Household appliances of this type have long become an indispensable attribute for most households. Purchasing and connecting washing machines to sewerage and water supply has long become commonplace and most of us know how it’s done.

However, in this article we will dwell on the issue in detail and analyze all the nuances of connecting to water supply and sewerage, what methods exist, what tools and materials we will need, and how to avoid common mistakes.

But first, let's briefly learn how to connect a washing machine: the hose for connecting cold water is screwed at one end to the water pipe, and the other to the filler fitting of the machine. The end of the drain hose at a certain height is connected to the sewer system. Below, we will look at all the processes in more detail.

Materials and tools for connecting to water supply and sewerage

The need for certain materials when installing and connecting washing machines to sewerage and water supply is determined, first of all, by the location of the unit and the accessibility of the designated objects. In some cases, it is necessary to incur significantly higher costs in order to subsequently use household appliances conveniently for many years.

If you plan to lay additional branches from the water supply in the groove, you will need a fairly powerful angle grinder with a saw blade for concrete. You can use a hammer and a chisel to break out the concrete.

A pipe without joints is laid in the groove to ensure its long-term operation without leakage. Otherwise, if a leak occurs, restoring the functionality of the pipe will involve a large amount of troubleshooting work.

To connect to the water supply network, a tee with a shut-off valve is usually used, and to install it in place, a set of wrenches or a universal adjustable wrench is used. All threaded connections are sealed with tow or FUM tape.

Installing an external pipe involves attaching the pipe to the wall; for this you will need an electric drill and concrete drills. Plastic dowels are installed in the drilled holes, fastening is carried out with screws of the appropriate size.

When installing washing machines, the main requirement is that the top cover is horizontal in relation to the floor. For precise installation of the washing machine, a building level is used; adjustment is made using screw support legs.

To arrange a drain for washing machines into the sewer, you will need a drain adapter with an outlet at an angle of 45 degrees.

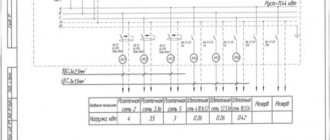

To connect washing machines to electricity, you will need a three-core cable with a cross-section of 2.5 square meters in double insulation and a 16-amp diffusion machine with a leakage current of no more than 30 milliamps.

In addition, it is possible to use control equipment - a voltmeter. Let’s take a closer look at how to properly connect the washing machine to the mains below.

Electrical and grounding connections

The power cord, pre-attached to the rear panel, is connected to the power supply through a two-pole socket with a grounding contact. If the outlet is located too far from the future location of the machine, it is necessary for a technician to carry out installation work to install it.

Electrical connection

Do not under any circumstances attempt to install an outlet yourself if you are not properly qualified. If the outlet is not properly grounded, a situation may arise when the machine receives an electric shock during operation. The power outlet must be at least 16 amperes. If you are installing for the first time in a new house or apartment, then the outlet must be grounded.

It is recommended to install the socket closer to the washing machine

If you notice that the washing machine generates current during operation, call a qualified specialist to check the grounding! The problem when an automatic machine generates electric current during operation is associated with improper grounding.

Preparing washing household appliances for installation

First of all, when the unit is delivered to the installation site, it needs to be unpacked. Usually the machine is packed in a cardboard box and secured with plastic tape. It needs to be cut and removed.

After this, the cardboard box is carefully removed and the foam pads are removed from the top and sides. Next, you need to lift the car and pull out the lower foam platform.

In this case, it is worth paying attention to its design - if there is no special boss in the middle on which the device drum rests in the transport position, then in this design it is manufactured and installed separately. You need to tilt it and remove this insert.

Please note that the cardboard packaging and foam pads must be retained for the duration of the warranty. If a situation arises in which you need to replace the machine due to its defect, this operation will not take place without packaging. These are the terms of the guarantee.

Inside the cardboard package there is an envelope or folder with technical documentation. It contains:

- A passport for the purchased washing machine indicating the personal unit number and other credentials. All entries in it must be certified by the store’s seal.

