Foam concrete flooring: monolithic, prefabricated monolithic slabs

Floor slabs are an essential element in the construction of any building; they ensure the reliability and integrity of the entire structure. Recently, experts have been using foam concrete floors, since this material has the necessary set of properties - strength, thermal insulation and durability.

During the construction of buildings, three types of floors are installed depending on the location:

- Interfloor – divide the space between floors;

- Basement – separates basements from living rooms;

- Attics - separate the roof and attic space from the living space.

Let's take a closer look at foam concrete floor slabs, find out what types of foam concrete floors are used for construction, determine their advantages and disadvantages, and also identify the key points for installing floors.

Foam concrete floors - main advantages

Today, most buildings being built use foam concrete floor slabs, so let's find out why. What advantages do they have? Why do experts single out this particular material?

Foam concrete is one of the varieties of lightweight concrete; the foaming agent included in the material saturates the body of the product with air bubbles, which in turn reduce the weight of the finished product and increase the thermal insulation properties.

Despite this, foam concrete slabs have high strength and density, they are able to withstand the load stated by building standards.

Foam concrete floor slabs are excellent for basement and attic floors; unlike conventional concrete, they do not require additional thermal insulation. Also, foam concrete does not require sound insulation; air cavities in the body of the slab almost completely absorb noise.

Main advantages

- Lightness of the product – reducing the load on the building foundation and supporting structure;

- Safety - environmentally friendly materials are used in the production of foam concrete; the slabs do not emit toxic and toxic substances.

- Fire resistance - foam concrete belongs to the first class of fire resistance, does not burn or melt, and can withstand exposure to open fire for several hours without loss of quality;

- Low thermal conductivity - foam concrete does not require additional insulation;

- Vapor permeability – foam concrete does not interfere with natural air circulation, thereby creating an optimal microclimate in the room;

- Frost resistance;

- Noise insulation;

- Durability.

Foam concrete floors have no obvious disadvantages; the main disadvantage of the material is its inability to be used in multi-story construction. Foam concrete is used only when the building height is no more than three floors.

Due to its characteristics, foam concrete has become one of the most popular materials in the construction market. It is used for the construction of residential and non-residential buildings, industrial and agricultural premises, fences, partitions and much more.

Types of foam concrete floors

Depending on the manufacturing technology, foam concrete floor slabs are divided into two types:

- Monolithic slabs;

- Prefabricated monolithic.

Monolithic floors

This version of the floors forms an even, flat base, which has increased thermal insulation and strength characteristics.

Installation of monolithic foam concrete floors is carried out by pouring the solution into pre-installed formwork. To construct the formwork, plywood or wooden boards are used.

The formwork must withstand a load of at least 500 kg per square meter.

Monolithic floors are necessarily reinforced; this is necessary to distribute the load and increase the strength of the structure.

There are several reinforcement options:

- On top of a monolithic slab;

- Pouring foam concrete solution into pre-installed reinforcement;

- Use of corrugated steel sheet.

Corrugated sheeting is used when installing floors between floors. For this purpose, corrugated sheets made of steel grade N are used (they are mainly used when arranging the roof of a building). Special notches are applied to the sheets to increase the tenacity of the base with concrete, and vertical anchors are also welded.

The main advantages of a monolithic slab:

- Ability to withstand heavy loads;

- Strength and durability of the structure;

- Affordable price category;

- Low thermal conductivity of the material;

- Soundproofing;

- Low load on the structure due to the lightness of foam concrete;

- Pouring foam concrete mortar with a large distance between load-bearing walls;

- Formation of slabs of non-standard sizes and configurations.

Despite the large list of advantages, monolithic foam concrete floors have several disadvantages:

- It is difficult to calculate the load capacity;

- It takes a long time for concrete to dry completely and gain sufficient strength;

- The need to use special equipment to produce the solution and supply it to the site;

- The need to strictly follow the recipe, any deviation will lead to cracking;

- Difficulty in carrying out work at subzero ambient temperatures.

Prefabricated monolithic floors

The next option for floors is prefabricated monolithic floors made of foam concrete, the installation of which involves the use of solid foam blocks in combination with a liquid concrete solution.

In production, a structure is made from foam blocks, beams and a metal frame, which is welded metal rods. When installing the structure, sheets of laminated plywood are laid on the beams.

Formwork is not required for a prefabricated monolithic structure; its role is performed by rows of foam blocks. The rows must be installed at the same distance from each other, and then the interblock space must be filled with concrete solution.

When laying blocks, it is necessary to leave a ventilated gap; its thickness should be about 3 centimeters.

Advantages of prefabricated monolithic floor construction:

- Vapor barrier;

- High levels of noise insulation;

- Increased safety margin;

- Ease of operation - you can do it yourself;

- There is no need to use special equipment.

