How to start choosing?

It is unacceptable to be negligent in choosing a neck for a pipeline or well. And here the matter is not at all in the completed form of the structure, or compliance with standards and GOSTs. Its presence is:

- Safety of children, adults, animals;

- Protection from debris and tree branches;

- Anticipating liquid freezing;

- Ventilation.

In the case of a sewer system, the cap performs the main function of protection against emergency situations when, due to improperly equipped ventilation, gases accumulate, which can cause an explosion. In addition to reinforced concrete products for well rings, pipes, gas and water pipelines, there are also options for floor slabs (PP with PPL). They close the joints between the floors themselves, giving the entire structure the necessary rigidity.

The product range includes options in different sizes. This will make it possible to select a product for a specific location. A certain standard is provided for gas pipelines, sewer systems, and water pipelines, which greatly simplifies the choice. We have the functionality of an individual approach, when products are made according to the buyer’s measurements.

How to solve a problem?

It is possible to eliminate the shifting of the rings. To do this, rigidly staple the joints between the rings in the well shaft.

This type of service appeared not very long ago, but is in deserved demand. Reinforcement of rings contributes to:

- increasing the strength of the well trunk;

- preventing vertical divergence of seams;

- prevention of rings moving to the sides.

Feedback from people who have used ring staples in personal wells is positive. Here's what they write:

- If the staples are installed correctly and the rings are locked, then even on quicksand the rings will not separate from each other.

- We often observe the beneficial effect of staples when we compare the quality of water in wells located nearby.

- Entrust reinforcement to specialists who can assess the nature of the soil, do everything efficiently and thoroughly, and give guarantees upon completion of the work.

Want to avoid unpleasant surprises? Place an order with organizations that have proven themselves well.

Our company employs professionals. By resorting to their help, you will save energy, keep your nerves in order, and receive guarantees and bonuses.

Who's interested?

Covers for wells are specific products, but at the same time we have our own customer base that is interested in just such products. This is about:

- Housing Maintenance Bureau;

- Utility companies;

- Owners of large objects.

After all, it is on their private territory that there may be hatches that require arrangement. And these people or their officials are responsible for observing safety precautions - preventing clogging of communications, maintaining their proper operational properties, taking measures to prevent injuries. We offer products that are not destroyed by water, temperature changes, humidity, mechanical stress and toxic fumes.

Purpose of covers for sewer wells

Polymer cover for sewer well

Covers for sewer manholes are made of two parts: a cover and a support ring. They are used in systems whose design provides for inspection wells. Each hydraulic structure must be properly operated and its above-ground and underground elements protected from damage. For this purpose, wear-resistant well hatches are used, which:

- block the well shaft from debris and foreign objects;

- ensure the safety of humans and animals;

- protect against the characteristic sewer smell;

- prevent precipitation from entering drains;

Covers are also used for decorative purposes - they add aesthetics to the hydraulic structure and blend harmoniously into the surrounding landscape. If the appearance of the sewer hatch does not suit the owner of the site, it can be disguised with decorative stones or a pot of flowers.

Characteristics of floor slabs

Such products must comply with the following characteristics and installation features:

- According to safety regulations, the well floor slab must be sized to match the diameter of the well ring, which will ensure the safety of vehicles and pedestrians;

- To ensure the immobility of this element, it is necessary to place it on cement mortar;

- Installing the hatch on the support ring will prevent rain or melt water from getting inside when opening. In addition, the presence of a support ring helps reduce the load;

- Installation must be done using specialized equipment.

Wall rings

Using these elements, you can not only significantly simplify the entire process of arranging a well, but also make it as airtight as possible. KS for reinforced reinforced concrete concrete are made from heavy concrete (grade M200-M500). Thanks to vibration pressing during the production process, the elements are dense in structure, resistant to deformation and waterproof.

