Concrete and reinforced concrete products are essential elements of the construction process. They appeared on the market about 50 years ago and quickly gained popularity. However, concrete wall panels have a large number of features that should be familiarized with before using them.

Kinds

There are several types of concrete panels, but all their classifications are considered conditional and depend on the specific use.

According to their intended purpose, reinforced concrete panels are used for the construction of:

- residential buildings;

- industrial facilities;

- technical structures;

- attics and basements;

- for installation around the perimeter and inside the building (internal wall slabs).

Depending on the type of construction, wall panels can be hollow, monolithic, combined or made from one brand of concrete. Depending on the number of layers, a reinforced concrete panel can be monolithic or prefabricated.

The last type has its own classification:

- Single-layer reinforced concrete panels. These products are made from one brand of concrete and are lightweight. Their peculiarity is that the inner layer is coated with a special cement mixture. This cement speeds up the formation of the product and simplifies interior finishing.

- Two-layer structures consist of a heat-insulating layer and reinforced tiles. In most cases, foam concrete, foam glass or mineral wool are used as a heat insulator. A surface with a thermal insulation coating for the walls is located inside the building.

- Three-layer products are made in the form of ribbed reinforced concrete panels that are connected to each other. Seals are installed between them. This material has large dimensions and weight, but at the same time it is the most functional option for the construction of high-rise buildings.

The panels are also classified according to the degree of resistance to mechanical loads. According to this feature they are:

- non-load-bearing;

- bearing;

- self-supporting;

- bearing floor by floor.

In addition, reinforced concrete products differ in binding ingredients, brand, type of reinforcement, purpose, etc.

Reinforced concrete wall panels

Reinforced concrete wall panels are a building material that is used in the construction of external walls of enterprises, residential and office buildings.

Concrete panels for the house come in single-layer and three-layer. Single-layer ones are made of homogeneous concrete with low thermal conductivity. Three-layer of two plates with insulation.

Plates are produced according to GOST 11024-84.

You can buy wall panels from the manufacturer from us at a low price. We have been producing and selling reinforced concrete structures of various types for several years, so we will help you with your choice!

To understand which wall panels are needed for the project, you should understand their markings and types.

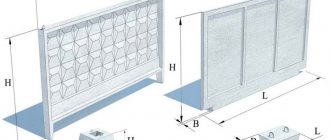

Wall slab dimensions

For example, when ordering, a slab may have a certain marking: 3NS30.29.35-200T-SM.

It means that:

- 3NS – panel type;

- 30 — length 2990 mm;

- 29 — height 2865 mm;

- 35 — thickness 350 mm.

Next comes the grade of concrete from which the panel was made. In our example, the concrete is grade M 200. And SM means that the panel can withstand frosts below minus 40 °C.

Wall panels for multi-storey residential buildings

For a multi-story building, it is customary to use three-layer panels made of heavy concrete. They are strong, can withstand heavy loads and have an insulating effect. Therefore, houses built from reinforced concrete walls are distinguished by comfort and good sound insulation. Houses with single-layer panels are also used in construction and meet all GOST requirements. What type of panel to use in construction depends on the project and the desires of the developer.

Wall panels for industrial facilities

Production facilities are most exposed to difficult technical conditions, which is why they use a high grade of concrete. As for multi-storey buildings, the panels are three-layer. Thanks to this, the building will last for decades and will avoid damage associated with temperature changes and other weather and technical phenomena.

Wall panels for basements

They have high performance properties. Concrete easily copes with temperature changes and high humidity, therefore it is suitable for construction and cladding of basement floors. It lasts for several decades and does not collapse.

Wall panels for attics

The attic is an indispensable structure for any residential or industrial facility. Reinforced concrete attic wall panels are used for its construction. They are strong, with high heat protection and sound insulation. Such panels are used to equip high-rise buildings; they can easily cope with loads.

Monolithic wall panels

Single-layer concrete structures, which consist of a reinforcement frame and concrete. Their thickness is not inferior to two- and three-layer reinforced concrete products. The inside of the stove is decorated. Does not require additional insulation, it has good thermal conductivity.

Prefabricated Wall Panels

They have a prefabricated part - these are two-layer and three-layer panels. They are additionally insulated. Welding of panels occurs during the construction of the wall.

