First, about the loads. According to table 3.3 SNiP 2.01.07-85*, the temporary load on the floor is considered to be 150 kg/m². That is, on each square meter of flooring it will be possible to place 150 kg of additional weight in addition to the constant loads. Constant loads include the weight of the floor itself with floor structures and the weight of interior partitions. Furniture, sanitary equipment and the weight of people are classified as temporary loads.

What load value should I choose for installing a wooden floor? The easiest way is to draw an analogy with something familiar. For example, our apartments use reinforced concrete floors with a load-bearing capacity of 400 to 800 kg/m². Recently, floor slabs with a load-bearing capacity of 800 kg/m² have been mainly used. Is it worth taking such a load into the calculation of a wooden floor? Probably not. As practice shows, the load on the floor most often does not exceed 350–400 kg/m². However, this does not exclude the possibility that when designing the floor to suit your specific needs, you will accept a different load value. In any case, it is better to take into account all possible loads in advance and design the floor with a small (no more than 40%) margin of safety, rather than having to strengthen it later, if necessary.

To select the sections of floor beams, the load calculated in kilograms per square meter must be converted into a load per linear meter of beam length. We can easily imagine, for example, a square sheet of iron with sides 1 m long. If we press on this sheet weighing 400 kg and place a wooden beam under its middle, then per meter of the length of this beam a force of 400 kg will be applied. It is obvious. And if we place two beams under the sheet and distribute them under the middles of the sheet halves, then per meter of beam length there will be a weight of 200 kg. This is also obvious. By placing three beams under the sheet and spreading them evenly, we get a load of 133 kg on each beam. Thus, by changing the number of beams located under one square meter, we can change the load pressing on them and thereby reduce the cross-section of the beams. Or, on the contrary, place one beam under two (three, four, etc.) square meters and increase its cross-section.

Floor beams are calculated not only for load-bearing capacity, but also for deflection. Living in a house in which the ceiling above your head has sagged, even if it was at least three times strong, is unpleasant. The standard deflection value of the beam should not exceed 1/250 of its length.

The load-bearing capacity of wood is known, the sections and lengths of beams are also no secret - they have been calculated thousands of times before us. Therefore, to determine the cross-section of beams for a known span (length from support to support), you can use the graph shown in Figure 37. When using the graph, you need to set the load and width of the beam and use them to determine its height for a given span of the beam. Or, knowing the span length of the beam and the dimensions of its section, determine what load it can withstand. By changing the installation pitch of the beams, achieve the required load value.

Rice. 37. Graph for determining the sections of wooden beams

The graph is intended for calculating single-span beams, i.e. beams lying on two supports. You can also use a calculator to calculate wooden beams. If two-span beams (on three supports) or beams of non-standard length are used, you can try

- Calculation of reinforced concrete monolithic floor slab

- First stage: determining the estimated length of the slab

- Determination of geometric parameters of reinforced concrete monolithic floors

- Existing types of loads that should be collected

- Determination of the maximum bending moment for a normal (transverse) section of a beam

- Some nuances

- Selection of reinforcement section

- Number of rods for reinforcing a monolithic reinforced concrete floor slab

- Collection of loads - some additional calculation

Calculation of reinforced concrete monolithic floor slab

Reinforced concrete monolithic floor slabs, despite the fact that there is a fairly large number of ready-made slabs, are still in demand. Especially if it is your own private house with a unique layout, in which absolutely all the rooms are of different sizes, or the construction process is carried out without the use of cranes.

Monolithic slabs are quite in demand, especially in the construction of country houses with individual designs.

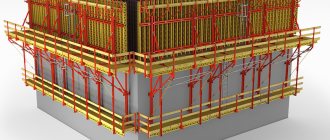

In such a case, the installation of a monolithic reinforced concrete floor slab makes it possible to significantly reduce the cost of funds for the purchase of all necessary materials, their delivery or installation. However, in this case, more time may be spent on preparatory work, including the installation of formwork. It is worth knowing that this is not what scares off people who are planning to concrete the floor.

Today it is not difficult to order reinforcement, concrete and make formwork. The problem is that not every person can determine what kind of reinforcement and concrete will be needed in order to carry out such work.

This material is not a guide to action, but is purely informational and contains only an example of calculation. All the subtleties of calculations of reinforced concrete structures are strictly standardized in SNiP 52-01-2003 “Reinforced concrete and concrete structures. Basic provisions”, as well as in the set of rules SP 52-1001-2003 “Reinforced concrete and concrete structures without prestressing reinforcement”.

A monolithic floor slab is a formwork reinforced over the entire area, which is filled with concrete.

Regarding all questions that may arise in the process of calculating reinforced concrete structures, you should refer to these documents. This material will contain an example of calculating a monolithic reinforced concrete floor in accordance with the recommendations contained in these rules and regulations.

An example of calculating a reinforced concrete slab and any building structure as a whole will consist of several stages. Their essence is the selection of geometric parameters of the normal (cross-section) section, reinforcement class and concrete class so that the slab that is being designed does not collapse under the influence of the maximum possible load.

An example calculation will be performed for a section that is perpendicular to the x axis. Local compression, shear forces, punching, torsion (limit states of group 1), crack opening and deformation calculations (limit states of group 2) will not be performed. It is worth assuming in advance that such calculations are not required for an ordinary flat floor slab in a residential private house. As a rule, this is actually the case.

