Roofing costs

The construction of a house cannot be considered complete if the box does not have a roof. This finishing work can be postponed indefinitely, and the installation of a roof for a wooden building must be carried out immediately after finishing the walls. Otherwise the tree will get wet.

So, everything is extremely simple here:

Drawing up an estimate for the construction of a frame house

- We know the roof area from the house design. Based on the available data, you need to determine the total volume of roofing material and multiply by the price per unit of its volume.

- To the resulting amount we add the cost of insulation and waterproofing, the volume of which will also be equal to the roof area plus a 10% reserve for joints and overlaps.

- Also, the cost of the timber for the rafters and the ridge should be added to the total amount. The amount of lumber is calculated by dividing the length of one roof plane by the pitch of the rafters. We get the number of rafters on one side of the roof. We multiply this number by two (two sides of the roof for a gable roof of a one-story house 6x6 m).

- Do not forget to take into account the costs of fasteners, fittings and payment for the work of craftsmen, if any are involved.

Calculation of materials

Therefore, we will now learn the simplest way to calculate materials for the foundation and frame, without taking into account the floors and roofing. For example, we will use a 6x8m building with a terrace, a kitchen and three rooms (the plan is shown in the figure above).

Foundation

- Of course, foam concrete is a fairly light material, and some use screw piles for such buildings, which are excellent, but still, such zero cycles are more often used for light structures, such as bathhouses, summer kitchens and country houses. More often, a strip foundation is used, which can be deep or shallow, monolithic or prefabricated. Such a foundation is more labor-intensive, and its price will be higher, but such arrangement allows you to equip a cellar or basement under a residential building (find out here).

- For calculations, we will choose a monolithic structure, as it is more complex to manufacture, but more reliable in operation, and the estimate for building a house made of foam blocks will include these costs. First of all, it should be said that we will not calculate the amount of money, but the amount of building material that we will need, and you can easily find out the amounts by multiplying this amount by the price of this material in your region at the moment.

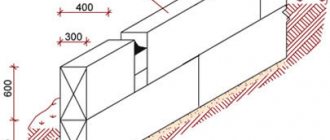

- First, let's decide on the size of the tape and imagine that the pouring will be done on non-heaving soil, which means that we will make a shallow foundation, 60 cm from the surface of the earth, but we will dig a trench 80 cm, since we need a sand cushion. The width of the tape for a block of 200X300x600 mm will be optimal 0.5 m if the masonry is done in half a stone (the remaining 20 cm will be used for finishing work). The outer part of the foundation (basement) will be poured into the formwork and the total height of the tape will be 0.6 + 0.4 = 1.0 m with a width of 0.5 m.

- Now, in order to find out the volume of the tape, we need to find out its length, and for this we add up all the trenches that were dug according to the plan drawn above: 8*3+7.3++6+4.3+3+4=48.6 linear meters . This means that we will need to pour 48.6 * 1.0 * 0.5 = 24.3 m 3 of concrete for a monolithic foundation. But we can order it and have it delivered ready-made in a mixer, or we can make it ourselves.

- The most commonly used brand of concrete is M 300, so we will calculate the quantity of ingredients according to it, as required by the instructions - for one cube it is consumed: 385 kg of M 400 cement, 1080 kg of crushed stone or gravel, 705 kg of coarse sand and approximately 220 liters of water (it all depends on humidity fillers). Now it remains to calculate how much each material will be needed separately: cement - 385 * 24.3 = 9355.5 kg; sand – 705*24.3=17131.5kg; crushed stone – 1080*24.3=26244kg; water – 5346l (approximately).

- We also need to fill a cushion under a monolithic tape with a thickness of 0.2 m, which means that we will additionally need 48.6 * 0.5 * 0.2 = 4.86 m 3 sand, and this will be approximately 5000 kg (it all depends on humidity). Then in total we will need 17131.5+5000=22131.5 kg of coarse sand.

Advice. When making a rough estimate for building a house from foam blocks or other building materials, you should always purchase slightly more bulk fillers (sand, crushed stone, cement). The fact is that they crumble and remain on the ground during unloading.

- For a monolithic base, you will need a frame made of reinforcement, and in our case, a design with two longitudinal load-bearing rows of 2 reinforcement each (section 12 mm) and lintels (section 10 mm) made of smooth-walled or corrugated reinforcement is quite acceptable. Their step will be 0.5 m, and the frame in cross section will be 30X65 cm, then the pieces of rod will be: horizontal – 0.35 m, and vertical – 0.7 m, for a total of 0.35*2+0.7*2= 2.1m one ring. In addition, for the longitudinal bearings, based on the fact that one profile has 6 m, we will need tires for the joints, which means 3 * 4 = 12 pieces of 1 m each, a total of 12 m or 2 rods.

