GOST 31310-2015

INTERSTATE STANDARD

THREE-LAYER REINFORCED CONCRETE WALL PANELS WITH EFFICIENT INSULATION

General technical conditions

Wall three-layer reinforced concrete panels with energy-efficient insulation. General specifications

MKS 91.080.10

Date of introduction 2017-01-01

Preface

The goals, basic principles and basic procedure for carrying out work on interstate standardization are established by GOST 1.0-92 “Interstate standardization system. Basic provisions" and GOST 1.2-2009 "Interstate standardization system. Interstate standards, rules and recommendations for interstate standardization. Rules for the development, adoption, application, updating and otsNIIEP housing - Institute of integrated design of residential and public buildings" (JSC "TSNIIEP housing")

2 INTRODUCED by the Technical Committee for Standardization TC 465 “Construction”

3 ADOPTED by the Interstate Council for Standardization, Metrology and Certification (protocol dated December 10, 2020 N 48)

The following voted for adoption:

| Short name of the country according to MK (ISO 3166) 004-97 | Country code according to MK (ISO 3166) 004-97 | Abbreviated name of the national standardization body |

| Kazakhstan | KZ | Gosstandart of the Republic of Kazakhstan |

| Kyrgyzstan | KG | Kyrgyzstandard |

| Russia | RU | Rosstandart |

| Tajikistan | T.J. | Tajikstandard |

4 By Order of the Federal Agency for Technical Regulation and Metrology dated March 17, 2020 N 166-st, the interstate standard GOST 31310-2015 was put into effect as a national standard of the Russian Federation on January 1, 2020.

5 REPLACE 31310-2005* ________________ * Probably an error in the original. Should read: GOST 31310-2005. — Note from the database manufacturer.

Information about changes to this standard is published in the annual information index “National Standards”, and the text of changes and amendments is published in the monthly information index “National Standards”. In case of revision (replacement) or cancellation of this standard, the corresponding notice will be published in the monthly information index “National Standards”. Relevant information, notifications and texts are also posted in the public information system - on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet

1 area of use

This standard establishes the classification, types, basic parameters of three-layer wall panels, general technical requirements for them, general rules for their acceptance, control methods, transportation and storage rules.

This standard applies to three-layer concrete and reinforced concrete panels with effective insulation (hereinafter referred to as panels) intended for external walls of residential, public and industrial buildings.

The requirements of this standard do not apply to:

- on composite panels;

— wall panels for rooms with wet conditions;

— filling window and door openings in panels.

Panels intended for operation in conditions of exposure to aggressive environments must meet the requirements of this standard and additional instructions in the design documentation established taking into account current regulatory documents and technical documentation*.

_______________

* In the Russian Federation, SP 50.13330.2012 “SNiP 23-02-2003 Thermal protection of buildings” is in force.

The requirements of this standard should be taken into account when developing regulatory documents and working documentation for specific types of panels.

Classification of wall slabs

There are different divisions of panels into categories, based on the underlying principle: typical features, purpose, structure, material composition.

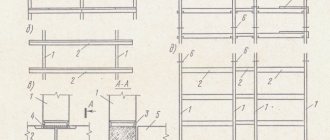

Slab design

Produced panels are divided into monolithic and composite analogues.

In turn, layered products can be solid or have layers of air.

- Single-layer analogues are made from homogeneous concrete, which has low thermal conductivity. The thickness of their outer part is 2/4 cm. The inside of the slab is decorated with cladding.

- Two-layer slabs have a continuous structure. Their supporting layer is made of reinforced concrete mortar. This is the inner part of the panel, which additionally plays the role of a vapor barrier. The outer heat-protective layer is covered with cement-sand mortar.

- Reinforced concrete three-layer panels are made of two slabs connected to each other by a welded frame made of reinforcement. Insulation is laid between them.

According to their load-bearing capacity, wall slabs are divided into:

- self-supporting products;

- load-bearing analogues.

- hanging panels.

Partition panels

Partition slabs.

- These large-sized slabs have a floor height and a length of up to 600 cm. They are intended for the construction of fully prefabricated buildings.