Hollow-core wall panels

They have small holes into which concrete or liquid foam is poured during construction for additional insulation.

Load-bearing wall panels

The reinforced concrete wall panel is a support for the overlying coverings. It transfers the load right down to the foundation. Characteristics: good resistance to stress, waterproof, with good sound insulation.

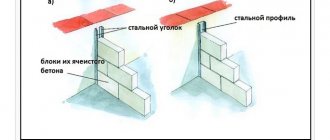

Self-supporting wall panels

The walls are made of cellular concrete. This is an artificial, porous, durable building material. It is made on the basis of mineral binder filling. Nothing rests on self-supporting walls; they only support their own weight along the entire height to the foundation.

Curtain wall panels

These are fences that only support their own weight within one floor. The curtain wall is made of lightweight panels and is easy to install. It can be single-layer or multi-layer.

You can order wall panels in Kazan at a low price and with delivery to the construction site from us. Call! Well-coordinated production of reinforced concrete panels is a guarantee of quality. We will answer all your questions and provide free advice on the range of wall panels.

Source: https://gbk-kzn.ru/zhelezobetonnye-stenovye-paneli/

Advantages and disadvantages

Reinforced concrete wall panels have many advantages. Among them:

- Fast construction. If there is a ready-made construction project, specialists assemble the building from reinforced concrete products quickly and without any delays.

- Construction using reinforced concrete products can be carried out in any season. Even in winter there is no need to stop the construction of buildings made of reinforced concrete products.

- No shrinkage. Reinforced concrete panels do not tend to shrink, i.e. After assembling the main box, you can immediately proceed to the subsequent stages - interior decoration, thermal insulation, etc.

- Excellent sound insulation. The highest levels of noise protection can be achieved by choosing special panels with built-in insulation.

- Possibility of constructing a warm building. High-quality reinforced concrete products have high resistance to heat transfer.

- No restrictions in terms of facade finishing. For this purpose, any solution can be used, including cladding with decorative plaster and siding.

- High level of fire safety. Reinforced concrete products that comply with GOST are not subject to combustion.

- Affordable price. Experts note that the cost of a reinforced concrete building is 1/3 less than a building made of brick.

In addition, the internal surfaces of reinforced concrete panels do not require pre-treatment, because they are initially smooth. They should be finished after the construction of the building, during the interior decoration of the home.

However, this material also has disadvantages. The main ones:

- installation requires the use of special equipment;

- large mass;

- the even shapes of wall blocks can create problems with the implementation of complex architectural compositions;

- increased requirements for the foundation base;

- possible problems with replacing damaged fragments;

- noise and heat insulation is worse than in buildings built from classic brick.

Panel walls - what are their features?

In recent years, construction from reinforced concrete panels has only been gaining momentum, although many citizens still have a prejudiced attitude towards them. The reason is in Soviet-built houses, the soundproofing of which was the subject of jokes. And such apartments could not boast of warmth.

However, today the situation has changed radically: three-layer reinforced concrete wall panels, used for the construction of walls in frame buildings, due to the internal insulation layer, are completely devoid of the above disadvantages.

Getting to know the products: what the standard says

Reinforced concrete three-layer panels with effective insulation, used for the construction of external walls of industrial and civil buildings, are produced in accordance with the requirements of standard 31310 (latest edition 2020). The document establishes the types and parameters of products, classification and technical requirements for their production.

Panel structure

Despite the multi-layer nature, the panel is a solid product, since the insulation is added to it at the molding stage. As you can see in the photo, this “sandwich” consists of two layers of concrete with a heat-insulating layer between them. It may consist not of one, but of several layers of insulation - either one type or several.

Note: The finishing (protective) layer, if present in the product, does not belong to the main layers. It can be made from roll, tile or film materials. This could be a layer of plaster, paint or simply a hydrophobic coating.

The panels can also have a finishing inner layer - it faces the inside of the room and serves as the basis for finishing. It may consist of cement or lime-cement mortar. Naturally, the price of such products is somewhat higher.

- Flexible connections are used to connect the outer and inner layers of wall panels. According to their purpose, they are divided into: spacers, suspensions and struts - depending on their static location.

