Airborne noise

Sound is a physical phenomenon produced by the vibration of particles in various media, including gaseous and liquid substances. All sound vibrations have operating parameters of frequency and amplitude that affect human audibility.

The average noise frequency for individual events is as follows:

- The noise of the forest varies depending on the wind strength within 10-24 dBA.

- A conversation between two people is about 65 DBA, while a child's cry is already 78 DBA.

- The operation of music centers and other audio systems for similar purposes is about 85 dBA.

- Active road traffic, depending on the number and type of vehicles, is within 78-92 dBA.

In general, noise standards are 40 DBA during the daytime and 30 DBA at night. People's tolerance to increased noise varies. For example, in noise conditions up to 60 dBA, some people may experience discomfort. At the same time, a stable noise level within 70-90 dBA contributes to the emergence of various types of diseases of the nervous system. Exposure to noise of more than 100 dBA negatively affects a person’s hearing and can lead to partial or complete loss of it.

Soundproofing methods

You can improve sound insulation performance in two different ways. Firstly, by reducing the level of noise production, and secondly, by providing additional barriers to its spread.

To soundproof fences, two main methods are also used:

- Reducing the volume of fluctuations. This is achieved by increasing the severity of the obstacle. The more massive and heavier the structure (wall), the less susceptible it is to vibration processes, and the more it protects the interior space from penetrating sounds.

- Absorption of sound waves. It is achieved through the use of multilayer structures, including those with porous materials, which promote wave dissipation inside the barrier due to its physical properties.

It is aerated concrete that has increased sound absorption capabilities. Its porous structure is much more capable of scattering sound waves than materials with smooth surfaces. Due to these properties, aerated concrete blocks are actively used for internal masonry in industrial enterprises, where it is necessary to ensure reliable isolation of production premises from the surrounding infrastructure.

Design Guidelines

For internal walls, it is optimal to use continuous jointing when there are no internal cavities. The top of the walls must be plastered (on both sides). When designing, special attention should be paid to the joints of structures in order to prevent the appearance of cracks. In cases where cracks and crevices have formed during the operation of the structure, they must be immediately eliminated using sealants, filling the cavities to their full depth without leaving voids.

Measurements for gas blocks:

Report on sound insulation of YTONG blocks. Thickness - 100 mm, D500. Rw = 35 dB (without plaster), Rw = 46 dB (total plaster layer 40mm) » >

Instrumental test reports for sound insulation of AGB produced by Sayanskgazobeton (D500-D600). Let's look at sample 1. Rw = 42 dB (total plaster layer 20mm) » >

Assessment of sound insulation of internal walls and partitions (same manufacturer). Test 1. Rw = 43.1 dB (total plaster layer 50 mm) » >

There's actually something strange here Rw = 29 dB ">

Internal walls

An effective way to improve sound insulation is to build double walls that touch each other at certain points using lintels. The distance between the walls should be 40mm or more. When using frame-sheathing type partitions, the sheathing must be fastened to the frame at a distance of at least 300 mm. When using a two-layer structure, gluing two sheets together is not allowed. The frame posts in such structures are installed at a distance of 600 mm from each other or slightly more.

The quality of sound insulation when using a frame-sheathing structure can be improved by using soft sound-proofing materials that fill the interior space. In addition, designs in which each side of the cladding uses its own frame, and the cladding is made in a multilayer design, have increased soundproofing capabilities.

The most common cladding materials are plasterboard, fiberboard sheets and other materials for similar purposes. Their installation is carried out using “beacons” or wooden slats hammered onto the wall surface. Between the wall and the cladding materials, the size of the air cushion must be at least 50mm, which provides an increased level of protection against sound penetration. The resulting cavity must be filled with insulating materials (glass wool, mineral compounds, and so on).

Application of partitions

Very often, partitions made of aerated concrete blocks are used to remodel large rooms. For example, when there is a need to make two rooms out of one. Of course, many owners of houses or apartments can use any frame materials (plasterboard, chipboard, etc.) for such work. But if you need a permanent wall or a wall on which a large number of shelves will be placed, then aerated concrete partition blocks will be the best way to solve the problem.

