For a long time it was believed that the foundation should be poured only when it gets warmer - in spring, summer or autumn. However, modern materials and devices in construction have radically changed this approach. Now pouring a foundation in the fall has become as common an activity as in the summer. The approaches to this matter have just changed a little.

It must be said that if pouring concrete can be postponed until the summer, then it is better to do so. Indeed, in the autumn, more resources are spent on additional equipment, fillers and materials that will prevent the concrete from freezing, creating conditions for its complete hardening.

How does concrete hydrate?

People are often interested in when it is possible to pour the foundation in the fall, and whether it is even worth doing it at such an unpredictable time of year. Now let’s look at how concrete hardens in order to better understand all the processes and plan construction accordingly:

- at the initial stage, a crust appears on the surface of the mixture; it is sodium hydrosilicate;

- after this, the harder particles of the foundation surface harden;

- the next stage of solidification is contraction of the shell due to evaporation of the liquid;

- this process begins to move towards the center until the mixture acquires the stated strength.

Based on this diagram and answering the question whether it is possible to pour the foundation in October, experienced builders confidently say: “It is possible!” And we will describe why, comparing this process in summer and autumn-winter.

Comparison of concrete poured in the heat and in the fall

It is logical that in the summer heat the foundation will dry out many times faster. But will its structure become as dense as necessary? After all, the whole house depends on this - how long it will last, whether cracks will appear in its walls. Rapid hardening occurs due to the rapid evaporation of water. However, this is not very good, because voids are formed instead, which make the concrete brittle.

In the fall, pouring the foundation—in October, for example—may be complicated by the onset of frost. As a result, the water crystallizes, and voids are formed due to the fact that ice forms in the mixture, which also expands, creating microcracks. That is why the foundation is poured in the cold season using special technologies.

Properties of concrete that benefit builders

When the mixture hardens, a chemical reaction occurs that causes heat. Thanks to this, the concrete dries better, but due to the fact that the ambient temperature is low, no voids are formed in it and it does not dry out. Therefore, the answer to the question whether it is possible to pour the foundation in the fall is unequivocal: yes. The most important thing in this matter is to carefully calculate everything. In addition, pouring concrete must be included in the construction plan; this will allow all the necessary materials, equipment and fixtures to be prepared in advance.

In cold weather it is better not to flood the pillars unless they are sufficiently insulated. Indeed, in such conditions, internal heat will be enough for a very short period of time, during which it will not have time to completely harden. It is better to limit yourself to only a low foundation, in which case the chemical reaction can continue and dry the solution much longer.

Concrete hardening factors

Often, in order to have time to build a house in the spring and summer, the owners are always interested in whether it is possible to pour the foundation in October, so that in the spring, when it gets warmer, they can immediately begin building the house. After all, when the foundation is ready, construction will go much faster. And this is especially important when the building is planned to be large, and there is a risk of not having time to rebuild it before the next cold weather.

The quality of concrete is influenced by the following factors:

- volumes and dimensions of the structure;

- proportions of fill elements;

- quality of cement and its grinding;

- climate;

- possibilities for heating and insulating concrete.

In order for the cement to react faster, it needs to be ground as finely as possible, then pouring the foundation in October will be of much better quality, because voids will not form in it. Only the aggregates and water need to be heated. Under no circumstances should this be done with cement, because it will lose the properties that are necessary for a high-quality foundation. But this is very undesirable.

When adding warm water to cement, its temperature should not exceed +30 °C. If it is added to the filler first, then it can be done hotter. If the solution is well mixed, it will withstand the temperature longer. In addition, it fills the mold more tightly, penetrating into all corners and crevices.

Where do legs grow from?

One famous movie character once said that smart choices come with experience, but stupid choices lead to experience. When everything is done correctly, we sometimes don’t even think about what serious troubles we avoided, but we remember our mistakes for the rest of our lives.

It all started with the construction of a small garden house. The classic strip foundation was chosen. To tell the truth, I didn’t even know about anything else at the time, and it began...

Many people then advised me to pour the foundation before winter, so that for a good quarter of a year the foundation would stand and find its place. Then, they say, not only a house, but an entire house can be built without fear.

No sooner said than done, at least I had to work hard.

First, I cleared the selected area of debris and leveled it in a horizontal plane, and therefore had to take up the shovel even before digging the trench.

Then markings. For this purpose, I hammered pegs into the ground and pulled the lacing along the lines of the future foundation.

But we had to dig a lot. Our freezing depth is more than a meter, and the tape cannot be raised shallower.

Then I put up formwork from the boards, poured out a small sand cushion,

And then I filled everything with homemade concrete grade M 350.

It’s a pity that at that time I was too green, and therefore, after listening to the assurances of my neighbors, I decided not to lay reinforcement in the foundation.

Let me remind you that all this happened in late autumn (oh, damn those advisors) and the first surprises were not long in coming. The frost hit exactly two weeks after pouring, while concrete needs at least 28 days to gain full strength. Not pleasant, right?

