Foundation for a bathhouse made of foam blocks - features and capabilities of the material

A real Russian bathhouse, built with one’s own hands, has always been the pride of the owner of a private household or summer cottage. Solid logs, used for centuries to build log houses, are becoming a thing of the past and are used less and less today. Wood is being intensively replaced by more modern materials that have lighter weight, a more affordable price and decent thermal conductivity characteristics, which is important for any structure, especially for a bathhouse. A worthy alternative is the use of foam block - a relatively new material that has many positive properties.

Some features of the foam block

Foam concrete products have become widespread in individual low-rise construction. They are used in the construction of cottages, garages or bathhouses. However, it should be noted that the material is least suitable for constructing a foundation. Insufficient plasticity of foam blocks when exposed to frost heaving forces negatively affects the strength of the underground structure. The porous structure facilitates the absorption of large amounts of moisture from the soil, leading to rapid layer-by-layer destruction of lightweight concrete.

Meanwhile, the construction of bathhouse walls from foam blocks is today one of the best solutions when choosing materials for such a building. The determining factors in this case are:

- excellent thermal insulation;

- small weight;

- affordable price;

- environmental friendliness;

- fire resistance;

- durability.

The cellular structure of the foam block, filled with a mixture of inert gases and ambient air, provides it with a low thermal conductivity coefficient, comparable to similar indicators for wood of various species. When using it, there is no need for additional insulation. In addition, porosity allows the material to “breathe,” which ensures the timely removal of moisture from a steamed room and the creation of a special microclimate.

The relative lightness of foam blocks makes working with them comfortable, and their rather impressive dimensions, unlike bricks, make it possible to quickly build a building with your own hands. But when choosing an artificial stone, you should not forget about the high level of water absorption of the material, so for a bath you should purchase foam blocks of maximum density. Otherwise, a structure associated with high humidity and steam formation will not last long.

Ready-made bathhouse projects made from foam blocks

When considering a finished bathhouse project, you need to make sure that it contains a competent layout of the steam room, sink and rest room. Depending on personal preferences, each zone is allocated the required area, and the distribution can be different: a large steam room and a small sink, or a large relaxation room and compact functional areas. The choice is up to the owners. The main thing is that the room is comfortable and properly organized.

The dimensions of the stove structure are determined by the volume of the steam room, but it is better to take a few centimeters of reserve. This rule is mandatory when placing the stove in another zone, due to which part of the thermal energy will be spent on heating the building itself.

With swimming pool

When building a sauna with their own hands, people prefer options with a swimming pool. But such a tank can only be installed in a spacious building. Otherwise, it will be bulky and will worsen the comfort of using the bathhouse. If you plan to build a 2-story bathhouse, the pool can be placed on the second tier. A prerequisite for this element is the presence of at least one ventilation window.

There are different types of sauna pools available for sale, differing in both shape and purpose. When choosing the appropriate option, you must be guided by the features of the construction layout and financial capabilities, because purchasing such a design is not a cheap pleasure.

With terrace

Projects for bathhouses made of foam blocks with a terrace are quite common. This is due to the stylish appearance of the building and the ability to make the most of every centimeter of space. The veranda of a block bathhouse can be combined with any type of design, regardless of the parameters of the room.

Foam block and any other alternative can be used as a material for creating a terrace, including:

- Wood.

- Metal.

- Plastic.

- Decorative rock.

On a well-equipped terrace you can place useful furniture elements (tables, chairs, sofas, armchairs). The main thing is that there are not many of them, because... an overloaded area will look unpresentable. When constructing a two-tier bathhouse, the veranda is located on the second floor.

The size of the bathhouse with shower and toilet is 5x9 m with a total area of 45 m². The structure has one floor and several separate zones:

- Shower.

- Toilet.

- Restroom.

This layout is especially convenient when constructing a country bathhouse.

Drawings of bathhouses with a summer kitchen and a plunge pool allow you to build a functional room for a cozy time with friends and family.

In such projects, the summer kitchen serves as a dressing room, and the kitchen stove structure is installed in the bathhouse itself. Both buildings are equipped with the same roof.

We suggest you familiarize yourself with: Plastering the surface with the installation of beacons, options for mounting beacons on the wall

The design of a bathhouse with an attic expands the functionality of the room and allows you to effectively use all the available space. The attic floor can be used as:

- A full rest room.

- A gym equipped with exercise equipment.

- Rooms with a billiard or tennis table.

- Rooms for storing bath accessories.

In most cases, the area under the roof structure acts as an attic where various accessories are located. But the designers decided to get rid of this stereotype and find a more competent use of the space - to equip the attic.

Such a project has the following advantages:

- The owner of the bathhouse receives additional space and rationally distributes useful space.

- A 6x4 bathhouse project made of foam blocks with an attic floor is often used to furnish a guest house.

- A bathhouse with an attic has a more presentable appearance than a simple one-story building.

Two-story bathhouse

To build a comfortable bathhouse from foam blocks with two floors, you need to select or create your own project with a detailed layout of each zone. Like the single-tier option, a two-story bathhouse should be created taking into account the following requirements:

- The design of a two-story bathhouse made of foam blocks provides space for the installation of ventilation holes.

- If a fireplace is to be installed on the second floor, a separate chimney must be made from it.

- Particular care should be taken when installing utility lines.