Diagram of a partition made of foam blocks

Brick can also be used to make interior partitions. True, its installation requires skills in working with such materials or the involvement of trained specialists (masons). And aerated concrete blocks can be easily installed with your own hands, while significantly reducing financial costs.

Aerated concrete for partitions is quite large in size and has a fairly low weight. This greatly simplifies the construction process and reduces the overall installation time. Partition aerated concrete blocks have good sound and heat insulation properties. In addition, they have excellent fire safety characteristics.

Due to the fact that partition blocks are light in weight, their installation does not need to be coordinated with housing organizations, since they will not belong to the class of heavy structures that can harm the supporting structures of the building.

Joints

When designing joints, including between partitions and load-bearing structures, the likelihood of cracks that negatively affect the quality of sound insulation must be completely eliminated.

Filling the joints between floors and walls is carried out using concrete or mortar, and at the joint there must be the necessary cavities that are to be filled with a cement-based composition. In addition, it is necessary to limit the possible movement of structures as much as possible, for which individual elements are welded, fastened using dowels, and so on. In turn, all parts used for connection should not become an obstacle to filling the cavity and contribute to the appearance of voids. The optimal material for performing such work is expanding concrete.

Types of noise

Different building materials react to sounds differently. Before considering the materials used for sound insulation, it is necessary to determine what noise is. Noise is unwanted sounds that vary in strength and frequency.

Aerated concrete block

There are airborne and impact types of noise. Airborne noise is sound waves passing through a medium and, when interacting with enclosing structures, creating oscillatory movements that spread further into adjacent rooms.

Impact noise is caused by shock or vibration loads on structures and travels directly through them. To stop the spread of noise, acoustic materials are used to absorb and reduce the strength of sound vibrations.

According to SNiP, the required sound insulation coefficient in an apartment (average sound absorption coefficient) is determined by the formula: acp = A / Sogr, where A is the sound absorption area, expressed in sq.m.; Sogr – total area of enclosing structures, sq.m. Most often, the sound absorption coefficient of insulation is 0.5 - this means that a wall made of insulation absorbs up to half of the noise energy falling on it.

Sound insulation of multilayer partitions

They alternate at least two layers: hard - from a high-density material with a high reflection coefficient (plasterboard, brick) and soft - from a material with a high sound absorption coefficient (mineral wool). Part of the sound wave is reflected by the first layer, and part is absorbed by the second. The amount of energy absorbed and dissipated depends on the thickness of the material, its density and elasticity.

Sound-absorbing materials

a special sound-absorbing material as a filler , and not ordinary insulation, although the latter is cheaper. The fact is that the acoustic properties of heat-insulating materials may differ several times from the similar properties of sound-absorbing materials. Thus, the average sound absorption coefficient of the most commonly used insulation materials is usually 0.4–0.5. This means that the material absorbs up to half of the energy of sound waves incident on it in a certain (standardized) frequency range. The indicator of special sound-absorbing material reaches 0.95. The conclusion is obvious: in order to achieve a certain effect, you need to use material designed to solve this particular problem.

It should be noted the low efficiency of using materials such as polystyrene foam, polyurethane foam or cork in soundproofing partitions. This is due to the fact that for good soundproofing materials they have insufficient density, and to classify them as sound-absorbing materials, they have low absorption due to the lack of air flow.

Sound insulation of aerated concrete partitions

The soundproofing characteristics of masonry depend on the density of aerated concrete blocks, the density of the mortar and the thickness of the mortar joint.

| Airborne noise insulation index Rw, dB | ||||

| Partition thickness, mm | Density of aerated concrete, kg/m 3 | |||

| γ=400 | γ=500 | γ=600 | γ=700 | |

| 100 | 39 | 40 | 41 | 42 |

| 120 | 40 | 41 | 42 | 43 |

| 150 | 41 | 42 | 43 | 44 |

| 200 | 43 | 44 | 45 | 46 |

| 400 | 50 | 51 | 52 | 53 |

When constructing inter-apartment walls and partitions, to reduce their weight, it is recommended to use layered structures consisting of two outer layers made of aerated concrete and an internal gap filled with sound-absorbing material.