Note! For the production of partition panels, high-strength ordinary or gypsum concrete should be used. The material must have good water resistance and frost resistance.

- Such plates are reinforced with iron wire mesh or rods made of thermally and mechanically stable steel, class A/III, AT/IIIC. All steel parts of the product must be coated with anti-corrosion primer.

Single layer boards

Single layer plate.

- For the production of single-layer wall panels, concrete is used, which has a uniform structure and a high level of thermal insulation. Most often it is a light (cellular) material.

- The outer side of the slabs is covered with a layer of cladding, 2/4 cm thick, to protect them from atmospheric influences.

- Various plaster, tiles, etc. are used to decorate the interior.

Double-layer panels

- The two-layer type of slabs, as a rule, has a solid structure. The first load-bearing layer is made of dense reinforced concrete. The other layer is heat insulating.

- It is located on the outside and covered with cement-sand mortar.

- The load-bearing layer is located indoors and at the same time serves as a vapor barrier.

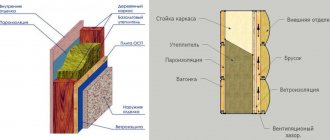

Three-layer type of products

The photo shows the structure of some brands of three-layer panels.

Reinforced concrete three-layer wall panels are most in demand now.

- The basis of the three-layer slab is the outer load-bearing side, and the inner panel is attached to it with reinforcement. Thanks to the gap between them, heat losses in the structure are reduced.

- The thermal insulator in such products can be mineral wool, cement-based fiberboard, foam silicate, or polyurethane.

- Three-layer slabs have standard sizes and vary in thickness. It is selected by designers based on the climate conditions of the area and the thermal parameters of the building.

- This type of panels is made from a light but durable concrete mixture or heavy types of concrete with a class of at least B-12.5.

- Products are reinforced with welded mesh or three-dimensional steel frames. All metal parts of the plates are protected with anti-corrosion primers.

- The characteristics of three-layer panels for walls are determined by the standards of State Standard No. 31310/2005 and State Standard No. 13015/2003.

- If it is necessary to process the slabs during their installation, reinforced concrete is cut with diamond wheels.

Roof sandwich panels

Calculations of the load-bearing capacity of wall sandwich panels take into account that tightly glued insulation helps distribute stress under loads and absorbs shear forces, while metal sheathing is subject to tension and compression.

The calculation does not take into account possible changes in the shape of the panels (cutouts, cut edges, etc.). Limit states of load-bearing capacity have been calculated for wall panels. The values indicated in the tables are reference material and must be calculated when carrying out design work.

Calculations were carried out taking into account the following simplifications and assumptions:

— the thickness of the sandwich panel is indicated by the thickness of the insulation,

— thickness of metal casings 0.6 mm,

— the width of external supports is at least 60 mm,

— the width of the internal supports is at least 80 mm,

— permissible deflection of the panel 1/100 L span,

— the calculation takes into account the panels’ own weight and a concentrated load of 100 kgf in the middle of the span

Table 12. Design load-bearing capacity of roofing sandwich panels with mineral wool

| Panel thickness, mm | Load-bearing capacity of roofing sandwich panels with a uniformly distributed load, kg/sq.m | |||||

| Span length, m | ||||||

| 1,5 | 2,0 | 2,5 | 3,0 | 3,5 | 4,0 | |

| 60 | 151 | 106 | 65 | 33 | 15 | — |

| 80 | 206 | 135 | 98 | 73 | 55 | 37 |

| 100 | 285 | 195 | 141 | 108 | 88 | 64 |

| 120 | 354 | 248 | 187 | 145 | 117 | 91 |

| 150 | 440 | 336 | 255 | 204 | 160 | 136 |

| 200 | 609 | 433 | 334 | 270 | 224 | 189 |

Fig.3. Graph of the load-bearing capacity of roofing sandwich panels with mineral wool under a uniformly distributed load. The loading scheme is single-span.

