick, which are connected to each other with wire in a horizontal position. In order to connect the post to the grillage, it is necessary to provide for the installation of reinforcement in a vertical position above the support at a distance of 1.5 cm.

- Pouring with concrete mixture. It is produced in several layers, each of which is 2 cm. Each layer is compacted with a hand-held vibrator.

- Waterproofing. This is carried out by laying any waterproofing material inside the formwork.

- Installation of the fence. A fence is a wall that covers the empty space under a columnar foundation. It is needed for communications, as well as to avoid the entry of cold air and various precipitation. The best option would be to think through the removal before starting the foundation, since it will be more difficult and inconvenient to do later. Brick can be used as a pick-up material. The intake device includes ventilation and communication openings. The only drawback of the pick-up is its possible settlement under the influence of ground movement.

The final stage is removing the formwork and grouting the ends.

The construction of a columnar foundation with a grillage is an advantageous option for a low-rise building on difficult, swampy and sandy soils, which are characterized by mobility. And the ease and speed of installation does not require the help of special equipment, unlike a slab foundation.

For small buildings with a volumetric weight of about 1000 kg/m3, one of the best solutions is a foundation made of pillars located in the ground at a certain depth. The step-by-step instructions on how to build a columnar foundation with your own hands are quite suitable even for a person who has basic construction skills.

To do this, it is necessary to carefully and correctly select materials, calculate and become familiar with the construction technology in all details.

If you go by the reviews of developers, the advantages of a columnar foundation are as follows:

- a large selection of materials that allow you to properly distribute the load;

- reasonable cost and low consumption of materials;

- small volume of construction;

For heavy buildings and high groundwater levels, a columnar foundation is not suitable.

How to calculate the foundation

When designing a house yourself, you always know what materials it will be built from.

1. Determination of loads on the house.

The weight of all parts of the building is easy to determine. Seasonal loads and the weight of objects inside are added to them. This also takes into account the influence of the grillage, which is usually made of reinforced concrete with a volumetric weight of 2400 kg/m 3.

2. Assessment of the nature of the soil.

A columnar foundation for a house is usually built with your own hands without laboratory studies of the composition and properties of the soil. The main indicator is its resistance, which is determined from tables and is in the range of 1-6 kg/cm2. Its value depends on the composition and porosity of the soil.

3. Number of supports.

The bearing capacity of the pillars depends on the area of the supporting surface. Usually used. It is desirable that they have an extension (shoe) at the bottom. It is important to consider the composition of the concrete mixture and reinforcement. The size of the step between the supports depends on the calculation and does not exceed 2.5 m. They must be present at all corners, at the junction of walls, under beams and in places of concentrated loads.

Installation of pillars

The posts are installed every 2.5–3.5 m.

Important!

Support points are required in the corners of the building and at the intersections of walls.

The number of pillars and the area of their base are calculated taking into account the load-bearing properties of the soil and the total weight of the future building. For the manufacture of pillars, poured concrete with reinforcement is used. Filling options:

- in formwork made of boards;

- in formwork made of steel or asbestos cement pipes;

- without formwork.

The latter option is possible if the soil is dry and the walls of the hole dug under the post do not collapse.

Columnar foundation with grillage. Step-by-step instructions for construction

Building houses is not so difficult when all the work is divided into separate and interconnected steps that smoothly transition into one another. If you are building a columnar foundation with your own hands, step-by-step instructions should include all stages of work:

1.

Preparation

. The construction site is cleared and a layer of black soil is removed under the base. If there is soil containing clay underneath, it is necessary to backfill with a layer of sand and gravel.

The site is leveled horizontally using a level. It provides convenient access for vehicles with materials and mixers with concrete.

2. Marking the house plan.

First, mark the contours of the building and the places for the pillars, which are located strictly along the axes. The corners of the foundation of the house must be straight. The correctness of the layout along the center lines is checked, as well as the lower elevation of the trench for compliance with the design.

3. Digging holes for pillars.

The foundation can be shallow (70-100 cm) and standard (from 100 cm). The first option is better suited for rocky and sandy soil. In clayey and wet areas, the pillars must be buried to great depth. It is not necessary to dig holes: if possible, the pillars are driven in or screw piles are screwed in. The most common and cheapest way is to drill wells and fill them with concrete.