Reinforcement corresponding to types A-I and A-III is not necessary, but the presence of a metal frame in the product makes it stronger and more durable. Concrete KS have special technological holes that are used when installing a well. According to GOST, the diameter of wall rings varies between 840-2700 mm, wall thickness - from 70 to 100 mm, and height - from 290 to 1790 mm.

Healthy! It is best to install a well in early autumn. It is during this period that the groundwater level is lowest.

Classification of wall rings:

- Through (these products are marked KS). Their cost can vary from 2000 to 6000 rubles. So, for example, KS 15-9 groove (outer diameter - 1680 mm, height - 900 mm) costs about 3,500 rubles.

- With a bottom (marked DK). The rings with the bottom are highly airtight. The cost of these elements varies between 3000-6500 rubles.

- With floor slab (PC). As a rule, they are used if the well is quite deep and this particular product will be installed as a finishing element. The cost of such products ranges from 2500 to 6500 rubles. So, for example, PC 10-6 groove (outer diameter - 1160 mm, height - 600 mm) costs about 2600 rubles.

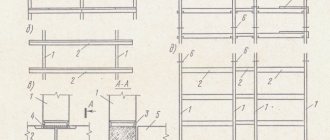

Wall rings can be fastened:

- Using only a cement-sand mixture.

On a note! Rings that do not have any fastening devices are called straight.

- Using steel brackets (or plates). Connections using metal fasteners (in 5-6 places) allow the products not to move relative to each other, that is, it contributes to greater tightness and stability of the entire structure of the well as a whole.

On a note! To join products, in addition to staples, you can also use a sand-cement mixture.

- Using a tongue-and-groove type lock (there is a protrusion at the upper end of the element and a recess at the lower end). Products with such a connection, as a rule, fit together more tightly. You can (for reliability) pour concrete mortar into the lock, or you can use a variety of sealants or cuffs.

On a note! The presence of devices in the rings for fastening them does not in any way affect their cost.

Advantages of reinforced concrete products

The high demand for reinforced concrete well floor slabs is explained by the following advantages:

- They are resistant to abrasion and mechanical stress, so they reliably close the hole throughout their entire service life;

- Products made from environmentally friendly materials do not harm the environment;

- Such products do not undergo changes under the influence of moisture, due to which they are installed in open areas;

- Affordable cost helps save money when creating communication networks.

Although we are located in Mytishchi, we work with delivery throughout Moscow. We are trying for you. We strive to please and delight with quality.

Model classification

In order for the covering of a sewer well to fit perfectly, it is necessary to take into account various parameters: from the material of the cover to the possible level of load.

Production material

Well ceilings can be classified according to the material used for their manufacture. Sewage hatches must meet increased requirements: strength, wear resistance, immunity to deformation and mechanical stress, corrosion and mold. Products must maintain performance characteristics under the influence of temperature changes.

The following types of lids meet all these criteria:

- polymer-composite or polymer-sand;

- concrete;

- cast iron;

- plastic.

The traditional material for lids is cast iron. It is valued by manufacturers for its strength, long service life and excellent resistance to aggressive influences.

Cast iron well cover

Coatings for sewer wells made from polymers have many advantages compared to models made of cast iron: they weigh less, look more beautiful, and are cheaper. At the same time, they are quite strong, practical and durable.

Their service life is estimated at several decades due to the material’s immunity to atmospheric influences and low coefficient of thermal expansion.

Polymer covers are perfectly installed on the seats of hatches installed many years ago.

Thanks to technological diversity, polymer manhole covers are manufactured for specific operating conditions. In places not subject to heavy loads, less durable, inexpensive, lightweight and easy-to-use models are used.

Polyethylene or polypropylene covering for a well cannot be installed on highways - it will not withstand the load. It is better to choose a cover made of metal or fiberglass and polyester resins. But for a summer cottage, polyethylene or polypropylene is quite enough.

Concrete well plugs are made for laconic structures made of reinforced concrete rings. Floors of this type are made either monolithic or with a folding wooden or plastic flap. Instead of a door above the hatch, you can build a superstructure made of brick or wood. In suburban construction, such ceilings are used to seal septic tanks and cesspools.