Table 13. Design load-bearing capacity of roofing sandwich panels with expanded polystyrene foam

| Panel thickness, mm | Load-bearing capacity of roofing sandwich panels with a uniformly distributed load, kg/sq.m | |||||

| Span length, m | ||||||

| 1,5 | 2,0 | 2,5 | 3,0 | 3,5 | 4,0 | |

| 60 | 184 | 134 | 84 | 48 | 25 | — |

| 80 | 249 | 161 | 121 | 93 | 71 | 52 |

| 100 | 345 | 237 | 172 | 131 | 107 | 83 |

| 120 | 429 | 298 | 225 | 174 | 139 | 112 |

| 150 | 540 | 405 | 306 | 243 | 193 | 161 |

| 200 | 738 | 522 | 399 | 319 | 265 | 220 |

Fig.4. Graph of the load-bearing capacity of roofing sandwich panels with polystyrene foam under a uniformly distributed load. The loading scheme is single-span.

Three-layer reinforced concrete wall panels

Particularly popular today in the construction of housing are reinforced concrete three-layer wall panels, consisting of two concrete layers (external and internal) and a thermal insulation material located between them.

Hard mineral wool or expanded polystyrene is most often used as insulation between the fencing sheets. And the calculation of reinforcement is based on the degree of probable loads to which the slab will be exposed during operation.

Three-layer reinforced concrete sheets are a kind of the same sandwich panels, but only with higher load-bearing capacities and a longer service life.

Precast concrete panels are used:

- During the construction of office buildings, as well as industrial and production facilities,

- For the construction of residential buildings,

- During the construction of basement floors.

to contents ^

Panel production

Production of fire-resistant wall and roofing “sandwich” panels based on environmentally friendly rigid basalt slab IZOVOl

The basis of three-layer “BELPANEL” panels is a core made of the best fireproof rigid high-performance mineral wool slabs “IZOVOL” based on basalt rocks. The heat-insulating mass is protected on both sides by facing layers (profiled galvanized and painted steel sheet produced by leading enterprises in Russia, Finland, Sweden, England, France). A strong connection between the three layers is ensured by high-quality adhesive. The transverse orientation of the insulation fibers and its tight adhesion to the steel cladding provides increased strength characteristics of the BELPANEL panels.

| Panel type | Panel thickness, mm | |||||

| 80 | 100 | 120 | 150 | 200 | 250 | |

| Regulatory fire resistance limit | ||||||

| Wall panels (for external walls and partitions) | EI 60 | EI 90 | EI 150 | |||

| Wall panels (as fire barriers) | Not recommended | EI 150 | ||||

| Roofing panels (for building coverings) | Standard fire hazard class K0(45) | |||||

| Note: | The fire spread limit for all structures is 0 cm | |||||

The high-quality materials that the company uses to produce BELPANEL panels are classified as non-flammable!

In terms of thermal characteristics, BELPANEL panels are several times superior to traditional materials. For example, a panel with a thickness of 100 mm provides thermal protection that is not inferior to masonry made of hollow ceramic bricks with a thickness of 1195 mm; clay brick masonry - 1445 mm; silicate brick masonry - 1570 mm.

The use of high-quality IZOVOL mineral wool boards as a heat-insulating core in three-layer building panels ensures increased stable strength characteristics of BELPANEL wall and roof sandwich panels, which do not deteriorate over time.

Highly efficient thermal insulation materials of the modern generation “IZOVOL” are produced using the “ECOSAFE” technology, which has no analogues and is fundamentally different from existing ones. Blast furnace slag and coke are not used in the production of IZOVOL stone wool! The unique super-pure technology for producing basalt fiber dramatically increases the physical and mechanical properties of IZOVOL mineral wool slabs.

The chemical purity of the melt made it possible to improve the structure of the basalt fiber. The use of a unique melting device (coke is completely excluded!) of a special design in the IZOVOL production technology ensures the highest quality of the melt due to its stable viscosity and fluidity, maintaining a constant temperature of the melt. This makes it possible to obtain IZOVOL products with increased stable physical and mechanical properties and, at the same time, optimal thermal conductivity indicators, ensuring maximum functional efficiency, safety, reliability and durability of BELPANEL sandwich panels.