4. Concreting.

A cushion of sand and gravel mixture is placed at the bottom of the pit. The pillars are concreted directly into the ground when it does not crumble. In all other cases, formwork is installed from the following materials:

Boards no more than 155 mm wide, planed on the concrete side.

Ready-made metal shields.

Pipes are ceramic, asbestos-cement or metal. Numerous reviews speak of the benefits of using pipes, especially on shift-prone and loose soil.

Roofing felt rolled into a roll and reinforced with wire or on the outside.

Rolled waterproofing is lined at the bottom with an overlap on the walls to prevent the solution from flowing out through the cracks of the formwork.

5. Installation of fittings.

The pillars are reinforced in the longitudinal direction with steel rods. They are installed vertically in the pit and tied with clamps. Part of the reinforcement should protrude 15-30 cm above the foundation for further connection with the grillage.

6. Installation of poles.

If the supports are made by laying concrete, it is supplied in layers and compacted with a vibrator. There should be no cavities left inside to increase strength. The concrete should not be too thin or thick in order to further provide the necessary strength and prevent cracks. Until the required strength is reached, it is covered with film and moistened.

When laying a columnar brick foundation with your own hands, it is fastened with cement mortar.

Deviation from the horizontal is allowed no more than 15 mm. It will be difficult to correct distortions in the future. There should be no gaps left during laying.

After hardening, the supports are covered with mastic or bitumen for waterproofing. The coatings are applied in 2 layers with roofing felt strips laid between them and outside.

Transverse dimensions of the grillage

The height and width of the grillage depend on the type of structure, the thickness of the walls, and the slope of the site.

For a wooden house

In the case when a wooden house (panel or log) is being built, the grillage should have a height of 40-60 cm. Then it will have sufficient flexural rigidity and will ensure insulation of the lower part of the building from an area with high humidity.

The ceiling of the first floor of a wooden house can be supported by:

- on additionally installed poles;

- on the grillage.

In the first case, the width of the grillage corresponds to the width of the wall. In the second, on the inside, its width must be increased to provide support for the floor beams.

When preparing the formwork for the grillage, it is necessary to provide ventilation holes (vents). Their distance from the surface of the blind area must be at least 30 cm. For this purpose, inserts are made from asbestos-cement pipes or boards.

For a stone house

If a stone house is being built, the width of the grillage is consistent with the width of the wall. External finishing and insulation are taken into account. The minimum height of the tape in this case is 15-20 cm.

Under the stone structure, the grillage connects the support points and provides a reliable foundation to support the first rows of masonry. Stone walls have good flexural rigidity themselves, so the grillage will not experience large flexural loads.

On a site with a slope

If the construction site has a slight slope, the base of the grillage is arranged along the surface and, thus, the tape will have a variable height.

On a site with a large slope, the grillage can be arranged with steps. The reinforcement of the pillars must be inserted into the tape by at least 20 cm. In the area of the steps, reinforcing mesh must be laid in the masonry. The height of the steps is set so that a whole number of rows of wall masonry can be laid on it.

Mistakes when laying the foundation

Developers who build houses themselves should not make mistakes with foundations, which significantly affect the durability of buildings. In most cases the errors are as follows:

- Uneven subsidence of a structure due to insufficient depth of pillars or their different depths.

- Uneven distribution of load on pillars.

- Use of low quality materials for construction.

- The composition and characteristics of the soil have not been assessed.

In order to correctly build a columnar foundation with your own hands, the step-by-step instructions must be completely followed during construction.

Making a grillage

To equalize the load on the pillars and prevent lateral displacement of the house, the instructions for creating a columnar foundation provide for tying the supports into a common monolithic structure using a grillage - horizontal fastening bars. It is installed at a height from the ground level.

For construction, timber, metal profiles or reinforced concrete are used. Particular attention is paid to the place where the grillage is attached to the pillars, since its reliability determines the stability of the entire building.

To construct a reinforced concrete base, wooden formwork is attached around the perimeter of the structure and at the locations of load-bearing walls. A frame made of reinforcement is installed inside, it is firmly connected to the protruding rods of the pillars, and then the concrete mixture is laid. The surface of the grillage is leveled and covered with a film to prevent it from drying out.