Load and marking

To choose the right well cover, you need to know the standard markings. It is indicated on each product in certain letters:

- PG – for underground fire hydrants;

- TS – for inspection well hatches of heating systems;

- D – for storm water inlets and wastewater structures;

- K – for sewer and fecal systems;

- B – for inspection hatches of water supply lines;

- M – for gas pipelines;

- T, MTS, GTS - for telephone lines.

Well slabs for sewerage are also classified depending on the load they can withstand. For domestic conditions, lightweight models are usually used. Such elements are designed for a maximum permissible load of no more than 3.5 tons. Lightweight hatches are used for constructing wells in places where there will be no significant pressure on the coating: in gardening areas, on personal plots.

Heavy hatches can hold loads of no more than 15 tons. Typically, this type of sewer covering is used in industrial areas or city roads that are not intended for the passage of heavy special equipment.

Heavy main sewerage slabs hold loads of up to 25 tons per second. Their installation is carried out in places with the systematic passage of a large number of trucks and other large vehicles. Such coatings are installed at gas stations, highways, and piers. Extra-heavy covers are used where the permissible load is more than 25 tons per second.

Sometimes lids are equipped with locking mechanisms to prevent theft and accidental opening. Locks come in expansion, flag and threaded types.

Concrete cover for a well: how to install correctly

Reinforced concrete covers for wells

A concrete well cover is, in fact, a floor slab for its trunk. It is installed in the case when the well is installed without a neck. Basically, these are communication wells located outside the zone of influence of mechanical loads, for example: roads. Our instructions and the video in this article will tell you everything about this product that owners of private houses who are engaged in arranging their home water supply or sewer system with their own hands need to know.

Precast concrete: well covers

Concrete covers for wells are produced in accordance with the dimensions of the wall rings. Despite the fact that this element during operation does not experience such loads as the walls of the barrel, they are still calculated with a margin of safety. Depending on the purpose of the tank being closed, the covers may have some design differences. So:

- The easiest option to implement is solid concrete floors. Many people prefer to install them, especially when the well is located outside the site. After all, everyone knows how often cast iron covers are stolen by lovers of non-ferrous metals. Another type has a round hole designed to install a hatch.

- Both products are manufactured: both with smooth ends and with a figured fold (quarter) - they are intended for installation on a lock ring, and are marked with the letter “C”. On some covers, the hole for the hatch is located asymmetrically, relative to their outer diameter - they are marked with the letter “C”.

Concrete cover for a well, with a built-in hatch

- Manufacturers also offer products with an already installed hatch: cast iron (see Cast iron well hatch: why is it always round) or, as in the photo, polymer. The price of well covers depends on the amount of concrete and metal spent on their production, as well as the presence or absence of a hatch. The choice of option is made according to the purpose of the well and its location on the ground. By the way, the lid does not have to be round.

- Wells can be both square and rectangular - the configuration of the ceiling must correspond to them. But, even if the lid is square, the hatch in it is made round, which reduces concrete consumption and improves the mechanical strength of the product.

- The exception is special-design ceilings intended for installation on water intake wells - in storm and drainage sewer systems. In such a cover they do not insert a hatch, but a grate for water drainage. It, as a rule, has a rectangular shape, which must correspond to the configuration of the hole.

Like any product related to the concept of “prefabricated reinforced concrete,” covers for wells are reinforced during the production process. There are reinforced covers designed for installation on wells located on roadways and factory areas. The cover of a well located on a personal plot is not subject to any surface loads, so covers with normal reinforcement are used for them.

Selection and installation of the cover

As we have already said, the design of the lid should be selected based on the type of tank. If this is, for example, a caisson over a well, then it is most convenient to take a cover with a central hole - this will make it more convenient to supply water. So:

- In inspection wells, on the contrary, the hole should be located asymmetrically, which makes it easier for a person to descend inside. Since the covers must ensure the tightness of the wells, you should pay attention to some nuances when purchasing them.