- In addition to the furnace structure, you will need to provide an independent heating system.

Foam block foundation

Many developers have a question about why it is not recommended to build a foundation of the same material for light walls built with their own hands from foam blocks. On the one hand, small loads from the load-bearing walls of a one-story bathhouse make it possible to get rid of a massive underground structure. On the other hand, frozen soil will have an irreversible effect on the fragile foam block under the influence of frost heaving forces, quickly destroying the foundation.

It would seem that in the southern regions, where the air temperature does not drop below positive levels, the construction of a bathhouse on a foam block foundation is quite possible. But here groundwater or heavy rains can play a role. In this case, it is possible that even the most advanced waterproofing will leak at the slightest opportunity and the porous concrete will begin to intensively absorb moisture, which will subsequently lead to the need to strengthen the underground part of the bathhouse.

There are no documents in state standards for the use of foam concrete when constructing foundations, and not a single manufacturer can give a guarantee on the use of blocks during its construction. So is it worth the risk?

However, there are daredevils who build bathhouses on a foundation made of foam blocks with their own hands. There is also evidence that similar technology is being used in some Western countries. In this case, several rules must be observed:

- the location of the groundwater level should be much lower than the base of the foundation;

- when laying, reinforcement elements should be used;

- when choosing blocks, you need to pay attention to materials with high density;

- It is worth taking care of impeccable waterproofing, which allows you to reduce the increased hygroscopicity of the material to zero.

Most often, foam concrete blocks are used as an auxiliary material in foundation construction. They fill the space at the base of the building, located above the ground between piles or pillars that take on the load-bearing load. But in this case, the masonry should be provided with reliable waterproofing.

Tips for finishing (do I need to coat it with what and how)

In order for the bathhouse premises to retain heat for a long time even in severe frosts, it is necessary to take care of high-quality insulation and finishing of its internal and external surfaces.

Attach horizontal beams to the inside of the walls at a distance equal to the width of the insulation. These bars are designed to hold the thermal insulation layer. Place mineral wool slabs into the resulting cells. Fix a vapor barrier layer on top of the insulation, which is a special membrane made of aluminum foil and polyethylene film.

We invite you to familiarize yourself with: Bathhouse in the country without a steam room

The layers are connected to each other with special glue. The joints of the vapor barrier coating must be sealed with tape. Install a wooden sheathing on top of these layers, which will create an air gap between the previous layers and the facing material. Install a wooden clapboard finish on the sheathing. You should select non-coniferous wood so that resin does not release at high temperatures.

Wooden lining creates a special atmosphere of comfort

In the steam room it is necessary to provide shelves on which you can sit or lie. Their basis will be a wooden frame made of strong beams, which are covered with clapboard. This material is also attached to the ceiling, only at the stove it needs to be replaced with a galvanized sheet. The heating area around the stove can be decorated with natural stone. It not only looks beautiful, but also retains heat thanks to the properties of the stones.

Exterior design can be of different shapes and shades

The floor in the bathhouse should be insulated using the same principle. Ceramic tiles can be used as a finishing coating.

External walls also require finishing, as this will become an additional layer that prevents the penetration of cold, as well as protection for the foam blocks. For this purpose, ventilated facades are often used, the design of which helps remove excess moisture into the atmosphere.

Foundation for a foam block bathhouse

In order to take full advantage of all the advantageous characteristics of foam blocks used in the construction of walls for a bathhouse with your own hands, it is necessary to qualitatively waterproof the foundation at the level of the sole and at the point of its contact with the ground part of the building. Fulfillment of this condition will extend the operational life of the structure.

The lightness of foam concrete makes it possible to build a shallow strip foundation from monolithic concrete with the obligatory installation of a sand cushion. To begin with, markings are made in accordance with the location and size of the bathhouse in plan. Pegs or pieces of reinforcement are driven into the corners, and a rope is pulled between them. For correct orientation when digging a trench and installing formwork, it is recommended to set additional marking stakes in increments of up to 2 meters.

A trench should be dug along the perimeter of the bathhouse to a depth that takes into account the level of soil freezing and soil composition. The width of the recess depends on the thickness of the load-bearing walls and formwork panels made from boards. In most cases, a foundation monolith width of 300 mm is sufficient.

Under light buildings, it is allowed to deepen the strip foundation by 60 cm, but only if there are no heaving soils and a high groundwater level on the site.

A layer of sand 10-20 cm thick is poured onto the bottom of the trench with mandatory step-by-step compaction. In some cases the size can be increased to 60cm. It should be taken into account that the pillow should be made wider than the monolithic foundation by 10-15 cm on each side. Sand in the design of shallow foundations performs the function of redistributing loads and is a kind of damper for the buoyancy forces of frost heaving.

Next, formwork is installed in the trench with the obligatory installation of spacers and supports. It contains waterproofing and a reinforcement frame made of rods 12-14 mm in diameter. It is placed on special linings that provide a lower protective layer of concrete 5-6 cm thick. An essential point when constructing a foundation for a bathhouse is the laying of sewer pipes into the monolithic thickness that drain used water from the washing compartment, so you should not forget about them.

At the next stage, the concrete mixture is poured, preferably at one time or with short breaks. The solution is leveled and compacted, getting rid of voids, after which the foundation is covered with film for several days, periodically watering it with water. Work on the construction of the walls of the bathhouse can begin after a 28-day break required for complete curing of the monolith.