You should limit yourself to only calculating the normal (cross-section) section for the action of a bending moment. Those people who do not need to give explanations regarding the determination of geometric parameters, the choice of design schemes, the collection of loads and design prerequisites can immediately go to the section that contains an example of a calculation.

Return to contents

Advantages of using a monolithic slab

A monolithic slab can be made of any shape.

The distance between the supporting elements (columns, beams, walls) does not matter when making a monolithic slab. The prefabricated frame is mounted taking into account the exact dimensions, for example, a shift in the foundation will lead to the failure of the reinforced concrete slab between the walls.

Advantages of monolithic sections:

- the weight of the floor is reduced due to a decrease in thickness, therefore the massiveness of the base changes;

- the production of horizontal fencing is transferred to the construction site, operations on sealing intermediate joints are reduced;

- The seamless structure of the horizontal membrane increases heat and sound insulation.

The concrete mixture is prepared independently, so it is possible to add modifiers or use lightweight filler (expanded clay, slag). They make complex structures in plan with a large number of turns and wavy lines, which is difficult to do with prefabricated elements, the main thing is to correctly calculate the floor slab.

First stage: determining the estimated length of the slab

The floor slab can be of absolutely any length, but the length of the beam span must be calculated separately.

The actual length can be absolutely any, but the calculated length, in other words, the span of the beam (in this case, the floor slab) is a completely different matter. The span is the clear distance between load-bearing walls. This is the length and width of the room from wall to wall, therefore, determining the span is quite simple. This distance should be measured with a tape measure or other available means. The actual length will be greater in all cases.

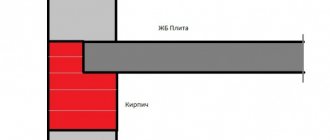

A reinforced concrete monolithic floor slab can be supported by load-bearing walls, which are made of brick, stone, cinder blocks, expanded clay concrete, foam or aerated concrete. In such a case, this is not very important, however, if the load-bearing walls are laid out from materials that have insufficient strength (aerated concrete, foam concrete, cinder block, expanded clay concrete), it will also be necessary to collect some additional loads.

This example contains a calculation for a single-span floor slab supported by 2 load-bearing walls. The calculation of a reinforced concrete slab that rests along the contour, that is, on 4 load-bearing walls, or for multi-span slabs will not be considered in this material.

In order for what was said above to be better understood, the calculated length of the slab should be taken as l = 4 m.

Return to contents

Determination of geometric parameters of reinforced concrete monolithic floors

The calculation of loads on the floor slab is considered separately for each specific construction case.

These parameters are not yet known, but it makes sense to set them in order to be able to make a calculation.

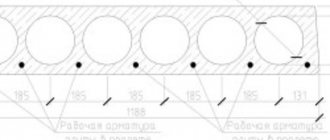

The height of the slab is given as h = 10 cm, the conditional width is b = 100 cm. Convention in such a case means that the concrete floor slab will be considered as a beam that has a height of 10 cm and a width of 100 cm. Consequently, the results that will be obtained , can be applied to all remaining centimeters of the slab width. That is, if you plan to produce a floor slab that has a design length of 4 m and a width of 6 m, for each of these 6 m it is necessary to apply the parameters defined for the design 1 m.

The concrete class will be B20, and the reinforcement class will be A400.

Next comes the definition of supports. Depending on the width of the walls, the material and weight of the load-bearing walls, the floor slab can be considered as a hingedly supported non-cantilever beam. This is the most common case.

Next, the load on the slab is collected. They can be very diverse. If you look from the point of view of structural mechanics, everything that will lie motionless on the beam, glued, nailed or suspended on the floor slab is a statistical and quite often constant load. Everything that crawls, walks, drives, runs and falls on the beam are dynamic loads. Such loads are most often temporary. However, in the example under consideration, no difference will be made between permanent and temporary loads.

Return to contents

What load can the floor slab withstand?

Contents: [hide]

During construction, it is very important to correctly calculate what load the floor slab can withstand. The fact is that it is precisely this that ensures the rigidity of the structure, so in this case we are talking, first of all, about the safety of the entire construction and the people carrying it out.

Floors consist of upper, lower and structural parts. The latter transfers its weight to the supports. Thus, a factor such as calculating the permissible load is very important.

As for the lower part of the ceiling, it is made of plaster, tile materials or various types of cladding. The upper part consists of floor structures and leveling screeds. They provide sound insulation and thermal insulation. Monolithic and prefabricated slabs are used to assemble the structural part of the floor. Basically, such slabs are made of reinforced concrete, however, in addition, prestressed concrete can be used, and the use of ceramic liners is acceptable.

You can make a monolithic ceiling with your own hands.

Calculations for any building structures are made, first of all, to ensure that the structures do not subsequently collapse. If the calculation turns out to be incorrect, then very soon cracks will creep along the walls. And there is no need to explain how this may end in the very near future.

Loads on the slab are calculated in two categories: dynamic and static. The latter includes all those objects that lie, hang or are nailed to the slab. And those objects that can run, fall and jump #8211 are already dynamic loads.

In order to calculate everything accurately, you will need:

- calculator

- long ruler

- building level

- roulette.

Considering the fact that dynamic loads can be distributed evenly and unevenly, they are not taken into account for an ordinary residential building.