- A warranty card, which is certified by the store’s seal indicating the date of sale, since the countdown of the warranty period begins with it.

- Operating instructions, starting from the moment of unpacking, and instructions on the installation procedure.

You should strictly follow all the manufacturer's requirements, since failure to comply with any of them will result in a waiver of warranty obligations.

Connecting a washing machine

The packaging also contains the components of the purchased washing machine. Typically they include:

- Flexible filling hose equipped with plastic union nuts for connection to the machine and water supply;

- drain hose for removing used water after washing and spinning clothes;

- reduction – an intermediate part for connecting the drain hose to the sewer pipe;

- bracket for fixing the drain hose on the wall;

- wrench for removing transportation screws and adjusting the position of household appliances in space before turning them on;

- plugs installed on the holes for transportation screws after they are removed.

These are the main items of the sales kit, which may differ from model to model.

If your washing machine breaks down, you can connect the motor from it to a 220 V network with your own hands.

Removing shipping screws

This is a mandatory operation before connecting washing machines to water supply and sewerage.

Their purpose is to secure the drum during transportation to prevent damage. As noted above, a tool for removing bolts is included in the sales package.

Under no circumstances should the removed screws be thrown away; they will be useful if you need to transport the washing machine to a warranty workshop. The holes where the transport screws were must be closed with the covers included in the sales kit.

Placement options for washing household appliances

Household appliances of this kind are not purchased spontaneously; the purchase is preceded by careful analysis and preparation. First of all, this applies to the installation location.

The need to drain used water determines the location of washing machines as close as possible to the distribution of the sewer system.

Such points are located either in the bathroom or in the kitchen. There is also a water supply network there.

As for connecting to electricity, washing machines may require a separate power supply line from the input panel to the location where the outlet is installed.

Connecting washing machines to the water supply - several connection methods

Watch the video - the first method of establishing a connection to the water supply

How to install a washing machine, connecting the washing machine to the water supply. Video tutorial Plumber

The sales package for such a unit always includes a hose for connecting cold water. Its length is 1.2-1.5 meters and at the ends the hose is equipped with two union nuts made of plastic.

One of the ends is installed on the hose at a right angle. It must be installed on the inlet of the unit. The installation angle prevents the hose from kinking or pinching. Connection is made in the following order:

- Turn off the water supply to the water supply by turning off the tap on the riser.

- Unscrew the flexible cold water line at the sink or sink.

- Install the tee onto the supply pipe in the water supply system so that the side outlet is located conveniently for connecting the washing machine hose.

- Screw the filling hose to the tee. When tightening the plastic nut, do not use a tool, and only tighten the nut until it stops by hand. Tool installation often results in breakage of the flimsy plastic nut.

- Install the flexible mixer hose.

A test supply of water to the system with the washing machine should be carried out with the tap on the crosspiece closed, and only after making sure that there are no leaks can it be opened to check the reliability of the hose connection.

This connection option is used when the installation location of the unit coincides with the location of the sink or sink.

Otherwise, you need to bring the water closer to it. To do this, a tee is inserted into the nearest water pipe.

An additional pipe of the water supply system is extended to the installation site of the washing machine, where it is connected in the manner described above.

Often, filling the household with household appliances occurs gradually; eventually, under the sink or sink, the entire space is filled with tees and a tangle of various hoses.

How to connect a washing machine (review video)

Providing for this possibility, a manifold with several outlets is installed on the embedded pipe. An output that is not currently in use can be closed with a plug and used at the right time.

How to connect to the water supply?

The main thing is that when performing such work you do not have to then extend the hose with fittings supplied by the manufacturer.

It is often necessary to place washing machines at a distance of more than three meters from the water supply pipe. In this case, it is recommended to make a separate connection using a metal-plastic pipe. Then there will be a greater chance of avoiding leaks in the most inconvenient places.