Walling

After the stage of waterproofing the base (with bituminous materials) is completed, you can begin the stage of wall construction. For such purposes, it is recommended to use products of type M25, which has a density index of D700. The dimensions of this material are considered optimal for various types of construction manipulations.

First you need to find out the highest corner of the building. This operation is performed using a building level. Taking this knowledge into account, further construction of the building from foam blocks is carried out.

Installation of the first row is considered to be the most important stage. The quality of subsequent rows and the entire building as a whole depends on it. When installing this series, the products are installed using a cement mixture. When the laying of the row is completed, the surface should be carefully leveled. Only if this stage is performed correctly will further steps be correct.

We suggest you read: How to paint an iron stove in a bathhouse

Subsequent rows are installed using special glue. The technology for its preparation is described in the manufacturer's instructions. However, there are no difficulties in breeding; this can be done directly on the site. This material is produced in the form of a dry solution. It will take 15 minutes to knead. Despite its considerable cost, its use is still profitable, because the consumption is minimal.

Screw piles

Sometimes a more expedient option for installing a foundation for a bathhouse is to install screw piles. Often in difficult soil conditions they become the only alternative to pouring shallow tape.

Metal piles are screwed into the corners of the building, and, if necessary, between them, with the involvement of relatives or neighbors, even without the use of mechanized equipment. In this case, there is no need to carry out excavation work and mix a large amount of concrete mortar with your own hands. The piles are tied together with a grillage, on which foam blocks are laid after waterproofing is installed.

Optimal base options for a bath

Considering that foam block is one of the lightest building materials, it makes no sense to build a foundation with a large margin of safety, so let’s consider foundations that will be effective both from a structural point of view and from a financial point of view:

- Columnar with grillage,

- Shallow tape,

- On screw piles.

The choice of a specific type depends on the characteristics of the soil, terrain, and groundwater level. For example, in swampy areas it is better to use screw piles or simply piles, “tape” or pillars are unprofitable and not always possible - it is necessary to make a deep trench, which is simply unrealistic to do when the groundwater level is high.

Columnar foundation with grillage

One of the cheapest options for constructing foundations for the construction of light buildings and structures, such as foam block baths. Suitable for non-heaving dense soil types. The big advantage of this base is the minimal excavation work (digging a trench) and the ease of the device as a whole.

The columnar foundation can be made from stone, rubble brick, or monolithic reinforced concrete pillars.

The task of any foundation is to evenly distribute the load transmitted from the building to the soil. This function is performed by pillars; their number is calculated depending on the project, but the distance cannot be less than 2 meters from each other. It is important to make the correct calculation of the number of pillars; too many will lead to overspending on the construction of the base, and less will lead to uncontrolled deformations, which is especially dangerous when building from foam blocks and will certainly lead to cracks or, even worse, destruction of the foam block masonry.

To make the correct calculation, it is necessary to determine what kind of soil we have, and also calculate the total weight of the bathhouse. You need to take everything into account: possible furniture, stove, foundation with grillage, walls, roof, possible snow load.

The table shows approximate specific gravities for calculation

Table for calculating the specific gravity of a house

To determine what kind of soil, it is best to conduct a geological survey. It is clear that such a project will be quite expensive for a private developer. If the construction budget is limited, you can use a pit to determine what kind of soil. To do this, at around 0.5-0.6 meters from the planned depth of the foundation, we take soil and make a small ball out of it.

Next, we try to roll a small ball out of the soil:

- if you can’t roll a ball, we have a sandy layer,

- if it rolls, but when squeezed it breaks up - sandy loam,

- if, when pressed, the ball retains its shape and there is no cracking along the edges, it is clay,

- if cracks appear, we have loam in front of us.

Now we need data on the calculated resistance of the load-bearing soil:

Table for determining the design soil resistance

We determine the minimum total area of the foundation; to do this, we multiply the weight of the entire house by the safety factor (usually a value from 1.3 to 1.5) and divide by the calculated soil resistance.

To determine the number of pillars, we first determine the area of one pillar, then divide the minimum total area of the foundation by the area of one pillar. We get the required number of pillars.

- We begin constructing a foundation for a bathhouse made of foam blocks with markings. Using cords of wooden pegs, we mark the perimeter of the future bathhouse and check the diagonals (they must be equal to each other).

- Marks the locations of the pillars. These are the corners of the house, the intersection of load-bearing and internal walls. The remaining number of pillars is distributed evenly around the entire perimeter; for symmetry, you can add several pillars

- An important rule: Pillars can be added as needed; making the quantity less than the calculated amount is strictly forbidden.

- After applying the markings, we dig holes using a drill or other device below the freezing level.

- Depending on the material chosen for construction, the pillars are erected or poured.

- After the foundation hardens, a reinforcement frame is made around the entire perimeter.

Using plastic to decorate a bath

Instructions for completing the interior decoration of the bath:

- Acclimatization of the material - all the material intended for finishing is brought inside the bathhouse and remains there for at least a day.

- To fasten the lining, a sheathing is installed, consisting of bars with a cross-section of 5x5 centimeters. The distance between the bars is 50 cm.

- Vapor and thermal insulation is being installed.