When choosing between these two types of floors, experts give preference to monolithic floor slabs. Despite the fact that their installation is not simple, they compensate for this with their technical properties - higher strength indicators, uniformity of structure, absence of tile joints.

Features of installation of foam concrete floors

The installation of each type of floor slab has its own characteristics, so we will consider their operating algorithms separately.

Monolithic foam concrete floor

For the work, a concrete solution made in production is used; pouring foam concrete that was produced using a homemade method is prohibited. It is also prohibited to carry out work in stages, that is, prepare the mixture in small portions and pour it into the formwork one by one.

Installation of monolithic floor slabs is carried out by pouring mortar into formwork, which is made of metal or wooden elements.

You can purchase standard formwork from manufacturers, or you can make it yourself.

Algorithm for installing a monolithic slab:

- First of all, install the vertical supports of the future structure;

- Attach horizontal transverse bars to the supports;

- Assemble and install the formwork, secure it carefully;

- Inspect the structure, find and seal all cracks and gaps so that the solution does not leak out;

- Place the reinforcement in the formwork, ensuring a distance of 4 cm from the level of the panels;

- Install beacons that will allow you to control the thickness of the layer. On average, the thickness of the slab should be 16 – 18 cm;

- Pour the foam concrete solution into the formwork along the beacons and level it - you will need a concrete pump to work.

The foam concrete solution must have a uniform structure.

Complete hardening of the concrete slab occurs after 4 weeks; after this time, the formwork can be removed and construction work can continue.

Prefabricated monolithic structure

Installing a prefabricated monolithic slab is not difficult; all work can be done independently without the use of special equipment. Installation work is carried out in two stages. First of all, the plant produces elements of the future structure - load-bearing supports and foam blocks.

Next, the frame is installed at the construction site. Installation of load-bearing supports and transverse beams, on top of which foam blocks are laid.

To make the structure more rigid, experts recommend further strengthening the load-bearing beams by pouring a concrete solution at the base.

Progress:

- Install and secure the support beams at a distance of 60 cm from each other;

- Lay the crossbars, the distance between them should not exceed the width of the foam block;

- Install rows of foam concrete elements that will act as formwork;

- Reinforce the floor slab - to do this, lay metal rods among the rows of foam blocks.

Pour the concrete mixture - pour each row one by one, level and thoroughly compact the solution. For compaction, it is advisable to use a vibrating machine.

betonov.com

The porous structure of cellular concrete is formed due to

— introducing gas-forming substances into the mixture (aerated concrete);

— mixing the liquid mass with pre-prepared foam (foam concrete). The second method of producing cellular concrete will be considered - producing foam concrete using foam concentrate.

Foam concrete is especially popular in Germany, Holland, Scandinavian countries, and the Czech Republic. Moreover, in the latter, blocks made from it are called “bioblocks”, since only environmentally friendly natural components are used as raw materials: burnt lime, sand and water, with a relatively small addition of cement. Recently, to reduce the cost of building materials, waste from various industries, such as slag, is often used in the form of components. Agree that it is unpleasant to live in a house built from someone’s waste, the environmental purity of which cannot be completely confident.

It is very convenient that foam concrete blocks (foam blocks) can be sawed, drilled, milled, and finishing elements can be fastened with nails, just like with ordinary wood. In terms of characteristics and consumer properties, this material is closest to wood, but has significantly greater durability.

Foam concrete's thermal insulation properties are several times superior to silicate and ceramic bricks, as a result of which walls can be significantly thinner with the same thermal conductivity.

It becomes possible to significantly improve the heating equipment of the house by thickening the walls of the house with blocks of foam concrete. Due to the fact that foam concrete and foam concrete blocks have a significantly lower density, the total weight of the frame of a foam concrete house is much lighter than a brick one. This significantly reduces the load on the foundation and, therefore, makes it lighter. The better thermal properties of foam concrete also make it possible to significantly reduce the cost of heating a building.

Construction from foam concrete reduces the labor intensity of wall laying, the consumption of mortar for wall laying, and does not require the use of highly qualified masons.

Houses made of foam concrete have high sanitary and hygienic properties and a low level of radiation (due to the absence of crushed stone among the components of foam concrete). The microclimate in the premises is the same as in wooden houses - the walls “breathe”, but do not rot. In terms of thermal and mechanical properties, of all materials, foam concrete is closest to wood, it is easy to process, nails well, and is fire-resistant and fireproof.

Why floor slabs cannot be laid on foam blocks

In an environment where technology is constantly developing and new types of materials are being invented, construction is no exception. New types of materials are much lighter and more reliable, they are very durable and quite convenient to use. One such material is foam block or foam concrete. With its help, you can quickly build residential buildings or other types of buildings.