Let's look at how the connection is made with a separate valve or a special end valve. We will also need to take mortise clamps, which have a guide sleeve, as well as a rubber gasket or a tee. Otherwise, connecting the washing machine to the sewer will become impossible.

The action plan is described as follows:

- The water pipe and clamp are screwed to each other. The bushing must be on the outside.

- We use a drill to drill the pipe. After this, a connection is made with pipe sections or clamps. If the latter is used, then an end valve is installed.

- At one of the pipe ends we create the same thread as the clamp.

- FUM tape or seals are used to close the threads from the outside.

- The end valve must be screwed onto the outer pipe, with some effort. The washing machine hose is connected to the second end.

- The end of the hose is connected to the machine itself.

- We check everything for the presence or absence of leaks.

When making a connection, you cannot do without taking into account some nuances:

- If somewhere there is a possibility of mechanical damage, installation in these places should be abandoned.

- Tension of the hose is unacceptable, even the slightest. Otherwise, when the speed is at maximum, due to the vibration of the machine, this part is subject to severe deformation. It is important to ensure that the hose is positioned inside as freely as possible.

- 100% tightness must be ensured for all parts.

- The filter is installed in front of the machine entrance. This ensures that small particles of rust are removed. Thanks to this, the unit will last longer.

If you fulfill the above requirements, the floor in the room will always be dry, even when water is poured.

Connecting washing machines to the sewer - consider 2 methods

Watch the video - the first method of installing a drain into a sewer

Washing machine. Drain through non-return valve. Eliminating the siphon effect

Draining used water into the sewer system is a mandatory process in the operation of units of this kind, because the purification of contaminated wastewater is becoming increasingly important.

If we simply talk about organizing the drainage of water from washing machines into the sewer system, we can do without directly connecting these two systems.

It is enough to use a U-shaped bracket from the unit sales kit, which fixes the drain pipe on the edge of the bathtub. At the same time, the issue of the height of the drain into the sewer is resolved, due to which a water plug is formed, preventing the reverse flow of water.

Many modern units include the installation of a check valve that prevents this process.

Considering the specific location of the sewer system in a house or apartment, there are no problems with connection, but it has its own specifics.

Connecting to the sewer directly is used quite often, being the simplest to implement. But this method has its drawbacks.

To implement this, it is necessary to install a spacer to the sewer pipe in the form of a tee, and the outlet should be at an angle of 45 degrees.

The drainage hose is connected to a sewer pipe with a diameter of 50 millimeters, while its size is 22 mm. Therefore, the connection is made using a special spacer called a “reduction”.

The drainage hose of washing machines is standardized on all models and has a diameter of 22 millimeters. There are no special adapters for draining this size; this simple rubber part is used on the transition.

When the machine is located in close proximity to the outlet of a sewer pipe, it is naturally connected to it using a tee.

Do-it-yourself connections of the washing machine to water and sewerage

But if the unit is located at the opposite end of the room, the most reasonable solution would be to lay an additional PVC pipe with a diameter of 32 millimeters and then switch to size 50.

In this case, it is necessary to fulfill the requirements for a slope of this pipe of 2-3 millimeters per meter of length. A reduction with these dimensions is produced and can be purchased on the market.

In some cases, if the machine is automatic, there is no need to use an intermediate pipe, since the used water is pumped out by a pump.

In this case, the connection is made using a rubber reduction. It is a rubber bushing. The outer surface has ribs like a cuff to seal the connection. The inner hole is arranged in the same way with a diameter of the appropriate size.

In the technical documentation, if there is no check valve in the machine model being installed, the height of the drain from the floor at which a water seal is formed must be indicated.

If this parameter is not maintained, very unpleasant odors will penetrate into the room through the drain hole.

The second way to connect washing machines to the drain is to connect through a siphon. Many of these products are available with a special outlet at the top.

When sold, it is equipped with a special plug that covers the pipe. Before connecting the drain hose of the machine, this part must be removed and removed - it has purely protective functions.