When determining the airborne noise insulation index of three-layer aerated concrete walls with a gap of 60–90 mm filled with sound-absorbing material, Rw1 is first calculated as for a single-layer wall, adding 5 dB to the resulting value.

Soundproofing of plasterboard partitions

Soundproofing scheme

- Sheathing with plasterboard in 1 or 2 layers

- Rack profile

- Guide profile

- Screw

- Sealing tape

- Stone wool TECHNOACUSTIC

- Finishing

Characteristics

Airborne noise insulation index Rw, dB

| Design | Plasterboard sheathing | Thickness, mm | ||

| mineral wool | partitions | |||

| 1 | One layer on each side | – | 75 | 35 |

| 2 | One layer on each side | 50 | 75 | 46 |

| 3 | Two layers on each side | 50 | 100 | 49 |

| 4 | One layer on each side | 100 | 125 | 54 |

| 5 | Two layers on each side | 100 | 150 | 57 |

To increase the soundproofing ability of partitions, sealing tape should be used between the guide profile of the frame and the ceiling, as well as in the places where the frame meets the walls and ceilings.

Installation of partitions is carried out before the installation of a clean floor under dry or normal temperature and humidity conditions.

The sealing tape is necessary to isolate impact noise from the doors.

Components of technical solutions: 1. Sheathing with plasterboard. 2. Mineral wool TECHNOACUSTIC. 3. Steel frame. 4. Sheathing with plasterboard. 5. Cleaning of the premises. 6. Sealing tape. 7. Sealant. 8. Reinforcing tape. 9. Screw. 10. Dowel-nail. 11. Extruded polystyrene foam TECHNONICOL. 12. Bitumen-polymer membrane Technoelast ACOUSTIC. 13. Prefabricated screed. 14. Floor slab. 15. Edge tape. 16. Floor covering. 17. Door frame. 18. Platband.

Soundproofing a brick partition

To increase the insulation of airborne noise by a wall made of light brick with a thickness of 1/2 brick (125 mm), it is advisable to use suspended soundproofing cladding (there is practically no point in sheathing a more massive wall).

Soundproofing characteristics of aerated concrete

Depending on the thickness of the aerated concrete, the noise insulation index, expressed in dB, changes. According to existing standards, the level of sound insulation between apartments should be 52 dB, between rooms within an apartment - 43 dB.

Sound insulation should vary depending on the tasks being performed. So, for dancing you will need one type of sound insulation, for sound recording - a completely different one. Sound protection can be of three types:

Sound-absorbing insulation traps sounds, preventing them from spreading and creating an “echo” effect. Soundproofing materials dampen sounds of mid- and high-frequencies, and damping (shock-absorbing) materials dampen sounds of low frequencies. The sound insulation of an aerated concrete wall can be improved by plastering the wall, using soundproofing boards, slag wool and plasterboard.

The advantage of aerated concrete is the high speed of laying and the low cost of overlapping. At the same time, drywall and slag wool absorb sounds better and weigh less. The minimum thickness of an aerated block bulkhead is 150 mm, the recommended thickness is 250 mm. Some selected properties of aerated concrete and similar soundproofing materials are reflected in the following table of comparative characteristics of soundproofing materials:

MaterialThermal conductivity, W/ (m*K) Noise insulation index, dB

| Polyurethane foam | 0,02-0,041 21 |

| Expanded polystyrene | 0,038-0,05 55 |

| Silicate brick | 0,7 51 |

| Cork | 0,047 12-15 |

| Mineral wool | 100 mm 0.056-0.07 54 |

Soundproofing of aerated concrete

Although sellers of gas silicate blocks talk about high sound insulation performance, they greatly exaggerate. Even a standard block 200 mm thick conducts sounds and noise well, and thinner partition blocks even more so.

