A private house made of polystyrene foam only at first glance seems like an impossible solution. In fact, the technology has been known for a long time, but it began to be used in Russia no more than 15-20 years ago. It has its pros and cons, but overall, it belongs to modern, energy-saving construction methods

and is becoming increasingly popular.

A polystyrene foam house is actually built from polystyrene foam, i.e. foam blocks

. Such elements are produced with a cavity inside into which it is poured.

In essence, this is a permanent formwork that ensures the formation of reinforced concrete walls, because Before pouring, steel reinforcement is inserted into the polymer. This creates a wall that is covered with insulation on the outside and inside.

.

Construction foam blocks can be of different types and sizes - blocks similar in size and laying to cinder blocks

;

non-separable panels and large collapsible panels

, which are assembled from 2 foam sheets, fastened with special ties.

For any type of these products, the principle of building a house is similar - a wall is assembled with an internal cavity for pouring concrete. At the final stage, wall surfaces are plastered or finished with facing materials

.

There is another option for foam houses. They are assembled from structural insulating (SIP) panels, which are a combination of (expanded polystyrene). Unlike the previous case, the polymer ends up inside the reinforced concrete structure

, because poured into cavities at the factory.

Features of the technology

- At the stage of constructing the foundation, it is necessary to lay vertical rods in it to connect it with the wall made of permanent formwork.

- Reinforcement outlets from the foundation must be long enough to install the first three rows of polystyrene foam blocks.

- Waterproofing of the first row of formwork is necessary. Without it, moisture will flow freely into the concrete, reducing the thermal insulation of the wall. For this you need to use compounds that do not dissolve polystyrene foam.

- Horizontal reinforcing bars are laid inside each row to provide longitudinal rigidity to the frame.

- Pouring concrete is carried out after installing three rows of formwork blocks. After the concrete has set, the wall can be built up further.

- To cover window and door openings, you need to buy special lintels and plugs that are used to seal the ends of the formwork to prevent concrete leakage. Above the opening, the formwork is reinforced with two rows of horizontal reinforcement and supported from below to avoid deflection.

The outside of polystyrene foam permanent formwork is finished with special adhesive mixtures that have a high coefficient of adhesion to polymer surfaces. To protect the plaster or putty from cracking, a fine-mesh fiberglass mesh is glued to the blocks, which is then covered with a finishing mortar.

Other types of permanent formwork cladding are not particularly problematic, provided you make a suitable base for them in advance. For example, for siding, at the installation and concreting stage, you need to attach bars or a metal profile to the wall. To finish with decorative brick or stone, wire loops are placed in the concrete formwork to connect it to the masonry.

Sheet plasterboard or glass magnesite are optimally suited for interior wall decoration. It can be attached using regular starting putty. Ceramic tiles are also easily attached to the surface of polystyrene foam using special adhesive.

Pros and cons of permanent formwork

Avoiding emotions and trusting laboratory tests and practice, let's say the following. The sanitary safety of this polymer is confirmed by the hygienic certificates that each manufacturer receives for permanent formwork. This is a fact that is difficult to ignore. Owners of houses built using this technology, having lived in them for quite a long time (3-5 or more years), do not notice discomfort or increasing health problems.

The fire safety of polystyrene foam blocks falls within the framework of current Russian norms and regulations. They belong to the category of low-flammability and low-flammability materials (G1 and B1). But their level of smoke formation is quite high - D3.

This is what we see in the hygienic certificate for polystyrene foam boards (analogous to blocks for permanent formwork).

But after studying the information on the scope of application, some questions arise.

The use of polystyrene foam as the middle layer of a wall structure is a requirement of Soviet GOST. Today, building facades are covered with this material everywhere.

But for indoor use (the blocks face one side into the room), high-quality foam insulation is required. That is, it is not enough to simply putty it and paint it. It is necessary to line the wall with fire-resistant plasterboard or glass-magnesite sheets (SML) and apply the finishing touches to them.

This polymer is not dangerous in operation, but in case of fire without proper protection it releases toxic gases. Fire-resistant drywall or plaster will allow people to leave the room before the gases from decomposing polystyrene foam fill it.

To be fair, it must be said that the use of polystyrene foam indoors, provided it is protected from direct contact with fire, is less dangerous than conventional household items - chipboard furniture and decoration (linoleum, curtains, wallpaper and other materials containing flammable polymers).

High-quality external finishing of permanent formwork is very important, since the direct action of ultraviolet radiation quickly destroys the polymer. Therefore, after finishing the construction of external walls, do not delay with plastering.

Is it possible to use penoplex for walls?

When visiting a construction market, you can find penoplex foam for foundations, walls, floors, ceilings, etc. on the shelves. Having succumbed to advertising, it is easy to go on unreasonable expenses. It is more rational to delve deeper into the issue.

The high cost of penoplex dictates rational areas of its use as insulation for building structures. If the price does not matter for the home owner, you can use penoplex indefinitely, however, without looking at the builders’ assurances that PP sheets 2-3 cm thick will block the cold well.

To insulate the facade of a house, it is more profitable to use polystyrene foam.

The effect of using thin-layer insulation is minimal and hardly noticeable, and the areas of facades covered with the wet facade method are significant. Unjustified overspending occurs. Often this is money thrown away. In many cases, it is more profitable to use polystyrene foam and then also protect it with plaster, because the same insulation should save the owner’s money.

Another reason to abandon penoplex is the operating conditions of the wall materials. Concrete walls can withstand conditions of complete vapor barrier quite undamaged. Brick and wooden walls, unable to remove the moisture that collects in the pores, begin to collapse faster. Consequently, for the sake of preserving the main load-bearing structures of the house, the use of foam plastic and mineral wool is more justified.

Penoplex is great for foundation insulation

Penoplex has its own areas of application. Thus, penoplex sheets are suitable for insulating loggias or foundations with shallow depths, as well as insulating the soil under the blind area around the house.