Main Factors

Slab parameters: L #8211 length B #8211 width H #8211 height.

When it comes to calculating loads on a hollow-core floor slab. then everything depends on its size. On average, it can withstand from 800 to 1450 kg per square cm. A standard hollow-core slab has a thickness of 200 mm, but it should be taken into account that there are slabs 150 mm thick. In addition, it must be taken into account that such slabs are quite fragile and it is not worth conducting experiments to see how much weight they can withstand.

When making calculations, it is necessary to take into account the approximate weight of furniture and other items that are in the apartment, as well as the weight of the people living in it. It should be noted that each slab manufacturer defines the load differently; there are some nuances here. On average, it ranges from 400 to 700 kg per square meter.

Laying floor slabs: 1 #8211 slab, 2 #8211 box with mortar, 3 #8211 shovel, 4 #8211 tool box, 5 #8211 crowbar

In order to find out with maximum accuracy what load the floors can withstand, the following data must be taken into account. If we are talking about a standard residential building, then the load will be as follows: from people, that is, useful, #8211 will be 200 kg per square m, from partitions #8211 150 kg per 1 square m, from the floor #8211 100-150 kg per one square m. It is not difficult to calculate that on average the following pressure will be exerted on the slabs #8211 500 kg per square m.

However, the above calculations are purely average, since all calculations must be made separately in each specific case. So, before calculating what load the floor slabs will withstand, you need to take into account such a factor as all the characteristics of the slabs, which are usually indicated when purchasing. It is not recommended to exceed the limit, since in this case everything can end very badly, deformation will occur, and it is possible that the ceiling will finally break.

Additional data

When calculating floors, you need to determine the class of concrete and reinforcement.

However, if you know all the technical characteristics of the ceiling and at least the approximate weight that will load them, then making calculations does not seem to be a very difficult task. It should be taken into account that there are several load classifications.

So, the first type depends on the duration of the load. That is, we must proceed from the fact that they can be permanent and temporary. Constants include: the weight of furniture, people, household appliances and other items that are constantly in the apartment. This should also include the weight of the supporting structure, soil and rock pressure. As for temporary loads, these include those that arise during the construction of a building, storage and transportation of various structures.

There are also special loads that involve seismic or explosive effects, as well as a changed soil structure. Short-term ones include #8211 from equipment, when a house is being built, as well as ice and wind (that is, climatic). When calculating the maximum load, long-term loads must be taken into account, these include the following:

Freezing of water in the internal cavities of the floor slab: 1 - ice formation 2 - cracks 3 - reinforced concrete stiffening belt 4 - half-brick wall 5 - concrete screed 6 #8211 floor covering.

- weight of temporary partitions in the house

- the weight of equipment that is intended for stationary operation (this includes conveyors, apparatus, solid and liquid bodies that are part of such equipment)

- pressure of solids, liquids and gases in pipelines

- the weight of racking equipment located in warehouses, granaries, refrigerators and other premises

- weight of deposited dust (this is also an important factor, many do not take this into account, which is completely unacceptable)

- various precipitation: snow, rain, hail (must be taken into account when calculating floor slabs).

Useful tips

To increase the load-bearing capacity of the floor, reinforcement is used.

When calculating the load on slabs of various production equipment, it is necessary to take into account what the standard load is (here it is worth taking into account, among other things, the weight of the pipelines). If we are talking about non-standard equipment, then you should be guided by the passport data from the manufacturing plants of such equipment. When making calculations, it is necessary to take into account the weight of conveyors, insulation, and devices. In most cases, the manufacturer indicates how much load the floor slab can withstand.

During construction, it is necessary to take into account the fact that the floor slab cannot be overloaded; it will only support the weight that was obtained in the calculations. There are builders who neglect the results of such calculations, loading the slab beyond the norm. As a result of this, unpleasant and often tragic incidents occur, so the saying #8220 Measure twice, cut once #8221 in this regard could not be more relevant.

Existing types of loads that should be collected

Load collection focuses on the fact that a load can be uniformly distributed, concentrated, unevenly distributed, and others. However, there is no point in going so deeply into all the existing options for combining the load that is being collected. In this example, there will be a uniformly distributed load, because a similar loading case for floor slabs in private residential buildings is the most common.

The concentrated load must be measured in kgf (kgf) or Newtons. The distributed load is in kgf/m.

Loads on the floor slab can be very different, concentrated, evenly distributed, unevenly distributed, etc.

Return to contents

How long can a floor slab withstand?

You should not install too massive plumbing fixtures or other items in old houses that will make the structure heavier. In addition, static loads can accumulate over time, which in turn can lead to deflections and sagging of floor slabs. To avoid mistakes in measurements, it is recommended to invite a specialist to carry out detailed calculations. Calculations must comply with established standards (SNiP).

Did you like the article? Share with your friends:

Some nuances

There is a note on the values in the table, an example of which is contained in the material. If the collection of loads for calculation is not carried out by professional designers, it is recommended to underestimate the values of the compressed zone ER by approximately 1.5 times.

Further calculations will be made taking into account a = 2 cm, where a is the distance from the bottom of the beam to the center of the cross-section of the reinforcement.

When E is less/equal to ER and there is no reinforcement in the compressed zone, the concrete strength should be checked according to the following formula:

B

The physical meaning of this formula is simple. Any moment can be represented as an acting force with a certain leverage; therefore, for concrete, the above condition will need to be observed.

