Why not do without a foundation?

The foundation for the fence is a necessary thing. There are a number of reasons why laying the foundation for a fence is a mandatory step.

So, the foundation is needed because:

- Protects the soil under the fence from erosion and flooding. During the period of spring melting of the snow cover, the foundation performs the function of retaining melt water, preventing it from flowing inside.

- Supports the base. The fence with the foundation does not deform or sag, and the materials from which it is made last much longer.

- Allows you to evenly distribute the load, which also protects the fence from deformation.

- Gives the fence an aesthetic and complete look.

Required tools and materials

To build a foundation for a fence made of corrugated sheets with your own hands, you will need:

- shut-off valve;

- felt grater;

- rolling machine;

- shovel;

- big screws.

Required building materials:

- cement;

- brick;

- boards for formwork;

- sand;

- gravel for backfilling.

Useful Which profile pipe is used to install a fence made of corrugated sheets?

You will need a measuring tape and reinforcing bars for the frame.

Saving Tips

An economical option for building a fence from corrugated sheets is to lay a columnar strip foundation. The following recommendations will help make construction less expensive financially:

- It is recommended to purchase building materials, necessary tools and auxiliary equipment in advance.

- Tape construction does not require labor costs; with minimal construction skills, it is better to do it yourself (there is no need for additional costs for inviting builders).

To save time and money, columnar and ribbon types are recommended.

Foundation for a lightweight structure

If the fence is built from picket fences, wooden boards, chain-link, corrugated sheets, etc., then it is classified as light. In this case, the foundation for the fence will require a minimum of costs. The base is built by concreting pillars.

So, you can make a lightweight base for a fence in several stages:

- The perimeter of the fence is marked, indicating the location of the posts. The distance between supports varies from 1 to 5 m.

- Holes are dug at the marked points. The required depth is 0.8-1.2 m.

- Columns are installed in the dug holes, they are pushed apart with stones and filled with concrete mortar.

If the fence is solid, as is the case with corrugated sheeting, for example, then the posts should be installed at a short distance from each other. It should not exceed 2m.

Installation of strip foundation

Stage 1: creating markings

The creation of a strip foundation begins with the formation of markings. It is necessary to mark the installation locations of the pillars, the distance between which should be no more than 2 meters.

Stage 2: excavation

The second stage is the largest - excavation work. It is necessary to dig a trench along the entire length of the fence. The depth of such a trench should be one third greater than the depth that will be allocated for the strip foundation.

Important! The depth of the trench is measured not from the lower boundary of the underlying soil, but from the lower line of the fence. If the plot of land is uneven, then the foundation can be laid in steps.

The width does not need to be greater than the width of the foundation. An exception will be the case if the corrugated board is insulated with sheets of expanded polystyrene. In such a situation, you need to increase the width by the thickness of the sheet. Try to make the walls of the trench as even as possible, but there is no need to level the bottom - it will be covered with sand.

Now you need to drill holes for the supports. This can be done using a drill, in which case the procedure will take less time and effort, but if there is no drill, you will have to use a regular shovel. In this case, installing the supports will take longer. Metal pipes with a diameter of 60 mm are usually used as supports.

Please note: the depth of the well must be greater than the depth of soil freezing; ideally, it should accommodate a support 2.5 meters high.

Stage 3: preparing the sand bed

A sand and gravel cushion is laid at the bottom of the trench. This allows you to make the foundation for a fence made of corrugated sheets more durable, and also prevents the destruction of the soil and increases its load-bearing capacity.

To make a pillow you need:

- Pour sand or sand-gravel mixture into the trench; the width of the layer should occupy a third of the trench.

- Pour the mixture with water.

- Compact manually or using vibrating equipment.

- Flatten.

- Cover the bottom and walls of the trench with a layer of waterproofing material. This will help achieve optimal hydration of the concrete when pouring.

Stage 4: reinforcement and formwork creation

The next important stage is the installation of reinforcement in the foundation. The strip foundation is often exposed to wind currents, which causes it to begin to sag. To prevent this from happening, you need a base made of steel reinforcement.

Reinforcement and wooden formwork

The reinforcement procedure is carried out as follows:

- A layer of bricks is laid at the bottom of the pit.

- Next, transverse horizontal reinforcement elements are laid so that their edges do not reach the walls by 3-4 cm.