Comparative characteristics of sound insulation of partitions made of different materials

According to standards, the sound resistance of partitions should not be lower than 43 dB, and it is better if it is higher than 50 dB. This will provide you with silence.

Sound insulation standards for different rooms

To get an idea of how “noisy” gas silicate blocks are, we present a table with standard indicators of sound resistance of blocks of different densities and different thicknesses.

Sound absorption coefficient of aerated concrete blocks

As you can see with the block, at 100mm thick it falls slightly short of the lowest requirement. Therefore, when finishing aerated concrete, you can increase the thickness of the finishing layer in order to “reach” the standard. If normal sound insulation is required, the walls are additionally sheathed with mineral wool. This material is not soundproofing, but it reduces noise by approximately 50%. As a result, sounds are almost inaudible. Specialized soundproofing materials have the best performance, but when choosing them, you need to look at their vapor permeability characteristics so as not to trap moisture inside the gas silicate.

If you need absolutely “quiet” walls, experts advise installing two thin partitions with a distance of 60–90 mm, which should be filled with sound-absorbing material.

Aerated concrete blocks are a popular material for constructing internal walls and partitions. They are suitable for low-rise buildings made of aerated concrete and for multi-storey new buildings with open floor plans.

What is the secret of the popularity of aerated concrete partitions?

- The blocks are relatively cheap, an excellent option for budget housing.

- The blocks are lightweight (weigh several times less than bricks) and therefore easy to transport, unload and install. One person can build masonry from aerated concrete blocks. Due to the low weight of the partitions, the load on the floors and foundations is reduced, which means the costs of the building structure are reduced.

- The blocks can be easily cut with a hand or electric hacksaw. You can drill them without any problems, cut out elements of complex shapes from them, make bevels, etc.

- The blocks are laid on a thin-layer cement mortar or polyurethane foam adhesive. These installation methods, combined with the low weight of the blocks and the ease of their processing, lead to a high speed of installation of partitions.

- The lines of leading aerated concrete manufacturers (for example, Xella Russia, YTONG brand) include products that allow you to implement the most unusual architectural solutions. In particular, there are arched blocks for creating semicircular partitions. Or O-blocks for constructing noise-proof and heat-insulating shells for ventilation ducts or chimneys passing through the walls of a house. Such blocks are simply built into the wall masonry.

Partition thickness

Typically, internal walls and partitions are built from blocks 100-150 mm thick, less often - 200 mm. Density grade D500. It is better not to use less dense aerated concrete, as it has worse sound insulation properties. From D500 blocks with a thickness of 100-200 mm, you can build walls up to 3 m high and up to 7 m long (without openings) without additional reinforcement in the form of reinforcement.

If larger partitions are needed (for example, in a cottage with a second light, with a large number of doorways, etc.), then a structural stability calculation will be required, according to SP *. And the masonry may need to be strengthened. There are standard solutions for this:

- Reinforcement of every third row of blocks with a steel or composite rod with a diameter of 8-10 mm. The rod is placed in a groove with a cross-section of 20x20 mm, made on the upper surface of the masonry, and then filled with an adhesive solution. It can also be reinforced with perforated metal plates recessed into the adhesive joint.

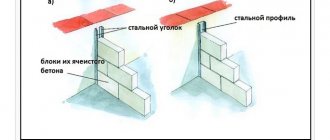

- Attaching the wall to the upper ceiling. This method is also suitable when there is a danger of the wall tipping over under load. Or when, for one reason or another, reinforcement of the masonry was not carried out. But an aerated concrete wall can only be secured to a concrete floor (in the case of flooring with wooden beams, this technology is not feasible). There are two mounting options:

- Metal corners. They are fixed to the ceiling with ordinary dowels, and to the blocks - with special fasteners for aerated concrete. The corners are installed one per block, the standard step between them is 625 mm. During subsequent finishing, the corners are covered with plaster.