Checking the strength of rectangular sections with single reinforcement, taking into account E less than/equal to ER, is carried out according to the formula: M

The essence of this formula is as follows: according to calculations, the reinforcement must withstand the same load as the concrete, because the same force with the same leverage will act on the reinforcement as on the concrete.

Floor slabs with different load-bearing capacities, from 400 kg/m2 to 2300 kg/m2.

A note on this. Such a calculation scheme, which assumes the leverage of the force (h0 – 0.5y), makes it possible to quite easily and simply determine the main parameters of the cross section according to the formulas that will be given below. However, it is worth understanding that such a calculation scheme is not the only one.

The calculation can be made relative to the center of gravity of the section that has been given. Unlike metal and wooden beams, it is somewhat difficult to calculate reinforced concrete based on the ultimate tensile or compressive stresses that arise in the normal (transverse) section of a reinforced concrete beam.

Reinforced concrete is a composite and very heterogeneous material. However, that's not all. Numerous experimental data report that tensile strength, yield strength, elastic modulus, and various other mechanical properties have somewhat significant scatter. For example, when determining the compressive strength of concrete, the same results will not be obtained even when the samples are made from a mixture of concrete from the same batch.

This is due to the fact that the strength of concrete will depend on a large number of different factors: the quality (including the degree of contamination) and size of the aggregate, the method of compacting the mixture, the activity of cement, various technological factors, and so on. Paying attention to the random nature of these factors, it is natural to consider the concrete strength limit to be a random variable.

The height of the compressed zone of concrete in the absence of reinforcement in it can be determined by the following formula:

y = Rs*As / Rb*b.

In order to determine the cross-section of the reinforcement, it is first necessary to determine the coefficient am:

am = M / Rb*b*h0^2.

Reinforcement in the compressed zone is not required at am

If there is no reinforcement in the compressed zone, the cross-section of the reinforcement must be determined according to the following formula:

As = Rb * b * h0 (1 – square root (1 – 2am)) * l * Rs.

DBN V.1.2-2:2006 “Loads and impacts” says sparingly about the collection of loads from partitions:

Let's figure out how to more efficiently collect the load from partitions for various situations.

What is characteristic load? This is a standard load without any coefficients, i.e. actual weight of the partitions. This actual weight is essentially distributed over a very narrow area (since the thickness of the partition usually does not exceed 150 mm), and it is most plausible to take the load from the partition as linear. What does it mean?

Example 1. There is a brick partition 2.5 m high, 0.12 m thick, 3 m long, its volumetric weight is 1.8 t/m 3.

It is plastered on both sides, each layer of plaster has a thickness of 0.02 m, the volumetric weight of the plaster is 1.6 t/m 3. It is necessary to find the standard (characteristic) load from the partition to calculate the floor slab.

Let's find the weight of 1 m2 of partition:

(1.8∙0.12 + 1.6∙2∙0.02)∙1 = 0.28 t/m2 (here 1 is the area of the partition).

Knowing the height of the partition, we determine how much a linear meter of the partition will weigh:

0.28∙2.5 = 0.7 t/m.

Thus, we received a linear linear load of 0.7 t/m, which will act on the floor slab under the entire partition (each meter of the partition weighs 0.7 t/m). The total weight of the partition will be equal to 0.7∙3 = 2.1 tons, but such a value is not always needed for calculation.

Now let’s consider in what situations the load from partitions should be left in the form of a linear load, and when it should be transferred to loads uniformly distributed over the area, as recommended in paragraph 6.6 of the DBN “Loads and Impacts”.

Let me make a reservation right away: if you are considering the ceiling in a software package that allows you to easily set partitions or the linear load from them, you should take advantage of this opportunity and make a calculation that is closest to life - one where all the loads from the partitions are located in the form of linearly distributed ones, each on its own place.

If you count manually or for some reason want to simplify the program calculation (suddenly, the computer does not pull such an abundance of partitions), you should analyze how to do it and whether to do it.

How to collect the load from partitions to calculate a monolithic slab

Let's consider options with a monolithic ceiling. Let's say we have a fragment of a monolithic floor, onto which we need to collect the load from the partitions, turning it into a uniformly distributed one.

What is needed for this? First, as in example 1, you need to determine the load from 1 linear meter of the partition, as well as the total length of the partitions.

Let's say our linear load is 0.3 t/m (aerated concrete partitions), and the total length of all partitions is 76 m. The area of the floor area is 143 m 2.

The first thing we can do is spread the load from all the partitions over the available floor area (by finding the weight of all the partitions and dividing it by the area of the slab):

0.3∙76/143 = 0.16 t/m2.

It would seem that you can leave it like that, and apply a load to the entire floor and make a calculation. But let's take a closer look, we have areas of overlap with different intensity of congestion. Somewhere there are no partitions at all, but somewhere (in the area of ventilation ducts) there are especially many of them. Is it fair to leave the same load throughout the entire floor? No. Let's divide the slab into sections with approximately the same load of partitions.

In the yellow area there are no partitions at all; it would be fair if the load on this area is equal to 0 t/m2.

In the green area, the total length of the partitions is 15.3 m. The area of the area is 12 m2 (note, it is better to take the area not strictly along the partitions, but by retreating from them somewhere by the thickness of the ceiling, since the load on the slab is not transferred strictly vertically , and expands at an angle of 45 degrees). Then the load in this area will be equal to:

0.3∙15.3/12 = 0.38 t/m2.