- Now you can calculate the total amount of reinforcement, which will include the estimate for building a house made of foam blocks with a strip monolithic foundation. For reinforcement with a cross section of 12 mm, we will need 48.6 * 4 + 12 = 206.4 m or 206.4/6 = 34.4 or 35 profiles. In total we will have 48.6/0.5+1=98.2 or 98 sets of rings for jumpers, which means that in total we will need 98*2.1=205.8 m or 205.8/6=34.3 or 35 profiles 6m each.

- Each connection requires 0.5 m of soft steel wire (folded in half), and the total connections will be 98 * 4 = 392 pieces on jumpers and 12 * 4 = 48 pieces on busbars, for a total of 440 ties of 0.5 m each. This means that you will need 440 * 0.5 = 220 m of wire, but since it is sold in coils, you will have to look for the optimal length.

Advice. To calculate the screed when pouring a floor, you can use the same calculation method as for concrete. Only the ratio of M 400 cement to sand here will be ¼.

Counting blocks for walls

- Now let's see how an estimate is made for building a house from foam blocks using the stone itself. For such a project, for which we calculated the foundation, we need to divide the load-bearing walls, where the masonry will be half a stone and the partitions, which can be raised with a quarter of a stone. Means. We will need the area of the spoon (the side of the stone) - 200*300=60000 mm=0.06m and the area of the bed - 300*600=180000 mm=0.18m (remember these numbers).

- If our walls are 2.8 m high, then it will take 14 half-stone blocks plus 14 0.5 cm seams and then the total will be 2.87 m, but indoors, taking into account the screed and ceilings, it will be no more than 2.7 -2.6m (if the floors are not lowered below the base). The total load-bearing walls will be (8+8+7.3+6+4+1.3)*2.8=96.88m2, then 96.888/0.06=1614.6 or 1615 blocks of half a stone will be needed.

- There are only (8+3+3)*2.8=39.2m2 partitions, then the quarter stone blocks will be 39.2/0.18=217.7 or 218 pieces. In total, the estimate for a house made of foam blocks based on the amount of stone will consist of 1615 + 218 = 1833 pieces.

- Now you can calculate the amount of glue that is spent on the joining seams (see photo above). The total length of the load-bearing walls is 8+8+7.3+6+4+1.3=34.6 m, then they will have 14 horizontal (2.8/0.2=14) and 58 vertical (34.6 /0.6=57.6) seams 0.005 m thick. This means that we will use 34.6 * 14 = 484.4 m of seam for load-bearing walls, then a total of 484.4 * 0.3 * 0.005 = 0.7266 m 3 glue. There are only 58 * 2.87 = 166.46 m of vertical seams, which means that the glue will be 166.46 * 0.3 * 0.005 = 0.249.69 m 3, and in total 0.249.69 + 0.7266 = 0.97629 m 3, which will be approximately equals 1000kg.

- We have only 14m of partitions and there will be 2.8/0.3=9.3 or 10 horizontal seams (14*10=140m in total) and 14/0.6=23.3 or 24 vertical seams (24*2 in total ,8=67.2m). If the total footage of the seams on the partitions is 140 + 67.2 = 207.2 m, then the amount of glue will be 207.2 * 0.2 * 0.005 = 0.20.72 or approximately 270 kg of glue. Then in total we will need 1000 + 270 = 1270 kg or 1270/25 = 50.8 or 51 bags of 25 kg.

- The estimate for the roof will be slightly different, because it will probably require the help of specialists who will have to pay not only for the material, but also for the work. And a lot will depend on the complexity of the roof itself, because it can be single-slope, gable, hipped, hipped, hipped, half-hipped, mansard and multi-gable.

- A separate expense item will be for heating and plumbing, not to mention insulation and finishing with facing materials.

Purpose of the construction estimate

The estimate for the construction of a house made of aerated concrete is the main financial document, which is an integral part of the construction contract.

The estimate for the construction of a house made of aerated concrete is the main financial document, which is an integral part of the contract for the construction of the construction company of the developer. The main components of the document are two sections:

- purchase of construction materials;

- execution of construction work.

In addition to the main part, technical and organizational issues are calculated:

- calculation of the scope of work;

- construction period;

- technologies used;

- amount of material;

- the number of specialists involved at the construction site;

- stages of project financing.

The convenience of the estimate allows you to exercise control at any stage of the construction process and track the work schedule. Experts believe that a well-drawn estimate fully pays for itself and justifies the planned construction. Another advantage of the document is the ability to minimize bureaucracy in various authorities; it helps the customer to present a picture of all construction processes, and also gives the opportunity to make amendments even before the start of construction.

Large construction companies that value their reputation can invite the customer to discuss the nuances, and will also help reduce the cost of the estimate without losing the quality of the structural features of an aerated block house.

How much does it cost to build a house from aerated concrete, price

If you decide to build a house from aerated concrete, then you have three options, the first of which is to completely entrust the work to professionals, the second is to build it yourself, and the third is to partially hire experienced workers.

To the question “how much does a house made of aerated concrete cost,” we will try to give an extensive answer, which should help you decide on the appropriateness of your choice when compared with other building materials, such as brick, ceramics, wood concrete and others.