- The lining is installed, depending on the room: hardwood for the steam room, softwood for the washing room and rest room.

- The lining can be mounted horizontally, vertically and also diagonally.

The floors are either made of wood or laid with ceramics on a concrete base. Many rest rooms and dressing rooms are equipped with a “warm floors” system. But such a system is not suitable for steam rooms where air humidity is very high.

The interior decoration of a foam block bath can be made of various materials

Not so long ago, finishing with plastic was not common - except perhaps the ceilings of kitchen areas were sheathed with such material, or something in the bathroom. That is, plastic was chosen for those rooms where the air humidity level is very high.

We invite you to read: Installation of a chimney through a wall - All about roofing

Today, this finishing material is very popular. In general, finishing a foam block bathhouse with plastic is a durable, practical solution. However, you can only use such material in the dressing room, which is usually located in front of the washing room.

Why is it worth using plastic, what are its advantages?

Nowadays, plastic can be of several types.

It is known that plastic is a very moisture-resistant material, but it is very durable. However, it is not difficult to damage it - any sharp object will cope with this task; Installation of this finishing material is not so difficult - you will definitely cope with the job, even if you get to work with your own hands without special training; Another important factor: the cost of plastic is affordable almost any family - this also affected its popularity in modern use

The material is used today not only for performing various finishing works indoors - it is also often chosen for external cladding; Climatic phenomena, various weather vagaries - all this does not pose a threat to plastic products; Experts recommend paying attention only to the fact that there are certain types plastic (we are talking about cheap products), which can fade due to exposure to direct sunlight. However, there is no need to worry about this if the material is used only indoors.

Plastic may be used inside some bathhouses

It is not difficult to attach plastic - this can be said about both wall material and plastic lining. For this purpose, a lathing should be made on the surface of the wall.

To make the interior decoration of the foam block with plastic in the bath ideal, you need the following elements:

- Construction level;

- Self-tapping screws for wood;

- Wooden bars, planks;

- Electric jigsaw;

- Sealant;

- Plastic;

- A construction stapler wouldn't hurt.

In general, it is not recommended to do this, since the work will take much more time. It is much easier to create a sheathing directly where you are going to attach the plastic.

And the installation is done in this way:

- The sheathing (frame) structure has auxiliary and load-bearing guides. All elements are fastened together with self-tapping screws - to make work easier, also use a screwdriver;

- The supporting guides are mounted to the surface using dowels. They will significantly strengthen your entire structure, making it as durable as possible - finishing a bathhouse made of foam block will only benefit from this;

- This type of sheathing should be done around the entire perimeter of your finish. Using a construction stapler, it will be necessary to attach sheets or strips of plastic to it;

- To connect the elements of the plastic lining with each other, special locks are used - they are at the end of the material. And if we talk about sheet plastic, then its installation is carried out on the frame using a construction stapler, and here you can also use self-tapping screws, the diameter of which is not too large.

But, if possible, wood remains the preferred material for cladding.

This work should involve:

- Styrofoam;

- Polyurethane foam;

- Mineral solid insulation;

- Mineral wool.

Insulation can be inserted into the sheathing cells immediately. That is, you will save not only the insulating material itself, but also the time that you will have to spend on insulation, because there is practically no need to take time off from the finishing work inside the bathhouse.

Shallow strip foundation

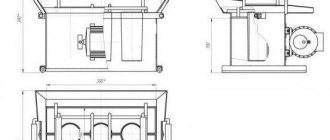

Schematic diagram of a shallow strip foundation

Soil analysis and foundation calculations are carried out by analogy with a columnar foundation, only instead of the number of columns, the width of the foundation base is calculated.

A shallow foundation for the construction of a bathhouse made of foam blocks can use different materials, as well as their combinations

- We carry out marking and excavation work to dig a trench. A geotextile backing is laid.

- We fill the pillow in several layers; it can be sandy or sand-crushed stone. The pillow must be compacted well; for this, a hand tool or a special platform vibrator is used.

- We install the formwork, check the geometry, and lay the reinforcement. If the foundation is up to the level of the plinth, communication pipes are laid

- Concrete is being delivered and poured.

- To prevent air pockets from remaining in the concrete, the mixture is compacted using a vibrator.

- When the concrete has hardened, remove the formwork

- We backfill and compact in layers.

- We immediately make an insulated blind area.

- After 28 days (this is how long it takes for concrete to gain strength), you can continue building a bathhouse from foam blocks.

Organization of strip foundation

Work on arranging the strip base begins with marking the site. It’s good if you have geodetic surveys available, but you can get by with a regular building level.

Stages of work:

- Using a cord and pegs, create a rectangle on the site, the dimensions of which will correspond to the parameters of the bath;

- Measure the length of the internal diagonals, which should be absolutely identical;

- Dig a trench along the contour of the created rectangle, 30 cm wide and 60 cm deep;

- Drive iron rods into the corners and the entire perimeter at a distance of 190 cm from each other. Check the accuracy of their location with a building level and a stretched cord;

- Using reinforcement with a cross-section of 12 mm, weld a strong metal frame;

- Assemble the formwork from boards, boards or other suitable material. Install and secure it in the trench;

- Lower the frame parts and secure them to each other with knitting wire with an overlap of 15-20 cm;

- Install sections of plastic pipes with a cross section of 5-10 cm, which will later be needed for laying communications;

- Pour the concrete mixture, periodically tapping and compacting. Control the upper level using iron pins. For a bathhouse made of foam blocks, a foundation height of about 70-80 cm will be sufficient;

- Level and compact the solution, cover it with polyethylene and wait for it to dry;

- Complete hardening of the concrete mixture will occur in at least 28 days, after which the construction of walls can begin.