- Spacers fix the relative position of concrete layers and their interlayers, compensating for tensile and compressive loads acting perpendicularly on the façade.

- The hangers transfer vertical loads to the internal frame of the panel. Their number is determined by calculation.

- A strut is a connection whose task is to prevent displacement of layers that may occur during transportation, unloading or installation of the panel.

With flexible connections everything is clear - but there are also rigid connections. These are thin reinforced lintels that are located inside the insulating layer and combine the inner layer of concrete with the outer one. Panels with rigid connections are more often used in the construction of industrial buildings.

Typical sizes

Reinforced concrete panels can have different configurations and dimensions. It is necessary to select the characteristics of the material at the design stage of the building. At this stage, it is necessary to calculate the dimensions of all existing elements, as well as the number and size of openings. Typical dimensions of such structures are established by GOST. According to it, the thickness of the panels should be in the range from 20 to 50 cm. The standard sizes of reinforced concrete slabs are 12 × 1.8 m and 6 × 1.2 m.

For industrial purposes, panels with a length of 12 and 6.9 m are taken. For walls with openings, products are used whose length varies between 1.5-3 m, and panels with a length of 1.48 to 2.98 m are suitable for doorways.

GENERAL TECHNICAL CONDITIONS G0ST 11024—84

Main panel sizes

2.2.1. The coordination dimensions of panels in the absence of separating elements in places where they interface with adjacent building structures (for example, walls in a perpendicular direction, floors and balcony slabs) should be taken according to Table. 1.

If there are separating elements at the junctions of the panels, the coordination length and height of the panels must be equal to the corresponding dimensions given in table. 1 and reduced by values depending on the coordination dimensions of the separating elements and determined in accordance with ST SEV 1001.

Dimensions

| View of a wall cut into a panel | Panel view | Panel size name | Multiplicity of coordination size to module (M=100 mm) | Coordination dimensions, mm |

| Single row | — | Length | 15M | 1500; 3000; 4500; 6000; 7500 |

| 12M | 1200; 2400; 3600; 4800; 6000; 7200 | |||

| 6M | 1200; 1800; 2400; 3000; 3600; 4200; 4800; 5400; 6000; 6600; 7200 | |||

| Height | 6M, ZM, M | 2800; 3000; 3300; 3600; 4200 | ||

| Horizontal strip | Strip | Length | 15M | 3000; 4500; 6000; 7500; 9000; 12000 |

| 6M | 3000; 3600; 42.00; 4800; 5400; 6000; 6600; 7200 | |||

| Height | ZM, M | 600; 900; 1200; 1300; 1500; 1800; 2100; 3000 | ||

| Prosten- night | Length | ZM | 300; 600; 1200; 1800 | |

| ZM, ZM/2 | 300; 450; 600; 750; 1200; 1800 | |||

| Height | ZM | 1200; 1500; 1800; 2100; 2400; 2700 | ||

| Vertical strip | Strip | Length | ZM, 3M/2 | 600; 750; 900; 1200; 1500; 1800 |

| Height | 6M, ZM, M | 2800; 3000; 3300; 3600; 4200; 4800; 5400; 6000; 6.600; 7200; 8400 | ||

| Podokonnaya | Length | 6M | 1200; 1800; 2400 | |

| ZM, ZM/2 | 900; 1200; 1350; 1500; 1800; 2100; 2400: 2700 | |||

| Height | 6M, ZM, M | 600; 700; 900; 1200; 1300; 1500: 1800; 2100 | ||

| Single row n strip | __ | Thickness | M/2 | 200; 250; 300; 350; 400 . |

| M/4 | 200; 225; 250; 275; 300; 325; 350; 375; 400 |

Notes:

1. Coordination heights of panels indicated in table. 1 refer to panels intended for above-ground floors, and the coordination panel thicknesses refer to single-layer and continuous laminated panels.

In cases where in the table. 1 shows several modules, the coordination size is a multiple of one of these modules.

2. The coordination length of the corner panels is determined depending on the thickness of the panels and the design of the corner butt joints.

3. The coordination length of the wall panels can be taken to be different from that given in the table. 1 in cases where this is justified by the peculiarities of the design of building facades.