If you succumb to the assurances of the builders and decide to insulate the walls with penoplex, then you need to reliably protect the cladding from external influences. For this purpose, polystyrene foam plaster is used.

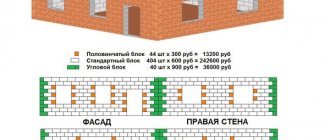

Approximate prices

When buying permanent formwork blocks, it is advisable to choose those made of denser polystyrene foam (25-35 kg/m3). They can better withstand the pressure of wet concrete.

The average cost of one block of permanent formwork (1500x250x250 mm, wall 25 mm) made of polystyrene foam with a density of 30 kg/m3 (M25) ranges from 150 to 170 rubles.

The cost of a one and a half meter collapsible block (wall thickness 25 mm) starts at 170 rubles. Its main advantage is the ability to adjust the width by installing jumpers of different lengths (150-250 mm).

For harsh climatic conditions, manufacturers produce permanent formwork with increased wall thickness (75 mm). The price of such blocks ranges from 190 to 210 rubles per 1 piece.

In addition to the standard length of 1.5 meters, ordinary meter blocks (1000x250x250 mm) are sold on the market. Their cost starts from 130 rubles per piece.

When choosing a material for building a house, hardly anyone thinks about polystyrene foam. Nevertheless, domed houses made of foam plastic are called “houses of the twenty-first century,” housing of the future. These energy-saving, durable structures can provide people with reliable and comfortable housing.

A domed polystyrene foam house has a number of advantages:

- high thermal insulation properties, which allows you to save on heating in winter and cooling in summer;

- they can be erected in different climatic zones, since the foam does not rot, does not rust, and does not attract insects;

- they are quickly assembled and disassembled, that is, they can be moved from place to place;

- reliability and durability, such houses can be used without repair for up to fifty years;

- minimum time for house installation;

- construction work is cheap.

What is the secret of the main advantage of such houses, their energy-saving and thermal insulation properties? The answer to this question lies in the structure of the dome itself.

The smaller the surface area, the higher the energy efficiency for indoor climate control

. The area of a sphere is four times less than the area of a parallelepiped of similar dimensions.

Separately, it should be noted the lighting features of the domed house. Everyone knows that rectangular rooms absorb light. The spherical surface contributes to its uniform distribution, which leads to the fact that the inside of domed houses is much lighter than in ordinary ones without additional lighting.

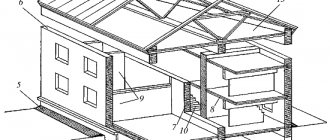

Dome house design

The design of a domed house is based on a geodesic dome. You can build it using widespread frame technology.

Four main ways to build a dome:

- connector (assembly using pieces of timber);

- quick connector (assembly of triangular panels);

- connectorless (assembled from precisely measured pieces of timber);

- lightweight geodetic structures (tent building made from sections of metal or plastic pipes).

Houses can be with or without a foundation. If you are building a foundation, then a lightweight monolithic strip or wooden foundation is recommended, since the weight of the dome and the house itself is quite low. Foundations assembled from impregnated wood can be used for up to a hundred years. If you build a house without a foundation, then it is installed on a wooden platform or piles.

Required Tools

Insulating a brick house using penoplex is a simple procedure that you can do yourself with your own hands. But for this you need to prepare the necessary tools and materials. Therefore, it is necessary to ensure the availability of such means as:

- perforator;

- drill with a whisk for preparing the solution;

- hammers;

- level for construction;

- ordinary spatulas (80-100 and 350-450 mm), serrated (20 cm with a tooth of 10 mm) and smooth;

- emery for grinding;

- plastic buckets;

- knife;

- roller for painting;

- penoplex in the required quantity;

- construction foam;

- reinforcement fiberglass mesh 5×5 mm;

- perforated corner made of aluminum;

- special glue for penoplex;

- plaster;

- primer;

- putty;

- special dowels, they are called “umbrellas”.

Split Frequency

Since the dome has a spherical shape, and building materials are usually rectangular, you need to calculate the shape of your future dome so that it is as similar to a sphere as possible. The degree to which the dome approaches the sphere is called the frequency of division (this occurs because the surface is divided into triangular fragments from which it will be built).

An important step in the construction of houses with a dome is the choice of the frequency of division. The calculation of the dome frequency is governed by two factors: the diameter of the dome, the ability to use standard windows and doors. Most often the frequency chosen is 2V or 3V.

Large domes, with a diameter of more than fourteen meters, are built with a frequency of 3V, smaller ones - with a frequency of 2V

. It is clear that a dome with a higher frequency will be smoother and, accordingly, will look more aesthetically pleasing, but the number of construction elements will be greater, which brings additional construction costs.

Further features of domed houses

The use of so-called “skirts” is also practiced. A skirt is a vertical wall inside a house that allows you to create a more vertical position of walls that is more familiar to people, increasing the volume of the room and adjusting the height of the building. The height of the skirt is from one to two meters. Such a vertical wall can be either a separate component or extend into the dome structure.

Installation of windows and doors when building a house from polystyrene foam with your own hands also has its own characteristics.

It is very tempting to glaze a large surface of the house; it should be remembered that this is a big disadvantage, since its heat-saving properties will decrease

and home costs will increase.

Rectangular, round and triangular windows are installed. Rectangular window shapes are mainly used for roof windows.

The door is mounted in two ways: with the help of an extension to the dressing room, or they try to fit it into the structure of the dome with the calculation of the maximum possible glazing of the entrance group.

Foam dome houses are also built multi-story. Unlike square frame buildings, in which all floors are installed at once, in domed houses the frame itself is first erected, then the roof, and in domed houses, on the contrary, the dome is erected first, and then the second floor.

