Strengthening the floor slab using FibARM carbon tape

Work to strengthen the floor slab was carried out on a 10-story residential building (RC MKD). Date of work - April 2012. Customer: Tekhstroy LLC (Kostromagorstroy).

The method of external reinforcement of building structures appeared thanks to such a high-tech invention as artificial carbon fiber (carbon fiber).

Carbon fiber is a high-strength, high-modulus, linearly elastic material. It is used in the form of canvases and ribbons. Carbon fiber reinforcement is classified as external reinforcement, since the materials are attached to the structure using assembly adhesive (epoxy, epoxy polyurethane or polymer cement). They effectively respond to incremental deformations of the structure; large increments of force arise in them.

First of all, this property led to the use of carbon fiber to strengthen reinforced concrete structures. Since the ultimate elongation of this material is significantly greater than that of concrete, in most cases the working forces in carbon fiber are significantly less than the ultimate ones and the destruction of a carbon fiber-reinforced sample usually occurs along the contact layer between the external reinforcement element and the concrete. An exception is the work of transverse bands of carbon fiber columns.

The speed and ease of installation of external carbon fiber reinforcement elements is the main advantage of the non-traditional method. In addition, external reinforcement does not distort the aesthetic appearance of the structure, and the reinforcement process becomes much simpler than traditional technologies.

This method is most justified when it is necessary to strengthen unique or expensive structures, for example, architectural monuments, transport and hydraulic structures, the reconstruction of which by other methods is difficult or impossible at all. This technology is currently the most practical way to improve the performance characteristics of any elements of a building or structure.

Methods of strengthening structures, buildings and structures

Concrete materials have been used in construction for more than four thousand years; for the last few centuries, this material has been supported by iron, but this does not help protect it from unfavorable external environments and disasters. In Russia alone, today, there are thousands of houses made of reinforced concrete that require structural reinforcement. The most progressive and economical way is to strengthen it with carbon fiber.

At the moment, there are only 3 main ways to strengthen structures:

- Traditional or standard.

- Innovative or technological.

- Combined.

The traditional method - first of all, upholstery occurs, concrete layers are applied to increase the cross-sectional area. Next, rolled steel is used, installation of metal tie rods, and reinforcement of holes with angles or channels. The installation of additional elements to strengthen columns and floors is being completed, and spacers or piles are being installed.

An innovative method - this method of strengthening structures is based on the use of composites. Its essence lies in gluing carbon fiber in layers onto load-bearing surfaces. Because of this, the dimensions of the room do not change; the thickness of the material does not exceed a few millimeters.

The combined method is a method of working to fill all cracks and cavities with material. This method helps to permanently connect the disparate parts of the structure. The work is done using various mixtures.

The third method (combined) is suitable for strengthening reinforced concrete structures. Thus, traditional and innovative methods are combined.

When might it be necessary to strengthen a reinforced concrete structure?

It should be remembered that strengthening of such a structure occurs only if necessary:

- Wear of the product due to corrosion.

- The construction of additional floors is required.

- Change of layout.

- Changing the functions of the structure.

- Deformation.

Scope of application

Strengthening reinforced concrete structures

Typically, reinforced concrete structures are damaged as a result of corrosion, overloading of individual elements, design and construction errors, and improper operation of the facility. Those that are very expensive or even impossible to replace require special attention. This applies, first of all, to bridges, hydraulic structures, and architectural monuments. In this case, you cannot do without external reinforcement. Strengthening ordinary structures using carbon fiber is not always economically feasible.

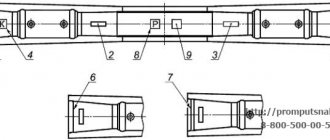

There are two ways to strengthen compressed (including eccentrically compressed) reinforced concrete elements such as columns, pylons, and piers using external reinforcement. To strengthen “short” elements (with a ratio of “height to cross-sectional dimensions” of no more than 10:1), carbon fiber bands are used, which create a “cage effect”. The second method is to install a carbon fiber canvas along the compressed element, which serves as additional working reinforcement.