Building a house consists of many stages, but in short: foundation, frame, roof. We will describe the construction in more detail and indicate the approximate cost of materials and work, although prices may vary greatly in different regions of the country.

Preparatory work for building a house

Any construction begins with a house design and soil research; surveyors are involved in such work.

They take a soil sample from a depth of a couple of meters and determine the optimal foundation required for the future structure. Also, builders need a change room - a room for storing materials, tools, clothes and other necessary things.

If you already have such a room on your site, you will save a little. If you don’t have one, then you can rent a cabin (trailer) for $50-200 a month.

Approximate estimate for building a house based on the estimated cost

Below is an approximate estimate for the construction of a house made of various types of timber. It included the approximate estimated cost of building a house from timber of various sections. When calculating timber for building a house, it is necessary to determine the length of all the walls around the perimeter and multiply this amount by the height of the building. Then the resulting amount of timber per house is divided into cubic meters.

As can be seen from the above data, wooden houses can be built from timber or turned logs. A characteristic feature of the timber is that it has the correct geometric shape, which simplifies the assembly of the house and transportation of the material, and also allows you to build a house in the shortest possible time.

In most cases, timber of sizes 150×150 mm and 150×200 mm is used in the construction of houses. As an example, below is an estimate for the construction of a wooden house made of laminated veneer lumber with a total area of 170 sq.m.

For the construction of a house from profiled and laminated timber, the price may vary!

Before you begin to study the estimate documentation, please note that the cost of materials may vary significantly. For example, the price for building a house from profiled timber will be higher initially due to the cost of materials than for planed lumber

The price for building a house from kiln-dried laminated veneer lumber may be even higher.

Table - Estimate for the construction of a wooden house with an area of 170 square meters. m:

| Item name | Unit | Quantity | Unit price | Price |

| 1. Preparing the foundation | 10 166,7 | |||

| 2. Walls | 35 280,8 | |||

| 2.1. Basic materials | 27 732,8 | |||

| Glued laminated timber for walls and partitions | cube m | 36 | 600,0 | 21 600,0 |

| Glued laminated timber for fencing | cube m | 1 | 600,0 | 600,0 |

| Imitation of timber | sq. m | 120 | 20,0 | 2400,0 |

| Frame wall posts 50×100 mm | cube m | 1,5 | 200,0 | 300,0 |

| Insulation | cube m | 6 | 83,3 | 499,8 |

| Hardware, fasteners | set | 100 | 23,3 | 2333,0 |

| 2.2. Job | 7548,0 | |||

| Assembling walls from beams | cube m | 36 | 150,0 | 5400,0 |

| Assembling walls from beams (fencing) | cube m | 1 | 150,0 | 150,0 |

| Installation of partitions | sq. m | 60 | 33,3 | 1998,0 |

| 3. Floors | 2911,0 | |||

| 3.1. Basic materials | 1500,0 | |||

| Board 50×200 mm | cube m | 5 | 200,0 | 1000,0 |

| Beam support | PC. | 250 | 2,0 | 500,0 |

| 3.2. Job | 1411,0 | |||

| Assembling floors without filing a rough ceiling | sq. m | 170 | 8,3 | 1411,0 |

| 4. Doors | 4359,8 | |||

| 4.1. Basic materials | 3860,0 | |||

| Balcony door block | PC. | 6 | 643 | 3 3860,0 |

| 4.2. Job | 499,8 | |||

| Door installation | sq. m | 6 | 83,3 | 499,8 |

| 5. Windows | 5132,6 | |||

| 5.1. Basic materials | 4032,6 | |||

| Window block (plastic double-glazed window 32 mm) | sq. m | 22 | 183,3 | 4032,6 |

| 5.2. Job | 1100,0 | |||

| Window installation | sq. m | 22 | 50,0 | 1100,0 |

| 6. Roof | ||||

| Edged board 50×250 mm | cube m | 12 | 200,0 | 2400,0 |

| Rough sheathing board | cube m | 4 | 200,0 | 800,0 |

| Item name | Unit | Quantity | Unit price | Price |

| Bar 50 x 50 mm | cube m | 4 | 266,7 | 1066,8 |

| Metal tiles with fittings and drains | sq. m | 160 | 33,3 | 5328,0 |

| Insulation | cube m | 35 | 83,3 | 2915,5 |

| Vapor barrier and wind barrier | roll | 6 | 50,0 | 300,0 |

| Fire bioimpregnation | l | 200 | 1,3 | 260,0 |

| Installation of rafters | cube m | 16 | 166,7 | 2667,2 |

| Lining ceilings with rough cladding boards | sq. m | 160 | 6,7 | 1072,0 |

| Gasket vapor barrier device in 1 layer | sq. m | 160 | 1,7 | 272,0 |

| Laying insulation | cube m | 45 | 16,7 | 751,5 |

| Layer waterproofing device in 1 layer | sq. m | 160 | 1,7 | 272,0 |

| Metal tile flooring | sq. m | 160 | 15,0 | 2400,0 |

Sources

- https://tpaservice.ru/smeta-na-dom-iz-brusa/

- https://glavstroy365.ru/articles/smeta-na-stroitelstvo-doma-iz-brusa

- https://KakPostroitDomic.ru/proektnaya-dokumentaciya/smeta-i-raschet/smeta-na-stroitelstvo-doma-iz-brusa.html

- https://MegaBeaver.ru/doma-brus/sovety-brus/smeta-stroitelstva-doma-iz-brusa-osnovnye-stati-rasxodov.html

- https://www.stroy-dom.net/?p=1371

How much money does it take to build a wooden house?