A significant advantage of domed houses is its natural ventilation. It does not need to install any ventilation, since the role of ventilation holes is taken over by the windows installed in its upper half and at its base. Sometimes a fan is installed under the ceiling of the house.

Air exchange inside domed houses also helps reduce heat saving costs, since the convex surface of the dome allows air to circulate naturally. Externally, the wind bends around with less resistance, while rectangular buildings provide a flat barrier to the wind. As a result, strong pressure arises on one side of the house and rarefaction on the other, drafts arise that take away the heat from the radiators, and the air inside is replaced by street air.

Japanese domed houses in the photo

Expanded polystyrene blocks are the result of the efforts of scientists from the German chemical company BASF, who tried to combine various properties and characteristics in one material.

Light and warm blocks made of foamed polystyrene foam for the home are now actively used in modern construction. We invite you to familiarize yourself with basic information about the material - its characteristics, dimensions, pros and cons of use - in this article.

Main characteristics of polystyrene foam blocks

Despite the fact that the first blocks of foamed polystyrene foam appeared back in the 70s in the USSR, developers only recently began to actively pay attention to this building material.

The production of polystyrene foam blocks is now established on an industrial scale at many domestic enterprises. Below are the main physical properties of the blocks,

standardized by GOST:

- the density of blocks for a house should be from 150 to 800 kg/m³;

- have good resistance to frost (without loss of properties, the block will last from 30 to 150 cycles of freezing and thawing);

- the compressive strength indicator ranges from B0.35 to B2.5;

- The thermal conductivity index varies from 0.055 W/mºC to 0.145 W/mºC;

- vapor permeability coefficient is 0.05 mg;

- The material belongs to the low-flammability group, that is, it is fire resistant.

1.1 Application of material

The use of building materials is allowed for:

- construction of external walls of buildings;

- arrangement of interior partitions on the upper floors of the house, in which, due to the weakness of the slabs, the use of cinder blocks or other heavy materials is impossible;

- as an additional insulation or soundproofing layer in a building;

- when constructing premises that require maintaining a certain temperature level, for example, for the construction of a bathhouse or a pen for animals.

1.2 Advantages and disadvantages

Having analyzed these characteristics, we will consider the pros and cons of the material for building a house. Based on GOST standards, one can assume that all the characteristics of expanded polystyrene concrete are normal and it is quite possible to build large buildings from it, but this is not the case.

For example, the compressive strength of blocks is not particularly high; therefore, experts strongly do not recommend building a house with a height of more than two floors from this building material.

A small coefficient of vapor permeability also has its pros and cons. The advantages are that the material does not absorb moisture,

which means it resists frost well. But the disadvantages are that this same property does not allow the building material to “breathe”. As for the environmental properties of the blocks, everything here is also not clear.

You can definitely say something about environmental friendliness only after many years of living in a house built from expanded polystyrene. This is only possible by analyzing the air to detect styrene, but no one is doing this today.

Today, consumers have only one proof - certificates received by the manufacturer, the authenticity of which, unfortunately, cannot be determined.

The undoubted advantage is that expanded polystyrene concrete has a long service life. Considering these advantages, many developers today choose this material for the construction of one- and two-story houses.

If you believe the reviews of experts, the disadvantages of houses built from expanded polystyrene concrete include the possibility of destruction of the material from constant sunlight. In addition, according to data posted on construction forums, polystyrene foam is not recommended for use in internal insulation.

Despite all the disadvantages, the building material still has three main advantages:

- Excellent energy-saving properties, as a result of which the owner of the house does not need additional insulation of the building.

- Expanded polystyrene concrete does not need waterproofing.

- Plasticity of the material and precise dimensional geometry. As a result, installation is greatly simplified, which helps save mortar.

1.3 Polystyrene concrete blocks: disadvantages and advantages (video)

1.4 Dimensions and approximate cost

Today you can find blocks in many sizes on sale. The most popular sizes that are in demand among consumers are the following (based on width-height-length):

- 188x300x588;

- 300x380x588;

- 92x300x588;

- 138×300588;

- 80x300x600 (can only be used when building interior partitions).

You can also find high-density polystyrene foam blocks on sale.

(about 600 kg/m³), which are lintels for doors or windows. Such blocks are reinforced and are intended for both load-bearing and heat-insulating structures.

Now regarding the cost. Of course, we cannot provide exact prices as they change from time to time. But the approximate price range is as follows: the price per cubic meter of polystyrene concrete blocks varies around 3,500 rubles (1,200 hryvnia). The cost of foam concrete material is approximately the same.

When compared with aerated concrete, the latter costs about 3,800 rubles (1,300 hryvnia) per cubic meter, and wood concrete costs around 4,500 rubles (1,500 hryvnia).

Thermal insulation of the house

The next stage of construction is insulation of the domed house. Everyone chooses a different insulation: mineral wool or expanded polystyrene. We are talking about polystyrene foam insulation.

Expanded polystyrene is one of the best and highest quality insulation materials in the modern construction industry.

The dome triangles are ready-made cells for laying polystyrene foam. If the edges of the triangle are longer, so-called “spacers” are made from the inside of the foam, which ensure the preservation of density and optimal thermal conductivity.

There is no fire hazard in the construction of such houses.

, since it is treated with substances that do not promote combustion. Naturally, the relevant safety standards must also be observed.

In all cases of using expanded polystyrene, the requirements of GOST 15588-86 should be taken into account. Plates of this material should not come into contact with interior spaces. This is easily achieved on floors - with concrete screed, on walls - with adhesive mixtures or other finishing materials. The second important requirement is that the surface temperature should not exceed eighty degrees.

In professional construction, all standards are observed, so negativity about the use of expanded polystyrene comes only from ignorant people.

Dome houses made of polystyrene have reliable stability. So, in 1994 in Taiwan, such a house withstood a cyclone whose wind speed reached two hundred and forty kilometers per hour.