On the pink site, the total length of the partitions is 38.5 m, and the area of the site is 58 m 2. The load in this area is equal to:

0.3∙38.5/58 = 0.2 t/m2.

In each blue section, the total length of the partitions is 11.1 m, and the area of each blue section is 5 m 2. The load in the blue areas is:

0.3∙11.1/5 = 0.67 t/m2.

As a result, we have the following load picture (look at the figure below):

Do you see how the loads differ significantly in these areas? Naturally, if you make a calculation for the first (the same for the entire slab) and the second (refined) loading option, then the reinforcement will be different.

We conclude: you always need to carefully analyze which part of the slab to load with a uniform load from the partitions so that the calculation result is plausible.

If you are collecting the load from partitions on a floor resting on walls on four sides, then you should be guided by the following principle:

Advantages and disadvantages of cavity slabs

Hollow slabs are popular due to their range of advantages:

- light weight. With equal sizes, they have high strength and successfully compete with solid panels, which have a lot of weight, accordingly increasing the impact on the walls and foundation of the building;

- reduced price. Compared to solid analogues, the manufacture of hollow products requires a reduced amount of concrete solution, which allows for a reduction in the estimated cost of construction work;

- ability to absorb noise and insulate the room. This is achieved due to design features associated with the presence of longitudinal channels in the concrete mass;

- increased quality of industrially manufactured products. The design features, dimensions and weight do not allow handicraft production of panels;

- possibilities for accelerated installation. Installation is much faster than constructing a solid reinforced concrete structure;

- variety of dimensions. This allows the use of standardized products for the construction of complex floors.

Product benefits also include:

- the ability to use the internal space for laying various utility networks;

- increased safety margin for products manufactured at specialized enterprises;

- resistance to vibration, temperature changes and high humidity;

- possibility of use in areas with seismic activity increased to 9 points;

- smooth surface, which reduces the labor intensity of finishing activities.

The products are not subject to shrinkage, have minimal dimensional deviations and are resistant to corrosion.

There are also disadvantages:

- the need to use lifting equipment to perform installation work. This increases the overall cost and also requires a free site to install the crane;

- the need to perform strength calculations. It is important to correctly calculate the values of static and dynamic loads. Massive concrete coverings should not be installed on the walls of old buildings.

To install the ceiling, it is necessary to form an armored belt along the upper level of the walls.

Calculation of the load on the floor slab

It is easy to determine by calculation what load the floor slabs can withstand. To do this you need:

- draw a spatial diagram of the building;

- calculate the weight acting on the supporting base;

- calculate the loads by dividing the total force by the number of slabs.

When determining the mass, it is necessary to sum up the weight of the screed, partitions, insulation, as well as the furniture in the room.

Let's consider the calculation method using the example of a panel with the designation PK 60.15-8, which weighs 2.85 tons:

- Let's calculate the load-bearing area - 6x15=9 m2.

- Let's calculate the load per unit area - 2.85:9 = 0.316 tons.

- Let us subtract the dead weight from the standard value 0.8-0.316 = 0.484 t.

- Let's calculate the weight of furniture, screeds, floors and partitions per unit area - 0.3 tons.

- A comparable result with the calculated value 0.484-0.3=0.184 t.

Hollow-core floor slab PC 60.15-8

The resulting difference, equal to 184 kg, confirms the presence of a safety margin.

Floor slab - load per m2

The calculation method allows you to determine the load capacity of the product.

Let's consider the calculation algorithm using the example of a PC 23.15-8 panel weighing 1.18 tons:

- Let's calculate the area by multiplying the length by the width - 2.3x1.5 = 3.45 m2.

- Let's determine the maximum loading capacity - 3.45x0.8=2.76t.

- Let's subtract the mass of the product - 2.76-1.18 = 1.58 tons.

- Let's calculate the weight of the coating and screed, which will be, for example, 0.2 t per 1 m 2.

- Let's calculate the load on the surface from the weight of the floor - 3.45 x 0.2 = 0.69 tons.

- Let's determine the safety factor - 1.58-0.69 = 0.89 t.

The actual load per square meter is determined by dividing the resulting value by the area of 890 kg: 3.45 m2 = 257 kg. This is less than the calculated figure of 800 kg/m2.

How to collect loads from partitions to calculate columns and foundations

Now, using the same example, let’s look at how to collect the load from partitions to calculate columns and walls or foundations underneath them. Of course, if you do a floor calculation, then as a result of this calculation you will get reactions on the supports, which will be the loads on the columns and walls. But if for some reason you don’t consider the ceiling, but you just need to collect the load from the partitions, then what should you do?

Here you need to start not with analyzing the workload of parts of the slab. The first step in this case is to divide the slab into load areas for each column and wall.

The picture shows how to do this. The distance between the columns is divided in half and horizontal lines are drawn. In the same way, horizontal lines are drawn exactly in the middle between the columns and between the columns and the lower wall. As a result, in the area of the columns the slab is divided into squares. All partitions that fall into the square of a particular column load that particular column. And the wall bears the load from a strip whose width is equal to half the span. All that remains is to calculate the total length of these partitions in each section where there are partitions and transfer their entire weight to the column.