Foundation on screw piles

Screw piles for a foam block bath

It is used very rarely for construction from foam blocks. Foam block is a fragile material and if you do not calculate it correctly or make inaccuracies when installing piles, there will be big troubles.

But the simplicity of constructing such a foundation and the ability to use it on unstable soils sometimes makes it almost the only option. The difficulty arises in the construction of a grillage connecting the piles to each other.

- Before starting construction, you need to calculate the number of piles, this is done as when building a columnar foundation.

- Next, you need to make markings, check the geometry, and mark where the piles will be located.

- Next, using a wrench, the piles are screwed into the ground to a depth of 0.5 meters below freezing.

- Using a water level, the piles are trimmed to one level.

- Connecting grillage devices are being produced.

To make the right choice of foundation for building a bathhouse from foam blocks, you need to start from the soil that is on your site, then determine its calculated definition, calculate the cost of this or that type of foundation. Having this data, analyze which design will be the most optimal in your region.

About

Do-it-yourself bathhouse made of foam blocks

A house or bathhouse made of foam blocks is second only to wooden buildings in terms of environmental friendliness and is far superior to brick and concrete structures. Unlike brick or ordinary concrete, a bathhouse made of foam blocks makes it easy to carry out interior finishing, since nails and other fastening methods are easily included in this material. If you take into account the reviews, a bathhouse made of foam blocks is one of the best solutions in terms of construction.

The fastest way of construction is a turnkey bathhouse made of foam blocks, in which there is no need to interfere with construction and solve many issues. Prices for baths made of foam blocks depend on many factors, primarily size, complexity of the project, conditions and construction time. You can build a bathhouse from foam blocks yourself, without resorting to the help of hired construction crews.

The process of building a bathhouse from foam blocks

You can build not only a one-story structure from foam concrete; the presence of a second floor will not make the structure too heavy. If openings of more than 2.5 meters are provided, then the structure is reinforced with lintels made of reinforced foam concrete. For such construction, a set of construction tools for processing blocks is required.

Since the shape and size of the blocks are standard, they require almost no additional work. Where a standard block does not fit, it can be easily reduced in any direction with a regular hacksaw. Masonry made of foam blocks is simpler than brick, due to the larger size and lighter weight of the blocks.

What should be the depth of the foundation for a bathhouse?

Are you planning to build a comfortable steam room near a country house? In this case, you will have to figure out how deep the foundation for the bathhouse should be.

Bathhouse foundation

It must be said that this parameter is determined by many criteria, but, first of all:

- structural features of the bathhouse;

- type of foundation being built;

- characteristics of the soil in a given area (type of soil, its homogeneity, presence of groundwater, etc.);

- budget allocated for construction.

Generalized instructions for constructing a bathhouse from foam blocks

Step 1. First of all, you need to create a bathhouse project, describing in detail all the dimensions and parameters of the structure. You should also select a suitable site on the site where the bathhouse will be built. So, according to SNiP, the site should be located at a distance of 1 m from the fence, 8 m from the neighbors’ house and at least 5 m from the border of the site. Also, the bath area itself must be dry.

First, a bathhouse design is drawn up

Step 2. Next, you can decide on the type of foundation and start building it. Foam concrete is lightweight, which means you can make a simple foundation (for example, a strip foundation).

Foundation arrangement

Step 3. After creation, the foundation must be covered with waterproofing, after which you can begin laying the first rows of blocks.

Laying the first rows of blocks

Step 4. The blocks need to be placed on top of each other in a checkerboard pattern, that is, so that the joints between adjacent blocks in one row do not coincide with the joints of blocks in the row below. It is recommended to fasten the blocks with special glue rather than standard cement mortar. It is important to ensure that the masonry is level and even, and do not forget about the presence of doors and windows. Every three rows the walls should be reinforced.

To fix the blocks it is better to use special glue

Step 5. When the frame of the bathhouse is ready, you can begin installing the roof. In this case, a simple gable roof is being built. The rafters rest on tie rods installed and secured to the load-bearing walls.

In this case, a simple gable roof is being erected

Step 6. The roof can be covered with metal tiles or corrugated sheets. The main thing is to install materials according to the rules.

Now you can start laying the roofing material

The roof is covered with corrugated sheets

Step 7. After this, you can move on to the interior decoration of the bathhouse - creating a floor, covering walls, etc. It is important not to forget to carry out waterproofing work!

Interior arrangement of the bathhouse

In general, the construction of such small buildings as a bathhouse made of foam blocks does not take much time. With proper skill, desire and the help of a couple of people, construction can be completed very quickly. Moreover, such a bathhouse will serve for many years without complaints. So you can safely choose the project you like and start implementing it on your site.

When we build a bathhouse from foam blocks, we must understand that the laying is carried out similarly to ordinary brick, however, due to the large dimensions of the foam block elements, the process is much faster.