- Where horizontal parts are laid, vertical parts must be installed. Their height should be such that the parts do not reach the future foundation by about 4-5 cm.

- Vertical and horizontal parts are connected with wire.

- If necessary, lay another layer of horizontal rods.

As a result, the reinforcement will create a structure in the form of a lattice; it is not difficult to create, but the procedure takes time. After its completion, you can proceed to installing the formwork.

For formwork, plywood or edged boards are suitable, but it is preferable to use the first option, since plywood is much smoother. When using planed boards on concrete, irregularities remain after pouring.

However, plywood is a more expensive material; to lay the foundation you will need sheets at least 15 mm thick, and their cost is high.

DIY strip foundation for a fence

More massive fences require a stronger foundation. A wooden, brick, stone, block fence, as well as a fence with forged elements, can be erected on a strip foundation.

The algorithm for constructing such a foundation for a fence is as follows:

- Marking is being done. Along the entire perimeter of the fence, pegs and twine are used to mark the boundaries of the future tape. The width of the foundation is chosen depending on the massiveness of the fence. If we are talking about a wooden fence, then 0.5 m is enough. For a brick or forged structure, a foundation 0.8-1 m wide is needed.

- After this, they begin to dig a trench. It is recommended to deepen the tape by 0.5 m. Support posts will be installed every 2m. At these points the trench is made deeper - up to 0.9 m.

- Then the pillars are installed. Each pillar will rise above the ground by approximately 1.8-2m. The columns are leveled strictly vertically. They are fixed using cameos, broken bricks, etc.

- Gravel is poured into the bottom of the ditch along its entire length. The minimum thickness of the pillow is 5cm.

- The next stage is reinforcing the foundation for the fence. To work, you need corrugated reinforcing bars with a cross section of 1-1.5 cm. The reinforcement frame is assembled on the surface of the earth. When connecting rods, it is better not to use welding; experts recommend fastening the reinforcement with binding wire.

- Then the formwork is installed in the trench. It can be made from old boards, slate, plywood, etc. The formwork is set and wedged above the ground level at a distance of 0.25-0.3 cm. This is a temporary structure, but it must be durable and impermeable to concrete mortar.

- The installation of reinforcement and formwork is followed by pouring the foundation for the fence. The bottom layer of concrete is mixed with gravel and crushed stone. The layer located above is mixed with cement and soft sand. If the weather is dry, hot, the concrete base is periodically moistened. This prevents concrete from cracking.

- The formwork can be removed after a week. The period of maturation and strengthening of the concrete foundation for the fence is 30 days.

Why is it necessary to install a foundation for a corrugated fence?

Installation of a high fence is always recommended to be done with the installation of a foundation, since high fences made of profiled plastic also have a lot of weight and exert their weight on the base of the structure. The stability of the fence is influenced by factors such as:

- Frosts and other seasonal effects on the soil.

- Subsidence of soil under the influence of groundwater.

- Ground vibrations caused by the movement of cars or railways near the fence.

- Strong winds.

But all external influences can be compensated by a reliable foundation. Since corrugated sheeting is quite light, it requires a less massive foundation than for stone or metal, but at the same time its depth should be greater.

By choosing the wrong foundation for a corrugated board fence, you run the risk of premature cracks appearing on the fence.

The type of foundation for such a fence depends on many factors, in particular:

- Soil type and complexity.

- Height of the fence.

- Soil condition.

- The presence or absence of groundwater at the site.

- Distance from fence to road.

The optimal foundation option for such a fence is a strip one. You can also build a columnar foundation, but a strip foundation has a number of advantages, in particular:

- Simple construction technology.

- Protection against soil destruction.

- The strip foundation has a high load-bearing capacity.

- Durability.

Such foundations resemble a cement tape that runs along the perimeter of the fence. They can be installed with your own hands if you have a minimum amount of necessary knowledge, and in addition, the cost of materials is quite low.

Typically, the width of the strip foundation ranges from 20-30 cm, and the laying depth is 30-50 cm, but these parameters are individual. They are laid for each individual fence and depend on the type of soil, its cleanliness and many other parameters. To create a single structure from a concrete strip, metal reinforcement is laid inside.

Experts say that in the conditions of domestic soils and the climate of central Russia, a foundation 20 cm wide and 50 cm deep is well suited. But in places where supports are installed, 10 cm of foundation should be added in depth.