The use of foam blocks is very common in various buildings, and this is not surprising. There are times when during work it is necessary to lay floor slabs. And here the question arises: is it possible to do this, and if not, then why?

Foam block: material features

To produce a foam block, you need to mix several types of materials:

- sand;

- cement;

- water;

- various chemical additives.

All this is sent to a kind of production mixer. The ratio of the components depends on the brand of the future material, which will determine their reliability, weight and give certain thermal insulation characteristics. When the mixture is well mixed, foaming agents are added to it.

The produced foam concrete is poured either into a three-dimensional form or into specially prepared molds of the sizes required for production. It takes 4-5 hours to harden, then the blocks are transferred to drying, which occurs using natural processes. This will take up to 2-3 weeks.

Important! If the foam block is poured into one large mold, at the end it is cut into smaller pieces for ease of use.

The material needs about six to seven weeks to acquire final strength. In terms of their composition, they are very environmentally friendly and in this regard are second only to wood.

Due to its porous texture, the material can regulate humidity in the room - it can absorb and release water without forming mold.

Important! Foam blocks do not burn because they have a high degree of fire resistance. This makes it a safe material that no insects or rodents are interested in.

Laying floor slabs on foam blocks

Builders note that you can’t just pick up and lay floor slabs on this material. Although it is durable in its composition, in this case it is necessary to take certain measures and create the necessary conditions.

To successfully complete roofing work, you should:

- It is necessary to make a monolithic reinforced concrete belt along the entire perimeter of the walls that will be involved in laying the slabs, the width of which should be equal to the thickness of the wall, and the height should not exceed 250 millimeters. In this case, reinforcement must be performed using a frame consisting of reinforcement. Its diameter should fluctuate around 12 AIII and have anchors on which the floor slabs will be welded to the mounting hinges.

- The slabs must have a support of at least 200 millimeters;

Sometimes covering walls consisting of foam blocks is not a rational and expedient solution. Everything depends on the height of the structure. If the height does not exceed a two-story building, then the walls made of foam blocks will withstand the load. But if the building is taller, then you should not resort to such solutions.

freegameinfo.ru

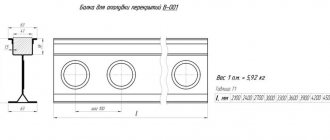

Reinforced concrete hollow slabs

This is the most popular and affordable type of slab.

Previously, the use of massive reinforced concrete floors was unavailable in the construction of a private house due to their high cost and heavy weight, requiring the use of special equipment for delivery and lifting. Now such problems do not arise, and a crane or manipulator has become a common occurrence in low-rise construction .

Hollow core slabs made of reinforced concrete have additional relief in the form of through chamber openings, and they themselves are made from heavy grades of concrete using reinforcement, which provides the necessary rigidity and strength . Such an overlap has a number of undeniable advantages:

- Lightweight construction compared to a monolithic slab; voids significantly reduce the weight of the product, which means they can be safely used in buildings made of aerated concrete up to 3 floors inclusive.

- High strength, which is ensured by internal cavities, reinforcement and high-quality concrete. The load-bearing capacity of slabs of this type is from 800 kg/m2.

- Simplified installation and the ability to mount on bases of any shape. The size of the slab can be 6 or 9 meters, which significantly expands the possibilities for planning.

- Internal cavities can be used to accommodate communications and wiring.

- Good sound insulation.

The installation of reinforced concrete floors will require the installation of an armored belt around the entire perimeter. It can be made monolithic using formwork and reinforcement with a thickness of 10 mm. The width of the belt is at least 150 mm - the distance over which the slab will rest. Thanks to this, the load on the walls is reduced, local stresses caused by the pressure of the upper floor and the slab itself are eliminated.

Marking

According to the configuration of the cavities, the slabs are divided into:

- PC – with round voids, rests on 2 sides;

- PKT – with round cavities, rests on 3 sides;

- PKK - with round voids, laid on 4 walls;

- PKT – with round cavities, installation on 2 end and 1 long side;

- PG – with pear-shaped voids; thickness – 260 mm; support on 2 ends;

- PB – made without formwork, using continuous molding; its thickness is 260 mm, hole diameter is 159 mm; The product is placed on 2 end sides.

Based on the size of the cavities and thickness, the slabs are divided into the following types:

- 1P - slabs 120 mm thick.

- 2P - slabs 160 mm thick;

- 1PK - slabs 220 mm thick with round voids with a diameter of 159 mm.

- 2PK - slabs 220 mm thick with round voids with a diameter of 140 mm.

- PB - slabs 220 mm thick, formed without formwork.

Slabs of types 2P and 2PK are made only from heavy concrete.