Specialists of the Belgorod Thermal Insulation Materials Plant, together with leading foreign specialists, selected (modeled) a uniquely balanced fiber composition, which makes it possible to increase and stabilize the acidity modulus of high-quality IZOVOL mineral wool insulation. Thus, standard deviations from the ideal acidity module are minimal, and its indicators range from 2.13 to 2.24, unlike other manufacturers, where the acidity module has a larger range of changes (1.2 - 9.0), which is negative affects the service life.

Testing of slabs for the manufacture of “sandwich” panels is carried out in accordance with STO 03-04 (developed by the Federal State Institution FTSS), according to three strength indicators, and all three characteristics are measured not on slabs, but on lamellas: compressive strength, tensile strength, shear/shear strength.

For “IZOVOL” brand SS (sandwich wall) with a density of 105 kg/m3, the actual average value of the compressive strength is 99.46 kPa, which is 80.84% (!) higher than the established indicator. The average tensile strength is 145.28 kPa, which is 45.28% (!) higher than the established value. The average shear/shear strength is 74.61 kPa, which is 49.22% (!) higher than the established value.

The use of fire-resistant “BELPANEL” sandwich panels provides ideal comfort indoors, thanks to the unique properties of highly efficient insulation “IZOVOL”, improves the functional characteristics and hygiene of premises, meets the expectations of Consumers and improves the quality of life in general.

Wall sandwich panels “BELPANEL C 4”

Profiles of the lower and upper skins:

Z-Lock lock with inherent perfect characteristics of strength and tightness. The connection maintains the perfect strength of a Z-Lock while providing the visual effect of no external fasteners.

Installation width - 1190 mm Installation width - 1000 mm

Hidden Lock Concealed Fix

Corner sandwich panels "BELPANEL"

RF Patent No. 36413

The minimum radius is equal to the panel thickness. Side sizes may vary.

Technical characteristics of wall sandwich panels "BELPANEL - C 4" and wall sandwich panels "BELPANEL - C 5"

| Thickness, mm | Installation width, mm | Length, mm | Specific gravity, kg/m2 | Reduced heat transfer resistance, Ro*, m2 0C/W | Airborne noise insulation index***, dB | |||

| S-4 | S-5 | S-4 | S-5 | S-4 | S-5 | |||

| 50 | 1000,1190 | 1170 | from 2225* to 13600** | from 2225* to 6000 | 16,0 | 1,59 | 30 | |

| 65 | 17,5 | 1,73 | 30 | |||||

| 80 | 18,5 | 2,40 | 31 | |||||

| 100 | 21,0 | 2,84 | 31 | |||||

| 120 | 23,0 | 3,30 | 32 | |||||

| 135 | 25,0 | 3,37 | 32 | |||||

| 150 | 26,5 | 4,10 | 33 | |||||

| 170 | — | — | 28,0 | 4,45 | 33 | |||

| 200 | — | — | 31,5 | 5,22 | 34 | |||

| 250 | — | — | 37,0 | 5,85 | 35 | |||

| 280 | — | — | 40,0 | 6,53 | 35 | |||

* wall sandwich panels with a length of less than 2225 mm are combined upon delivery ** with the exception of wall sandwich panels S-4-250 (maximum length - 11,000 mm) and wall sandwich panels C-4-280 (maximum length - 9,500 mm) ** * Research Institute of Building Physics RAASN recommends BELPANEL sandwich wall panels for use as acoustic structures in construction to protect residential areas from traffic noise (Certificate of Conformity No. 030006.024/254-08)

Ro* was obtained as a result of tests in accordance with GOST 26254-84 to determine the heat transfer resistance of three-layer metal panels.

Test conditions:

1. Ambient temperature +18ºС. 2. Relative humidity 75% 3. Atmospheric pressure 103 kPa

offers you a new product: the use of aluminum-zinc steel with a pattern - Printech - (photo-offset technology) and embossed steel as facing layers.

Printech coating lies in the variety of colors and patterns made by offset on an aluminum-zinc sheet. Colors like wood, brick, natural stone, imitation tiles and many others give the products a unique look. In addition to its excellent appearance, Printech is an extremely corrosion-resistant material. Printech is manufactured using polyester and PVDF coating.