No, I knew that in the spring the hardening process would continue, but the result would still not be the same.

After wintering, another “gift” was waiting for me - this is the level, or rather, its complete absence (and I wasted so much time to clearly set the formwork).

“You see,” the friend continued. “And the house could have sunk!”

But the soils were reliable, and the weight of the foundation was not so significant that the difference after subsidence was up to 5 cm.

The enemy came from where they did not expect: frost heaving. I thought that if I put the foundation on non-freezing soil, I would be completely protected from it, but that was not the case.

It turns out that heaving acts on the foundation and through the side walls tangentially, however, these forces are insignificant and cannot lift the entire house, but they are quite capable of handling an unloaded belt. Therefore, the frozen soil twisted the foundation as it wanted. To top it all off, the base cracked in several places.

We invite you to read: What should I do with Veronica?

My “joy,” as you can guess, knew no bounds. How much cement was wasted, and how much labor... But I didn’t want to put a stone building on a defective foundation, and therefore, as soon as the soil melted, I started construction again.

I decided not to touch the old foundation, but simply pour a concrete strip along its outer perimeter. At the same time, the house increased in length and width by almost a meter, but the prospect of digging a concrete monolith out of the ground made me shudder.

Despite the fact that the foundation pit was dug in April and the formwork was installed, I only started concreting in mid-May. The lesson was learned, and therefore I did everything according to science. So, knowing at what temperature concrete sets best (which is 15-20 ° C), I took time so that the thermometer could reach this mark at night.

As for the workflow, some adjustments were also made here.

Firstly, I had to admit that saving on reinforcement is not the best idea, and even though I spent three days tying the reinforcement frame, but lazy people do it twice, and I definitely didn’t want to redo it a third time.

Secondly, I had to give up making my own concrete and buy commercial concrete. The fact is that the foundation needs to be poured not in separate sections, but as a whole and in one day, only then can you count on quality.

And most importantly, thirdly, this time I didn’t delay too much with the construction of the walls. He waited the required four weeks and began laying bricks. By autumn the box was already covered. Therefore, this winter passed without any incidents.

To tell the truth, I sold that vineyard, but the house, as far as I can see, still stands today and I don’t think the owners have ever spent money on repairing the foundation.

Solving the problem of concrete freezing

The next insurmountable problem for builders of past years was that in frost, concrete loses its qualities, becoming brittle. This happens because its components do not mix under such conditions due to crystallization of water due to exposure to frost. Therefore, pouring the foundation in the fall, and even more so in winter, was something unrealistic.

Now everything is solved with the help of chemical additives that prevent water from freezing. In addition, special concrete is sold, which already contains substances that promote its normal hardening at sub-zero temperatures. Its properties are no different from its summer counterpart.

Foundation insulation

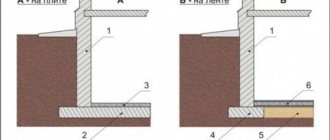

When building a foundation in the fall, another method can be used to protect against low temperatures. Nothing is added to the concrete, its consistency remains the same as in the summer, only the foundation is insulated. This can be done with different materials. Mainly used:

In general, you can use any available material. In severe frosts, the foundation is even covered with sawdust, which perfectly protects from sub-zero temperatures. The main thing is that the top layer is waterproof and can protect against precipitation. In addition, you need to make a slope so that the water does not remain on the material, but goes sideways from the foundation. In general, it’s worth doing everything in the form of an awning, it will be more convenient.

The question often arises about whether it is possible to fill the foundation in the fall, also because there is a lot of dampness around, in addition to frost. This can also be solved very easily: a heat gun is directed under an awning made of polyethylene, roofing felt or tarpaulin. It drives warm air inside, heating the solution and promoting the evaporation of moisture. This way you can easily dry the foundation even in January frosts.

Quite often, in places filled with concrete, greenhouses made of polyethylene are installed, inside which a heater or heat gun is placed.

Rules for pouring a foundation - answers to frequently asked questions

Pouring the supporting part of the house with concrete is carried out in specific weather conditions that directly affect the strength of the foundation. This is the main criterion for the durability of a residential building.

The stability of the foundation is also affected by: the technology of laying work, the composition of the concrete mixture, and the working conditions of specialists.

Before starting the practical part, it is necessary to study the theory. Try to understand when it is better to build a foundation, what weather conditions produce high-quality concrete, and how to avoid additional installation costs.

The natural process of hardening of cement stone occurs only at positive ambient temperatures, on average 15-25 degrees Celsius. The greatest strength of the foundation is achieved if the humidity level is high - from 80 to 100%.

Based on the above requirements, there is a clear answer that it is better to make the foundation of a residential building during the season of stable heat and damp weather.

It is not recommended to carry out work in rainy weather. Excessive moisture impairs the strength of the base, especially if it gets into a fresh solution at the time of setting. If it starts to rain and the pouring has taken place, it is better to protect the structure by covering it with plastic film.

After the concrete has hardened, rainwater will no longer have a negative effect, but will save the foundation from excessive drying.