Dimensions

The size of the hollow core slab is indicated in its marking.

Below the spoiler are the standard sizes of the slabs. To view, click on the “Table” heading.

Coordination dimensions of the slab, mm

3pcs

Support depth

It is important not to exceed the maximum support depth. Otherwise, the slab will act as a lever and, under heavy loads, the wall may rise slightly above the slab. It is not noticeable to the eye, but is critical for the structure. Under loads from installed furniture, equipment and erected internal interior partitions, cracks may appear in the walls due to the resulting stresses.

The length of support (the depth of insertion of slabs into the walls) should not exceed:

- for brick walls - 160 mm;

- when supporting floor slabs on aerated concrete blocks of class B3.5-B7.5 - 200 mm;

- when resting on a concrete reinforced belt - 120 mm.

The minimum support length is also standardized. It should not be less than:

- 80 mm - for brick walls;

- 100 mm - for walls made of cellular concrete blocks;

- 65 mm - when resting on dense concrete class B10 and higher.

Installing a floor made of reinforced concrete structures will necessarily require the use of a crane or manipulator with a large lifting capacity. The weight of a standard 6-meter slab reaches 2 tons. In addition, installation will require certain skills. Thus, leveling is carried out along the seams on the smooth side of the ceiling, after which the slabs are fastened with anchors, and the joints are filled with cement mortar. Mineral wool and polystyrene foam can be used as insulation.

Monolithic foam concrete floors

Foam concrete became known as a building material relatively recently - in 1890. The world fame of foam concrete began in Germany with the opening of the first large-scale industrial production of YTONG.

Monolithic foam concrete slabs in the form of a diagram.

The construction of any house involves the arrangement of interfloor and attic floors, leveling cement-sand floor screeds. Professionals classify this work as the most labor-intensive and expensive.

Foam concrete floors are a cast, highly porous mixture of cement, foaming agent, sand, additives and water. During the process of laying it into a building form, it hardens, turning into a durable and lightweight artificial stone.

Physical and technical characteristics

Small houses (up to 4 floors) are built using foam concrete. If we are talking about larger-scale construction, a load-bearing metal or reinforced concrete frame is required. Wall panels, wall blocks, floor and roof slabs and lintels are manufactured under production conditions.

Table of physical and technical characteristics of foam concrete floor slabs.

The most significant characteristic of a material, which determines its technical properties, is volumetric mass. 1 m? foam concrete included 5 m? air, thanks to which the material is endowed with high thermal properties. The porous structure of foam concrete does not prevent it from having high frost resistance. Destruction of a foam concrete slab at low temperatures occurs when moisture content is more than 30%. This result can be caused by improper storage or systematic humidification during operation.

Foam concrete belongs to the category of fireproof materials of Euroclass A1, which in terms of fire resistance is not inferior to clay bricks. At a temperature of 100°C, absorption moisture evaporates; a further increase in temperature leads to the evaporation of structurally bound moisture, which results in shrinkage and cracking. The low volumetric weight of foam concrete floors gives the material worse sound insulation compared to clay or sand-lime brick.

Heat transfer between two surfaces of one wall is 4 times slower compared to walls made of other stone materials. This quality allows you to maintain comfortable temperature and humidity conditions in the room, regardless of weather conditions.

Benefits of use

Monolithic foam concrete flooring has a number of advantages that make it one of the most popular types of flooring:

- slabs can reduce the load on load-bearing walls, foundations, columns;

- reduce the amount of concrete used, reinforcement and the volume of concreting;

- increase sound insulation and fire resistance of the ceiling;

- do not use formwork.

Installation process

Installation diagram of foam concrete floors.

Floors made of foam concrete belong to the class of prefabricated monolithic floors, since they are performed in two stages. The first stage involves the production of load-bearing beams and filler in the form of foam concrete blocks in the factory. At the second stage, the direct installation of structures on site is carried out: load-bearing beams are installed, which were made of square frames or triangular reinforcement, on the lower load-bearing part of which concrete was poured to impart rigidity.

Thanks to the use of foam concrete floors, it is possible to avoid the installation of floor formwork, which reduces the cost of the structure and construction time. At the next stage, the beams are re-supported with telescopic monolithic floor racks or ordinary boards to support future loads without sagging or deflection. The gaps between the beams are filled with foam concrete blocks, which allows you to create a geometric ribbed shape of the future foam concrete floor. In such structures, foam concrete blocks serve as a void former and lightener of the floor structure.

Construction of floors made of monolithic foam concrete.

Foam concrete slabs are elements of permanent formwork in the floor, forming a ribbed unidirectional structure, after which the blocks remain in the body of the floor, increasing the sound insulation of the prefabricated ribbed monolithic floor.