When strengthening earthquake-resistant structures, it is recommended to use a three- or four-directional canvas for the outer bands.

Flexible columns are reinforced with both longitudinal and transverse elements of external reinforcement. Longitudinal elements are installed in such a way that the location of the physical axis of the section does not change.

Strengthening of metal structures Tensile steel structures are strengthened symmetrically relative to the center of gravity of the section. In this case, carbon fiber is used with the highest possible strength and elastic modulus, close in value to the elastic modulus of the reinforced material.

Installation of carbon fiber canvas or tape is usually preceded by cleaning the surface of the metal structure (for example, sandblasting) and applying an adhesive layer - mounting epoxy adhesive. Upon completion of installation, protective or fire-retardant painting is applied to them, and then additional mechanical fixing devices are installed.

When strengthening eccentrically compressed steel elements, carbon fiber canvases or strips are also installed symmetrically relative to the center of gravity of the section, but their asymmetrical arrangement is possible, in particular, when restoring a section damaged by corrosion. In this case, carbon fiber with a maximum elastic modulus is also used.

If it is necessary to increase the stability of steel plates, for example, high walls of beams from the bending plane in the zone of shear force, carbon fiber canvases are glued symmetrically relative to the center of gravity of the section.

Strengthening stone structures External reinforcement made of carbon fiber materials is much more effective than traditional methods of strengthening stone pillars, pylons, and piers using steel clips. After all, it is possible to ensure the necessary joint operation of the steel cage and the reinforced column only by creating initial forces in the cage by heating the clamps and using expanding solutions. And this process is labor-intensive, low-tech and not modern. Carbon fiber clips are included in the work of the reinforced element simply during its installation through the adhesive layer.

Elements of external carbon fiber reinforcement make it possible to widely regulate the forces in a masonry structure and at the same time minimize violations of its integrity. This is fully true for the structures of reconstructed and restored buildings.

In traditional reinforcement of brick walls with windows, doors and other openings, steel brackets and profiles are installed. All this is fixed to the walls through anchors, followed by caulking with expanding solutions. The modern method of strengthening walls using carbon fiber canvases and tapes allows one to avoid the installation of point anchors, involve a larger volume of material in the work of a separate element, realize the existing design reserves, while at the same time taking care of undamaged areas.

Strengthening wooden structures. Carbon fiber sheets are effective in areas where the main tensile stresses act and there is a danger of splitting along the fibers. It is also advisable to glue them to flexible plywood walls in the area of lateral force.

These external reinforcement elements are usually either glued to the surface or glued into pre-prepared cuts. It is preferable to make the cuts vertical for minimal disruption of the integrity of the section.

The second option is preferable when it is necessary to preserve the original appearance of the beams and make the reinforcement itself invisible. Invisibility, along with technological simplicity and high installation speed, are among the main advantages of reinforcing wooden structures from carbon fiber elements.

APPLICATION AREA

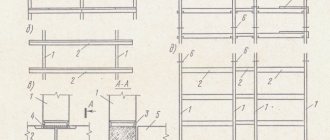

1.1. This standard flow chart has been developed for the process of strengthening reinforced concrete beams and crossbars by installing an intermediate support.

1.2. The map is recommended for use in the reconstruction and repair of industrial and other buildings with monolithic or prefabricated beam floors with spans of 6-18 m.

1.3. This map discusses the features of performing work with various structural reinforcement schemes and variants of the technology used.

1.4. When linking the technological map to real objects and conditions of work, it is necessary to recalculate the volume of work, calculations of labor costs and wages, work schedules, material and technical resources and final technical and economic indicators based on the facet classifier of factors.

Strengthening the floor slab using FibARM carbon tape

Work to strengthen the floor slab was carried out on a 10-story residential building (RC MKD). Date of work - April 2012. Customer: Tekhstroy LLC (Kostromagorstroy).

Strengthening reinforced concrete floor beams - YUG-ZhBK

All parts of building structures lose strength during operation. Floor panels and support beams are no exception.