Armed with the necessary equipment, we begin laying the walls. Using a level, the highest fundamental angle is found. This is where the laying will begin.

For the steam room, a foam block marked M25 is selected. The blocks are fastened with a conventional cement-sand composition. They are placed on the edge.

The second row is laid with a shift. The elements are attached with a special adhesive composition for working with porous materials. It is applied in a layer of half a centimeter.

A reinforcing mesh with a fine mesh is placed on top of every 3rd row of blocks.

During installation, door and window openings should be left. After completing this stage, the building is left for three days.

Choosing a suitable foundation

The photo shows the formwork for pouring a strip foundation

So, let's try to figure out which base for a bath is better, and at what distance it should be located from the surface.

The foundation is the foundation of a building, the main function of which is to bear the load of the construction site.

In addition, a properly made foundation with your own hands can protect the building from the negative effects of groundwater and excess humidity.

Depth depending on soil type

Before carrying out technical work on installing the foundation for the bathhouse, it is necessary to conduct a geological survey .

Depending on the identification of the exact type of soil, its load-bearing properties, the possibility of changing quantitative parameters as a result of tectonic changes, the best material for the foundation is determined, and most importantly, its depth is calculated. Correct calculation of the burial depth, in some cases, will save the foundation and walls of the bathhouse from subsidence, cracks, distortion, and deformation.

Fine and dusty sandy soils contribute to strong shrinkage of the bathhouse foundation. To reduce or level out this process, the depth of the foundation can be significantly increased. Instead of the planned 50 cm depth, it would be advisable to increase it to 70-100 cm. With increasing foundation depth, the compression resistance increases proportionally. This value in fine sands is approximately two times lower than in coarse sands. In order to make up for the missing load-bearing capacity, the depth of the foundation is doubled.

Gravelly and coarse sandy soils are quite reliable in terms of load-bearing qualities. Sandy soils are not heaving, so regardless of the amount of precipitation per year or the depth of freezing, you can choose any type of foundation for a bathhouse. Coarse sandy soils exhibit insignificant shrinkage compared to fine ones. On them it will be easy to build a shallow foundation, ranging in size from 20 to 50 cm.

Rocky soils have the best load-bearing qualities of all other types of soils. They practically do not shrink, supporting the weight of fairly large-scale structures. Rocky soils are not heaving because they do not retain water in their pores. The depth of soil freezing will not be taken into account when building the foundation. There is no excess moisture in the soil, so they will not expand due to the conversion of water into ice. On rocky soils, foundations can be installed more economically.

Clay soils , unlike most others, have a finely porous structure. The main disadvantage of clay soils is their ability to swell. The proximity of groundwater and abundant rainfall contribute to the rapid accumulation of water in the pores of the soil. With the onset of sub-zero temperatures, water turns into ice. The density of water, after turning into ice, increases, which leads to an expansion of the volume of the entire soil. Changes in soil volume place additional load on the foundation, causing its deformation, cracking, distortion, and lifting of the bathhouse building.

Calculations for deepening the foundation on clay soils are carried out taking into account the freezing depth . It is necessary to build the foundation below the soil freezing level, then the loads will be exerted only on the side walls of the foundation, eliminating pressure on the base of the foundation. For example, the depth of soil freezing is 1.5 m, which means the foundation lies at a distance of 1.6 m. The high level of groundwater will not allow the necessary deepening of the foundation.

The base of the foundation is at an indentation of no lower than 0.5-1 m. Sufficient distance will be required in case of capillary rise of water in the soil and in case of an unexpected increase in water level due to heavy floods or prolonged downpours. To drain excess water from the ground, a drainage system is installed around the foundation. They dig a trench deeper than the base of the foundation. They lay the foundation around the perimeter with a pipe and lead it into the inspection well. Water will not accumulate and freeze in the pores of the soil, and excess water will also be automatically drained in the event of a strong rise in the groundwater level.

And this article talks about metal sauna stoves.

Types of technologies

Having decided on the characteristics of the soil and the weight of the building made of expanded clay concrete blocks, you can begin to select the type of foundation.

Bases are divided into two main types:

- shallow;

- deep.

Shallow ones are easier to do with your own hands. They do not require a large amount of excavation work. In addition, this type is the least expensive in terms of material.

Tape base

The strip foundation is shallow. The easiest way to install it with your own hands is under a building made of expanded clay concrete blocks. This type of foundation is best used in conditions of stable soils and deep groundwater, as well as for buildings of relatively light weight. Such a foundation will perfectly support a bathhouse made of blocks, a garage or a one-story house made of expanded clay concrete blocks.

The depth depends on the type of foundation

The columnar foundation is formed by horizontal pillars located along the contour of the bathhouse walls. The main advantage is considered to be high wear resistance, suitability for many types of soil and cost-effectiveness. Its versatility deserves attention. Depending on the material for the walls of the bathhouse, you can use concrete, wooden, or brick pillars. The standard length of pillars is from 2 m. It is laid at 1-1.5 m. There is a shallow columnar foundation, occupying a height of only 50-70 cm. It is laid at 40-60 cm.

The pile foundation is prepared for construction by drilling wells. It is laid in several ways. The easiest way is to pour concrete mixture into pre-dug wells using a hand drill. Wooden and steel piles are laid. The main advantage of a pile foundation is that the foundation lies below the soil freezing level. A team of workers will be able to install the piles in just 1-2 days. The burial depth is determined for each structure, the maximum is more than five meters.