To make an estimate for the construction of a house made of timber, we will have to take into account not only its walls, but also the foundation and roof. Since we will be making calculations for an example, our attention will be paid exclusively to the box, without any finishing, that is, to the foundation, walls and roof.

We will try to understand the principle itself so that you can use it when using any timber - profiled and smooth, solid and glued.

We are drawing up a project

- So, our estimate for a house made of timber will be drawn up according to the project plan given above, where there is a living room, bedroom, kitchen, bathroom, vestibule and terrace, which requires a foundation and a roof, but no walls. We will take a monolithic shallow strip foundation as the base, we will make the walls from solid non-profiled timber 200×200 mm, and the partitions from the same material, but 100×100 mm. You can use a different type and a different section and profile configuration, but the essence of the calculations will not change.

- As a result, we will get load-bearing walls: 9m - 1 piece; 7m – 1; 5.5m – 2; 3.5m – 1; 1.5m – 1. Partitions: 5.5m – 1 piece; 4m – 1; 3.5m – 2; 3m – 1; 2m - 1. To arrange the strip foundation, two more edges of the terrace will be added: 3.5m -1 piece; 1.5 - 1 - here it is better to fill in a full-fledged tape in order to easily install supports under the roof, and, if necessary, build walls.

Foundation

- MF we will not delve into the technological side of the issue, since we are more interested in the estimate for building a house made of timber, so we will immediately move on to the calculations. Let's assume that the width of the tape will be 0.4 m, the depth from the ground surface will be 0.5 m, and the upper part (base) will be 0.4 m, which means that in the end we will get a section of 0.4 × 0.9 m, and the total length we'll find out now. We also do not forget that the monolith requires a reinforcement cage, which will also participate in the calculations.

- Now we need to calculate the total length of the entire trench and for this we need to use the design plan and add together all the walls and partitions: 9+7+5.5*2+3.5+1.5+5.5+4+3.5 *2+3+2+3.5+1.5=58.5m including terrace. Now we need the volume of the tape to find out the required amount of concrete to fill it: 58.5 * 0.9 * 0.4 = 21.06 m 3 . You can buy ready-made concrete by ordering it at a concrete concrete factory or prepare it in a concrete mixer yourself, using the table shown in the photo above, and the cost will depend on the price of the ingredients.

- You can include in the estimate a cushion that is poured under the base of the tape and has a minimum thickness of 0.2 m and for this you use either gravel (crushed stone, screenings) or coarse sand. The calculation is made in the same way: 58.5 * 0.4 * 0.2 = 4.68 m 3 sand or crushed stone.

- To arrange the frame with our own hands, we will need 4 (four) longitudinal supporting rods of corrugated reinforcement with a cross-section of 12 mm and for the connecting ring vertically - 2 pieces of smooth reinforcement of 0.7 m each and horizontally - 2 pieces of 0.25 m each (the cross-section of the rod for the ring is 8 or 10 mm). The distance between the rings is 0.5 m, connections are made with soft steel wire.

- So, we calculate the longitudinal reinforcement: 58.5 * 4 = 234 m, but we have two strips of more than 6 m each (rod length), which means we need to add a meter to each joint for the bus, which means 234 + 8 = 242 m of total length. And if we convert this into rods, we get 242/6 = 40.3 or 41 pieces.

- Now let's count the rings: 58.5/0.5=117 plus one on the edge, totaling 118 pieces. Each ring has 0.7*2+0.25*2=1.9 m. Then 118 * 1.9 = 224.2 m, and in rods it will be 224.2/6 = 37.4 or 38 pieces. Knitting wire can only be purchased in coils, so there is no point in calculating its footage, but just in case, you can take into account that about 0.5 m is consumed per joint.

Walls

- First, we set the salary and if we make it from the same material, then we will need for it 9+7+5.5*2+3.5+1.5+5.5+4+3.5*2+3+ 2=53.5 m of timber with a cross section of 200×200 mm (we do not take into account the terrace). You install logs on it, most often in such cases they have a cross-section of 150×50 mm or 200×50 mm - we will not count them, since this is already the floor. Now we need an estimate for a house made of timber for load-bearing walls and let’s take their height of 2.8 m for calculations (you can substitute other numbers).