After installing the prefabricated part of the foam concrete structure at the site, they proceed to reinforcing the top layer of concrete. In most cases, reinforcement is performed using reinforcement mesh with cells. In places where it rests on the walls and along the contour of the ceiling, a reinforcing beam frame is installed. At the next stage, the end formwork of the foam concrete floor is installed, either made of plywood or in load-bearing wall structures. Then concreting is carried out. It is worth paying attention to the fact that it must pass without breaks, otherwise you risk getting cold, non-working seams in the concrete body of the floor.

Features of use for floor screed

Scheme of using foam concrete for floor screed.

The construction of the floor using a foam concrete slab must comply with the requirements of GOST 25485-89. Using foam concrete screeds with a density in the range of 800-1200 kg/m? makes it possible to reduce loads by up to 40%. Filling the floor in this situation is carried out using an installation that is capable of producing up to 15 m? foam concrete per hour. It can supply foam concrete through a hose to the pouring site vertically up to 30 m and horizontally up to 60 m. The thickness of the floor can vary between 3-5 cm. Most often, a combined method of applying foam concrete is used, which involves the use of material with a density of 300-500 kg /m? in the lower layer and 600-1200 kg/m? for the top one.

The technology of monolithic foam concrete when arranging floors and floors does not require the use of additional thermal insulation materials (mineral fiber or expanded clay slabs).

Using foam concrete for wall coverings

Installation of foam concrete slab for wall covering.

For laying walls made of foam concrete blocks, light thermal insulation solutions or special adhesives are used. In this case, the thickness of the horizontal seams varies between 1-3 mm. Vertical seams belong to the category of hollow labyrinth seams, which reduces mortar consumption, increases labor productivity and eliminates cold bridges that are typical for brickwork using heavy mortars.

The least labor-intensive during construction are single-layer foam concrete walls with a thickness of 24 cm. Plastering of such walls is carried out using hydrophobic mineral solutions, which have high vapor permeability. When using dense plasters, moisture accumulates in the walls, leading to premature destruction and the appearance of fungi and mold.

If construction is carried out in regions with a humid climate and intense precipitation, then the external walls are made with slotted walls, which requires the presence of a load-bearing inner layer of foam concrete blocks, a protective layer of clay or silicate brick and an air gap, the thickness of which varies from 40 to 150 mm.

Diagram of foam concrete floor blocks.

An important element of the connection between walls and floors is a reinforced concrete monolithic stiffening belt, which is a continuous structure laid out along the perimeter of load-bearing walls at the floor level. The design differs from foam blocks in its thermal insulation qualities; for this purpose, the belt is protected with liners made of mineral wool slabs or expanded polystyrene on the outside of the wall and lined with foam concrete slabs.

This monolithic solution can increase the cost of construction, but has a number of important advantages, which include increasing the spatial rigidity of the structure, absorbing the forces that arise during uneven settlement of the foundation, and ensuring the integrity of the building in case of local destruction.

Door and window lintels are made from prefabricated elements manufactured at the factory or directly during the construction of walls by filling trough-shaped elements made of foam concrete with concrete. Small piers are reinforced with reinforced concrete monolithic pillars, which are made in permanent formwork.

Causes of deformation processes

Cracks in foam concrete slabs appear due to deflections of the supporting floors.

Deformation processes of the block and foam concrete slab take a long time and can provoke cracking. This negative phenomenon occurs when a building is used that has not gone through the complete process of drying the walls. Areas around door and window openings are susceptible to cracking.

The appearance of cracks can be a consequence of excessive deflections of the supporting floors, which arise as a result of creep deformations. In order to minimize this negative consequence, mesh reinforcement is used in places where shrinkage deformations are expected.

Economic justification

When assessing the economic performance of foam concrete structures, the reduction in loads on foundations should be taken into account. This fact is of particular importance when building on sedimentary and soft soils. Thanks to the presence of smooth, flat wall surfaces and thin mortar joints, the cost of finishing work is reduced. For a foam concrete slab, a putty layer of 5 mm is used. Compared to internal plaster of 10-15 mm thick brickwork, the savings look significant.

The use of foam concrete floors makes it possible to obtain favorable performance indicators, for example, to reduce the cost of heating rooms while maintaining a comfortable microclimate, and allows for flexible redevelopment by dismantling and erecting lightweight foam concrete partitions. The experience of many European countries shows that monolithic foam concrete construction allows the fastest solution to the issue of housing construction in conditions of shortage of energy and financial resources. The above facts have made foam concrete the most popular material in mass low-rise housing construction.

o-cemente.info

Foam block wall thickness for a home: interfloor ceilings

Foam blocks are a building material used for the construction of buildings of different heights. Thanks to its foamed structure, the product is lightweight, easy to process, does not burn, and therefore today is an alternative to such common materials as brick and wood. However, when arranging floors for a house made of foam blocks, you need to take into account all the nuances and understand the options for installing floors made of various materials.