The screw foundation got its name due to its manufacturing technology. Screw piles resemble the shape of a screw and, thanks to special blades, are easily screwed into the ground. Building a foundation on screw piles has many advantages. For such a foundation you do not need to dig a trench or even level the ground. Suitable for all types of soil, except rocky. Service life more than 100 years. Disadvantages include average load-bearing qualities.

The slab foundation consists of a monolithic reinforced concrete slab. Its minimum thickness is only 15 cm.

A shallow foundation is laid 30-40 cm deep into the ground.

Floating foundations are a type of shallow slab foundation. It differs from other foundations in the presence of stiffening ribs - dense placement of reinforcement along the entire perimeter of the slab.

The peculiarity of the floating slab is the ability to move. Unlike other types of foundation, a floating slab does not compete with the pushing forces of the soil, but moves slightly as they rise in the cold season, due to their lowering with the arrival of spring.

And here is an article about building a garage from corrugated sheets.

How to save money when preparing an estimate?

By calculating the cost of construction work in advance, you have the opportunity to save quite a lot. The fact is that by calculating the necessary expenses in advance, you can see ways to reduce them. If you make payments as certain works are completed, you can overpay a very serious amount.

If we give specific examples of savings, the main one is the preliminary purchase of building materials. The thing is that by purchasing the same brick in advance, when construction is not underway, you get the opportunity to purchase it at a reduced price. In addition, by visiting several databases of building materials, or by studying the websites of suppliers of such materials, you will have the opportunity to compare prices for the products they offer and choose the cheapest.

It is also worth comparing different types of building materials depending on their technical characteristics. For example, insulation may have different prices, but its various types may have completely different heat retention properties. As a result, you can refuse to purchase more expensive insulation, choosing instead a cheaper one, but with the same characteristics.

You can also save money by not using centralized utility networks.

For example, a centralized sewer system can be replaced with a septic tank. You can also save on heating costs by choosing a wood-burning stove. In the latter case, you get the opportunity to build your own bathhouse, in accordance with all the canons of the Russian traditional bathhouse.

In order to save money, you can also simplify the decoration of the interior. For example, decorating walls and floors with mosaics can cost from 25 to 100 dollars per 1 sq. m. m. It can be easily replaced with eurolining or MDF boards, which can easily replicate any mosaic pattern.

However, there are some expense items that cannot be reduced in any case. These are ventilation, waterproofing and fire safety. It is these systems that make it possible to prevent rotting of a building, its fire, and also remove unpleasant odors from the atmosphere. At the same time, good fire safety systems can protect you from a fine that the state fire inspectorate may impose on you.

Depth of strip foundation for bathhouse

The classic depth of a strip foundation consists of a twenty-centimeter, well-compacted sand cushion. Above is a foundation 60 cm high: 40 cm lies in the ground, and the remaining 20 cm extends to the surface. Since the strip foundation has become the most popular, universal option for bathhouse foundations, the correct calculation of its depth needs to be studied in more detail.

First of all, they start from the properties of the soil . Frequently encountered problems related to the structure of the soil when designing a foundation affect the depth of its construction. The risk of cracks arises when erected on rocky soil. In this case, a shallow or non-buried foundation is used. Soil prone to swelling requires the foundation to be sunk deeply below the freezing level. The possibility of foundation failure is characteristic of fine sandy soils. When building a foundation on such soil, a deep foundation is designed to increase compression resistance.

And here is an article about a bathhouse made from a heat block.

This section of our website https://ru-house.net/postrojki/banya/pechi/ is all about stoves for your bathhouse or sauna.

Stages of building a foam concrete bathhouse

Foundation

According to the rules, any construction of a bathhouse begins with laying the foundation. Errors and savings are not allowed here.

At the primary stage, a pit is created with parameters of 60 cm (depth) and 30 cm (width). The depth may be greater depending on your frost depth. Next, using a laser level, insert pins into the corners of this recess. A clearly visible bright rope is stretched around the entire perimeter and pins are added. They should be located along the entire length every 190 cm. This is how the horizontal level of the foundation is checked experimentally.

At the next stage, the frame is prepared. Its basis is 12 mm reinforcement (thickness) and wood formwork. Then comes the concrete filling. The appropriate concrete in this situation is grade 200.

Usually the height of the foundation reaches 70-75 cm. This value is enough for a modest bathhouse.

Since there will be a washing room in it, it is necessary to organize a sewerage system. The recommended receiver is a minimum of 10 cm.

In the final phase, a grid is laid on the foundation. She stays on it for several days until the concrete hardens thoroughly. After which the foundation is waterproofed. After all the stages with the foundation, you can build the walls.

Walls

To begin with, a certain point is selected - the highest corner of the future building. The height is calculated by the level. When working, maintain minimal seams between the working elements - foam blocks. Any “cold tunnels” are excluded here. The initial row implies maximum accuracy and responsibility. In it, the elements are connected with a cement composition. They are laid out very smoothly, without errors or savings. To maintain the markings, a laser level is used. To shrink the blocks you need a rubber hammer.