- We have 9+7+5.5*2+3.5+1.5=32 m load-bearing walls, and for a given height we will need 2.8/0.2=14 rows. In this case, 32 * 14 = 448 m of timber with a section of 200 × 200 mm. If the price of wood of this kind is determined in cubic meters, then you can easily find out its volume: 448 * 0.2 * 0.2 = 17.92 m 3 .

- Now let's calculate the amount of wood for the partitions, taking into account that they have the same height as the load-bearing walls, but we will not make deductions for door and window openings - there is no point. In total, the partitions will be 5.5 + 4 + 3.5 * 2 + 3 + 2 = 21.5 m, but here the section is already 100 × 100 mm, then 28 rows will be needed: 21.5 * 28 = 602 m of timber with a section of 100 × 100 mm , but if we convert this into cubes, we get 602 * 0.1 * 0.1 = 6.02 m 3 . This means that a total of 17.92 + 6.02 = 23.94 m 3 will be used for the walls.

Advice. As we said above, when calculating, you should not subtract timber for openings for windows and doors. You'll still need wood to make the dowels, and the scraps will come in very handy here.

Roof

- It is not difficult to calculate the amount of material for a roof, having a project plan in hand, but you need to know exactly what kind of roof you are going to make. We will not list all types of roofs, but consider a simple gable option, which is suitable for this, although it is quite possible to equip an attic here. The distance between the rafters here is determined by the height of the ridge and the higher it is, the smaller the step will be, which can be from 0.4 to 1.0 m, as required by the instructions.

- If there is no attic, then in this case you can make the height 1.5 m, therefore, the rafter legs will be exactly like that, and the step here is 0.7 or 0.8 m. For rafters and racks in such cases, use a profile with a section of 150X50 mm, and for struts you can use a block of up to 100 mm. For sheathing, you can use an unedged board with a thickness of 20-25 mm - it will be somewhat cheaper than an edged one.

Advice. Place roofing material under the roofing material (usually corrugated sheeting or metal tiles, less often slate). In this case, the estimate will not increase much, but the benefits will be undoubted - it will reduce noise during rain (drops hitting the roof) and will serve as a heat insulator.

Calculating the purchase of timber

Before you begin the calculations, you need to decide on the type of timber for construction and its cross-section. This way we will find out the price of the material needed to build a house. Now you need to calculate the total volume of the timber in m3.

You need to calculate it this way:

- First, we calculate the total perimeter of the house. In our case, it is 24 meters (we count without internal partitions, since they will be constructed using timber of a smaller cross-section for subsequent finishing).

- Now we multiply the perimeter by the height of the walls. Let's take 2.6 m as an example. In total, we have 24x2.6 = 62.4 m2.

- And then you need to multiply the resulting value by the thickness of one beam. In our case, it will be a beam with a cross-section of 150x150 mm and a thickness of 15 cm. 62.4x0.15. In total, we get 9.36 m3 of timber required for the construction of all external walls.

- Now you need to calculate the amount of timber in one m3. And since for each section of lumber its quantity per m3 varies, calculations are made by dividing the total timber required for construction by the volume of one unit.

- All that remains is to enter all the received data into the estimate table and multiply the result by the price of one beam or by the price of m3 of lumber. Don’t forget to include dowels and insulation in the cost.

Foundation - slab

The foundation of this house is a monolithic slab.

It is also a subfloor. The slab is suitable for all soils. Tape will be cheaper. But without knowing the soil, it is dangerous to make a strip foundation. The slab is made according to all the rules: we remove the plant layer of soil, make geotextiles, make a sand cushion. Next comes the insulation, 2 reinforcement meshes. A double mesh of reinforcement is required and nothing else.

I am an opponent of such slabs when they make widening in places of load-bearing walls, and where you have a floor, a slab with single reinforcement is usually poured 10 centimeters thick. The way the stove works is not exactly how I like it.

In terms of savings, there is none. Where you decrease the height of the concrete slab, you increase the height of the insulation. Penoplex currently costs 4,200 rubles per cubic meter. Concrete with delivery currently costs 4,200 rubles per cubic meter. I don't see any savings. If the conversation is about how this creates a larger layer of insulation, therefore warmer, I will not agree here. If we carry out thermal insulation correctly, then we insulate the entire blind area and insulate the perimeter of the house. It doesn't make any sense in this house.

General construction processes

One of the most important construction processes is the installation of the roof of a structure. It serves to protect buildings from external influences and creates a harmonious image of the house. The roof must be strong and reliable

It is very important to adhere to construction technology and use high-quality materials. The construction of floors and partitions is also of considerable importance.

What is included in the estimate of general construction processes:

- required amount of materials and fasteners;

- the cost of work on the construction of the structure’s floors;

- the cost of work on arranging the required number of internal partitions and installing the roof.

Principles for calculating cost estimates

When calculating the costs of materials, it is necessary to build on the following parameters:

- Material type

- Cost per unit volume

- Required amount

- Total price for the entire volume

Separately, the costs of loading and transportation of purchased material are added to the amount received.