Types and types of floors in a house made of foam blocks

The following flooring options are available:

- prefabricated reinforced concrete structures;

- monolithic reinforced concrete systems;

- frame-lined floors;

- prefabricated monolithic from gas silicate cubes.

Now about each type in more detail:

Reinforced concrete structures

Monolithic floors are quite suitable for a house made of foam blocks

Reinforced concrete can be prefabricated and monolithic, but it is not entirely appropriate to use massive slabs due to:

Recommended reading:

- increasing construction costs by calling in special equipment to deliver slabs;

- in the case of a limited size range in a shaped type building;

- heavy slabs require strengthening the load-bearing capacity of the walls, which will also increase the cost of development.

Important! Before using monolithic reinforced concrete structures, it is necessary to equip an armored belt.

Monolithic floors are quite suitable for a house made of foam blocks. It is worth considering an example of arranging a floor by pouring it on site using a reinforcement frame. Required:

- fittings with a diameter of 14-16 mm;

- wire;

- boards for formwork;

- sand, crushed stone, cement;

- kneading equipment.

Step-by-step instructions for arranging a ceiling for a foam block wall are as follows:

- Cut the rods to the length of the distances between the walls, taking into account the reserve width of the plane of the wall panels;

- Lay the rods in increments of 8-10 cm;

- Lay perpendicular pieces of reinforcement covering a shorter distance between the walls; here the thickness of the wall is important; the reinforcement is cut taking into account the size;

- Fasten the reinforcing pieces with wire;

- Arrange the formwork, and it must be nailed along the entire perimeter of the walls no lower than the desired thickness of the future slab.

Advice! It is better to support the structure from below with logs.

- Check the levelness of the site;

- Make a batch: 1 kg of cement (grade 500), you need to take 1.6 kg of sand and 3.2 kg of fine or medium-fraction crushed stone. Stir the mixture, add water and fill the formwork, moving from the far edge to the near one.

Important! Checking the evenness is mandatory, as is one-step pouring of the mixture. It is not recommended to stop pouring work.

All that remains is to spray the slab for a couple of days, preventing the layer from cracking, and let the structure mature for about 4 weeks. But it is better to refuse welding, since at the junctions of the reinforcing bars there will be a threat of corrosion, which is not at all uncommon given the high hygroscopicity of the block material.

Frame-sheathing option

The type involves the use of dried and planed timber, which must be coated with an antiseptic composition

The type involves the use of dried and planed timber, which must be coated with an antiseptic composition. The beams are lifted onto the wall, then:

Recommended reading:

- Install galvanized anchor bolts with threaded connections;

- Put on roofing felt pads and wooden pillows, also treated with an antiseptic;

- Drill holes for studs in the beam elements;

- Place the beams on the anchors and tighten them with nuts and washers.

Now that the support beams are ready, you can install a floor, for example, a plywood floor, which is covered with insulation and this subfloor is also covered with a plywood sheet.

Important! According to the requirements of SNiP, wooden beam systems are allowed to be used only with a span width of no more than 5 meters!

Aerated concrete blocks

The principle of arrangement is simple; beams with special monolithic reinforcement are used for it.

This is a fairly new option for arranging floors, but a foam concrete house is ideally suited for aerated concrete blocks, the size of which can be varied. The principle of arrangement is simple; it uses beams with special monolithic reinforcement and blocks equipped with cuts for supports.

Assembling such structures takes no more time and effort than assembling a construction set: the blocks are placed between beam elements, tightly “sitting” on special shelves, then a reinforcing mesh is laid and everything is filled with concrete.

Important! When arranging floors, the thickness of the wall is of great importance. The smaller the dimensions, the lighter the structure should be, or you will have to reinforce the wall panel with an armored belt.

kakpostroitdomic.ru

Which floors to choose for an aerated concrete house

To decide on the choice of flooring for an aerated concrete house, you first need to make calculations on the load-bearing capacity of the walls, that is, what maximum load the walls can withstand.

After all, if your walls are only 200 mm thick, made of D400 aerated concrete with strength class B1.5, and at the same time the span length is quite large, then the load-bearing capacity for a monolithic or slab floor may not be enough. In such a situation, it is necessary to use wooden, aerated concrete or prefabricated monolithic floors.

Also important factors influencing the choice of floors are:

- Floor bearing capacity

- Maximum span length

- Soundproofing

- Price

- Construction time

- Possibility of access for special equipment

We will talk about all these factors and nuances further, considering and comparing each of the flooring options.