There are 2 more important notes on construction: the strip foundation must rise above the ground level by at least 8-10 cm and if the pillars are made of brick, then the width of the foundation must be greater than the width of the support.

Foundation for a stone fence

Concrete base for a fence is certainly one of the most popular. However, a worthy alternative is a stone foundation. It is also sometimes called rubble.

One of its obvious advantages is its aesthetic appeal. Stonework looks impressive and very atmospheric; it goes well with a forged structure or a stone fence.

Such a foundation should not be built on clayey soil; the movement of soil layers will contribute to the deformation of the foundation. A stone foundation can only be built on stable, non-problematic soil.

It is quite difficult to build such a foundation for a fence on your own. To create beautiful masonry from stones of different shapes and sizes, you need some experience. If you want everything to be perfect, it is better to hire a specialist.

A stone foundation, built in compliance with all technological nuances, is an incredibly reliable and durable structure.

Important points:

- During the masonry process, liquid or dry mortar is used.

- To obtain a beautiful design, the stones are matched to each other. They should be located very tightly relative to each other.

- The inner part is filled with stones of any texture. They do not require special attention. Only the façade is important.

- Smaller stones are placed between large stones.

- According to the experience of builders, laying on a dry mixture is preferable. Such designs can last longer.

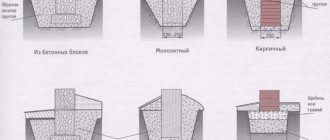

Types of foundations

Several types of structures can be used as foundations for a corrugated fence.

For installation of a low fence made of corrugated sheets on non-heaving soil, especially if the installation is planned for a certain period of time with its subsequent replacement.

For the construction period, for example, you can simply drive the support pillars into the ground to a depth of 1.5-2 meters with an ordinary piledriver, sledgehammer or hammer.

To make the work easier, you can lightly drill holes into the ground with a small diameter auger. As an advantage of this type of installation of supports, it can be noted that if, as a result of seasonal movements of the soil, the supports are pushed to the surface in the spring, then they can be straightened again and driven in with a sledgehammer.

Pillar foundation

- For support pillars, holes are dug (deeper for corner ones), into which they are installed level and leveled.

- Then the pits are either filled with crushed stone or gravel of large fractions and shallowly concreted on top (butting) or completely filled with concrete mixture (concreting).

- Then all pillars must stand on spacers for 28 days until the concrete gains full strength.

- A strip foundation is made under the entrance group.

This foundation is easy to install and low in price. Used for low fences made of corrugated board. Much attention should be paid to the installation depth of the support pillars: they must be buried below the freezing point of the soil.

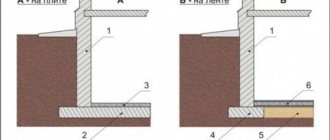

Strip and pillar foundations

The best option for corrugated board fencing is to install a corrugated board fence on a strip foundation. The pillar foundation holds the supports in place, and the tape holds the entire structure together into a rigid system.

The diameter of the pillars is selected depending on the height of the fence, the depth of burial depends on the type of soil and the level of its freezing.

To ensure the reliability and durability of the foundation, the tape must be reinforced. This allows you to distribute the load evenly across all structural units.

Scheme of a strip foundation for a fence

Traditional construction technology:

- The area is marked, and pegs are placed in the places where the pillars are installed.

- They dig holes for supports and a foundation strip.

- The bottom of the holes and tape is sprinkled with sand to a depth of 5 cm. The sand is moistened and compacted to create a sand cushion.

- The supports are installed on spacers and leveled.

- The formwork is laid in the tape.

- The reinforcement cage is laid in such a way that it does not reach 2-3 cm from the edges of the foundation on all sides. This will avoid metal corrosion.

- Concrete is poured in layers of 15 cm and bayoneted with reinforcement or worked with an in-depth vibrator to expel all air bubbles from it.

- After 12 hours, the concrete is moistened and covered with film. Thus, you should wait for the concrete to gain strength in accordance with its brand, periodically watering the concrete with water to prevent cracking.

- After a week you can remove the formwork.

To strengthen a heavier gate group, it is possible to provide for the creation of deeper holes for support pillars and a wider belt.

A fence made of corrugated board with a strip foundation is also used for a combined fence made of brick and corrugated board.

The brick-lined support contains a core - the same metal pipe. Therefore, the foundation for the support pillars is made as described above.