Calculation of estimates for the purchase of timber

First of all, to determine the cost of purchasing beams, it is necessary to calculate their quantity. The practice of measuring this material in cubic meters is usually found on sale. Therefore, difficulty can arise when comparing the volume in cubes to the actual number of individual beams. To do this, you will have to make preliminary calculations of the amount of timber in one cubic meter. This can be done using the following principle.

Next, the indicators are entered directly into the estimate - knowing the cost of one beam or one cubic meter, all that remains is to multiply the required amount of material by its retail cost per unit of volume.

This calculation is made when calculating the costs of materials for wall surfaces. Calculation of costs for beams for partitions is carried out using a similar algorithm.

Calculation of estimates for the foundation

In accordance with the design of a house made of timber, it is possible to determine the dimensions of the foundation, based on which the volume is calculated. By multiplying the perimeter of the base by its thickness and height, you can obtain data on the volume. Next, the cost of one cubic meter of concrete mixture is applied to the information obtained and this value is multiplied by the volume of the foundation.

Communication systems estimate

This category is also one of the most difficult, since the list of materials and means includes a large number of items. First of all, these are pipes, cables, connecting elements, as well as meters and shut-off valves. In addition, the estimate for this equipment and materials may include instruments and apparatus to ensure the functionality of the systems - boilers, pumping stations, generators, and so on.

The double beam was invented in Finland. This country is the founder of another construction technology - the construction of Finnish houses from laminated veneer lumber, which are described in this article.

Using Finnish technology, you can build not only houses from timber, but also frame houses. Read about frame houses using Finnish technology here. You can build such a house with your own hands.

Conclusion

It is quite possible to draw up an estimate on your own - after all, it is enough to have a project, the ability to use a calculator and knowledge of tariffs for building materials. Even in the absence of professional skills, it is possible, if not to draw up an accurate picture of costs, then at least to significantly minimize costs.

But if doubts about your own abilities cause concern, then it would be safer to turn to professionals. Moreover, the costs of its preparation will not include critical indicators in the estimate itself.

Box cost

Our slab is 250 thick with double mesh. Reinforcement will cost us 112,000 in terms of materials alone. Walls made of aerated concrete blocks will cost us another 120 thousand rubles. These are external walls with a thickness of 400 millimeters and an internal partition with a thickness of 100 millimeters. The materials for the roof will cost us a little more than 60,000 rubles. It includes completely wooden floors and a rafter group. All necessary films, insulation and metal roofing. Since we have a budget house, we do the cornice hemming with a regular, simple inch board.

After the box is assembled, all we have to do is install windows and doors. I don’t recommend saving on doors. This element must be bought for normal money - at least 22,000 rubles. These are the cheapest doors that are suitable for private construction. We also have three more windows measuring 1.2 x 1.5 meters. Of these, two are opening and one window is solid. Therefore, let’s take the average cost of 6,200 rubles per window.

Exterior finishing

There are entire methods for studying aerated concrete structures. They say that aerated concrete is not destroyed by precipitation. I don’t agree with this, so I include the cheapest siding in the estimate. If you don’t have the funds now, you can, for example, leave it unfinished for the first winter. But next summer, after you have spent the winter in an aerated concrete house, I still strongly recommend sheathing it.

Delivery

Only 5,000 rubles are allocated for delivery. The cost of delivery of aerated concrete blocks, the cost of delivery of concrete, the cost of delivery of reinforcement is included in the cost of the product itself. Therefore, we spend 5,000 rubles on the delivery of lumber to the roof, on the delivery of metal tiles, films and insulation.

Tools

My last two favorite points are unaccounted expenses, which I included in this estimate at 10,000 rubles. These are the little things that I either didn’t want to highlight separately, or simply forgot. And the second point is equipment and tools - 8,000 rubles: For one day, rent a vibrator for pouring a monolithic slab. Set of spatulas for laying aerated concrete blocks. A screwdriver to install metal tiles and of course you will need several buckets, hammers and other small things.

Builders' work

If you do not have the opportunity to build it yourself or do not want to do this, then the cost of specialists installing the frame of your house with such a configuration will be 133,000.

the total cost

The cost of material for the construction of a house box 6.8 by 6.8 meters with siding trim and a metal tile roof with load-bearing walls made of aerated concrete blocks and a monolithic slab foundation will cost us 383,000 rubles. This is at prices for 2020. If you don’t build it yourself, then 36 square meters of a bare box for year-round use will cost a little more than 500,0000 rubles.

Where to start building a house from timber

When ordering a project, you need to know exactly what result you expect from building a house. In this case, each owner can choose several options:

- Take a standard project and change it to suit your desires and tastes.

- Opt for a ready-made project provided by the selected company.

- Decide on the company to which you will entrust the implementation of an individual project.

Each project can be divided into 3 parts:

- Documents for production.

- Sketch documents.

- Documents for assembly.

The cost of the project may vary depending on the company that compiles it.

What to include in the estimate for a log house

To build a log house, you need to take into account the cost of the material and its processing. More specifically:

- Characteristics of the timber itself (size of the log or timber).