Summer is considered the optimal time for work. In spring or autumn, there are also warm and humid days at the same time, ideal for carrying out the important procedure of general house construction. The duration of the setting period of the solution is affected by temperature.

Modern technologies and materials in construction have made it possible to lay the foundation of a house in winter, significantly changing approaches.

In hot weather, the foundation dries out quite quickly, which is not an indicator of the high quality of the foundation for the building. During the rapid evaporation of water, voids are formed, making the concrete brittle and the residential building unstable.

When planning to pour the foundation in the summer, you will need:

- Temperature not exceeding 15-25°C and remaining stable day and night, for a long time, until the concrete has completely hardened;

- Air humidity over 80%;

- Concrete maintenance (moistening) to avoid surface cracks.

From the above, the conclusion is drawn: the beginning of June is the most optimal period for pouring the foundation of a house in the summer. But do not forget about the climatic features of a particular area. In June it is not hot, but quite warm, the humidity is normal.

As for July/August, during this period it is either quite hot or there are noticeable cold snaps in the evenings. When choosing between July and August, it is better to give preference to the second option.

Due to frosts, autumn and spring are the most dangerous periods for pouring the foundation for a building. When planning work for the spring-autumn period, you should follow weather forecasters or add anti-frost compounds to the concrete.

The first half of autumn and the second half of spring are the most optimal periods for working on a construction site.

Pouring the foundation can be done without fear if the scale of the street thermometer does not fall below zero at night and reaches positive values during the day. Temperature changes during the day are undesirable.

The durability and stability of a building directly depends on the strength of the foundation. The strength of the foundation, in turn, is determined by the composition of the concrete mixture, laying technology and the conditions under which the pouring was carried out.

Therefore, it is necessary to take a closer look at how to properly care for concrete in order to achieve maximum quality of the foundation at a minimum cost.

Many developers are interested in the question of whether it is possible to fill the foundation in parts, since it is not always possible to prepare concrete in such quantities that it is enough to fill the entire formwork.

Let's see what SNiP says about this. The best method of installation, according to building regulations, is concreting in horizontal layers without interruptions.

If the volume of the foundation is large and does not allow laying in a continuous layer, then laying in inclined layers is allowed. In this case, the length of the joint on which fresh concrete will be laid must be at least 1.5 meters, and its slope no more than 30 degrees.

When pouring the foundation layer by layer, it is important to follow one more rule. Fresh concrete must be laid on the top layer before it sets to ensure the solidity of the entire structure.

If several days have passed after pouring and the concrete has hardened, before laying fresh concrete mixture it must not only be rinsed well with water, but also the cement film must be removed from the surface. It forms the interface along which the foundation fails under load.

Many developers are interested in the question of the possibility of laying concrete in a trench without formwork. According to the requirements of SNiP, this cannot be done, since the formwork not only gives the foundation the desired shape, but also protects the concrete from soil contamination.

In addition, it prevents the loss of laitance, the main binder of the concrete mixture. Without formwork, it is impossible to perform lateral waterproofing of the foundation, and without it, groundwater will freely penetrate into the concrete. When it freezes, it can destroy the foundation.

Pouring without formwork, which builders call “by surprise” concreting, can be done only for light foundations of outbuildings, garages, gazebos or bathhouses. Such work can only be done in dense clay soils that do not crumble into the trench after digging it.

First of all, the question of whether it is possible to pour a foundation in October arises due to the fact that the ground is frozen and it is impossible to dig it by hand. Of course, this is true, but you can use a technique that can dig a pit of any length and depth. Simply calling an excavator will require a financial investment.

Concrete is an artificial stone that is created by hardening a liquid solution. A foundation made of concrete must be poured under certain conditions that affect the rate at which it gains strength. To understand when it is better to fill the supporting part of the house, you need to familiarize yourself with the theoretical part of the question.

The most important indicator for a supporting structure is its strength. The strength gain of cement mortar occurs gradually, and two stages are distinguished. The first is the loss of mobility by the mixture and is called setting. The second is hardening, the process by which the material gains strength and becomes rigid. It is worth talking about each of them in more detail.

Grasping

The period lasts several hours after preparing the solution. At this stage, you need to have time to complete the following processes:

- Transportation of the solution to the work site. This is especially true when ordering pre-fabricated concrete, since the production site may be located at a sufficient distance from the area where the foundation needs to be poured. The issue is solved by using special equipment - concrete mixers. Constant stirring increases the life of the solution.

- Laying the concrete mixture into the mold.

- Compaction (vibrating or pinning) and leveling.

The setting time depends on the ambient temperature, which is why it is so important to decide when it is best to pour the foundation for a house. To select the appropriate time, it is recommended that you familiarize yourself with the following table.

| Ambient air temperature (average daily value indicated), ᵒС | The period during which setting occurs (on average), the beginning and end of the process are indicated in hours |

| 30 | 1-2 |

| 20 | 2-3 |

| 6-20 |

Hardening

Immediately after setting is completed, hardening begins. This is the name given to the process of crystallization of concrete mortar and its transformation into artificial stone. Knowing the hardening time is necessary in order to understand when it is better to start removing the formwork from the foundation of the house and engage in further construction processes. An important task for builders is to reduce the duration of work without compromising quality. This can only be done by studying the regulatory documentation.