4. The coordination thickness of the panels, a multiple of the M/4 module equal to 25 mm, should preferably be taken for laminated panels.

5. It is allowed, with an appropriate feasibility study and with the permission of the state construction authorities of the Union republics, to accept a coordination thickness of panels of more than 400 mm.

6. It is allowed to produce panels with coordination dimensions different from those indicated in the table. 1, on existing equipment before 01/01/91, as well as in cases provided for by ST SEV 1001.

INTERNAL WALL PANELS

CONCRETE AND REINFORCED CONCRETE FOR RESIDENTIAL AND PUBLIC BUILDINGS

GENERAL TECHNICAL CONDITIONS G0ST 12504—80

Marking

According to GOST, manufacturers must mark the edges of a fragment of a reinforced concrete slab with information about the main characteristics of their products. In this case, all inscriptions are applied with a special indelible dye. Thus, information on reinforced concrete slabs is presented in the form of a special marking of 3 numbers and letters, which are separated by a hyphen.

The first symbol of the designation indicates the manufacturing method (4-6 - composite, 1-3 - monolithic). The next symbol indicates the type of slab (H - external, B - internal). This is followed by the designation of the place of use (H - attics, C - basement, C - walls). In addition, the marking contains information about sizes. The width of the panel is expressed in centimeters, and the length of the product is expressed in decimeters.

Projects of houses made of reinforced concrete panels

Number of projects 112

- 4 rooms

- 4 bathrooms

MS-345 House Project

- To favorites

- 320.3² Total area

- 38 x 21m Construction area

from 9,643,707 rub.

Construction time individually

- 8 rooms

- 4 bathrooms

House project MS-346 (house with 4 apartments)

- To favorites

- 342.14² Total area

- 16 x 15m Construction area

from RUR 10,452,290

Construction time individually

- 5 rooms

- 2 bathrooms

MS-152 House Project

- To favorites

- 152.4² Total area

- 11 x 9m Construction area

from RUR 4,674,197

Construction time individually

- 6 rooms

- 5 bathrooms

MS-224 House Project

- To favorites

- 136.4² Total area

- 14 x 9m Construction area

from 5,731,410 rub.

Construction time individually

- 7 rooms

- 3 bathrooms

House project MS-606

- To favorites

- 607.4² Total area

- 17 x 25m Construction area

from RUR 12,545,763

Construction time individually

- 4 rooms

- 2 bathrooms

MS-97 House Project

- To favorites

- 92.55² Total area

- 7 x 8m Construction area

from RUR 3,532,652

Construction time individually

- 2 rooms

- 1 bathroom

MS-51 House Project

- To favorites

- 45.4² Total area

- 5 x 7m Construction area

from RUR 2,428,162

Construction time individually

- 6 rooms

- 3 bathrooms

MS-187 House Project

- To favorites

- 185.1² Total area

- 11 x 11m Construction area

from 5,363,056 rub.

Construction time individually

- 5 rooms

- 2 bathrooms

MS-107 House Project

- To favorites

- 104.5² Total area

- 7 x 9m Construction area

from 3,405,002 rub.

Construction time individually

- 6 rooms

- 2 bathrooms

House project MS-240/4

- To favorites

- 237.6² Total area

- 12 x 14m Construction area

from 6,814,802 rub.

Construction time individually

- 4 rooms

- 2 bathrooms

House Project BP-138

- To favorites

- 115.7² Total area

- 9 x 16m Construction area

from RUR 5,199,119

Construction time individually

- 4 rooms

- 2 bathrooms

MS-120 House Project

- To favorites

- 114.9² Total area

- 13 x 10m Construction area

from 5,102,593 rub.

Construction time individually

- 5 rooms

- 2 bathrooms

House project MS-162/1

- To favorites

- 163.5² Total area

- 17 x 10m Construction area

from RUR 4,827,726

Construction time individually

- 5 rooms

- 2 bathrooms

MS-213 House Project

- To favorites

- 210.1² Total area

- 15 x 15m Construction area

from RUR 5,347,114

Construction time individually

- 5 rooms

- 2 bathrooms

MS-180 House Project

- To favorites

- 180² Total area

- 9 x 13m Construction area

from 4,457,981 rub.