- Treatment of material ends with protective agents.

- Treatment of the surface of the material with fire retardants.

Most often, two types of timber are used in the construction of a house: natural moisture and chamber drying.

Communication costs

This section of the estimate is one of the most complex and painstaking. Here it is necessary to include a large number of components and fittings. So, for a water supply system it is worth considering the cost of the following elements:

- Digging a well or drilling a well;

- Arrangement of a water intake point (purchase of concrete rings, etc.);

- Digging a trench to supply pipes to the house;

- Laying the entire water supply system (meterage of pipes of the required cross-section;

- Taps, filters, mixers and water meters;

- Pumping equipment for supplying water to the house;

- Construction of a caisson or room for a pumping station;

- Installation of all plumbing equipment (toilet, sink, bathtub, dishwasher, etc.).

Now, based on the length of the water supply system in the house, we calculate the costs of sewer communications, the pipes of which will be located parallel to the water main. But now the pipes will have different and larger cross-sections. So, the sewerage estimate includes the cost of the following elements:

- Pipes in the required quantity in accordance with the design documentation;

- All adapters, tees and fittings;

- Work on digging a trench for installation of external sewerage (if workers are invited);

- Insulation of the external pipeline (consumables for this type of work);

- Septic tank or biological storage device.

And of course, don’t forget about electrical wiring. The estimate includes the cost of the work of a professional who will carry out the entire scope from the removal of electricity from the common line in the village to the installation of all sockets and power points in the house. In addition, the estimate documentation also includes the amount of costs for cables, wires, sockets, switches and other accessories.

Foundation

The basis on which a structure is erected and stands is the foundation. For a house to be stable and durable, it must be strong. Therefore, you should choose the right type of foundation. To determine this, you should take into account the type of soil on which the structure is being built, the location of groundwater and the size of the expected load.

The load on the foundation depends on the area of the building, its number of storeys and the material used. To determine the type of soil and the depth of soil water, geodetic work is carried out. Based on their results, acceptable types of foundations are determined. The soil is drilled and samples are taken for analysis.

Estimate for a house made of timber

Of course, an estimate for the construction of a house made of timber should be drawn up at the building design stage. This will allow the developer to correctly assess upcoming material costs. Depending on the financial capabilities of the developer, the technologies and materials used for construction, or the designs of houses made of timber, are adjusted. A standard estimate includes calculations for ground, basement, installation work (construction of walls, roofs and roofs), wiring of communications, as well as finishing of the house.

Construction of houses from timber is quite economical. At the same time, this type of construction has a number of advantages:

• Glued laminated timber is durable and practically not subject to unraveling, therefore, the shrinkage of a house made of timber is significantly less compared to houses in the construction of which other types of materials were used.

• The walls of a log house “breathe”, which allows you to maintain a favorable microclimate, which practically does not depend on the time of year.

• High construction speed. To build a house from timber, you will not need a powerful foundation, since wood is a fairly light material.

• Saving. When building a house from timber, there is virtually no earthwork, no labor-intensive stone and concrete work is required, and there is no need to purchase and deliver large quantities of consumables.

• Aesthetic aspect. The construction of houses made of wood is traditional for the territory of Russia. A house made of timber has its own unique atmosphere, which will allow you to enjoy a country holiday.

Building a house from timber is a very affordable option for any class of developers. Such houses are well suited for seasonal living, as they quickly warm up and slowly release the accumulated heat. When preparing an estimate for a house made of laminated veneer lumber, the developer needs to know the features of this type of house. As a rule, when building houses from timber, a pile type of foundation is erected, which is characterized by shallow depth. Steel pipes are screwed into the ground, on top of which concrete is poured, or concrete mixture is poured into the pits. The number of piles is reduced due to the sufficient length of the timber. Construction of the foundation lasts from two to five days, depending on the technology used to build it.

The estimate for a house made of timber includes the cost of installing formwork under the grillage. A gap remains between the foundation and the ground, which helps protect the wooden foundation from seasonal changes in soil conditions. The plinth greatly simplifies the installation of utilities into the house and ensures good ventilation of the house. The gables and walls are assembled from timber and are additionally insulated with jute tape and tow, after which the joints must be treated with a special fire-retardant compound. The estimate for houses made of timber should take into account the costs of antiseptic, jute tape and dowels. On average, the cost of building walls is about a quarter of the entire construction budget. It is worth noting that the service life of the house depends on the quality of the timber, so it is recommended to entrust the selection and purchase of materials to professionals.

The cost of roofing and roofing equipment is 1/6 of the total budget. When building in winter or constructing an attic, costs increase significantly. Many roofing materials have been created for houses made of timber. Depending on what material you prefer, the cost of all work will change. The budget material is ondulin, which is usually used in the construction of garden houses, gazebos, garages, outbuildings, garages and bathhouses. In addition to ondulin, bituminous shingles can be called a relatively cheap material.