There are people to whom the expression “foam house” seems stupid and not everyone is able to take it seriously. In a way, this phrase is correct, because foam plastic blocks are used to build a house, which are later reinforced with concrete.

We are building a house from polystyrene foam

Today, one Japanese company offers consumers kits for building a foam house with their own hands. Such Japanese houses, in their opinion, have many advantages, one of which is resistance to earthquakes. This manufacturing company loudly called its Japanese houses housing of the 21st century.

The technical features of such a unique material are shown in the table.

Later in the article we will talk to you in more detail about foam structures, and tell you what positive qualities such cladding can boast of. We will also reveal the secret of the technology for performing the work, after which you will be able to build a house from foam plastic with your own hands.

Advantages of a polystyrene foam house

We build a house from polystyrene foam

To tell you about buildings made of foam plastic, it is worth highlighting a number of advantages that a building made of foam blocks can boast:

- Foam blocks help build a very warm structure

Such insulation, as it were, envelops reinforced concrete profiles on each side.

- A house made of foam blocks can serve as a “thermos”

Such a building can sufficiently retain warm air not only in the cold season, but also keep it cool on hot days.

- Available formwork

Formwork is not the familiar panels that need strengthening and installation. At their core, these are blocks of foam plastic, in the middle of which there is a cavity. According to some characteristics, this material is very similar to cinder block, but externally you can’t tell them apart from each other. When constructing a building from block foam, you fill its interior with concrete mass, installing reinforcement there in advance.

- Possibility to use permanent formwork

This formwork is presented as a complete material. The installation technology is the same: install the blocks, install the reinforcement and pour the concrete solution into it. In principle, such formwork can be presented in 3 varieties: as slabs, blocks or standard panel formwork, which is fixed together with specialized jumpers. Using panel formwork is the most affordable option from a financial point of view, but working according to such a scheme is not as easy as we would like.

The most suitable solution when doing construction work yourself is to use blocks that are so reminiscent of the long-familiar cinder block.

Also, foam plastic and concrete structures have some negative aspects, the most significant of which is considered to be the “thermos” effect. It can only be overcome by installing a high-quality forced ventilation system in the house, which makes the work performed more expensive.

Another, no less unpleasant point is the environmental friendliness of the structure, which, even if tightly sealed with plaster, is out of the question. It is also worth noting the possibility of the material igniting, after which toxic substances will be released during combustion, which can even kill a person.

As you can see, not everything is as rosy as it might seem at first glance.

Features of the thermal house

Why does a foam house stand out so much from the rest? The fact is that blocks made of foam plastic, or polystyrene, act as insulating formwork, which reduces heat loss. But it’s not enough to just order a house made of foam plastic; you need to plan it correctly. All windows of the house should be oriented to the south; it is recommended to create so-called buffer zones at the entrance. For houses that are built from blocks poured with concrete, you cannot skimp on doors and windows.

Among the features of such foam plastic buildings, it should be noted that they require the installation of a ventilation system and heating, that is, in the winter months such a house must be warmed up, although energy consumption will be minimal.

People who have built such a warm house, but neglected the rules for installing it (not so complicated), often complain about dampness and fungus that has appeared on the walls. But this is a consequence of a violation of technology, and not a defect in the material. Walls made of foam plastic and concrete are vapor-tight, so to maintain a comfortable atmosphere inside, a forced ventilation system should be installed. The best option is air handling units with recovery.

Finish options

The construction of foam plastic houses has its own characteristics, but one of the advantages over others should be noted that the walls in this case can be covered with almost any type of finishing materials.

Exterior façade walls are usually treated with a layer of decorative plaster, which is inexpensive and attractive in appearance, but other options are also possible.

Scheme of thermal insulation of the foundation with polystyrene foam.

For example, you can use ventilated facade systems, which are not only attractive and give the building a modern, stylish look, but also provide an optimal microclimate in the house.

Interior walls can be finished with a variety of materials. Today, they are most often sheathed with plasterboard, which provides many design options.

There are no restrictions on roofing materials for foam houses. Due to the fact that concrete mortar is poured inside the blocks, the house turns out to be virtually monolithic, capable of withstanding even heavy loads. That is, even natural ceramic tiles, which are heavy, can be laid on the roof surface.

In order not to spoil the interior decoration of the polystyrene foam house, all engineering communications can be laid directly within the walls of the house, but this must be done during the construction stage. The only difficulty is the use of only those materials that are acceptable for indoor installation.

We build a house from polystyrene foam

DIY foam house

Basically, all buildings, no matter what material, are built using the same technology:

- the foundation is laid;

- walls are being built;

- the structure is covered with a roof.

The only difference can be noticed only during the construction of walls, which we will discuss in more detail a little further.

Well, the technology for performing work is carried out in the following order:

- The base layer of foam formwork is laid on a carefully prepared foundation, which is previously insulated from moisture.

- The fittings are immediately mounted on the foam blocks, which are not installed in every cavity. Better reinforcement will be required in the corners.

- There is no question of canceling the tying of the blocks, so you will have to act in the same way as if you were laying a brick. The foam will need to be laid with a slight shift, and every second tier will need to be laid perpendicular to the previous one. Such a bond will not have any additional strength, but the insulating features of the structure will increase significantly.

- At the top of the structure it is necessary to pour an armored belt, the height of which should be at least 200mm. For these purposes, panel permanent formwork is most often used.

That seems to be all, these are all the nuances and features that you need to know about when constructing surfaces from permanent formwork. The most important point that I would like to mention is that the cavity of the blocks must be thoroughly filled with concrete, without leaving the slightest gap.

Specifics of different types of finishes

Depending on the location of the insulated structure of the house, penoplex plaster has nuances. First of all, this concerns what can be used to finish penoplex.

Base finishing

Since the plinth is part of the building structure, installed directly on the foundation, it especially needs protection from moisture. Therefore, additional measures are taken to protect against water ingress, but only those that prevent the occurrence of cold bridges.