Construction time individually

- 5 rooms

- 3 bathrooms

MS-253 House Project

- To favorites

- 189.97² Total area

- 13 x 11m Construction area

from 6,142,886 rub.

Construction time individually

- 4 rooms

- 2 bathrooms

House Project BP-171

- To favorites

- 101.8² Total area

- 8 x 9m Construction area

from RUB 3,983,638

Construction time individually

- 5 rooms

- 4 bathrooms

House project MS-253/1

- To favorites

- 197.8² Total area

- 11 x 13m Construction area

from RUR 5,827,784

Construction time individually

- 5 rooms

- 3 bathrooms

MS-161 House Project

- To favorites

- 161.5² Total area

- 9 x 11m Construction area

from RUB 5,240,122

Construction time individually

- 4 rooms

- 2 bathrooms

House project MS-146/5

- To favorites

- 119² Total area

- 8 x 9m Construction area

from 4,022,360 rub.

Construction time individually

View all projects

Concrete products began to appear en masse on the construction market about fifty years ago; These were ready-made reinforced concrete panels, thanks to which the construction of houses proceeded much faster. The development of technology has led to the emergence of a large number of not only construction, but also decorative varieties of this practical material. Modern concrete panels have become one of the most popular building materials; they are increasingly used in private housing construction, both in the construction of walls and in their finishing.

Embossed wall panels in the interior Source klad.ca

Production methods

Reinforced concrete products are produced at enterprises in the construction industry. In this case, different types of concrete and different reinforcement technologies are used. Concrete can be extra-light, light, heavy and extra-heavy. Reinforcement can be standard and initially stressed.

The following methods are used for the production of reinforced concrete wall panels:

- bench - large elements are placed in fixed forms, after which formation occurs using aggregates;

- flow-aggregate - during continuous moisture and heat treatment, elements are transferred around the workshops, taking into account the manufacturing technology;

- cassette - fixed forms are used, but after processing the structures are removed using special lifts;

- vibrating rolling - the entire production process takes place on a special vibrating rolling conveyor.

Three-layer reinforced concrete panels

Three-layer reinforced concrete panels with insulation are used for external walls of residential and industrial buildings and premises, including in agriculture with effective insulation. They are also called PST panels, plinth panels (PC), wall panels (W) and fire wall panels (FW) . We make panels from both heavy concrete and lightweight concrete using expanded clay (expanded clay concrete) . Walls made of three-layer panels with thermal insulation made of polystyrene foam have a fire resistance limit of 2.5 hours. Depending on the purpose, there are basement and wall ones. They are made of heavy and light concrete, including high grades. Our plant produces three-layer reinforced concrete panels of any length up to 9 meters (6 m, 7 m and 8 meters) with the only limitation being the possibility of transportation and different thicknesses, including taking into account the aggressive environment . polystyrene (foam) or mineral wool is usually used as , but there is also a specific insulation, such as polyisocyanurate foam

(PIR), which creates the effect of a thermos, which is usually used in agriculture for poultry breeding. We can produce a panel with a textured front surface formed using structural matrices ( lined panel PSF and PSFV ). The price depends on the size and type of insulation, as well as embedded parts. Our plant produces high-quality three-layer reinforced concrete panels according to individual customer drawings. buy a PST panel without overpayment at prices lower than factory prices from us; each product comes with a quality certificate.

We deliver by road and by rail to all cities of Russia.