When the concrete gains strength, waterproofing is installed on top and the installation of floors and walls begins.

Complete instructions for installing a columnar foundation also include operations for arranging waterproofing and backfilling.

Methods for tying pile foundations with timber, corrugated pipe and angle

Types of tying pile foundations

Pile foundations are popular in industrial and private construction when the slope at the construction site is quite large or there is a large depth of strong rocks in the area.

It is not advisable to dig deep trenches in such soils, since the soil may shift or the bottom of the trenches will be flooded with groundwater. In turn, pile structures are ideal, given their features, design characteristics and low cost in general.

What is the harness used for?

Scheme of grillage arrangement in a columnar-pile foundation

To ensure greater structural strength and uniform transfer of load from the building to the ground, a special foundation frame or grillage is often used. The grillage is connected to the piles using a hinge joint, reinforcing mesh, rigid welding and wire. In private construction, tying with a grillage made of wooden beams, corrugated pipe or channel is practiced. The harness is used:

- To ensure geometrically even and correct location of all piles.

- Prevent the foundation from shifting under the influence of lateral, tangential and vertical ground displacements

- Ensure uniform distribution of loads from the mass of the future building through the piles to the ground.

When designing pile-grillage foundations, the number of piles must be taken into account. The more piles are used, the smaller the cross-section of the piping reinforcement will be. In addition, you can also use a regular wide board or small-diameter corrugated pipe; you need to connect all the links with corners.

Types and types of harnesses

The use of corrugated pipes for tying foundation piles of buildings

Pile-grillage foundations are highly durable; they almost completely neutralize vertical and horizontal soil movements. They are used for the construction of houses on mobile and unstable soils prone to heaving. Piles are also actively taken into account not only when designing a new house, but are also used during the renovation of an existing one, since they are strong enough and can withstand the load of buildings of several floors.

It is important to take into account the human factor, as well as the presence of hard rock in the soil. During the installation of piles, a small slope angle is inevitably formed due to the displacement of the core, so after installation of the structures they need to be leveled and strengthened.

Methods for strengthening piles used in private construction:

- Tying with corrugated pipe, additional connection to the top of the pile with angles, welding or flexible wire.

- The use of metal channels with different installation directions.

- Use of wooden beams.

It is not necessary to do the tying at all if the location of the top point of the pile is no more than 60 cm from the ground level. But if it is higher, then it is impossible to do without strapping, since the load-bearing structures will shift even under the influence of wind or rain, and over time the building itself may become skewed.

Necessary materials for tying a pile foundation:

- wooden beam, you can use thick boards;

- metal channel, I-beam and connecting angle;

- flexible wire, rod or reinforcement with a cross-section of up to 8 mm.

You will need a welding machine and building levels.

Channel or corrugated pipe piping

Channel and corrugated pipe for tying foundation piles

A channel is a rigid metal beam of great thickness, has its own stiffening ribs, to which reinforcement or the top of the pile are attached by welding.

A profiled pipe is cheaper, it weighs less, but it is no different in strength; the connection principle is similar to a channel. The optimal connection method is to lay two beams on top of each other or overlap. Peculiarities:

- It is unacceptable to use separate beams on different piles; it must be a monolithic structure.

- If the foundation is large enough, then a crane will have to be used to install and fix the channel, so this strapping method is used in the construction of warehouse and industrial buildings.

- To ensure greater strength, it is recommended to use not only welding, but also bolted connections; the joints should be coated with anti-corrosion paints and checked with ultrasound.

- Channels are heavy load-bearing structures, so such grillages are not used in private construction.

Source: https://fundamentclub.ru/svajnyj/obvyazka.html

Pickup device

The underground space is protected from atmospheric influences by installing a fence - a fence between the supports. It is made of wood, brick or stone. A concrete screed is laid underneath to serve as a base. To do this, first make a trench and fill the bottom with sand. For the screed, formwork from boards and a reinforcement cage are installed. The connection between the fence and the supports is not made in order to avoid the appearance of cracks in it when the house settles.

They try to make the base higher, which makes the structure look attractive. It corresponds to the height of the supports.