Zinc-alumina steel is a corrosion- and high-temperature-resistant product that combines the characteristics of aluminum, which provides strength, heat resistance and ductility, and zinc, which provides heat resistance and excellent corrosion resistance.

Embossing – galvanized or aluminum-zinc embossed steel coils are weather-resistant and at the same time very elegant material, which is successfully used for the production of sandwich panels.

We present to your attention a list of the main large objects in the construction of which wall and roof sandwich panels of the BELPANEL system were used:

- Vnukovo Airport Hangar No. 2

- Auto, Moscow

- Plant named after Khrunicheva, Moscow

- Car dealership "HYUNDAI", Moscow

- Sports complex of the Ministry of Emergency Situations, Moscow

- "TOYOTA-center", Moscow region, Balashikha district

- , Krasnogorsk

- Warehouse complex Logo-Art LLC, Moscow region, Gryazi village

- Mining and processing plant "Voskhod", r. Kazakhstan

- Reconstruction of the roof at Kursk CHPP-1, Kursk

- Warehouse of finished products of OJSC “Pharmstandard-Leksredstva”, Kursk

- Regional distribution center, Tambov region, Tambov district, village. Sagittarius.

- Warehouse complex "Magnit", Veliky Novgorod

- Warehouse complexes of OJSC “345 Mechanical Plant”, Moscow region, Balashikha

- Shopping center, Moscow region, Podolsk

- Hangar roof at Kievsky railway station, Moscow

- Substation of Sheremetyevo Airport, Moscow region, Khimki

- Special parking and maintenance building. equipment, Moscow region, Vnukovo airport

- Educational and training complex, Moscow region, Odintsovo

- Sanatorium complex, Moscow region, Shatura, Lake Beloe village

- Shopping center “METRO”, Novosibirsk

- Shopping center “METRO”, Pyatigorsk

- Shopping center “METRO”, Izhevsk

- Shopping center “METRO”, Magnitogorsk

- Shopping center “METRO”, Smolensk

- Shopping center “METRO”, Cheboksary

- Gas stations “BP”, Moscow, Moscow region.

- TNK gas stations, Ryazan region.

- Roof of the “HONDA” dealership center, Moscow, Zhulebino district

- Granulated urea production workshop of EuroChem OJSC, Tula region, Novomoskovsk

- School and gym, village Katravozh, Priuralsky district

- Reconstruction of the uncoupling repair shop of JSC Russian Railways, Smolensk

- Glass factory, r. Ingushetia, p. Sagopshi

- Swimming pool, Ryazan

- Dry sand storage warehouse of OJSC "GOK "Muraevnya"", Ryazan region, Miloslavsky district, village. Muraevnya.

- Sports and recreation center, Voronezh

- Sports and recreation center, Grozny

- Agro-industrial complex "Miratorg", Belgorod region.

- Pig farm buildings, Prokhorovsky district, village. Malye Machaki, village. Dragunka, s. Radkovka

- Pig farm, Belgorod region, Shebekinsky district, village. White Well

- Poultry houses, Shebekinsky district, village. Moore

- Poultry houses, Belgorod region, p. Olkhovatka

- Cowsheds, Suzdal district

- Poultry houses, Gayvoronsky district

- Poultry houses, Belgorod region, Shebekinsky district, village Maslova Pristan

We present to your attention a list of the main large objects in the construction of which IZOVOL mineral wool insulation was used:

- Buildings of poultry complexes, Belgorod region (2008)

- Livestock complex, Leningrad region (2007)

- , Moscow region (2006)

- Mozhaisk reinforced concrete plant, Moscow region. .(2006)

- Shopping center "MEGA", Samara region (2007)

- Shopping center "Auchan", Samara region. (2007)

- Shopping center "IKEA", Samara region (2007)

- Shopping center "Metro Cash and Carry", Orenburg region (2007)

- Shopping center "BOSHER", Belgorod region (2007)

- Shopping center “Everything for You”, Belgorod region (2007)

- Factory for the production of packaging tape, Leningrad region. .(2006)

- Trade and office center, Nizhny Novgorod region (2007)

is not a complete list of facilities built using BELPANEL and IZOVOL mineral wool insulation .