| Name | volume, m3 | Weight, tons |

| PST12.12.2,5-P | 0,37 | 0,925 |

| PST12.18.2.5 | 0,53 | 1,325 |

| PST12.18.3.0 | 0,64 | 1,6 |

| PST12.24.2,5-P | 0,78 | 1,95 |

| PST12.9.2.5 | 0,27 | 0,675 |

| PST12.9.3.0 | 0,34 | 0,85 |

| PST30.12.2,5-P | 0,88 | 2,2 |

| PST30.18.2,5-P | 1,32 | 3,3 |

| PST30.9.2,5-P | 0,745 | 1,863 |

| PST33.18.3.0 | 1,76 | 4,4 |

| PST36.18.2.5 | 1,57 | 3,925 |

| PST36.18.3.0 | 1,91 | 4,775 |

| PST36.9.3.0 | 0,95 | 2,375 |

| PST38.18.3.0 | 2,02 | 5,05 |

| PST39.18.2.5 | 1,75 | 4,375 |

| PST41.18.3.0 | 2,2 | 5,5 |

| PST42.18.2.5 | 1,86 | 4,65 |

| PST42.18.3.0 | 2,24 | 5,6 |

| PST45.18.2.5 | 2 | 5 |

| PST45.18.3.0 | 2,4 | 6 |

| PST51.18.2.5 | 2,26 | 5,65 |

| PST51.18.3.0 | 2,7 | 6,75 |

| PST6.12.2,5-P | 0,18 | 0,45 |

| PST6.12.3.0 | 0,21 | 0,525 |

| PST6.18.2.5 | 0,25 | 0,625 |

| PST6.18.3.0 | 0,3 | 0,75 |

| PST6.24.2,5-P | 0,36 | 0,9 |

| PST6.9.2.5 | 0,13 | 0,325 |

| PST6.9.3.0 | 0,16 | 0,4 |

| PST60.10.2.5 | 1,497 | 3,743 |

| PST60.9.2,5-P | 1,32 | 3,3 |

| PST63.9.2,5-P | 1,37 | 3,425 |

| PST8.18.3.0 | 0,42 | 1,05 |

| PST9.18.2.5 | 0,4 | 1 |

| PST9.18.3.0 | 0,46 | 1,15 |

| PCT60.15.2.5 | 1,51 | 3,08 |

Base panel for the Wildberries Distribution Center at the address: Moscow region, Podolsk, Koledino village:

Specially manufactured formwork for plinth panels PC-14 WILDBERRIES in Koledino:

Three-layer reinforced concrete panels with polyisocyanurate foam as insulation for the Tambov Turkey poultry farm, Tambov, Zmeevka village

Lightweight concrete panels (expanded clay concrete) GO Podolsk, Novoselki village, OMAKS warehouse, p. 15

Three-layer reinforced concrete panels

Wall panel

Transportation rules

Reinforced concrete panels are large in size, so for their transportation in Moscow and other cities, special transport is used - panel carriers.

Reinforced concrete structures are unloaded using a construction crane. During transportation there is a risk of minor damage to the products.

To avoid problems, you must adhere to the following rules:

- Reinforced concrete products are stacked in a car body. However, it is prohibited to stack more than 4 structural elements together.

- The installation nuts are located at the top. This is necessary so that the crane can hook the reinforced concrete slabs without affecting their position.

- Wood beams are placed between the individual slabs.

- To prevent the movement of reinforced concrete products during transportation, massive concrete blocks are placed on top of them.

If you follow these rules, you can quickly transport reinforced concrete structures to the construction site with a minimum amount of waste.

Warehousing and storage

When storing reinforced concrete products for a long time, it is necessary to pay special attention to the room. In particular, the surface on which the slabs will lie must be flat. A covering sheet must be laid on top and bottom of the building materials. It is prohibited to store reinforced concrete structures on the ground or without a suitable shelter.

Between the laid panels you need to place wooden planks. If it is not possible to place concrete wall slabs indoors, you should try to isolate them from aggressive external influences and moisture. Water has a negative effect on the load-bearing properties of concrete. In addition, it degrades its strength.

To avoid problems, concrete slabs must be covered with steel sheets, slate sheets, plastic film or roofing felt.

In addition, if concrete products will be stored in an open area, the following preparatory measures must be taken before storing them:

- First you need to inspect the storage area. It is better to give preference to a flat place with a slight slope. Products are stacked. In this case, it is necessary to take into account the possibility of passage of special equipment and transport. It is better to lay reinforced concrete slabs so that you can easily see their markings.

- The storage area must be carefully prepared. To do this, its surface should be leveled using available tools or a bulldozer.

- To ensure that the building material does not have contact with the ground, it must be placed on prepared bars.

Reinforced concrete panels are very popular because... they are durable and strong. The use of such products ensures reliable and efficient mass construction, which does not depend on the time of year. But the main part of these characteristics depends on the quality of the components of the composition and adherence to technology at each stage of production.