Example 2. Collect the standard (characteristic) load from the partitions on the pink column and on the wall from the figure above.

The weight of one linear meter of the partition is 0.35 kg. The total length of the partitions in the square of the pink column is 5.4 m (of these 5.4 m, one partition 1.4 m long is located exactly on the border between the two columns, and 4 m is in the load collection square). The total length of the partitions on the load collection strip for the wall is 18 m, the length of the wall is 15.4 m.

Let's collect the load on the column:

0.35∙4 + 0.35∙1.4/2 = 1.65 t.

Here we took the entire load from four meters of walls and half the load from a 1.4 m long wall (the second half will go to another column).

The column will also experience a bending moment from the weight of the partitions (if the ceiling is supported rigidly), but without calculating the slab it is difficult to determine the moment.

Let's collect the load on the wall. The load is collected on 1 linear meter of wall. Since the partitions are located quite evenly, the total weight of all partitions is found and divided by the length of the wall:

0.35∙18/15.4 = 0.41 t/m.

How to collect loads from partitions to calculate (or check) a precast slab

Since prefabricated slabs have a clear configuration and support pattern (usually on two sides), the approach to collecting loads from partitions must be special. Let's look at options for collecting loads using examples.

Example 3. The partition runs across the slab.

The thickness of the partition is 0.12 m, height 3 m, volumetric weight 1.8 t/m 3 ; two layers of plaster, each 0.02 m thick, with a volumetric weight of 1.6 t/m3. The width of the slab is 1.2 m.

Since the slab is considered as a beam on two supports, the load from the partition should be taken concentrated - in the form of a vertical force applied to the “beam” at the point where the partition is supported. The magnitude of the concentrated force is equal to the weight of the entire partition:

0.12∙3∙1.2∙1.8 + 2∙0.02∙3∙1.2∙1.6 = 1.0 t.

Example 4: A partition runs along a precast slab.

In this case, regardless of where the partition is located - in the middle or at the edge of the slab, the load from it is taken to be evenly distributed along the slab. This load is collected per 1 linear meter of the slab.

The thickness of the partition is 0.1 m, height 2.5 m, volumetric weight 0.25 t/m 3.

Let us determine the uniformly distributed load of 1 linear meter of the slab:

0.1∙2.5∙1∙0.25 = 0.06 t/m.

Example 5. Partitions are located above part of the slab.

When a slab is crossed by several partitions, we have two options:

1) classify the load from the longitudinal partitions as uniformly distributed, and the load from the transverse partitions as concentrated;

2) make the entire load evenly distributed, “spreading” it over the area of the slab with partitions.

The thickness of the partition is 0.1 m, height 2.5 m, volumetric weight 0.25 t/m 3. The width of the slab is 1.5 m, the length of the longitudinal partition is 3 m, the length of the two shortest partitions is 0.7 m.

Let's determine the load on the slab according to option 1.

0.1∙2.5∙1∙0.25 = 0.06 t/m.

The concentrated load from the rightmost partition is:

0.1∙2.5∙1.5∙0.25 = 0.1 t.

The concentrated load from each of the two short partitions is:

0.1∙2.5∙0.7∙0.25 = 0.044 t.

Let's determine the load on the slab according to option 2.

Let's find the total weight of all partitions:

0.1∙2.5∙0.25∙(3 + 1.5 + 0.7∙2) = 0.37 t.

Let's find the length of the partition on which the load acts:

3 + 0.1 = 3.1 m.

Let us find the value of the uniformly distributed load on a section of 3.1 m.

- Types and advantages of this product

- Materials and structural findings

- Various types of loads

- Marking of reinforced concrete products

- Calculation of maximum permissible loads

- Method for converting loads per square m

- Loads during renovation of old apartments

Who doesn’t dream of owning a house in the village or renovating an apartment in the city on a grand scale? Anyone involved in private construction or renovation should think about how much the floor slab can withstand. How much load, useful or decorative, will it bear without bending? To answer all these questions, you must first understand the design of the slabs and their markings.

Before constructing a multi-story building, it is necessary to calculate how much the floor slab can withstand.

Types and advantages of this product

Floor slabs, manufactured in factories in compliance with temperature conditions and hardening time, are of high quality. Today they are produced in two modifications: solid and hollow.

Solid slabs, which not only have a lot of weight, but also a lot of cost, are used only in the construction of especially important objects. For residential buildings, hollow core slabs are traditionally used. Their advantages include lighter weight and lower price, combined with a high level of reliability.

It should be noted that the number of voids is calculated so as not to disrupt the load-bearing properties. Voids also play an important role in providing sound and thermal insulation of a structure.

The dimensions of the slabs range in length from 1.18 to 9.7 m, in width - from 0.99 to 3.5 m. But most often in construction, products with a length of 6 m and a width of 1.2-1.5 m are used. This a favorite format for the construction of not only high-rise buildings, but also private cottages. To install them, an assembly crane with a capacity of no more than 3-5 tons is required.

Return to contents

What load can a floor slab usually withstand?

- Main characteristics

- How to calculate the load correctly

- Point load calculation

- Some additional information

- Some useful tips

The finishing material is selected based on the load the floor slab can withstand. This indicator will influence the arrangement of the roof of the building. Basically, when any building or object is constructed, the rigidity of the frame and its stability are first of all observed. All these characteristics directly depend on the strength of the floor being created.