Estimate calculation of a wooden house

| Base: | construction of a wooden house | |||||

| Technologies: | log house | |||||

| Total area: | 150 sq. m | |||||

| Estimated cost: | RUB 1,630,244 | |||||

| Update date: | valid until 03/01/2010 | |||||

| Name of works | Unit change | Qty | We're standing. work per unit change | Amount (rub.) | We're standing. mater. per unit change | Amount (rub.) |

| Geodetic works | m 2 | 200 | 100 | 20 000 | 0 | |

| Removal of the fertile layer of soil followed by horizontal leveling | m 3 | 10 | 450 | 4 500 | 0 | |

| Construction of a 600 mm trench for a shallow foundation | m 3 | 50 | 575 | 28 750 | 0 | |

| Manual filling and compaction of soil under the foundation (group 3 soil) | m 2 | 22 | 680 | 14 960 | 0 | |

| Installation and dismantling of formwork | m 2 | 60 | 100 | 6 000 | 250 | 15 000 |

| Tying reinforcement from a calculation of 60 kg per m 3 of concrete | m 3 | 20 | 1800 | 36 000 | 26 | 31 200 |

| Vertical waterproofing of foundation walls (with hot bitumen twice) | m 2 | 80 | 150 | 12 000 | 45 | 3 600 |

| Pouring concrete | m 3 | 20 | 2500 | 50 000 | 5000 | 100 000 |

| Filling the sinuses with sand with layer-by-layer thrombosis manually | m 3 | 12 | 1200 | 14 400 | 600 | 7 200 |

| Assembling the log frame onto the foundation | m 2 | 150 | 550 | 82 500 | 1500 | 225 000 |

| Sanding a log for a plane | linear m | 572 | 66 | 37 752 | 0 | |

| Aligning angles | PC. | 8 | 1500 | 12 000 | 0 | |

| Rolling up a log | PC. | 2 | 1500 | 3 000 | 0 | |

| Antiseptic treatment of logs with ready-made solutions | linear m | 580 | 15 | 8 700 | 20 | 11 600 |

| Tow curling (on both sides) | linear m | 572 | 50 | 28 600 | 3 | 1 716 |

| Log caulking (on 2 sides) | linear m | 572 | 140 | 80 080 | 3 | 1 716 |

| Finish sanding of logs (on 2 sides) | m 2 | 572 | 400 | 228 800 | 0 | |

| Cutting the opening | PC. | 1000 | 0 | 0 | ||

| Cutting an opening and installing a window (door) | PC. | 14 | 2000 | 28 000 | 2500 | 35 000 |

| Assembling floors with laying beams and laying floors (subfloor) | m 2 | 128 | 80 | 10 240 | 6,7 | 37 000 |

| Finished flooring, wall, ceiling, roof cladding with clapboard | m 2 | 390 | 325 | 126 750 | 5,8 | 44 000 |

| Painting | m 2 | 144 | 50 | 7 200 | 70 | 10 080 |

| Assembling roof elements with sheathing device | m 2 | 135 | 750 | 101 250 | 2,5 | 13 500 |

| Roof covering device (roofing felt) | m 2 | 95 | 0 | 0 | ||

| Roofing installation (metal tiles) | m 2 | 135 | 300 | 40 500 | 350 | 47 250 |

| Finishing the base with artificial stone | m 2 | 22 | 2200 | 48 400 | 0 | |

| Installation of metal door blocks (set) | m 2 | 2 | 3500 | 7 000 | 4500 | 9 000 |

| Total (direct costs according to estimate): | rub | 1 037 382 | 592 862 | |||

| Total (materials and work): | 1 630 244 | |||||

Calculating the cost of building a “box” of a house

need to include:

— price

cabins for

construction workers

(the cost of construction cabins ranges from 30,000 to 60,000 rubles);

— transport services for the delivery of building materials

and equipment to

the construction

site (approximately another 3% of the construction amount);

— cost of unloading construction materials

;

— many construction

organizations and teams include depreciation of tools and equipment in

the construction cost

(approximately 1% of the total amount);

— cleaning and removal of construction

waste;

— the cost of services of many construction

companies can increase up to 18% of the total cost for non-cash payments.

Thus, the final cost of building a house

will be

1,891,083 rubles

.

Please note that this price

does not include:

Installation of terraces and porches; — cost and installation of roof windows; — filing of overhangs; — installation of door blocks; — approval of the finished house project

in the relevant authorities; — materials and installation of internal and external engineering networks; — materials and work on interior decoration; — materials and works for landscaping.

This, of course, is an average calculation of the cost of building a house.

.

The final estimate

will depend on which option

for building a house

you choose for yourself and

building material

you will use.

For more information about which construction

to choose, read the article

Saving time in our high-speed age is almost always inextricably linked with saving money, so ready-made projects of houses made of foam blocks with estimates are always very popular and it seems that this demand will not weaken in the near foreseeable future.

But it’s one thing when you get a building according to someone else’s taste, and it’s completely different when you yourself participate in the development of the project and can independently determine all the costs awaiting you.