Plastering the base on polystyrene foam is usually done in a thicker layer, because:

- a) the likelihood of strong mechanical impacts on the base is higher;

- b) often for the base the finishing is done with cladding: stone-look tiles or pebble plaster (heavier).

When using heavy cladding, reinforcement is made with metal mesh, which also requires a thickened plaster coating. Only façade plaster over penoplex is used.

How to plaster penoplex indoors

If for a number of reasons it is impossible to perform penoplex insulation outside the house, it is performed indoors. Here polystyrene foam will “eat up” more area than polystyrene foam. To plaster penoplex indoors or on warm loggias, you can use gypsum plaster to protect penoplex.

The sequence of performing these works is similar to performing penoplex plaster on the outside, however, the installation of a base profile is not required. In addition, when plastering, putty is used over the reinforced layer.

There should be no drafts in the room. You should also not use heaters and fans to speed up the drying of the plaster coating. Depriving the solution of the moisture necessary to gain strength leads to a sharp decrease in moisture, as well as to the appearance of shrinkage cracks.

For plastering from the inside, not only compositions intended for interiors are suitable, but also plasters on polystyrene foam facades.

How to plaster penoplex outside

To apply plaster to penoplex from the outside, special façade plasters for penoplex or adhesive compositions (for reinforcement) are used, on top of which suitable façade or universal plaster compositions are applied.

At a height of more than 2 m from the ground surface, reinforcing mesh is practically no longer needed for reinforcement. However, it is necessary to ensure strong adhesion of the plaster coating to the PP. It is better to choose plaster that firmly “sticks” to polystyrene foam.

For example, for gluing penoplex boards to the wall, as well as for attaching reinforcing mesh, you can use the plaster-adhesive composition Ceresit CT 85. Ceresit also produces plaster compositions for decorative finishing, for example, polymer-cement “bark beetle” - ST-35, pebble - ST- 137.

Wall decoration

We build the walls of a house from polystyrene foam ourselves

Building floors from foam blocks with your own hands is only half the battle. When the concrete hardens, the walls will have to be covered with plaster. The plastering technology is slightly different from the usual work and looks like this:

- A metal plaster mesh is stretched over the surface of the walls (for which it is worth choosing durable materials), which is nailed to the concrete. This process is very labor-intensive, so for quality work with your own hands you will have to work a little.

- At the next stage, the mesh is glued with special glue to the foam blocks. This work is similar to the process of throwing on a fur coat. The glue is applied in drops onto the wall surface, after which the excess is removed with a spatula.

- Then beacons are installed, which are glued vertically.

- After the work has been done, you can use plaster made from a mixture of sand and cement. It can be applied either with your own hands or with a specialized machine.

Please note that some types of facade wall panels can be installed not on the frame, but glued directly to the surface of the walls.

In conclusion, I would also like to mention this method of constructing buildings from foam plastic, such as building a frame house. Using this principle, it is much easier to build a building with your own hands than using the above. At its core, this is a familiar building based on a durable frame, in which foam plastic takes on the role of insulating material.

That's all I wanted to talk about. On the one hand, building a house out of foam plastic with your own hands is a good solution, but as soon as you remember the “thermos” effect, you don’t really want to move into such a building.

But we all have our own opinion on this matter, and it is likely that for some such buildings will be the only and ideal solution. We will not dissuade you under any circumstances; the choice, as always, is yours.

Modern technologies make it possible to use polystyrene foam in the construction of houses for summer cottages and hotels, change houses and other similar structures. Some may argue that polystyrene foam is not a suitable material for building buildings. But time does not stand still, and it is already possible to build a house using extruded polystyrene foam, the density of which is at least 35. Dome houses have received many positive reviews and are in demand in Russia today.

Installation

Initially, before performing any construction work, it is necessary to prepare all tools and materials. One of which will be spatulas (small and large).

Small - for applying the solution to a large spatula. In the case when the surface of the walls is perfectly flat, then to apply the adhesive you will need a notched trowel . In other cases, you will need to throw them on the wall surfaces in large piles.

Next comes the most interesting part, applying the sheet and pressing it tightly against the wall. On the foam sheets there are quarters on the end sides, which are specially made to ensure tight joining of the material. After which, during the application of sheets, the appearance of bridges is eliminated during the cold season.

Preparatory work

- Leveling wall surfaces from depressions and bulges. Because then the penoplex can break from pressure.

- Determining the quality of the surface (so that the glue sticks well).

- Next, it is advisable to walk over the surface of the walls with a primer.

- Process the sheets on both sides with a toothed roller or a drywall brush (so that the mixture fits tightly).

- Fixation of window sills, ebbs, slopes in openings. The protrusion is 1 cm when insulating slopes.

Insulation sticker

When the main work is completed, they begin to fix the insulation itself directly to the wall. The example will show the option with a sticker and nailing, since this is most often found in practice.

Bottom corner . To securely fasten the penoplex, first fix the initial profile, which will hold the sheets on the wall.

Nailing insulation

For this, special plate-shaped dowels are taken - umbrellas . They resemble a plastic dowel with a large head and a plastic or metal dowel. More often they use completely plastic ones, their cost is much less, and they will not give off cold, unlike metal.

It is important to know: it is better to buy at an average price, otherwise the dowels may bend when driven in!

Processing of joints

After completing the fixation of one part, proceed to checking the joints. If the job is done well there shouldn't be any problems. But if a gap larger than 5 mm is formed, it is necessary to use construction foam. The holes are filled completely with foam, and nothing will be visible anymore. Dries in about 5 hours.

When holes are larger than 2 cm, pieces of insulation are inserted.

Reinforcement

- Plastic corners or mesh are glued to the corners that exist in the room . If you take a mesh, then with a margin of up to 5 cm, an alkali-resistant mesh is well suited for street work.