- Flexible connections. These are perforated stainless steel strips, which are placed at one end in a vertical adhesive seam (usually driven into the wall of the block with nails), and at the other end they are secured with dowels to the ceiling. The connection consumption is the same - 1 piece/block.

Masonry: quick and easy!

As already mentioned, the blocks are laid using thin-layer cement adhesive or polyurethane foam adhesive. Both options cost about the same amount, but foam glue has a number of advantages:

- It is more convenient for renovations in a multi-storey building or arrangement of a cottage where rough work has already been completed. Cement glue means dust, dirt, and high humidity in the room. Foam glue allows you to avoid all this.

- Laying blocks on foam glue is faster than on cement glue. We take a construction gun, insert a can of foam, apply one strip to the horizontal and vertical surfaces of the masonry - and fix the block. After 10 minutes, the foam hardens, firmly holding the block. Fast and easy!

- Foam glue seams have little elasticity and therefore prevent the appearance of cracks when the floor sag.

A few words about the block laying technology. The first row must be mounted on a regular cement-sand mortar to ensure the rigidity of the entire wall. If the work is carried out on the ground floor of the cottage, then a cut-off waterproofing made of roll or coating bitumen materials is provided between the masonry and the lower floor. This is protection against capillary penetration of moisture.

A gap of 30-50 mm is left between the wall and the upper ceiling, which is filled with polyurethane foam or other elastic material. The fact is that the floor slab may bend slightly as the building settles. For an aerated concrete wall, this is nothing critical, but the finishing may be damaged. To prevent this from happening, a gap is provided.

Non-load-bearing walls are attached to load-bearing walls made of aerated concrete using flexible connections - metal perforated strips: one for every third row. Such connections compensate for uneven settlement of the external and internal structures of the house. One end of the tape is mounted in the load-bearing wall, the other in the adhesive seam of the partition.

In addition, a small gap is left between the partition and the outer wall, which is filled with mounting foam or damper tape made of foamed polyethylene. This is necessary so that the plaster in the corners of the room does not crack when the building vibrates, caused, for example, by strong winds. Moreover, the damper tape also improves the sound insulation of the wall.

How to choose optimal sound insulation

After completing the preliminary work, you can begin soundproofing the premises. Soundproofing systems can be framed or frameless. The frame consists of anti-noise material covered with gypsum fiber (GVL) and plasterboard sheets (GKL). The system without a frame consists of already prepared gypsum plasterboard sheets with glued slabs, on which gypsum plasterboard sheathing is placed.

Frame systems have a number of advantages, including:

•they mechanically level the surface, the walls are smooth without plaster;

•the number of mounting points is three to four times less than for frameless ones, and this reduces possible vibration loads on the slabs;

•the frame can withstand increased loads - you can hang a TV or air conditioner on it, for example;

•no specialists are required during installation; work is carried out using standard KNAUF technology.

Defective seams

Troubleshooting of the gas block seams is carried out (embroidering and filling with repair materials) to restore the calculated noise insulation indicators:

Next you can plaster the wall. A layer of plaster increases the weight of the fence (plaster is several times heavier than any porous concrete) and eliminates all the defects of the masonry (through cracks, cavities, porosity of the block); in total, the sound insulation of the plastered wall will increase by 3-4 dBA. In addition, plaster allows you to obtain a smooth surface (necessary for frameless sound insulation systems).

At the end, sound insulation is installed either according to a thin version of 5 cm, or according to reinforced schemes of 8-9 cm. In the first version, completely fitting into the previous dimensions, we get a total of 53-55 dB (40 + 13-15 dB) and enter the Sanitary norms. In the second case, with a final thickening of the wall of only a couple of centimeters - a significant 56-58 dB.

Aerated concrete plaster

Another option for improving the sound insulation of aerated concrete is plastering on both sides. It is used for thin walls, together with reinforcement it gives additional strength. Plastering will prevent moisture from getting inside the blocks; the finishing material should protect the material from destruction on both sides.