The drain hose of the washing machine is simply put on this pipe and, if necessary, additionally secured with a clamp.

This product can be equipped with several taps, which allows the connection of several units at the same time.

If there is such a possibility, connecting washing machines should be done in such a way that is quite reliable and solves all problems of tightness and safety.

Connection to water supply and sewerage

The machine is connected to the cold water supply network through the inlet hose, and only then through the drain hose to the sewer. Water is used automatically, so the connection to a stationary water supply must be strong.

The delivery set includes a standard length hose, which is connected to the rear panel using a plastic gateway. In order to secure the drain hose to the sink, the kit includes a hook with which it is secured to the edge of the bathtub or sink.

Washing machine drain installation

The drain hose must be located within a standard sink, sink or bathtub, that is, at a height of 40 to 90 cm!

In order to lead the drain hose directly into the sewer, the drain hose is connected to the sewer pipe. The water pressure is quite strong, so we additionally install a shut-off valve, which reduces the likelihood of water spillage if the water hose is damaged, the equipment is not used for a long time, and for the convenience of its dismantling.

Correct connection of the washing machine Connecting to the water supply Connecting the drainage

Various options for connecting the drain to the sewer.

We connect the washing machine and turn on the water. We check whether water flows where there are connections. The machine is ready for use.

Connecting washing machines to the electrical network

When making repairs in a bathroom or kitchen, you must provide wiring for connecting a washing machine or other similar equipment. It should be understood that combining water and electricity in one unit makes it a means of increased danger. Therefore, separate wires are pulled to connect them.

Connecting the washing machine drain to the sewer system, what problems and errors occur

Based on the maximum total power possible in such household appliances, you should usually focus on 2.3-3.0 kW.

What you need to connect

The list of materials for creating an autonomous network for connecting household appliances is not extensive and includes:

- Conductor products are selected from copper samples. At the same time, taking into account the place of application, they must be double insulated.

- An emergency shutdown control device that will save household appliances from failure due to voltage surges, and the building from a possible fire. The equipment will not be damaged if moisture gets into the electrical network.

How to connect a washing machine to a Miele three-phase network

To connect washing machines, a 16-amp device with a leakage current of no more than 30 milliamps is used.

- An automatic switch with the same parameters is installed in case of a short circuit and protects the network from damage.

- High security socket with moisture protection.

- Additional materials include common parts for electrical installation - clamps, terminals, junction boxes, cable ducts, etc.

Electrical installation

We draw your attention to the need to follow all the rules in order to ensure your own safety and the safety of your property and home:

- During installation, you must use only professionally designed connection diagrams.

- Do not twist aluminum and copper wires together.

- To carry out wiring, you need to use wires only of the appropriate cross-sectional power.

- Grounding cannot be done by connecting a wire to a water pipe or hot water supply.

- The sockets used must be made on a ceramic base in a waterproof casing.

- It is strictly not recommended to use an extension cord or adapter from a regular outlet to a Euro plug to connect washing machines.

- It is prohibited to connect the ground wire to the neutral wire.

- The connection wire must be laid as a separate line.

After completing the electrical installation, it is recommended to carefully check the entire circuit with a tester to eliminate the possibility of a short circuit.

Connecting the washing machine to water supply, sewerage and electricity.

Washing machine installation

Modern washing machines are the height of technology. You just need to load the laundry, add conditioner and powder, set the program and that’s it. After some time, you will receive clean, pleasant-smelling and almost dry laundry, but before the device starts working properly, it must be connected and installed correctly. This process is carried out in stages, each step does not require much effort, everything is easy and simple. If difficulties arise, the answers to them can be found on the Internet in photos or videos. The installation procedure includes:

- Finish transportation and remove any used parts. After the washing machine has been brought to its permanent location, in most cases it is placed in the bathroom, because this is the most convenient place, based on its proximity to water pipes. Nowadays the kitchen has become popular because bathrooms, especially in older houses, are too small. You need to remove the packaging and protective film from the machine.