- Next, the mesh is glued to all other parts of the insulation. Using a wide spatula over 35 cm, in areas of about 1*1 m.

- A liquid several millimeters thick is applied to a certain area and a mesh is applied on top.

- It is important to remember: leave about 10 cm, the un-glued edge is for joining.

- Afterwards, using a wide spatula, carefully smooth the surface where the mesh is located from the center to the edges.

- Moving on to the joining, the required area is taken and coated with the prepared solution, moving to the untreated edge of the previous zone . Each subsequent piece of mesh goes on top of the previous one. Thus, the joint areas will remain invisible after drying.

Finishing

At the last stage of finishing, after drying the reinforcing layer, they proceed to troweling (using sandpaper). After which, an even layer up to 3-4 mm thick will appear on the surface.

Before starting work on finishing the surface, it is necessary to treat the wall with a primer mixture.

Advantages of expanded polystyrene for domed houses

- Not subject to rotting or rusting.

- Insects don't like him.

- Creating a comfortable microclimate inside the building.

- The versatility of the material allows you to choose any finishing option.

As a result, ready-made domed houses have many positive aspects. Good thermal insulation characteristics allow you to save on heating costs in the cold season. The possibility of erecting a house is provided on any basis: be it a regular strip foundation or a concrete pad, a light wooden platform or an OSB board base.

Useful video: Dome construction of a polystyrene foam house

Pros of polystyrene foam houses:

– Saving money on the purchase of materials and their delivery, since you are already delivered a fully equipped house, ready for assembly.

Interior of a domed house

– There is no need to buy roofing materials, since in a domed house the walls are also the roof at the same time.

– The sphere provides a uniform load on the entire surface, with excellent compression and deflection characteristics.

– Quick installation of the structure. The house is completely ready in 4 hours. It does not require any special experience or equipment.

See photos of spherical houses

:

How to make a domed house from polystyrene foam by molding on an inflatable frame, see the video

A house with an original shape will become a real decoration of your suburban area. Construction of a domed house will help to significantly save on materials and on further finishing during DIY repairs.

Lately, one can increasingly hear talk about the so-called thermal house. This may seem like a made-up term from some science fiction novel, but in reality everything is much simpler. A thermal house is a house built from polystyrene foam. This construction technology is also called permanent formwork.

This article will discuss how to build a polystyrene foam house with your own hands.

Characteristics of foam blocks

These blocks are hollow boxes. Their dimensions are standard (95x25x25 cm), but for the construction of internal walls, products of a slightly smaller width are used - 95x13x25 cm.

Note! Expanded polystyrene blocks are produced using industrial conveyor production technology. During a work shift, the production line produces about one hundred and twenty blocks.

The advantages of building materials include:

- ease of processing and installation;

- resistance to permanent moisture;

- light weight;

- excellent noise insulation characteristics;

- high-quality thermal insulation due to the multilayer structure;

- resistance to rot and fungus.

It is also worth noting that polystyrene foam is a “breathable” material, that is, one that allows air to pass through.

But there are also disadvantages that need to be taken into account before construction begins.

- Foam blocks cannot withstand temperatures above 90? C.

- The strength of polystyrene foam is just an illusion; in fact, you can easily pierce it with your finger. In this regard, the walls will have to be puttied.

- The material is highly flammable.

The cost of one such block is approximately 300 rubles, which is relatively inexpensive. Let's consider the costs of building a polystyrene foam house in comparison with a brick one. Thus, a thermohouse is a structure that is ready for final finishing and can be covered with either plaster or paint, or siding. At the same time, a brick house needs putty and thermal insulation (with the same foam), which, of course, increases construction costs.

In a word, a thermal house is an inexpensive pleasure, since it already includes both finishing and insulation. Moreover, according to GOST, the height of such a house can reach 15 m, which is equivalent to 5-6 floors.

What are the benefits of foam blocks for building a house?

They have a number of undeniable advantages:

- Thanks to the use of this technology, the construction process is greatly accelerated. A house made of foam plastic blocks can be built in two weeks, which cannot be said about a house made of bricks. It does not require a large number of builders or special machinery or equipment.

- Polystyrene foam is an environmentally friendly material that does not transmit radioactive radiation. After all, it has long been used for food packaging.

- Since polystyrene foam has excellent sound insulation, a house made from it will have the same property. Therefore, peace and quiet for the inhabitants of the house are guaranteed.

- Blocks for building a house with foam plastic have high thermal insulation qualities - this reduces the cost of heating a house by 10-12 times. The need for heating arises only at temperatures below -5 degrees.

- Due to its low weight, compared to brickwork, it becomes possible to use lightweight foundations when building a house. Again, saving the family budget.

- Thinner but warmer walls made of foam blocks allow you to increase the living space.

- Another important property that foam blocks for construction have is their fire safety.

- Foam blocks are resistant to biological influences, microorganisms do not settle on them and they are inedible for all kinds of rodents.

- Due to the fact that foam blocks for construction are priced much lower than classic building materials, they initially have a regular geometric shape with a flat surface, which also does not require additional costs for labor-intensive wall finishing.

- And the most important characteristic, as mentioned above, is the low cost of foam blocks, and, accordingly, the cost of building the entire house.

But when buying foam blocks for building a house, the price of which is very attractive, you should still take into account the quality of the material. In our store you will find only high quality foam blocks at an affordable price. You can buy foam blocks for construction on our website with the click of a button. And all your questions will be answered by our highly qualified consultants, who are well acquainted with all the new products on the global construction market.

Buying foam blocks for building a house in our store is very profitable, because by doing so you reduce not only the time for building your home, but also the costs of building materials, labor, and in the future, heating the house, as well as additional sound insulation.