Three-layer wall panels according to the Finnish model: a new era of panel construction in Perm

Finnish panel housing construction is the latest technology for building houses, which has nothing in common with the usual “panels”: today, European-quality structures have been improved to meet the comfort of the client. This technology is actively used and has long proven itself in the Scandinavian countries, whose climate is almost identical to the Russian one, and due to the geographical prevalence of use, such panels began to be called “Finnish”.

The Krasnokamsk reinforced concrete plant was the first in the Perm region to launch production using Finnish panel construction technology, and the developer PAN City Group was the first to use this technology in the construction of the Mayak residential complex in Perm. The decision in favor of panel construction was made based on several indicators: the most safe, high-quality and efficient technology in terms of building operation, which allows expanding the possibilities of planning solutions, makes it possible to provide a comfortable life for future residents. In addition to the speed of construction, precast concrete technology has a number of significant advantages:

• The basis of the technology is a three-layer self-supporting panel, in which the outer and inner layers are made of reinforced concrete, and a reliable non-combustible insulation is laid between them. On the outside there is a layer of concrete, not plaster, which increases the durability of the facade and its resistance to damage.

Inner load-bearing layer

–

reinforced concrete 150–200 mm thick.

Average

– insulation 150 mm thick.

Outer layer

80 mm thick.

Floor height

– 2.7 m.

Lifespan of the building

– more than 100 years.

• Channels, electrical wiring and other communications are laid inside the panel, which has a positive effect on the aesthetics of the life of future owners, reducing the period of finishing.

• The absence of a stressed steel frame improves sound conductivity characteristics, providing the proper degree of sound insulation

.

The frame of the house is reinforced concrete, thanks to which the building

practically

does not shrink

.

• Finnish panels are laid out using modern overlapping technology, strengthening areas of increased heat transfer. The heat transfer resistance of walls is twice the norm in Russia and is energy efficient

even by strict European standards.

According to statistics, heating costs

in houses made of three-layer slabs

are 30% lower

than in houses made of brick, which, in combination with their own gas boiler room, will provide future residents of the Mayak residential complex with savings on utility bills.

• Safety and environmental friendliness

- another principles that are embedded in the technology.

The insulation is made from environmentally friendly material - 100% basalt crushed stone, produced by the vertical blowing method. The walls in this design are vapor-permeable, ensuring the principle of a “breathing wall”

.

The technology involves removing moisture through special ventilation grooves into the insulation. The structure remains dry - the risk of corrosion and fungus is reduced

, the coating does not crack or peel.

The Mayak residential complex1 has modern, well-thought-out layouts: no non-functional spaces or useless corridors! All apartments are rented with full, high-quality finishing

, which allows you to move into a new apartment immediately after delivery of the house, without wasting time and money on finishing it.

The new residential complex is located in the center of the Industrial district, on the street. Stakhanovskaya, 1a. Nearby is everything you need for a comfortable life:

kindergartens and schools, shops and shopping centers, and Balatovsky Park is a 10-minute drive away. Thanks to the location of the Mayak residential complex next to key transport routes, you can quickly get to anywhere in the city in the shortest possible time.

Hurry up to book your desired layout while it is available - almost 60% of the apartments are already sold! Choose a convenient payment option: installments from the developer2 on individual terms without overpayments and additional documents, mortgage3 or full payment. Understanding the importance of the process of selling secondary housing, the developer prepared special conditions for the purchase of 4 apartments in the Mayak residential complex while simultaneously selling existing housing through specialists from PAN City Group5.

Find out more details from the sales department by phone or at the offices of PAN City Group at the following addresses: Perm, st. Lenina, 72a, and Kosmonavtov Highway, 111, building 43, 2nd floor.

1Developer – LLC Specialized Developer “CITY Project”. The project declaration is posted on pancityproject.ru and dom-mayak.ru, as well as on the website of the Unified Information System of Housing Construction https://nash.dom.rf/.

2Instalments are provided by SZ CITY Project LLC.

3PJSC JSCB "Ural FD". General license of the Central Bank of the Russian Federation No. 249 dated May 12, 2015.

4Details - in the sales offices of PAN City Group or by calling 257-17-17.

5PAN City Group LLC is the managing organization of SZ CITY Project LLC.