As a result of increased load on the floors, as well as partial destruction of the slab reinforcement, cracks appear on the surface of prefabricated slabs, as well as inside the concrete mass of monolithic floors.

To increase the load capacity and increase the service life, the floors are reinforced. The choice of the optimal method of strengthening the panels is determined by their design features.

Strengthening floors is a necessary measure

The need to carry out restoration work aimed at increasing the strength of floors arises quite often:

- when performing planned repairs of an ordinary apartment located in a multi-storey building;

- when carrying out repair work inside industrial or warehouse premises;

- in the process of restoration of architectural monuments and restoration of interfloor structures of old buildings;

- when carrying out repair activities associated with serious redevelopment of various types of premises.

The technical condition of these structural elements is one of the main factors that determine the need for reconstruction of civil and residential buildings

The reasons for the destruction of load-bearing structures are various:

- non-compliance with technology requirements when performing construction work;

- use of low-quality building materials;

- a significant increase in load on load-bearing walls and ceilings;

- reinforcement corrosion associated with damage to the protective layer.

In addition, sometimes there is a need to strengthen interfloor panels, the condition of which is quite satisfactory. This situation is associated with a change in the functional purpose of the premises. After all, new building owners quite often place massive equipment, carry out significant reconstruction, and also increase the number of floors of the building.

Depending on the characteristic features of the destruction, repair work includes:

- removal of collapsing elements and their local replacement with new ones;

- restoration of the concrete mass or increasing the thickness of the slabs;

- reinforcement of panels with steel mesh or additional reinforcement bars;

- installation of steel plates and powerful clamps in the areas where beams join.

The choice of the optimal reinforcement method is determined by the builders depending on the material of the overlapping structures. The following materials are used as flooring materials:

- wood;

- metal profile;

- reinforced concrete.

These works include a whole range of measures that are aimed at restoring the load-bearing capacity of the floor and individual parts

In some cases, concrete reinforced with steel reinforcement is used to increase the load capacity; in others, supporting elements are installed or metal clamps are used.

It is allowed to install support posts made of rolled metal or wooden beams in the problem area.

When carrying out restoration measures and installing floors, you should adhere to the requirements of the technology and use high-quality raw materials.

Following these recommendations will allow you to avoid problematic situations during the operation of the building.

Reinforcing the floor slab - common types of panels

Reinforcement of reinforced concrete floors is carried out using various methods depending on the design features of the slabs. The following types of plates are used:

- compound. They are widely used in reinforced concrete floors of residential, industrial and commercial buildings. Prefabricated concrete panels rest on load-bearing walls, as well as longitudinally located transom beams or reinforced concrete trusses;

- whole. They are formed by continuously pouring graded concrete into pre-installed formwork with reinforcement cage. The monolithic structure is also assembled from standard reinforced concrete elements, which, after installing the floor slabs, are filled with a thick layer of concrete mortar.

Various types of panels are used for the construction of floors:

- full-bodied. They have no internal cavities. Solid slabs are mainly used for the lower floors of buildings, as well as at production facilities. Typical types of solid panels are ribbed, coffered, and beamless slabs. Ribbed slabs are easily distinguished by their trapezoidal cross-section and the presence of longitudinally located ribs. The length of the elements reaches 12 m, which allows them to be used to form floors at various construction sites;

- hollow. They are distinguished by the presence of six longitudinally located channels of round or oval cross-section. The length of hollow-core slabs ranges from 3 to 6 m. Hollow-core products with reduced weight are in demand in the construction of residential and administrative multi-storey buildings. The design features of the panels, associated with the presence of internal cavities, negatively affect the strength properties. To increase the reliability of building structures, products need to be strengthened.

Restoration and strengthening may involve identifying safety margins

Along with the indicated types of floors, the following structures are used:

- formed by a frame of wooden beams;

- made of metal beams of I-section.