We suggest you read: When is the best time to saw off branches from an apple tree?

The most important characteristic of a concrete mixture is its grade strength. Due to the introduction of a new designation for this value, confusion in the labeling is possible. It all depends on what GOST the plant operates on. If the marking is carried out in accordance with GOST 26633-2012, then we are talking about concrete strength classes, which are designated by the letter B, for example B20.

You can remove the formwork from the foundation of the house and start building walls only when the concrete has gained strength of at least 70% of the original grade. This requirement is given in the joint venture “Load-bearing and enclosing structures”. It is better to comply with these conditions, but if there are justifications, you can remove the formwork when the strength gain is more than 50%.

Most often, when it is necessary to pour a foundation for a private house, concrete of classes B15-B22.5 is used (which corresponds to grades M200-M300) mixed with normally hardening Portland cement grades TsEM32.5 or TsEM 42.5 (according to the old markings PTs400 or PTs500). It is for such a solution that the table below is given, which shows the dependence of the speed of hardening on ambient temperature conditions.

| Time interval from the beginning of hardening, days. | Percentage of brand strength at average daily air temperature | ||

| 5ᵒС | 10ᵒС | 20ᵒС | |

| 1 | 12% | 21% | 34% |

| 3 | 23% | 38% | 60% |

| 7 | 31% | 51% | 78% |

| 14 | 37% | 60% | 90% |

| 28 | 43% | 70% | 100% |

For a fast-hardening and slow-hardening mixture, the values will differ greatly during the first week, and after that they will become approximately equal to the percentage for a normally hardening binder.

Based on the previous point, we can say that the most optimal temperature at which concrete supports should be laid is the daily average value of 20ᵒC. In most regions of the country, this value corresponds to only one or two summer months. Such conditions provide very little time to complete the task, so it is not always possible to lay the foundation of a house in the most favorable conditions.

This option will allow you to complete the work at the lowest financial cost and in the shortest possible time. Without taking additional measures, you can fill the foundation of a house under the following conditions:

- The ambient temperature is in the range of 15-25 ᵒC. It is important to take into account that this temperature must be maintained not only during the day, but also at night. It is also worth studying the weather forecast for the next two weeks, since it is better if this temperature persists for a long time while the concrete gains strength. Temperatures above 30 ᵒC have a bad effect on the concrete mixture used in Russia (in countries with hotter climates, concrete is designed for use at high temperatures).

- The highest strength indicators are achieved when air humidity is more than 80%. At the same time, it is important not to forget about caring for the concrete (that is, moistening it), which will prevent the appearance of surface cracks.

Procedure

Electric foundation drying

There is another great way to dry out the foundation. When pouring it, a wire is placed in the solution. It can be copper, steel or aluminum. On one side, all ends are divided into two bundles; they will be connected to the welding machine. Light bulbs are connected to the other side, two ends to each. The lamps must be 36 V, the most important thing is that everything needs to be connected correctly. If there is an error somewhere, then nothing will work. Next, the wires are connected to the lamps in pairs and connected to the device. The first ones should light up, at first with a dim light, but as the concrete begins to dry out, they will burn brighter and brighter. This way you can perfectly monitor the progress of the entire operation and know when the foundation is ready. This method is also suitable for heating the foundation in October or other cold months.

Many builders generally prefer pouring concrete in the fall, because it does not dry out, as happens in the summer heat. The pouring method, or more precisely, the method of retaining heat in the mixture, must be chosen based on weather conditions, available equipment and materials.

Most people have a stereotype that it is necessary to fill the foundation only in spring and summer. Modern builders are proving that pouring concrete can be done in the fall if the necessary recommendations are followed. Such a properly executed foundation will not be inferior in performance characteristics to its summer counterparts.

Some information about autumn filling

Construction of the foundation is one of the main procedures of building construction. Depending on the correctness and accuracy of construction, taking into account all external factors, you can obtain a solid concrete base and begin building walls. If the construction process was carried out incorrectly, there is a risk of subsequent disposal of the foundation due to its unsuitability. The result is wasted time, money and effort.

In addition to the human factor, the pouring of the foundation is influenced by weather conditions. In autumn, as a rule, air humidity increases, temperature decreases, precipitation increases, the amount of groundwater increases, and so on. The listed factors may seem undesirable for pouring a foundation in the fall, however, most of them are advantages.

Taking into account the influence of temperature, we can conclude that it is advisable to fill the foundation in the fall, and not in the summer.

The best temperature regime for concrete hardening is from +15 to +25 °C. In most summer periods, the temperature significantly exceeds this range, which leads to anisotropy of properties, when concrete hardens, and the appearance of significant and minor defects. Therefore, from the point of view of the influence of temperature, it is better to fill the foundation in the fall. In the autumn, concrete hardens much more slowly, but the quality will remain high.