The next rows are formed using special glue. As a rule, it is a dry composition, soluble in water. The maximum thickness of the adhesive layer during operation is 5 mm. You need to spend it very sparingly. The composition will prevent the appearance of “cold tunnels” and will reduce the formation of defects at the joints to a minimum. This way the bath will have excellent thermal insulation.

To enhance the strength of the wall, a reinforced lattice can be installed after every third line of masonry. The main thing in this work is to strictly adhere to the horizontals and verticals. The level here is applied very intensively. After the walls stage, it is the turn of the roof.

Roof

Here the initial stage is the installation of rafters. The interval between the rafters is 100 cm. A half-meter sheathing is also made. After which the initial layer is the rough ceiling. It is formed by boards 2.5 cm wide. The next layer is foam. The final phase is flooring. Similar boards are used for it.

Ceiling and trim

There must be two holes in the ceiling. This is ventilation. The outer side of the roof is finished with corrugated sheeting. The finishing of the bathhouse itself begins with waterproofing the walls. Here we need water repellents and a special film from which the gaskets are formed. Such “defense” will prevent moisture from entering the foam blocks and will significantly prolong the excellent condition of the structure.

For external cladding, it is better to use basement or vinyl siding. An important condition is that the sheathing retreats from the wall by at least 5 cm. These centimeters are insulated with vapor-permeable membranes. This improves the heat-shielding properties of the structure.

Inside the bathhouse

For interior decoration it is better to choose coniferous wood. The steam room contains aspen and linden trees. All working wood is coated with waterproofing preparations. The specified building materials are not a mandatory criterion. Here space is created for engineering thought. The main thing is that the materials retain heat and are protected from moisture. They must also create a suitable, cozy atmosphere.

These are the stages of creating a high-quality warm and soulful bathhouse from foam blocks. The ease of the construction process is the key to a good pace for construction. For example, owners who build bathhouses from timber or brick face many more problems during construction.

Other parameters affecting the depth of the foundation

The depth of the foundation depends on the material from which the walls for the bath are made. A stone bathhouse requires from 1 m, preferably from 1.5 m. A bathhouse made of logs or timber also needs a foundation of at least 1 m. Laying cinder block walls is 1.5 times lighter than brick, so the foundation can be laid from 0.5 m. Aerated concrete and foam concrete blocks need foundation with a depth of 40 cm.

a significant influence on the depth of the foundation for a bathhouse.

Choosing the type of foundation

The construction of any building is not complete without the construction of a strong and high-quality foundation. If construction work on buildings is carried out without creating a solid foundation, the risk of rapid destruction of the building increases. The construction of a bathhouse also requires the construction of a solid foundation. This article discusses the issue of creating a foundation for a bathhouse.

When choosing a foundation for a bathhouse made of foam blocks, you must be guided by certain factors:

- Take into account the characteristics of the soil at the site of the proposed construction;

- Selected materials for the construction of bath walls.

In order to understand what type of foundation should be built, it is necessary to examine the soil. To do this, you need to dig a small hole and look at the composition of the soil. The type of future foundation depends on the characteristics of the soil. And the money spent on its construction depends on the chosen foundation.

- If there is a huge amount of garden, swamp or forest soil in the ground, then it is necessary to create a strip type of foundation. A sand cushion will serve as the foundation.

- If the soil consists of clay rock, coarse sand and gravel, then a strip or columnar version is suitable for creating the base of the bathhouse. It is with this composition that the earth is considered the most convenient option for construction work.

- For soil containing fine sand, quartz or rock, any type of foundation will do.

One of the most important factors when choosing the type of foundation will be the material from which the walls are planned to be built.

- With a strip foundation, you can build walls using brick or concrete blocks, logs, beams.

- For the columnar version, only walls built using wooden materials are suitable.

Attention: The choice of foundation depends on the soil, the proximity of groundwater and the weight of the structure. These three factors will be the main ones. Be sure to take into account the distance from the foundation to the roof of a foam block bathhouse

Soil requirements

Before choosing a construction site, we look at the soil.

Here we take into account the following:

- Particularly important characteristics that the soil must have are: uniform distribution of moisture, the soil should not swell or sag.

- The best option would be soil with a dense and uniform composition.

- If the ground freezes strongly during the cold season, it is necessary that the bottom of the foundation be a couple of tens of centimeters below the level to which the soil freezes. Thanks to this, you don’t have to worry that the walls may crack over time.

- To prevent the earth from swelling around the foundation, it is necessary to fill the perimeter of the foundation with sand.

Choosing the location of the bathhouse foundation

Before starting construction work to create a foundation, it is necessary to prepare the site:

- You need to find an area that has a slight slope. The slope does not allow standing water to form; all fallen water will flow down the slope, which will ensure constantly dry soil under the foundation of the bathhouse.

- To begin with, the top layer of soil is removed from the site. When marking the future foundation, it should be taken into account that its width should exceed the width of the walls. To plan the foundation, you can use a construction tape, a special cord, a building level, or pegs made of wood or metal.

- Pegs are used to mark the internal contour of the room. To do this, you need to create one of the corners of the bathhouse and install a triangle in it. Along the sides of the triangle, the longitudinal and transverse walls of the building are marked.

- Next, to mark the foundation, a cast-off, constructed using various boards and columns, is installed. This structure should be located a few meters from the peg. All boards must be attached to a height of about 1.5 meters above the ground.