Before installation, the washing machine should be carefully unpacked.

- It is necessary to remove bolts and other unnecessary parts. There are shipping bolts and plastic spacers on the back of the machine. They definitely need to be removed. This action is one of the most important in the first - second step. Why is this so important? If you do not remove the bolts, then when turned on, deformation or breakage of the drum and internal parts of the machine may occur, this will disable it, and no one wants this. In order to remove the bolts, you need to loosen the secured bolt, then lift it up and secure it with the hole of the plastic spacer. After this, we remove the parts from the car. Step two has been successfully completed.

- Hiding bolt holes. For a harmonious and neat appearance of the machine, we close the bolt holes with decorative plugs made of plastic. Be sure to check the instructions that come with the kit, because each manufacturer puts something special into its equipment that distinguishes its products from others. All these nuances are written in the instructions; they will help to avoid problems.

- Connection to the sewer The next step is that the machine needs to be connected to the sewer. If the machine does not have a check valve capable of passing water in one direction, then a certain level must be maintained. The manufacturer must indicate its maximum and minimum values in the instructions supplied with the machine. In order to connect the drain to the water pipe, buy a special valve. The hose is securely connected to the pipe from the sink drainage system. This connection method eliminates the possibility of water leakage.

You should carefully choose the location for installing the machine

- The next installation step is connecting the machine to the water supply. To do this, use hoses of a suitable diameter, the most common option being 3/4 inch. In order to prevent leakage, because even the most expensive and good hose eventually falls into poor condition, immediately buy a hose with the Aquastop system. To lengthen the hoses, they are connected to each other using rubber gaskets. There are two options here. The first option is using an additional valve. A thread is made in a certain place in the water supply and the valve is secured using special fasteners. The main disadvantage is that after each wash you need to completely shut off the access to water. The second option is to connect through a water tap. This is a temporary method, used when the machine needs to be connected very quickly. This method protects against leaks during non-working hours.

- Machine height adjustment. Here you need to achieve the most even position possible. If the position is uneven, there may be problems with access to water and electricity.

- Electrical connection.

Important! Follow all safety precautions and take this step very seriously. Before connecting, make sure all parts and hands are dry. It is necessary to ground the shield using a bus with a cross-section of at least 3 mm. It is important to know that the outlet to which the machine is connected must be three-wire.

How to level a washing machine

This operation is final and is performed after it is connected to all communications. If this is not done, the machine will be overloaded during operation, and strong drum vibrations will occur, which will not extend its service life.

The top cover of the unit must be positioned horizontally. To do this you need to perform the following operations:

- Install the washing machine in its permanent location. The distance from the back panel to the wall should be no more than 5 centimeters, otherwise the hoses may be deformed or broken.

- Loosen the locknuts on the machine legs.

- Use a spirit level to determine the direction of rise or fall.

- Adjust the position of the unit by unscrewing or tightening the screws. The tolerance for non-parallelism of the cover in relation to the floor is no more than 2 degrees.

- Having achieved the correct position of the machine body, you need to tighten the locknuts to the body.

- It is important to prevent vibration of the unit, which can occur if there is a gap between the leg and the floor. To do this, you need to try to swing the body in different directions. If necessary, tighten the legs until the same tightening force is achieved.

First start

To check the functionality of the installed washing machine, it is necessary to carry out a test wash. This is done in the following order:

- Connect the machine to the network.

- Select the desired washing mode and set it on the display.

- Enable work mode. When pouring water into the tank, monitor its filling time in comparison with the passport data. If the machine fills slowly, it is necessary to check the pressure in the water supply and, if necessary, take measures to increase it in accordance with the passport recommendations.

- Check the water heating time for the selected mode.

- When filling the tank with water, check for leaks; if there are any, eliminate the cause and repeat the tests.

The program and rules for conducting a trial run are described in detail in the relevant technical documentation. Recommendations for different models may differ, but these should be used as a guide.