The process of building a foundation and its quality are affected by air humidity. Contrary to popular belief, increased humidity has a positive effect on concrete drying. When pouring in the fall, there is no need for additional moisture.

Precipitation negatively affects such construction work in the fall. You can pour concrete during this period, however, you should choose non-rainy periods. A large amount of water reduces the quality and performance properties of the solution.

An advantage for laying a foundation in the fall compared to summer is the groundwater level, which is often significantly lower than in the summer . There should be no water in the trench. If water appears during digging, construction work must be stopped immediately and postponed indefinitely, depending on the terrain and weather conditions.

What conditions must exist for pouring a foundation?

To ensure that the foundation does not begin to crumble immediately after construction, it is necessary to take into account the temperature conditions for pouring the mixture, the grade of concrete, and the implementation of reinforcement. Also, it is necessary to decide whether additives are needed in the concrete mixture or not. As a rule, during the summer months, builders are not faced with the question of when to pour the foundation. Warm weather allows this to be done at any month and time of day. But there is also the possibility of pouring the foundation in winter.

The brand of concrete is selected depending on the type of structure and type of soil. On soils with high water content, it is necessary to use high grade concrete. These types of cement do not absorb water. For reinforced foundations, it is very important not to leave the steel in the formwork for a long time. That is, after reinforcement is completed, concrete must be poured immediately. Moreover, layer-by-layer filling cannot be done either. This is due to the fact that in autumn the air temperature at night is lower than during the day. And this leads to the formation of condensation, which negatively affects the steel.

As a rule, the temperature at which the foundation can be poured in the fall is determined at the beginning of construction. Moreover, they take into account not only the time of year, but also the month. After all, different months have different temperature conditions, which means this is a very important indicator. This is important to consider when working with a monolithic base of a tape type or columnar type.

Preparation before pouring the foundation in the fall

To carry out foundation construction work in the fall, it is necessary to carefully plan the entire process in order to make the most of the advantages and avoid the disadvantages of the autumn period as much as possible.

The first step in planning will be choosing the area and marking it. These jobs can be done in the summer. Experts recommend digging a pit by the end of summer, beginning of autumn, so that the soil is not sufficiently wet or frozen. This choice is aimed at making digging easier. Also, before digging a pit, it is necessary to check for the presence of groundwater below the surface. When part of the pit has been dug, it is necessary to drill a small test shaft, as before digging wells, but to a much shallower depth. A few meters will be enough. If there is no water, you can safely continue work. If a source of water appears, it is necessary to choose another place to build a house, since the groundwater level rises significantly in winter and spring.

Experienced workers recommend pouring the foundation closer to mid-autumn, at the end of September and the first half of October.

A significant disadvantage of autumn is the unpredictability of the weather, as rain can appear at any moment. You should use the most accurate available weather forecasts to select a period with minimal precipitation and no frost. The presence of frost spoils the foundation that has not yet hardened; it tends to collapse from the inside during frost. Precipitation is not dangerous if it appears at least 2 days after pouring the foundation, by which time the concrete will have partially hardened.

It is necessary to take into account the characteristics of the soil in order to avoid subsidence of the foundation in winter due to water crystallization. The foundation hardens and stabilizes, depending on the area, for up to 6 months. In most cases, you can start laying walls already in winter. According to these recommendations and modern construction methods, it is definitely possible to build a foundation in the fall.

In addition, the price of building materials most often decreases in the fall, which allows you to save money. But if you carry out such work in winter, it will be difficult to make concrete yourself. There will be a need to order concrete from the plant, which will increase the cost of work.

Useful video about what to do at a construction site in late autumn:

Preparing to pour the foundation

Initially, it is advisable to calculate the required amount of solution. Then you can roughly calculate the costs of construction work. Then begin marking the future foundation. Wooden pegs are driven around the perimeter outside and inside, and a cord must be pulled along them. Using the markings as a guide, they dig a pit. The depth depends on the freezing of the soil in the area. In the northern regions, the pit depth can be even one and a half meters. And, for example, in the middle zone - 50-70 cm. A small layer of sand is poured into the already dug pit. It is advisable to use coarse sand. Waterproofing is laid along the walls of the pit and to the very bottom. Then the reinforcement is laid, and the metal rods are tied together with wire. The finished formwork should protrude above the soil level. Usually boards are used to make formwork, but sometimes other materials are used (slate, sheets of metal, chipboard). Then they immediately begin to fill the pit.

Method of pouring the foundation in the fall

According to the recommendations of specialists and experienced builders, for the construction of foundations in the autumn and winter periods it is necessary to follow certain rules. These rules are also specified in SNiP, “Load-bearing and enclosing structures”:

- It is necessary to carry out work on mixing the solution in warm, enclosed spaces;

- during the mixing process, it is necessary to use heated water, at a temperature not exceeding +70 °C, the structure of the mixed concrete should be as homogeneous as possible;

- the concrete mixing time increases by a quarter relative to the mixing time in the summer;

- the reinforcement frame for the future foundation should be slightly heated to prevent the appearance of ice crystals on it;

- formwork, supports and foundations should also not be very cold in order to prevent pre-freezing of concrete;

- the time of pressing the foundation by vibration increases by a quarter, as well as the time of mixing concrete, relative to the time of pressing the foundation in the summer.