Stacking concrete covers

- First, look at how they are stored. Ideally, these are stacks of no more than six products in height, located in the working position, that is, horizontally. According to the rules for storing reinforced concrete, there must be wooden spacers between the products, located under the mounting loops. Violations during storage are fraught with the formation of cracks in concrete.

- You may not notice them right away, but during operation, moisture will get into them. In the cold season, after freezing and thawing, the cracks will expand, which will significantly reduce the service life of the product. When purchasing, it is worth inspecting the cover, and if you see that the internal reinforcement is on the surface of the concrete, there is a reason to refuse the purchase.

- This fact indicates a manufacturing defect, as does the presence of shells in the concrete, the depth and width of which exceed 5 * 15 mm. Minor deviations from the stated dimensions of the plate are allowed, but no more than 5-6 mm: both in diameter and in thickness. If you have chosen the correct version of the cover, then its installation is a matter of technique.

- Installing a well cover is the final stage of its construction, prior to backfilling the pit. The cover with the hole is placed on the head of the well, and its significant weight guarantees a static position. All that remains is to seal the joint so that rainwater does not penetrate through it into the tank.

- When a well is built from concrete rings, all seams must be sealed, and the joint between the lid and the ring is sealed in the same way. It is primed around the perimeter, if there is a shaped seam, a hemp rope is placed in it, and the whole thing is covered with cement mortar on an adhesive basis. It is even better to use dry glue for laying ceramic tiles for this purpose.

Decorating the cover of a concrete well

After the solution has hardened, the seam is primed again, after which you can install the hatch and backfill the sinuses. If the well is located in the courtyard of a house or in a garden, it can be used in landscape design. It can be a beautiful decorative hatch, or a polymer hollow stone like the one in the picture above. Such decoration will not only decorate the garden plot, but will also additionally protect the well head from rain, snow and freezing.

moikolodets.ru

Why is the shaft of the well rings scraped?

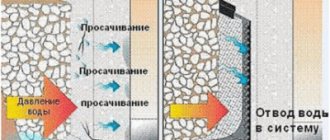

The craftsmen offer to scrape the well. This solution provides a number of advantages, which the owner can appreciate after the first winter season:

- Tightness of the finished structure, regardless of the type of soil. Heaving soils during floods or winter frosts cause disruption of the tightness of the joints of the rings and clouding of the water.

- Increased durability of the structure. The use of brackets reduces the load on the lock-groove system, which helps to increase the service life of the hydraulic structure.

Selection criteria and material

The coating must meet the following parameters:

- Tight fit to the well;

- Corrosion resistance;

- The presence of an additional insulating layer.

The lid for a well can be made of different materials, for example, concrete or metal.

Depending on the method of opening, they can be solid or double-leaf. It can be installed on hinges or in the usual mechanical way.

The shape of the lid is rectangular, round, square. But sometimes they are made in individual form. For example, in the form of decoration for the yard. When choosing, you need to consider the material from which the device is made.

The most common:

- Wood;

- Cast iron;

- Concrete;

- Plastic.

It is important to understand in advance which material is best to use to make a well cover.

Advantages of reinforced concrete well covers

Reinforced concrete structures have many advantages:

- A high-quality brand of concrete that meets the level of reliability. The initial concrete solution consists of a dense class of at least B20, with an average compressive strength of M261.9.

- Availability of durable reinforcement.

- Industrial treatment with a hot chemical composition gives the product special strength and resistance to external influences.

- The service life is over 50 years.

- The material is not affected by the atmosphere and insects.

- Installation does not pose any particular difficulties.

- The weight category of the product will not allow children or animals to move it from its place.

- Complies with the standards of the sanitary and epidemiological station, which allows you to cover the drinking well.

- The presence of structures of different sizes allows you to choose a hatch for any water source shaft.