Column and strip foundation

A pillar base combined with a monolithic concrete frame combines all the advantages of both types of bases. When a columnar strip foundation is being erected, the step-by-step instructions are the same as for construction with a grillage. The supports penetrate far into the depths, creating reliable protection against seasonal ground movements.

They are rigidly connected to a shallow shallow base running under the load-bearing walls of the building. The entire structure is poured with concrete at the same time, as a result of which it becomes monolithic and durable. When preparing the solution yourself, the concrete is laid in layers. The use of vibrators is mandatory to remove air bubbles from the mass as much as possible.

What are the features of a columnar foundation?

Despite the external visual similarity with the structure of pile systems, columnar foundations have their own specifics, which are reflected in the design of the foundation:

- Columnar supports are most often made with a square section, much less often - round. This is determined by the manufacturing method. A support in the form of a pillar can be laid out with brickwork, stone - plastic, assembled from rubble, cast from concrete or folded from rubble in formwork;

- The ratio of the length of the supporting element of a columnar foundation to the cross section is significantly less than that of piles. The stability of a building raised to a considerable height when using a columnar foundation is higher than that of a pile scheme, even when using a reinforced grillage;

- Due to the high rigidity and strength, the number of supporting elements of a columnar foundation can be made significantly less than if classic screw or bored piles were used.

Important! One of the most remarkable properties of this scheme is that building a columnar foundation with a grillage with your own hands is much easier and cheaper than a strip or pile version.

Fill

Important!

The inside of the formwork should be lined with waterproofing material to reduce the loss of “cement laitance”.

The grillage should be poured with concrete without long breaks. Concrete is laid in layers of 15 cm. The layers can be inclined (30° to the horizontal). To prevent air from remaining between the reinforcement and the formwork, it is necessary to bayonet the concrete with a piece of reinforcement while simultaneously tapping the formwork from the outside.

When building a columnar foundation with a grillage with your own hands, it is important to pay special attention to the quality of the tape reinforcement and the quality of the concrete. The reliability and durability of the foundation of the house will significantly depend on this.

A short video about a pile-grillage foundation

With a grillage is a fairly popular construction solution. It is excellent for the construction of relatively light structures. Its construction is relatively economical - it will take less effort, money and building materials than the construction of a classic strip foundation. The only disadvantage of a columnar foundation with a grillage is the impossibility of creating a full-fledged basement or basement without additional work.

The support pillars of the grillage foundation themselves can be made of various building materials. One of the most popular methods is to construct pillars using steel-reinforced concrete. This option will probably be the most reliable and durable.

Which columnar foundation options are most popular?

The choice of a specific solution largely depends on the specific design of the house, its weight and the rigidity of the building frame. To prevent the pillars from tilting and falling like candles, the supports are tied with a special horizontal belt made of reinforced concrete, rolled metal, or even just a wooden beam.

There are several basic schemes for using the design of a columnar foundation:

- The classic option is columnar support elements buried in the ground with a hinged grillage; 90% of all columnar foundations are built according to this scheme;

- Pillars without penetration into the ground, supported on a gravel cushion, most often a monolithic columnar foundation with a grillage. In this case, it is possible to obtain a high rigidity of the foundation, which allows minimizing the risk of tilting or subsidence of the building;

- Columnar foundation without grillage. A very popular option used for arranging small compact buildings.

For your information! Supports for a columnar foundation with a grillage can have a very different design, for example, brickwork can be combined with concrete casting or with a rubble base. In fact, this does not change the properties of the foundation, but such solutions can greatly simplify and reduce the cost of construction.

Scheme of a columnar foundation with recessed supports

In fact, such a system is not much different from a pile foundation on very thick and short supporting elements. Visually, the difference is manifested in a significantly smaller number of supporting elements located at a greater distance from each other. For a pile, the optimal step is one and a half meters, and for a columnar version, the distance between the supports can be 2.5-3 m, with the same thickness of the grillage.

Conventionally, the structures of such a foundation are divided into shallow and with depth to the level of soil freezing. The first of these schemes is used on slightly heaving soils. The latter option turns out to be very expensive, but it is resorted to in cases where it is necessary to limit the number of piles on the site. In both cases, a brick or concrete frame cast from rubble concrete is installed on a sand and gravel cushion, and the columnar foundation is drained and waterproofed.