Types of floors:

- Monolithic

- Prefabricated monolithic

- Reinforced concrete slabs

- Aerated concrete slabs

- Wooden or metal beams

Reinforced concrete floor slabs

Floor slabs are a common choice for aerated concrete houses. Reinforced concrete slabs have the following advantages and disadvantages:

- Low cost.

- Good load-bearing capacity (from 400 to 800 kg/m2).

- High speed of installation of the slabs themselves.

- Good sound insulation of the ceiling.

- Slab length up to 9 meters.

- Installation requires hiring a crane.

- It is necessary to build an armored belt around the perimeter of the walls.

Aerated concrete floor slabs

Such floors are made from reinforced autoclaved aerated concrete with a density of D500 or D600. It is possible to order your own version of the slabs at the factory. Although the thermal insulation of these floors is good, there is little point in it, since the second floor also needs to be heated, and there is little point in separating them with thermal insulation.

If we consider an aerated concrete floor as a ceiling from a cold attic, then it is too expensive; it is cheaper to make it from wooden beams insulated with mineral wool.

Advantages and disadvantages:

- High installation speed.

- Lightness of the slabs.

- Excellent thermal insulation.

- You can do without an armored belt, although it is desirable.

- Average load-bearing capacity (up to 600 kg/m2).

- The length of the slabs is up to 6.4 meters.

- High price.

- Requires hiring a crane.

Monolithic ceiling

The main advantage of monolithic slabs is that you can fill the slab of almost any shape, which gives greater freedom when planning your house. To strengthen the structure, reinforced reinforced beams are made, which increase the load-bearing capacity of the floors and the possible span length. Unlike floor slabs, the monolith distributes the load along the entire perimeter of the walls.

Advantages and disadvantages:

- Load-bearing capacity (up to 1000 kg/m2).

- Span length up to 9 meters.

- Excellent sound insulation.

- No armor belt required.

- You need to hire a concrete mixer and a concrete pump.

- The highest cost of all flooring options.

- It takes a long time to build and wait for the concrete to harden.

If you are planning large halls and rooms in your house, then the load-bearing capacity of aerated concrete itself may not be enough for a monolithic floor; in this case, you can use reinforced concrete columns, reinforced slabs and beams. You can get acquainted with such reinforced concrete products by following the link.

Prefabricated monolithic floor

Prefabricated monolithic floors consist of factory-reinforced beams, between which aerated concrete blocks are installed, acting as fillers. Reinforcement is laid on top and high-quality concrete M250-M300 is poured.

Advantages and disadvantages:

- Span length up to 9 meters.

- Freedom in planning.

- An armored belt is not required.

- Relatively light weight.

- Load-bearing capacity (up to 600 kg/m2)

- Average price.

- Greater savings in concrete compared to pure monolith.

- Good sound insulation.

- No installation of an armored belt is required.

- No tap required.

Foam concrete floor slabs - Reinforced concrete structures and more

Foam concrete is a mixture of cement, sand, water and foaming agent. At the end of the 19th century, German builders began to use an analogue of this material. But foam concrete became popular only at the end of the twentieth century.

Characteristics of foam concrete

- Low production costs make it cheap and economical.

- Long service life.

- High levels of heat resistance and vapor permeability.

- Environmental friendliness of the material. The composition of the material is cement, sand and air.

- A light weight.

- Foam concrete blocks, for all their strength, can be easily sawed and given the required shape.

- The unique feature of the material is that it increases strength over the years. Recent studies have shown that over 40 years of operation, the strength of the product has increased by 3-4 times.

The technology for producing foam concrete is elementary, but if you make it yourself, the quality of the resulting material is very different from the factory one, and not for the better.

Foam concrete slabs can be used in any building structure, but the material is especially popular in low-rise construction.

However, when using it as floor slabs, it is worth considering some features:

- Due to insufficient strength, the foam concrete slab requires reinforcement of the frame structure using reinforced triangular frames or additional load-bearing beams.

- The lower part of the structure requires reinforcement of rigidity - that is, pouring concrete. If the area is large, you will even have to install additional reinforcement mesh.

- After laying the slabs and processing all the seams and joints, the top layer must also be filled with concrete.

The process technology requires certain experience and accuracy of the work performed. But despite all the complexity, foam concrete floors remain one of the cheapest options for construction.

stsxxi.ru

The use of hollow core slabs in cellular concrete houses

Very often, individual developers neglect or do not know the rules for installing floors with hollow core reinforced concrete slabs when building houses made of foam blocks or gas silicate. Mistakes lead to big problems later, some time after construction is completed. In many cases, the house simply begins to fall apart at the seams. This article is devoted to the consideration of methods for preparing the base for laying hollow core slabs supported on walls made of cellular concrete.