Filling should be done as carefully as possible, slowly. Any even minor defect can cast doubt on the normal operation of the building in the future.

There are times when the situation gets out of control. In the midst of work, it may start to rain. The situation is unpleasant, but not critical. First of all, it is necessary to prevent excess water from entering the concrete mixture. Protection of poured concrete is carried out using film, tarpaulin and other waterproofing materials, which are covered over the poured concrete solution in the formwork. Before starting work, it is necessary to prepare waterproof materials or build small portable shelters from wood and slate, for example. If detected late, excess water can be carefully removed manually when it accumulates on the concrete surface. If rain catches the foundation two days after it was poured, excess water will not harm the concrete.

Watch a video about the consequences of pouring a foundation in the rain:

When to pour the foundation

Based on the previous point, we can say that the most optimal temperature at which concrete supports should be laid is the daily average value of 20ᵒC. In most regions of the country, this value corresponds to only one or two summer months. Such conditions provide very little time to complete the task, so it is not always possible to lay the foundation of a house in the most favorable conditions.

Pouring concrete in summer

This option will allow you to complete the work at the lowest financial cost and in the shortest possible time. Without taking additional measures, you can fill the foundation of a house under the following conditions:

- The ambient temperature is in the range of 15-25 ᵒC. It is important to take into account that this temperature must be maintained not only during the day, but also at night. It is also worth studying the weather forecast for the next two weeks, since it is better if this temperature persists for a long time while the concrete gains strength. Temperatures above 30 ᵒC have a bad effect on the concrete mixture used in Russia (in countries with hotter climates, concrete is designed for use at high temperatures).

- The highest strength indicators are achieved when air humidity is more than 80%. At the same time, it is important not to forget about caring for the concrete (that is, moistening it), which will prevent the appearance of surface cracks.

Based on these conditions, we can draw the following conclusion for the summer season: it is better to fill the foundation of a house in early June (but it all depends on the climatic characteristics of the area). This month is usually quite warm, but not hot, and the humidity remains normal. July may surprise you with drought and high temperatures, which will have an adverse effect on concrete. In August, sharp drops in temperature sometimes occur, which will increase the hardening time. But if you choose between dry July and cool August, it is better to go with the second option. The main thing is that the temperature at night does not fall below 5ᵒC and its drops are taken into account when dismantling the formwork.

Advice! It is better not to carry out work when it is raining. If it starts when pouring is already in progress, then it is worth protecting the structure from excess moisture. To do this, immediately after laying the concrete in the formwork, cover it with plastic film. Rainwater is terrible during the setting period. Once hardening begins, it no longer has a negative effect, but rather protects against excessive drying, which causes surface cracks to appear.

Pouring concrete in spring and autumn

In the first half of autumn and the second half of spring, concrete can (still) be prepared at the construction site. The temperature at this time usually does not drop below zero even at night, so pouring is done without fear. When working at this time of year, the following recommendations should be observed:

- you can introduce antifreeze additives into concrete, which will help protect against troubles;

- work cannot be carried out at a time of year when the temperature at night and during the day differs in sign (alternate freezing and thawing is the worst of all possible conditions for concrete hardening, so it is better to do the pouring in September or May, when the temperature is constantly above zero).

Also, when performing work in the fall, you need to take into account when the walls of the house will be erected. If you plan to do this work immediately after the foundation of the house, then you should take into account the time that you will have to wait until the concrete gains strength. If the supporting structure is made in the fall, and the walls will be built in the warm season, then it is necessary to provide for the conservation of the foundation for the winter.

Pouring the foundation in winter

The most labor-intensive process. If you fill in the cold season, the cost may increase by 30-40%. Taking into account the fact that the estimate for foundations sometimes amounts to up to 30% of the entire cost of the house, we are talking about an increase in the costs of all construction to 10-12%. This is quite a large amount. For example, if when pouring foundations in the summer, the entire house will cost the future owner 2 million rubles, then when pouring in winter, the estimate will increase by 200-240 thousand rubles. You can only save on building materials, which sometimes become cheaper during the off-season.

Work is carried out at an air temperature not lower than -15 ᵒC, taking the following measures to protect the structure from freezing:

- use of hardening accelerators;

- introduction of antifreeze additives into concrete;

- thermos method.

These recommendations for the preliminary selection of a concreting method are given in Table 1 of the “Guidelines for the production of concrete work in winter conditions in the regions of the Far East, Siberia and the Far North.” At temperatures below -15°C, preliminary electrical heating of the concrete solution is performed to a temperature of 50-60°C or heating formwork is used. For more detailed recommendations on concreting in winter, read the article: Is it possible to pour a foundation in winter?