Types of slabs and floor design.

Main characteristics

Installing a floor slab on a load-bearing roof structure allows for the construction of multi-story buildings. In order to correctly complete a building project, you need to know exactly what pressure the selected floor slab will withstand. It is necessary to have a good understanding of the variety of slabs.

Drawing of a hollow core slab.

Before starting the construction of a multi-story building, it is necessary to calculate the load. The selection of the building design will depend on the future weight, and the load depends on what type of slab should be installed.

The production produces two types of slabs:

- full-bodied

- empty.

Solid systems are heavy and very expensive. This design is used in the construction of serious objects that are considered socially significant.

In the construction of residential buildings, hollow core slabs are mainly used. It must be said that the main technical parameters of such a slab meet all standards for residential construction:

The plate is distinguished by:

- high reliability

- light weight.

The most important advantage of these products is their low cost. This made it possible to use such a system much more often when compared with others.

To calculate the overlap, the location of the voids is taken into account. They are located in such a way that the load-bearing characteristics of the product are not impaired. Voids also affect the sound insulation of the room and its thermal insulation properties.

The plate is made in a variety of sizes. Its length can reach a maximum of 9.7 m with a maximum width #8211 of 3.5 m.

Calculation of punching of interfloor slabs.

When constructing buildings, structures with dimensions of 6 x 1.5 m are most often used. This size is considered standard and the most popular. This system is used for the construction of:

- high-rise buildings

- high-rise buildings

- cottages.

Since the weight of these slabs is not very high, they are easy to install, for which a five-ton crane is used.

How to calculate the load correctly

The construction of any house cannot be done without correctly calculating the load that the floor slab can support. The rigidity of the entire building depends on it. Therefore, these calculations #8211 are the key to safe construction, this is a guarantee of the safety of people’s lives.

In each house, the floors have two structural parts:

Floor load diagram.

The upper part transfers the load to the lower structure. Therefore, it is very important to accurately calculate the permissible value.

Basically, the calculation of any building structure is simply necessary so that the building does not subsequently collapse. If the calculation is incorrect, the walls will begin to crack very quickly. The building will quickly collapse.

The calculation of the slab load is done in two categories:

- dynamic

- static.

Static calculation takes into account all objects that load the slab. All moving objects carry dynamic magnitude.

To perform the calculation, you must have:

- calculator

- roulette

- level.

The size of the slab determines its resistance to various loads.

To determine the load that the future floor slab can withstand, a detailed drawing is first made. The area of the house and everything that can create a load are taken into account. These elements include:

- partitions

- insulation

- cement screeds

- flooring.

The main support system of the roof is located at the ends of the slab. When slabs are made, the reinforcement is positioned so that the maximum load falls on the ends.

The center of the slab should not take the load; it is not included when calculating the structure.

Standard, design loads and reliability coefficient.

Therefore, the middle of the structure will not hold up, even if it is reinforced with main walls.

To understand how the calculation is done, let’s take as an example a design like “PK-50-15-8”. According to GOST 9561-91, the mass of this system is 2850 kg.

- First, the area of the entire load-bearing surface is calculated: 5 m × 1.5 m = 7.5 sq.m.

- Then the weight that the stove can hold is calculated: 7.5 square meters. m × 800 kg/sq.cm = 6000 kg.

- After this, the mass is determined: 6000 kg #8211 2850 kg = 3150 kg.

At the last step, it is calculated how much of the load will remain after insulation, screed laying and floor covering. Professionals try to choose flooring so that it and the screed do not exceed 150 kg/sq.cm.

Then 7.5 sq. m is multiplied by the value of 150 kg/sq.cm, the result is 1125 kg. From the mass of the slab equal to 3150 kg, 1125 kg is subtracted, resulting in 3000 kg. Thus, 1 sq. m can withstand 300 kg/sq. cm.

Return to contents

Point load calculation

This parameter must be performed very competently and prudently. If the load falls on one point, this will greatly affect the service life of the floor.

Construction reference books give the formula:

800 kg/sq.cm × 2 = 1600 kg.

Therefore, one individual point can support 1600 kg.

However, for a more accurate calculation, it is necessary to take into account the reliability coefficient. Its value for a residential building is taken to be 1.3. As a result:

800 kg/sq.cm × 1.3 = 1040 kg.

But, even with this safe size, it is advisable to place the point load next to the supporting structure.

Return to contents

Some additional information

Characteristics of reinforced concrete floor slabs

Of course, if all the technical parameters of the floor are known, the approximate mass, which will be the main load, is quite easy to perform the necessary calculations. In this case, it is necessary to take into account the existence of several types of loads.

First of all, this is the duration of the load. It can exist in the form:

- constant

- temporal.

Temporary loads are understood as those that appear during the construction of a wide variety of structures.

Special loads include seismic effects and possible changes in soil properties.

Short-term loads arise from equipment used in the construction of a building under atmospheric influence. When calculating the heaviest load, it is necessary to take into account long-term loads. They make up a large group, they include:

- water freezing

- appearance of ice

- occurrence of cracks

- hardness line

- brick wall:

- cement screed

- floor covering

- mass of partitions

- a lot of equipment for performing stationary work, these can be conveyor units, various devices, solid or liquid bodies

- weight of racks located in a warehouse or other premises

- the mass of accumulated dust, this factor is often ignored, but it must be taken into account, it is also excess weight

- precipitation.