Immersion of a very heavy and massive support into the ground, even to a small depth, increases the rigidity of the columnar foundation so much that in some cases it is possible to do without a rigid transverse frame - a grillage.

Columnar foundations without the use of a grillage

The classic design of a grillage is a reinforced concrete beam laid on vertical supports or pile caps. In addition to reinforced concrete, a metal profile, for example, a channel or T-bar, or even large-section oak beams can be used to construct a grillage. The main function of the grillage is to transfer and distribute the weight of the building between all supporting elements of the columnar foundation. The second function of the grillage is to fix and hold the support in a strictly vertical position.

Heavy and rigid stone supports have enormous lateral rigidity, so an overturning moment can only occur during spot heaving of the soil, when frozen soil squeezes out one support more than the others. In this case, the grillage helps to compensate for the uneven load and stop the roll.

On “quiet” soils made of coarse sand or with a large inclusion of limestone, the grillage loses some of its functions, and for a house with small walls - 4x4, 4x6 m, you can completely abandon it. Most often this is done during the construction of timber or log bathhouses, summer cottages, fishing and hunting lodges. To avoid transverse tilt, the supporting elements of the columnar system are deepened into the ground by half a meter, and the first row of timber plays the role of a grillage.

To fasten the walls to the supports in the masonry or casting, at the molding stage, anchor bolts are sealed and a double layer of waterproofing made of roofing felt and polyethylene foam is laid. The construction and casting of a grillage beam made of reinforced concrete requires a significant amount of time and effort. Therefore, owners of small houses try to abandon what they consider unnecessary parts in the building design.

One of the problems that must be solved when refusing to use a grillage is the problem of ensuring equal heights of all supporting elements. Otherwise, the beams of the first row will fall on the columnar system with a slope, and this can lead to the tilt of the entire building structure.

In some options, the grillage is replaced with ordinary thick beams, which are laid on a solid bed of gravel and sand, leveled in a horizontal plane, and secured with staples and stakes. Next, the main frame of the building is assembled from logs or timber, with the rows of supports tied together according to the standard scheme.

Columnar foundation with a grillage without going into the ground

The advantages of the columnar scheme include the possibility of installing a building box without going into the ground at all. Most often, this method is implemented in the form of a monolithic structure, in which the grillage and supports are cast as a single unit from reinforced concrete. This frame has increased rigidity and strength, which is especially important for frame aerated concrete walls of houses.

Before casting, it is imperative to concrete the supporting platforms, on which formwork is subsequently installed to form the body of the pillars and grillage.

A simpler version of a surface foundation is the “shoe” type of supporting elements. Each of the foundation pillars is cast in the form of a cube or a truncated pyramid with a height and base of 30-40 cm. This configuration makes the supports extremely strong and stable; it is enough to level the platform in a horizontal plane and pour pillows under the support blocks from a three-layer sand-gravel mixture.

Tying the foundation with timber

Foundations on piles, as well as on poles, due to their low economic component and relative ease of installation, are deservedly popular among developers. They are convenient because they do not require a large amount of excavation work, are suitable for almost any soil, and are suitable for any structure. For private construction, unless a basement is needed under the building, this is the most acceptable option. Especially for a small building, like a bathhouse or barn.

Just drilling wells and installing piles is the beginning of the work, which is quite easy to do yourself. But the piles themselves cannot serve as a foundation, since they can only work as a foundation in conjunction with a framework, which is also called a grillage. It is made of reinforced concrete, metal, wood from logs or timber. For frame or frame-panel buildings, tying a pile foundation with timber is most suitable.

Purpose and types of grillage

The strapping is both an action and a device, which means that this element connects the pile heads into a single structure. It serves to uniformly distribute the load from the building onto each pile. The types of grillages depend on the material they are made of:

- The metal one is made from a channel, which is attached to the pile heads by welding. For this case, and in other cases too, the top of each pile ends with a horizontal steel plate with holes for bolts or with welded studs. All metal structures must be coated with anti-corrosion compounds.