Based on all of the above, it is worth drawing a conclusion: it is best to fill the foundation in the second half of spring and summer months. In this case, it is desirable that the temperature does not rise above 30 ᵒС, and the air is not too dry.

Advice! If you need builders to build a foundation, there is a very convenient service for selecting specialists from PROFI.RU. Just fill out the order details, the experts will respond and you can choose who to collaborate with. Each specialist in the system has a rating, reviews and examples of work, which will help with the choice. Looks like a mini tender. Placing an application is FREE and does not oblige you to anything. Works in almost all cities of Russia.

If you are a master, follow this link, register in the system and be able to accept orders.

Frost protection measures

The most negative factor for foundation construction in the fall is frost.

Low temperatures not only reduce the strength of the emerging concrete structure, they can lead to complete destruction of the foundation.

If frost takes builders by surprise, it is necessary to use the recommendations from the set of measures for protection against frost.

The simplest way is to simply cover the concrete with a heat insulator, which can be made from either special or improvised materials, such as straw, leaves, etc. The essence of the method is that during the first frost, excess heat remains in the ground. By using a thermal insulation layer, this heat can be retained longer. The method is very cheap and ineffective.

These additives allow concrete to gain strength, despite frosts at temperatures down to -20°C.

More serious protection against frost are special anti-frost additives in the concrete itself. Depending on the type of concrete used and the composition of the additives, they have different properties, dosages and prices.

The most effective protection is electrical heating of the foundation. Previously, pit and portable ovens were used for such purposes, but this method is quite labor-intensive. Electric heating provides high-quality protection from frost with minimal effort from builders. The disadvantage is the increased cost compared to other methods. The heating cable is installed on the foundation along with a heat insulator. It is important to prevent the foundation from overheating. The amount of cable and power of electricity depends on the area of the foundation, the ambient temperature, and the composition of the concrete. You can determine the required values yourself, but it is better to leave this work to professional consultants.

Typically, the solidification and initial formation of the foundation is carried out within a month, which is how long it is necessary to protect it from frost.

All methods of heating concrete can be used separately and in combination.

The strength characteristics of a construction project depend on the quality of the foundation pouring. This serious stage of work requires a thorough approach. Time and weather factors sometimes change the plans of developers. Situations arise when the foundation is poured in the fall.

Specifics of autumn filling

Construction in the rainy autumn is not as comfortable as in the summer, when concrete quickly gains strength. But if there is no alternative, you managed to dig a trench before frost, pour the concrete solution in early autumn, then the foundation will have time to acquire the required strength characteristics. By performing the work correctly, you can avoid subsidence of the foundation and subsequent deformation of the building walls.

Let's consider what weather factors determine the quality of work if the foundation is planned to be poured in the fall:

- Temperature regime.

The favorable temperature for setting and hardening of the concrete mixture is considered to be from 3 to 25 degrees Celsius. Elevated temperatures negatively affect strength, and at lower temperatures, hydration occurs worse. Favorable temperatures ensure slow hardening of the concrete solution in the autumn, significantly improving the strength characteristics. It is important to have time to complete the work before the soil freezes, when it swells under the influence of moisture. If a sharp drop in temperature is not expected, then get to work. - Ground water level.

If work is carried out in a swampy area or soil characterized by high humidity, pay attention to this factor. Despite the fact that in the first autumn months, when it does not rain, the level of groundwater layers is low, but the beginning of autumn rains contributes to a rise in the level. In unfavorable conditions, it is not advisable to build a foundation. We'll have to reschedule work until the spring.

If the construction process was carried out incorrectly, there is a risk of subsequent disposal of the foundation due to its unsuitability

Think through everything carefully, take advantage of the autumn period. Is it possible to pour the foundation in the fall? Naturally, remembering the main points:

- the optimal period for pouring is the beginning of autumn, when it is not hot, far from severe frosts or autumn showers;

- Focus on the long-term weather forecast, plan the start of work so that the concrete has time to gain strength within a month. During this period there should be no frosts that turn water into ice, which destroys the foundation;

- the degree of negative impact of precipitation is somewhat exaggerated. 3 days after pouring, they will not be able to cause serious harm to the hardening base, additionally moistening the surface.

While the issue of protection from autumn precipitation is easy to solve, protecting yourself from freezing temperatures is not easy. But this is possible, although the estimated cost of construction activities increases significantly. Let's consider this situation in more detail.

When pouring in the fall, there is no need for additional moisture

Is it possible to pour the foundation in the fall - technology features

Most people have a stereotype that it is necessary to fill the foundation only in spring and summer. Modern builders are proving that pouring concrete can be done in the fall if the necessary recommendations are followed. Such a properly executed foundation will not be inferior in performance characteristics to its summer counterparts.

Some information about autumn filling

Construction of the foundation is one of the main procedures of building construction. Depending on the correctness and accuracy of construction, taking into account all external factors, you can obtain a solid concrete base and begin building walls. If the construction process was carried out incorrectly, there is a risk of subsequent disposal of the foundation due to its unsuitability. The result is wasted time, money and effort.