But for brick fences filled with corrugated sheets, it is typical to use a base, which:

- Protects the corrugated sheet from contact with the ground and, as a result, from corrosion.

- Protects the internal space of the site from the penetration of rodents and wild animals.

- Improves the aesthetic appeal of the fence.

Therefore, on an already solidified strip foundation, a brick base is made using reinforcing elements and the core is lined with brick to create an aesthetic support.

Strip-column foundation

Both of the above types of foundations are excellent for traditional corrugated fences with pipe supports.

But you can often find a do-it-yourself combined fence made from corrugated sheets with a foundation: the supports are stacked europoles, and the filling is made of corrugated sheets.

Typically, combined fences are made with a base. These are more durable, aesthetic fencing that can be installed in a cottage community, for example.

They look quite civilized and perfectly perform their function of ensuring safety on the site. In this case, a fence is also made from corrugated sheets on a strip foundation with some characteristic features.

Its main difference from the foundation , in which pipes were used as supports, is that here the base for the supports is reinforced and filled with concrete.

That is, first, holes are dug into which a sand cushion is also poured, roofing felt is compacted and rolled into a roll, which will serve as formwork and waterproofing.

A reinforcement cage is inserted inside to the entire height of the future column. The formwork for the tape is made taking into account the height of the base. After concreting the foundation and plinth, the stacked pillars are poured.

Block type foundation

In fact, such a foundation is a type of strip foundation. However, it is not poured entirely from concrete; it is assembled from reinforced concrete or sulfur-free blocks.

Builders do not recommend erecting such structures from cinder blocks or aerated concrete due to their instability to moisture and insufficient strength.

Sulfurless blocks are made from pressed cement with the addition of sand. The material has a wide range of colors and options for imitation of natural stone.

Such a base will be in perfect harmony with a stone, brick, or wrought iron fence.

Progress:

- A trench is prepared for the foundation. In places where the posts will be installed, the trench should be 0.3 m deeper. The trench width is usually 2 blocks.

- A cushion of crushed stone or medium-fraction gravel is formed at the bottom. Its thickness is 10cm.

- Sprinkle the top with a sand cushion, which should be well shed with water and compacted.

- Then the bottom and walls of the trench are waterproofed using sheets of roofing felt.

- Assembling the formwork.

- Concrete solution is poured. Layer thickness – 15cm.

- The pre-assembled wire reinforcement frame is laid in the ditch so that it does not touch the formwork.

- Metal tubes are installed in the recesses. Support blocks will be installed on them. The pipes must first be treated with a product that protects the metal from corrosion. To install the pipes vertically accurately, spacers are welded to them.

- The columns are connected to the reinforcement frame due to the reinforcement allowance, approximately equal to 15 cm.

- Then the formwork is filled with concrete.

- Dismantling of the formwork can be carried out after 14 days.

- Sheets of roofing felt are fixed to the walls using bitumen mastic.

What to look for when choosing a base

When choosing a base for a fence made of corrugated sheets, you should consider:

- The final weight of the fence. If the foundation bears heavy loads, the soil may sag.

- Depth of groundwater. In wetlands, it is recommended to build a monolithic type foundation. Despite the fact that it is usually not used for fences made of corrugated sheets, the arrangement of such a foundation in places where the groundwater level is close to the surface is justified. If the site is dry, the groundwater is low, any construction is allowed: strip, strip-column, columnar.

- Proximity to highway or railway tracks. The road passing next to the site will create a vibration load on the base of the fence.

- Soil type. On loose soils, a columnar foundation is used, but it should be further strengthened: the pillars are not only covered with crushed stone, but also filled with mortar to the full depth.

A strip-column foundation most fully meets all the requirements for a foundation for a fence made of corrugated sheets. It has high strength, gives the entire structure stability, allowing it to withstand large wind loads.

When constructing a foundation for a fence made of corrugated sheets, you should calculate the load, select the required thickness and depth, and strictly adhere to the work technology. Only a foundation made in accordance with all building codes will perform its function and last a long time.

Foundation depth for fence

In order to determine at what depth to lay the foundation, you should know the depth of freezing, as well as the nature of the surface.

If we are dealing with heaving soil, then it is necessary to lay the foundation 15 cm below the freezing level.

In cases where the soil freezes very deeply (more than 2 m), you should think about organizing a drainage system.

When the surface on which the fence will be erected has a difference in height, the foundation is laid at different depths, taking into account the slope of the ground.