Why you can’t rest floor slabs directly on aerated concrete blocks

The answer to this question lies in the low load-bearing capacity of foam concrete. As a matter of fact, the stone that almost all individuals use for construction has a strength of M50 to M100 with a block density of 600 to 800 kg/m3. But that's still half the problem. The main problem of foam blocks is their main advantage over other wall materials. Foam concrete consists mainly of bubbles separated from each other by thin walls of solution. The strength of such a structure is low, since the load that is applied to the surface of such a block is distributed only over thin partitions that are not designed for it. And the partitions break.

At the same time, there is a great temptation to construct floors from ready-made reinforced concrete. And hollow slabs in this case can be considered a real find. Especially if you managed to get your hands on used slabs at bargain prices. But here you should exercise reasonable caution and estimate some additional costs that you will have to incur so that these slabs do not fall on your head along with the house.

Indeed, despite their apparent lightness, hollow core slabs have a very decent weight. Thus, a slab 6 m long, 1.2 m wide and 220 mm thick with a void diameter of 150 mm has a mass of 2.2 tons. This mass will be distributed over two wall supports, each 15 cm wide and 1.2 m long. Which will be 0.18 m2 on each side. Or 0.36 m2 in total. Thus, 2.2 tons will exert the same pressure as a reinforced concrete block weighing 10 tons will exert on a foam concrete support with an area of 1 m2. But this is not the whole load! Since after moving in, the floor will contain a screed, flooring, furniture, the upper level ceiling, the walls of the next level, and the roof.

And let it seem at first that the pressure from the floor slabs is not too great for the foam blocks to withstand it, but in the future, as the load increases during construction and finishing work, the load will increase many times over. And immediately thread-like cracks will appear on the walls, which will later open to emergency levels.

Construction of houses made of aerated concrete and foam blocks

The basement, floors, roof - all of the listed parts of the building require floors. What material makes the best floors? Of course, made of reinforced concrete.

In addition to this, there is another excellent method of covering buildings, which is called monolithic casting, but its implementation requires durable formwork, the purchase or rental of which will cost a considerable amount.

In this section we will look at the different types of floor slabs for aerated concrete houses and methods of laying them.

Floor slabs are divided into 2 main types - solid and hollow. Each of these varieties is suitable for a specific type of building.

But, as with many other building materials, hollow core slabs made of reinforced concrete are in greatest demand, as they are versatile and compatible with most building structures.

The same applies to low-rise residential buildings made of aerated concrete, the construction of which you can order from our company. Let's look at everything in order.

Solid slabs

In total, there are 3 types of such slabs: beamless, coffered and ribbed.

Beamless

Beamless slabs are smooth monolithic slabs, which during house construction are installed with support from both walls and columns.

This type of solid reinforced concrete products is ideal for creating floors in residential buildings.

The absence of roughness in their texture makes it possible to avoid the installation of suspended or suspended ceiling systems, as a result of which the simplest treatment of the tiled surface is sufficient - puttying and painting.

Caisson

Caisson products look like a network made up of beams of similar sizes, the gaps between which are filled with a thin layer of concrete.

This type of flooring is not used either in urban housing construction or in the construction of cottages. Such slabs, like ribbed ones, are used mainly in the construction of industrial complexes and buildings - plants, factories, etc.

Coffered slabs are designed to withstand heavy loads and cope with them excellently.

Ribbed

Ribbed slabs are essentially a series of beams intersecting each other, the empty gaps between which are filled with concrete mortar.

This type of slab is also designed for increased loads, therefore, as a rule, they are used in the construction of industrial buildings and complexes, as well as shopping centers and sites designed to accommodate heavy machinery and equipment.

Such slabs are not used in urban and private housing construction, which is due to the lack of feasibility and their high cost.

In practice, all solid slabs have almost no restrictions on dimensions, since their production is carried out directly at the facility under construction. During the process, horizontal formwork is installed, a frame made of reinforcement is laid, and finally everything is covered with a concrete layer, while concreting is carried out without interruption. This is the only way to obtain a monolithic floor.

Hollow core slab

Hollow-core products come in many types, and they can also have different parameters - geometry, hole radius and dimensions. Taking these parameters into account, all hollow products can be divided into 15 varieties, and each of them is marked in a certain way.

1) 1-PC – a product with rounded voids. Its purpose is to install on top of walls with double-sided support.

2) 1-PKT - a reinforced concrete product with rounded voids, whose diameter is 15.9 cm and the thickness of the product is 22 cm. It is mounted with a three-sided support.

3) 1-PKK – round-hollow reinforced concrete product. The hollow diameter is 15.9 cm with a product thickness of 22 cm. The purpose of the product is installation on walls with four-sided support.