In addition to the human factor, the pouring of the foundation is influenced by weather conditions. In autumn, as a rule, air humidity increases, temperature decreases, precipitation increases, the amount of groundwater increases, and so on. The listed factors may seem undesirable for pouring a foundation in the fall, however, most of them are advantages.

Taking into account the influence of temperature, we can conclude that it is advisable to fill the foundation in the fall, and not in the summer.

The best temperature regime for concrete hardening is from +15 to +25 °C.

In most summer periods, the temperature significantly exceeds this range, which leads to anisotropy of properties, when concrete hardens, and the appearance of significant and minor defects. Therefore, from the point of view of the influence of temperature, it is better to fill the foundation in the fall. In the autumn, concrete hardens much more slowly, but the quality will remain high. The process of building a foundation and its quality are affected by air humidity. Contrary to popular belief, increased humidity has a positive effect on concrete drying. When pouring in the fall, there is no need for additional moisture.

Precipitation negatively affects such construction work in the fall. You can pour concrete during this period, however, you should choose non-rainy periods. A large amount of water reduces the quality and performance properties of the solution.

An advantage for laying a foundation in the fall compared to summer is the groundwater level, which is often significantly lower than in the summer . There should be no water in the trench. If water appears during digging, construction work must be stopped immediately and postponed indefinitely, depending on the terrain and weather conditions.

Freeze protection methods

If the foundation must inevitably be poured in the fall, be sure to use one of the following methods to prevent the mortar from freezing while curing:

- The use of anti-frost additives allowing concrete to achieve the required strength at temperatures down to -20 ° C. The negative point is a significant increase in the cost of construction, which does not allow using the technique for arranging large foundations.

- The use of electrical heating of concrete with a special heat cable laid over the surface and covered with insulation. The method of passing voltage with high current is effective, but expensive, given the high cost of energy.

- Covering the base with sheets of polystyrene foam, tyrsa, mineral wool, film or any heat-insulating materials. An inexpensive, justified method of protection that allows the slowly cooling composition to retain heat throughout the week and provide a comfortable setting.

- Installation of thermal formwork. Carried out by specialized construction companies. This is an expensive but effective method that allows you to increase the temperature of the massif to + 30 ° C and maintain it throughout the setting period.

Of course, it is best to complete the work before the onset of cold weather. If you build in September, then laying the foundation will not lead to additional costs. The closer to winter, the greater the likelihood of problematic situations.

An advantage for laying a foundation in the fall compared to summer is the groundwater level, which is often significantly lower than in the summer

Do not forget that the hardening period of concrete is 28 days. If concreting is delayed, the foundation will need to be protected from negative temperatures for a whole month. Are you ready for this?

Do-it-yourself foundation pouring

Pouring the foundation yourself is perhaps the most economical, but labor-intensive approach.

This process requires a concrete mixer and at least three people. In this case, it is most rational to choose a larger volume concrete mixer. If you can’t pour the foundation in one day, you can stretch the work into two stages. It is important that the interval between stages does not exceed 12 hours. For example, we finished in the evening and started in the morning. The first layer can be poured over the total area of the formwork. When finished, cover the filled part with some plastic wrap. The next morning, after washing off the cement laitance, you can continue working. This mode of filling in two parts is called “hot seam”. Most experts do not recommend using a “cold joint” (this is when a second layer of mortar is poured after the first has hardened).

We must remember! The seam should be no closer than 50 millimeters from the longitudinal reinforcement bars. Each layer of concrete must be compacted so that cavities do not form near the reinforcement ties. After the foundation has been poured, it is covered with a protective layer of film, thereby protecting it from exposure to sunlight and possible precipitation.

Using a concrete mixer will be more expensive, but this is a good opportunity to quickly and efficiently complete the work and lay a reliable foundation for a future building.

How to fill it correctly?

If you have any doubts about whether it is possible to pour a foundation in the fall, we recommend that you familiarize yourself with the requirements of building codes and regulations that regulate the algorithm for performing work at subzero temperatures:

- use hot water at a temperature of +70 °C with special fillers that prevent freezing;

- prepare the mixture using a mixer equipped with a heating system, or work in a heated room;

- increase the mixing time by 25% compared to the standard interval;

- insulate the bottom of the trench and formwork using thermal insulation materials;

- heat the reinforcement frame, preventing the formation of moisture around the reinforcement during pouring;

- extend the time of vibration compaction of the composition by a quarter compared to standard standards;

- Periodically check the condition of the concrete.

Is it worth filling in the fall?

To sum up, to the question of whether it is possible to pour the foundation in the fall, we answer in the affirmative - of course, it is possible. However, additional conditions must be observed. If you do not intend to postpone the construction of the foundation until the spring and have the financial means, then modern technologies allow you to carry out this process in the fall.

- Author: Maria Sukhorukikh

Rate this article:

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Share with your friends!