Living in a house made of foam plastic blocks is also very comfortable, because it is cool in the heat and warm in winter. And the construction of a house can not be delayed even in the winter months, since low temperatures do not affect the properties of foam blocks. And you can build absolutely everything from blocks that can be built from bricks. But thanks to the plasticity of foam blocks, it is possible to realize various architectural fantasies, which cannot be done with brick. Therefore, the built house will be beautiful and at the same time cozy, standing out among standard buildings with its originality.

Lately, one can increasingly hear talk about the so-called thermal house. It may seem like this is a made-up term from some science fiction novel, but in reality everything is much simpler. A thermal house is a house built from polystyrene foam. This construction technology is also called permanent formwork.

This article will talk about how to build a polystyrene foam house with your own hands.

These blocks are hollow boxes. Their dimensions are standard (95x25x25 cm), but for the construction of internal walls, products of a slightly smaller width are used - 95x13x25 cm.

Note! Expanded polystyrene blocks are produced using industrial conveyor production technology. During a work shift, the production line produces about one hundred and twenty blocks.

The advantages of building materials include:

- ease of processing and installation;

- resistance to permanent moisture;

- light weight;

- excellent noise insulation characteristics;

- high-quality thermal insulation due to the multilayer structure;

- resistance to rot and fungus.

It is also worth noting that polystyrene foam is a “breathable” material, that is, one that allows air to pass through.

But there are also disadvantages that need to be taken into account before construction begins.

- Foam blocks cannot withstand temperatures above 90ᵒC.

- The strength of polystyrene foam is just an illusion; in fact, you can easily pierce it with your finger. In this regard, the walls will have to be puttied.

- The material is highly flammable.

The cost of one such block is approximately 300 rubles, which is relatively inexpensive. Let's consider the costs of building a polystyrene foam house in comparison with a brick one. Thus, a thermohouse is a structure that is ready for final finishing and can be covered with either plaster or paint, or siding. At the same time, a brick house needs putty and thermal insulation (with the same foam), which, of course, increases construction costs.

In a word, a thermal house is an inexpensive pleasure, since it already includes both finishing and insulation. Moreover, according to GOST, the height of such a house can reach 15 m, which is equivalent to 5-6 floors.

About the environmental friendliness of the material

Most people are sure that polystyrene foam, like any other “chemical”, is unsafe or even harmful to health. This fact has not yet been confirmed, but it has not been refuted either. It is worth noting that there are a number of requirements, in particular sanitary and GOST, to which the manufactured products fully comply.

But some people are difficult to convince even of obvious things, which is most likely due to a psychological factor. And even the fact that foam plastic is widely used in insulation and interior decoration, as well as in the manufacture of disposable tableware, for some reason is not a compelling argument in this case.

Advantages and disadvantages

Penoplex is made using a special machine, an extruder, which makes it a fairly durable building material.

Extruded polystyrene foam is the most affordable and functional means for insulating external walls made of brick or wood. The material has the following advantages:

- ease of transportation;

- affordability;

- high thermal insulation abilities;

- application for insulation of external and internal structures;

- waterproof;

- fire resistance;

- good sound insulation;

- ease of installation.

But there are no ideal building materials to insulate a brick house. Penoplex has 2 disadvantages:

- low adhesion (ability to absorb adhesives);

- instability in front of rodents.

Foam house: construction instructions

Having understood the strengths and weaknesses of the material, you can begin installation. But first you need to prepare everything you need.

Stage 1. Tools, materials

The work will require:

- foam blocks;

- finishing material;

- sand;

- wires, pipes;

- metal fittings o12 mm;

- steel wire for the bundle;

- “six hundredth” grade cement;

- water;

- crushed stone;

- concrete mixer.

Stage 2. Foundation

Construction of a house begins with the foundation. The best option is an ordinary strip foundation, although it all depends on the characteristics of the soil in the selected region.

After pouring, the base is supplemented with support. To do this, wooden blocks measuring 50x60 mm are laid along the entire perimeter of the foundation. The entire remaining area must be laid with boards of similar thickness.

Note! After laying, the wood is treated with a fire retardant and antiseptic.

Stage 3. Assembling the structure

The construction of a thermal house is similar to the assembly of a construction set - the blocks are joined groove to groove, laid with reinforcement and assembled into walls.

Step 1. Foam blocks are prepared for installation: cleaned, leveled and thoroughly dried.

Step 3. Concrete solution is prepared. To do this, cement, crushed stone and sand are poured into a concrete mixer in a ratio of 1:3:3 and filled with such an amount of water that the resulting liquid mixture is obtained.

Step 4. After running five rows, the solution is poured into the voids between the layers of blocks. When pouring, it is advisable to tap the side surface of each block - this will make the concrete shrink more densely.

Step 5. Part of the wall is assembled from the next five rows of blocks and filled with mortar again. The procedure is repeated until construction is completed.

Step 6. Sewage, wiring and other communications are laid directly into the walls of the house, after which it is covered with a roof and the final finishing of the walls is carried out. It is typical that it is recommended to lay the pipeline in still hollow walls, while the electrical wiring is routed through pre-made grooves (there should be no problems with grooved foam).

There are also no restrictions in the choice of roofing material. In fact, a foam house is a monolithic structure that can withstand any load, so even natural tiles can be used for covering.

Note! It is better to start the construction of a thermal house in the warm season at a temperature not lower than -10? C.

Foam blocks retain their original properties for a long time. There is even an opinion that a house built from these blocks, under appropriate conditions, can last up to 100 years.

Stage 4. Finishing

As already mentioned, there are practically no restrictions when decorating the walls of a thermal house internally/externally. From a financial point of view, it is more profitable to use decorative plaster or ordinary paint, and cover the inside with plasterboard.

The thermohome may look different. Below are instructions for constructing an arched building of standard dimensions: the height of the walls is 3 m, the total area is about 10 m?. Of course, such a structure cannot be used as permanent housing.

What will be required at work

Before starting construction, you need to take care of everything necessary. Below is a list of materials:

- foam blocks;

- building level;

- concrete solution;

- polyurethane foam;

- dowels, screws;

- ruler;

- marker.