Building structures made from wood and steel beams were used in buildings constructed in the 19th and 20th centuries. The free space between horizontally located elements made of wood and metal was reinforced and filled with concrete. As a result, a monolithic surface was formed. Floors based on wooden and metal beams have been well preserved to this day, but require additional reinforcement.

What factors indicate the need for strengthening

The need to strengthen the slabs is mainly due to temporary factors:

- during long-term operation, the ability of floors to absorb loads decreases;

- with prolonged use of floors, their technical condition deteriorates;

- When the integrity of the roof is gradually compromised and moisture penetrates into the room, corrosion of the reinforcement occurs.

It is not always possible to detect weakened areas of the ceiling. Damaged areas located in the lower part of a monolithic or prefabricated floor can be difficult to visually identify. Quite often they are located under a layer of decorative plaster, under a suspended ceiling or covered with a layer of paint.

Strengthening floor slabs may involve increasing the cross-section of structural elements

When examining, it is important to pay attention to the following points:

- peeling of concrete from the top or bottom surface of the panels;

- deep and superficial cracks on the surface of slabs;

- peeling of the cement screed from the reinforced concrete base;

- violation of the integrity of the floor covering;

- corrosion destruction of the reinforcement frame;

- the appearance of light or dark spots on the concrete surface;

- formation of rusty stains on the surface of the slabs;

- destruction of the protective layer of concrete and exposure of reinforcement;

- increased deflection of floor elements;

- uneven cross-section of supporting structural elements;

- significant destruction of wooden and reinforced concrete floor beams.

Depending on the type of defects, specialists decide to reinforce the floor slab from below or strengthen the surface with a new reinforcement cage and concrete on top.

Strengthening floors - preparatory activities

The correct approach to carrying out repair activities affects the reliability and durability of the structures being restored.

Repair work requires preparation and is carried out in the following sequence:

- Vulnerable areas are identified.

- The scope of construction work is determined.

- Design documentation is being developed to strengthen the floor.

- The calculations necessary for restoration work are carried out.

- A suitable recovery method is selected.

- Construction tools are being prepared.

- Construction materials provided for by the project are purchased.

Let us dwell on the features of performing individual stages.

Strengthening floor slabs is sometimes accompanied by the inclusion of new elements in the work

To assess the actual condition of the reinforced concrete floor and determine its actual load capacity, an examination is carried out using one of the following methods:

- by visual inspection, the correctness of the geometry, the integrity of the reinforcement, the degree of exposure to increased loads from technological equipment, and the presence of local defects in the concrete mass are determined;

- The method of instrumental control determines the strength factor of concrete, the cross-sectional size of reinforcing bars, the width and thickness of cracks, the amount of deflection of floor panels, the thickness of the cement screed or protective layer of concrete.

Having completed the survey activities, they determine the methodology for performing the work, which involves solving the following tasks:

- restoration of the load capacity of reinforced concrete slabs;

- carrying out work to additionally strengthen the panels;

- elimination of factors that caused defects in the reinforced concrete base.

Regardless of the type of ceiling, the following work is performed before starting restoration activities:

- vertically located supports made of steel pipes or wooden logs are installed under the structure to be strengthened. Fixation of supporting elements intended for redistribution of forces is carried out using spacers or linings;

- remove remnants of old paint, a layer of plaster and whitewash. It is important to remove concrete delaminations, as well as thoroughly clean the reinforcement frame elements from corrosion using a wire brush;

- clean the surface of the floor covering and old screed, and also dismantle the technological equipment located in the room.

In areas where local restoration is planned, dust should be removed and the surface of the concrete mass and reinforcement should be degreased.

Sometimes additional supports may be installed

Common schemes for strengthening monolithic floors

Professional builders use various schemes for strengthening floors:

- additional reinforcement of the damaged area followed by concreting;

- increasing the thickness of the slabs due to the formation of an additional layer of reinforced concrete;

- shotcreting the surface of a reinforced concrete base with branded concrete mortar.

The choice of the optimal strengthening scheme is made individually depending on the design features of the floor.

Source: https://yzgbk.ru/usilenie-zhelezobetonnoy-balki-perekrytiya/