Materials and structural findings

The weight that a floor slab can withstand directly depends on the brand of cement from which it is made.

Floor slabs are made of concrete based on M300 or M400 cement. Marking in construction is not just letters and numbers. This is encoded information. For example, M400 cement can withstand loads of up to 400 kg per 1 cubic cm per second.

But the concepts “able to withstand” and “will always withstand” should not be confused. These same 400 kg/cm3/sec are the load that a product made of M400 cement will withstand for some time, and not constantly.

M300 cement is a mixture based on M400. Products made from it can withstand smaller simultaneous loads, but they are more plastic and can withstand deflections without breaking.

Reinforcement gives concrete high load-bearing capacity. The hollow core slab is reinforced with stainless steel of class AIII or AIV. This steel has high anti-corrosion properties and resistance to temperature changes from – 40˚ to + 50˚, which is very important for our country.

In the production of modern reinforced concrete products, tensile reinforcement is used. Part of the reinforcement is pre-tensioned in the mold, then a reinforcing mesh is installed, which transfers the stress from the tensioned elements to the entire body of the hollow core slab. After this, concrete is poured into the mold. As soon as it hardens and acquires the required strength, the tension elements are cut off.

Such reinforcement allows reinforced concrete slabs to withstand heavy loads without sagging or bending. At the ends that rest on load-bearing walls, double reinforcement is used. Thanks to this, the ends do not “sink” under their own weight and can easily withstand the load from the upper load-bearing walls.

Return to contents

Various types of loads

Any overlap consists of three parts:

- the upper part, which includes the flooring, screeds and insulation, if there is a residential floor on top;

- the lower part, consisting of ceiling finishing and hanging elements, if there is also a living space below;

- the structural part that holds it all in the air.

Floor slabs weigh a lot, so they need to be installed only with the help of a crane.

The floor slab is a structural part. The upper and lower parts, that is, the finishing of the floor and ceiling, creates a load that is called constant static. This load includes all elements suspended from the ceiling - suspended ceilings, chandeliers, punching bags, swings. This also includes what will be placed on the ceiling - partitions, columns, bathtubs and Jacuzzis.

There is also the so-called dynamic load, that is, the load from objects moving across the floor. These are not only people, but also their pets, because today some people acquire exotic pets, for example, boars, lynxes or even deer. Therefore, the issue of dynamic loading is more important than ever.

In addition, loads can be distributed and point. For example, if you hang a 200 kg punching bag from the ceiling, then this will be a point load. And if you mount a suspended ceiling, the frame of which is attached to the ceiling with hangers every 50 cm, then this is already a distributed load.

When calculating point and distributed loads, more complex cases are also encountered. For example, when installing a bathtub with a capacity of 500 liters, you need to take into account not only the distributed load that the weight of the filled bathtub will create over the entire support area (that is, the area between the legs of the bathtub), but also the point load that each leg will create on the floor.

Return to contents

Marking of reinforced concrete products

Cut floor slabs have the same load resistance as regular ones.

What do these 333 kg mean? Since the weight of the slab itself and the flooring has already been subtracted, 333 kg per 1 sq.m is the payload that can be placed on it. According to SNiP from 1962, not less than 150 kg/sq. m of these 333 kg/sq.m should be allocated for future introduced loads: static (furniture and household appliances), and dynamic (people, their pets).

The remaining 183 kg/sq.m can be used to install partitions or any decorative elements. If the weight of the partitions exceeds the calculated value, you should choose a lighter floor covering.

Maximum load on hollow core slabs

Many people, when building a house, do not pay due attention to such a question as “how long will the floor slab withstand.” Although, even at the design stage, it is necessary to approximately calculate the static load that the slab will have to withstand. Of course, all calculations must be made “with a margin” in order to eliminate the possibility of collapse or cracking of the floors.

With rare (and expensive) exceptions, modern hollow-core floor slabs can withstand a load of 800 kg/sq.m. This value, by the way, is shown in the labeling of the plate. For example, PK-24-10-8 or PK-41-12-8. The last figure means the weight in centners per 1 sq.m. surface that the slab can support. And, although this figure is indicated with a margin, it is highly not recommended to exceed this value. After all, it is impossible to take into account all the dynamic loads to which the slab will be subjected.

It is extremely important to remember that serious weights should not be placed in the middle of the slab, only along the edges. Even if you place a support column under the slab, the slab will inevitably crack.

When calculating the mass that the floor will bear, it is necessary to take into account the weight of all partitions, the mass of the screed and floor covering, as well as the mass of the slab itself. Let us make an indicative approximate calculation using the example of one of the most popular hollow-core floor slabs - PK-60-12-8.

The mass of such a plate is 2150 kg. The load-bearing area of the slab, according to its dimensions, is 6m x 1.2m = 7.2 sq.m. Based on this, the maximum load on the slab should not exceed 7.2 sq.m. x 800kg/sq.m. = 5760 kg. In this case, the payload is obtained by subtracting the mass of the slab itself from the resulting number: Mp.n. = 5760kg – 2150kg = 3610kg.

Without going into details, we will assume that the cement screed and floor covering will have a specific gravity of 150 kg/sq.m. This means, taking into account the area of the slab, this will load it by 150 kg/sq.m. x 7.2 sq.m.