- Reinforced concrete framing can be made from prefabricated elements in the form of lintels or crossbars, which are connected to each other and to pillars. The second option is a monolithic reinforced concrete structure, which is made according to the principle of a strip foundation. It is very convenient and practical to make such a grillage in permanent formwork, which simultaneously serves as an enclosing element and thermal insulation.

- Wooden lining of the foundation on screw piles with timber or logs is usually done for buildings made of wood. Rounded logs are used for arranging the foundations of log houses. Natural or laminated timber - for frame buildings. For the grillage, products with a cross-section of 150×150 mm are used, and steel studs or bolts are used as fastening elements. Fastening can be carried out by landing on the threads coming out of the piles. Or bolts through holes in the embedded parts of the pillar heads. Sometimes tying the foundation with timber is done using wire rod clamps. But, in any case, the head of the pile is covered with roofing felt or pieces of flexible tiles to create a waterproofing layer.

Grillage construction

Sometimes wooden buildings are erected without a foundation at all. The first crown, carefully treated with tar or bitumen, is placed on a sand-clay cushion. A barn or bathhouse built in this way lasts a long time. At the same time, there is a risk of soil erosion and drifts in winter. Therefore, it is more reliable to construct any building on a solid foundation. Let's consider two options.

On a strip base

There are cases when a strip foundation is tied with timber. It may be needed if the walls of the building are made of frames. The first crown is a grillage, which is constructed from thick timber. Its installation is carried out on anchors or studs provided during the process of pouring the strip base. The construction order looks like this:

- checking the horizontality of the upper surface of the reinforced concrete strip with a building level and leveling it with cement-sand mortar (if necessary);

- laying a waterproofing layer of roofing felt on bitumen mastic;

- mark on the beams of the future grillage the places where it connects to the foundation and drill holes for the anchors;

- each anchor must be protected with a gasket and washer;

- the timber is carefully “put” through the holes onto the studs and the anchors are secured with nuts;

- The corners of the grillage beams and the junction of the beams under the partitions are connected using the “claw” or “bowl” method, fastening them with self-tapping screws or nails.

If we talk about materials, it is best to tie the foundation with larch beams. Since this tree is a hard species, it is perhaps the only coniferous tree.

On a pile foundation

There are two ways to attach the crown to the pile heads - with bolts or studs, and also using wire rod clamps. However, many professionals in practice use both methods simultaneously and recommend that craftsmen do this if they tie the pile foundation with timber with their own hands.

The double method of fastening the first crown will give the base additional strength and confidence in reliability. It should also be remembered that metal structures must certainly be coated with anti-corrosion protection, and wooden structures must be treated with antiseptics. Such procedures must be repeated periodically, at least once a year.

The pile heads must be covered with steel plates with anchors and further tying of the screw foundation with timber is carried out in the following order:

- pieces of roofing felt or other waterproofing material must be laid at all places where the first crown comes into contact with the metal;

- With pre-drilled holes, the timber is placed on the anchors of the supports; it is convenient when the plates with studs are made with small vertical walls; in this case, the beam will sit exactly in its place, without displacement;

- The strapping parts are connected to each other with self-tapping screws and nails; in this case, metal plates and corners can be used for strength; anchor bolts are secured with nuts; If it is impossible to use anchors or studs, use strong clamps.

A similar fastening method must be performed at all points of contact between the crown and the pile. By the way, the same method is used when tying a columnar foundation with timber. The process of arranging the grillage must be accompanied by a systematic check of the horizontal and vertical structures, as well as the correctness of the angles of contact between the parts and with the wall studs.

Things to remember

In order for the grillage to be made with maximum accuracy and good quality, before starting work, you need to check with a level that the top marks of all supports coincide. And also, the accuracy of their location according to the construction plan. That is, all geometric parameters horizontally, diagonally and vertically must correspond to the specified values. Otherwise, it will be impossible to link the individual parts of the harness into a single structure.

The timber for the grillage must meet all quality standards and norms. You cannot build a harness from material that is damaged by pests and has high humidity.

Fastening elements (screws and nails) should be placed along the central axis of the structural elements to prevent cracking. And the connecting points between the wooden parts must be laid with jute or tow.

Source: https://stroikadialog.ru/articles/fundament/obvyazka-fundamenta-brusom