One of the disadvantages of aerated concrete is its low moisture resistance. In the case when it is the only building material, plaster is carried out outside and inside the building. Plaster for aerated concrete is selected especially carefully, because it serves not only to preserve its properties, but also to improve them.

Aerated concrete primer

You can use a roller or brush to apply the primer. Aerated concrete has increased absorbency, and this makes its priming difficult. You will have to repeat this operation 2-3 times.

The choice of primers in stores is impressive, so you can choose the right one yourself. Often the plaster is reinforced with reinforced mesh and the plaster is applied over it.

This is necessary when plastering the facade of a house. Finishing begins from the inside, because... There are different humidity levels for external and internal walls. And while you are plastering from the inside, all the moisture will leave through the outer wall.

How to soundproof aerated walls

The easiest way to soundproof interior partitions is to plaster them before applying the finishing touches. If such insulation is not enough or a thin block was used for the partitions, then any soundproofing materials can be used.

Materials for soundproofing internal walls made of aerated concrete blocks are produced in rolls or slabs. To fasten slabs or rolled rolls, dowel-nails or universal self-tapping screws, as well as aerated concrete adhesive, are used. External finishing is done on top of the sound insulation.

Displaying beacons

Beacons are required to level the plaster. These are special guides of the required height. After use, the beacons can be carefully removed and used again if necessary. There are steel and plastic beacons for plaster. The disadvantage of plastic products is their excessive flexibility. Metal ones are much more practical.

There are also L-shaped and T-shaped beacons; The choice of section is determined by the tasks assigned to the profile. Beacons can be attached with a solution (on a cement-gypsum mixture) or using special fasteners (dowels, self-tapping screws, etc.).

You can display beacons using the artisanal method or the “spider” method. Each method has its own advantages and disadvantages. The cost of beacons starts from 4-5 rubles per meter. If necessary, you can order these products online at a lower price.

Device and features

If aerated concrete partitions are installed during the renovation and redevelopment of apartments or houses, markings must first be applied. The line is upholstered around the entire perimeter: on the floor, ceiling, walls. The easiest way to do this is with a laser plane builder. If it doesn't exist, it's better to start with a stream:

- Mark a line on the ceiling (two points on opposite walls). A painting cord, painted with blue or some other dry dye, is pulled between them. With its help they beat off the line.

- The lines on the ceiling are transferred with a plumb line to the floor.

- Then the lines on the floor and ceiling are connected by drawing vertical lines along the walls. If everything is done correctly, they should be strictly vertical.

The next step in constructing aerated concrete partitions is waterproofing the base. The floor is cleaned of debris and dust, waterproofing roll material is laid (any: film, roofing felt, waterproofing material, etc.) or coated with bitumen mastics.

Vibration dampening strips

To reduce the possibility of mother-in-law formation and increase sound insulation characteristics, a vibration-absorbing strip is laid on top. These are materials with many small air bubbles:

- hard mineral wool - mineral wool cardboard;

- polystyrene foam of high density, but small thickness;

- soft fiberboard.

The first row of blocks is laid on this strip with glue. Glue thickness is 2-5 mm, consumption for a thickness of 1 mm is 30 kg/m3. Next, the construction of partitions occurs using the same technology as load-bearing walls. Read more about the technology of laying aerated concrete walls here.

On short spans - up to 3 meters - no reinforcement is done at all. On longer ones, a reinforcing polymer mesh, a perforated metal strip, as in the photo, etc. are laid.

Aerated concrete partitions can be reinforced if desired

Connecting to a wall

To ensure connection with adjacent walls at the masonry stage, flexible connections are placed in the seams - these are thin metal perforated plates or T-shaped anchors. They are installed in every 3rd row.

Connecting the wall and partition using a T-shaped anchor

If a gas silicate partition is installed in a building where such connections are not provided, they can be fixed to the wall by bending them in the shape of the letter “L”, inserting one part into the seam.

When using anchors, the connection with the wall is rigid, which in this case is not very good: a rigid rod due to vibrations (wind, for example) can destroy the adjacent adhesive and the body of the block. As a result, the abutment strength will be zero. When using flexible connections, all these phenomena will not affect the blocks so much. As a result, the bond strength will be higher.