Construction technology

Step 1. First, the foundation is built. In this case there are no differences from the previous option.

Step 2. A 50x60 mm beam is laid along the entire perimeter of the base, fastening is done using anchors. In this case, the structure is periodically checked with a level.

Note! To optimize fastening, you can use any mounting foam, except extra-class. This is explained simply: this type of foam expands greatly.

Step 3. The side walls of the base, protruding above the ground, are finished with decorative stone. The stone is placed on ordinary concrete mortar and lightly knocked down with a hammer.

Step 4. The foundation is covered with a waterproofing layer (polyethylene film is suitable). A brick can be laid on top of the film to increase the strength of the foundation and protect against subsidence.

Step 5. Next, foam blocks are prepared. They are cut and glued in accordance with preliminary measurements. For the frame of the arch you need to use only shaped blocks, and to fill the walls you can use ordinary thick sheets. Polyurethane foam is used for gluing.

Note! For fixation, you can also use special glue for polystyrene foam, but polyurethane foam is consumed more economically. The only drawback of foam is that its expansion must be constantly monitored, otherwise the tightness of the frame may be compromised.

Step 6. The finished foam arches are attached to the base with screws and dowels. To do this, holes are made along the entire perimeter of the foundation (with equal spacing) into which high self-tapping screws are installed. Then, holes are made in the appropriate places in the lower part of each arch, after which the arches are mounted on self-tapping screws.

Note! For ease of assembly, dowels can be inserted into the holes in the arches in advance.

Step 7. The arches are additionally fixed. If polyurethane foam is used, then it fills the gap between the frame and the base using a thin tube. If glue is used, then all working surfaces are lubricated with it before installing the arches.

Step 8. All that remains is to seal the cracks between the blocks with concrete mortar and plaster the walls of the house. For further finishing, as already mentioned, you can use any material - it all depends on financial capabilities and personal preferences.

As you can see, building a foam house is not such a complicated procedure. The main thing is to correctly calculate the consumption of building materials and securely fix the blocks on the foundation. By the way, not only blocks can be used in construction.

Cons of construction

A lot has been said about the advantages and benefits of thermal houses, but is foam plastic really that good as a frame? And is it possible to avoid some of the disadvantages of such houses made of concrete and foam plastic? Let us consider the main difficulties and disadvantages that may arise during the construction and operation of such a structure.

Diagram of a polystyrene foam wall.

- Operational problems. This disadvantage is associated with the material itself - polystyrene foam. To attach shelves or cabinets to its surface, it is necessary to install special overlays during construction, which are fixed directly to the concrete. If this is not done, then when repairing or installing new furniture, you will have to cut the foam layer down to the concrete, and then attach wooden blocks to it, on which the cabinets will be hung. As you can see, this problem is solvable, although there is a certain inconvenience here, since additional, not the most simple, work is required.

- Heat capacity. Despite the fact that houses made of foam plastic are considered very warm, they still require good heating in winter.

- One of the main disadvantages of using concrete and foam plastic as building materials for walls is that the walls are vapor-tight. According to reviews from the owners of such houses, the atmosphere in them is always a little humid, which creates discomfort and not the most pleasant microclimate. This problem can be solved, so it is not critical, but it requires some effort and expense. You can make the microclimate in your home more comfortable by installing a forced ventilation system. And taking into account the fact that such ventilation systems are installed today not only for foam houses, but also for many other buildings, such a drawback often goes simply unnoticed.

- Labor intensity. The construction of such a house requires certain efforts and skills. In this case, it is not just about installing blocks filled with concrete, it is necessary to install them correctly, in strict accordance with all technology requirements. But it cannot be said that installing foam blocks is more difficult than building a house, for example, from brick. In many cases, it is even easier to build such a house, although you will have to work hard when laying the first rows. External and internal finishing of a wall made of foam plastic requires effort and skill, as difficulties may arise during fastening. Therefore, it is necessary to use only special materials.

Many consider the disadvantages to be that the blocks are made of polystyrene foam. Not everyone prefers this material as the main material for building the walls of a house, but this is a rather controversial issue. The harm of polystyrene foam has not been proven; during operation it does not emit toxic substances, but it cannot be called natural either.

It is also necessary to note this point: today the number of houses built from foam plastic and concrete is not so large, that is, it is too early to talk about their advantages or obvious disadvantages over all others. These houses are stable and very comfortable, have an attractive price and the ability to take different forms, but a more complete analysis of their operation still requires more than one year.

Construction requirements

Today, a foam house is one of the options for building housing quickly and inexpensively. This design can take on any, often very unexpected, but such attractive forms, which greatly distinguishes a thermal house from a traditional brick or wooden one. But if you have chosen just such a material, that is, blocks of foam plastic poured with concrete, you need to remember some features.

Diagram of an expanded polystyrene panel.

- transportation, unloading and installation of blocks must be careful, since the foam can be damaged at the ends, where the edges can chip. This problem can be solved by simply gluing the material, but this takes time, which makes installation longer;

- When purchasing, you should choose the right blocks, since unscrupulous manufacturers may make defects. All angles must be smooth, the dimensions must match the stated ones;

- When concrete is poured into blocks, not only the installation of formwork is required, but also constant checking of verticality using a building level. This is necessary, since the foam expands when poured, that is, the blocks can move, but this should not be allowed;

- after the installation of the house structures is completed, it is necessary to immediately begin exterior finishing so that the foam has as little contact as possible with direct sunlight.

Today, for the construction of houses, not only traditional materials are used, such as brick, wood, concrete and others, but also unusual ones at first glance, but no less high-quality and reliable. We are talking about foam blocks, the cavities of which are filled inside with a concrete mixture. After hardening, the house takes on attractive shapes, it is durable, holds heat well, and is comfortable to live in.