Flexible connections in the seams; if there are none, the plates are simply screwed onto self-tapping screws

To prevent the formation of cracks in the corners, between the wall and the partition, a damper joint is made. This can be thin polystyrene foam, mineral wool, a special damper tape that is used when laying heated floors, and other materials. To prevent moisture from leaking through these seams, after laying they are treated with a steam- impermeable sealant.

Openings in gas silicate partitions

Since the partitions are not load-bearing, the load will not be transferred to them. Therefore, there is no need to lay standard reinforced concrete beams over the doors or make a full-fledged lintel, as in load-bearing walls. For a standard doorway of 60-80 cm, you can lay two corners that will serve as a support for the overlying blocks. Another thing is that the corner should protrude 30-50 cm beyond the opening. If the opening is wider, a channel may be required.

In the photo, two metal corners (on the right) are used to strengthen the opening of a standard door; a channel is walled up in the opening on the left, for which grooves are selected in the blocks.

If the opening is not wide, and only two blocks are joined in it, it is advisable to select them so that the seam is almost in the middle of the opening. This will give you a more stable opening. Although, when laying on corners or channels, this is not the table: the load-bearing capacity is more than enough.

Doorways in aerated concrete partitions

To prevent the metal from bending while the glue dries, the openings are reinforced. In narrow openings, it is enough to nail boards; in wide openings, a supporting structure resting on the floor may be required (put a column of blocks under the middle of the opening).

Another option for how to strengthen a doorway in aerated concrete partitions is to make a reinforced tape from reinforcement and glue/mortar. A flat board is stuffed strictly horizontally into the opening, nailing it to the walls. Sidewalls are nailed/screwed to the sides to hold the solution.

The solution is placed on top of the board, and three bars of class A-III reinforcement with a diameter of 12 mm are placed in it. Partition blocks are placed on top, as usual, making sure that the seams move. The formwork is removed after 3-4 days, when the cement “sets.”

Opening in a partition made of blocks

Last row - adjacent to the ceiling

Since floor slabs can bend under load, the height of the partition is calculated so that it does not reach the floor by 20 mm. If necessary, the blocks of the upper row are sawn. The resulting compensation gap can be sealed with damping material: the same mineral wool cardboard, for example. With this option, sounds from the upper floor will be heard less. An easier option is to moisten the seam with water and fill it with polyurethane foam.

Cork covering

Improved sound insulation of aerated concrete blocks can be achieved by installing a cork covering. Soundproofing with cork is becoming more and more popular every day, and its advertising in construction stores is becoming more and more common. Cork is made from a natural material and is environmentally friendly; it does not emit foreign odors into the air of the room.

The material absorbs high-frequency sounds well. It may happen that you have noisy neighbors, then when covering oak with a layer of 1 cm with cork, you will not experience much of a difference before and after. The noise reduction will be about 18-20 dB (conversation is kept at a level of 45 dB, noise in offices is up to 60 dB).

Cork is supplied in sheets or rolls. Currently, the best producer of cork is Portugal. A new product in this area is cork spraying, applied with a spray gun and reaching a thickness of 3 cm.

For fastening, it is better to use quick-setting rubber glue, then you will not have to hold the slabs suspended for a long time. It is important to keep in mind that it is better to create several thin cork surfaces than one thick one.

Sound insulation of aerated concrete, aerated concrete walls and partitions

Modern society lives at a frantic pace. Therefore, a person experiences discomfort from the environmental situation, stress and noise. A number of innovative materials can solve the latter problem. Builders suggest using gas block. The sound insulation of the material is at the level. It will cope with airborne and structural noise. The indicator depends on the thickness of the layer and the brand of material.

Types of noise

Soundproofing of aerated concrete is suitable for urban environments. The following types of noise are distinguished:

- The air group includes the voices of people, nature or music. They are fought in city apartments and country houses.

- Structural noise occurs after an object falls, from footsteps or pops.

- When operating heavy equipment or machines, a shock sound is detected. It is also obtained during the operation of machinery and industrial equipment.

In a metropolitan apartment, a high level of sound insulation is observed between ordinary partitions. It is equal to Rw up to 60 dB. The value decreases if the wall connects the apartment with a common space - up to 50 dB. In one residential sector the value will be 41-45 dB.

The sound insulation index of aerated concrete is high. The material is environmentally friendly and can reliably protect against all types of noise.

There are three brands of aerated concrete on sale: D400, D500 and D600. The difference lies in thickness and soundproofing ability. From switching to another model, sound insulation increases by 2 dB. For example, the D500 is 3.6 cm thick. Its index is 48 dB. An important feature is the sound insulation of the gas block. The characteristics will allow you to create the most comfortable conditions in the room.

Soundproofing characteristics

The material has the necessary properties with low density and large volume. The gas block fully meets the requirements. Sound insulation is provided by the structure. The material is obtained through a chemical reaction between aluminum and lime. After the interaction, a cellular mass emerges, inside which contains a large number of bubbles. Thanks to this, it is possible to effectively resist the propagation of sound in the surface. Sound cannot penetrate into the room. It “dissolves” inside the finishing material.

The sound insulation properties of aerated concrete blocks are capable of absorbing waves from 43 to 44 dB. For ordinary rooms, 41 dB is considered normal. This implies a clear advantage of the material over traditional ones.

Experts also express sound insulation using sound absorption coefficient. It is informative only at a frequency of 1000 Hertz. For each material, the indicator is determined individually.

We increase the indicator

The sound insulation of aerated concrete partitions is increased by performing the following manipulations:

- Carrying out additional plastering.

- Use of special finishing tiles.

- Innovative designs consisting of several layers also help to get rid of unpleasant sound from the outside.

The sound insulation of aerated concrete blocks will increase by 3 dB if the surface is additionally covered with a layer of plaster. This option is used most often. You don’t need to spend a lot of money on it, and the work is done with your own hands. The method is also used in combination with other materials. For example, this increases the sound insulation of gas silicate blocks.

You can achieve a coefficient of 47 dB if you apply putty and plaster to the outer and inner parts.

The sound insulation of aerated concrete walls will be from 39 to 43 dB if the putty material is applied to both sides of the wall. The process will give a result that will also depend on the thickness of the spraying.

Aerated concrete partitions must be installed efficiently and correctly. Sound insulation is ensured at the maximum level after processing the seams. Analysis of external factors that can negatively affect the process is important.

The structural unit of thermal insulation of external walls made of aerated blocks is strengthened by various types of facing slabs. The main material is gypsum or acoustic mineral. Polystyrene foam is very popular. It's lightweight and cheap. For installation you do not need to have special skills in construction.

Polystyrene foam has many varieties. Among them, penoplex and expanded polystyrene are popular. The materials are safe for humans. Their main characteristics in work are ease and convenience. Thanks to them, it is possible to reduce the level of external noise to 36 dB.

Experts with extensive experience in construction recommend combining aerated concrete with various finishing materials. Thanks to this, it will be possible to obtain an additional attractive surface. Modern building materials are easy to install. The effect depends on the individual preferences of the owner

Even decorative material has sound absorption properties. Before choosing, pay attention to this characteristic, which is indicated on the packaging.

For additional sound insulation, mineral wool is placed between the slab and the finishing layer. Its thickness should not exceed 30 mm. Wooden beams or blocks are fixed at a short distance from the block. Professional builders also insist on installing a waterproofing layer. Thanks to this design, it will be possible to absorb another 5 to 10 dB of external noise. If you leave an air gap, you will be able to achieve an additional 20 dB.

Gas block is a popular material today. With its help, it is possible to provide the required level of sound insulation. They think about the criteria in advance, especially if the building is located in a noisy place. Thanks to this, it will be possible to create optimal conditions for relaxation for the whole family. They get used to the sound, but why do it if there is another possibility?

betonov.com